Anti-thunder overvoltage protection component

An overvoltage protection and component technology, applied in the direction of emergency protection circuit devices, emergency protection circuit devices, electrical components, etc. for limiting overcurrent/overvoltage, which can solve the limitation of rated working current, increased probability of damage, circuit operation Overvoltage and fault power frequency overvoltage protection capability is reduced to achieve the effect of preventing deflagration accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

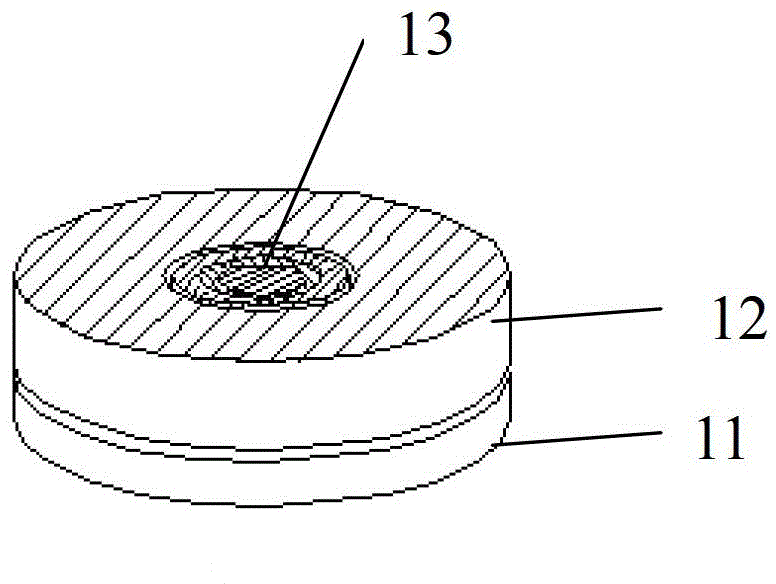

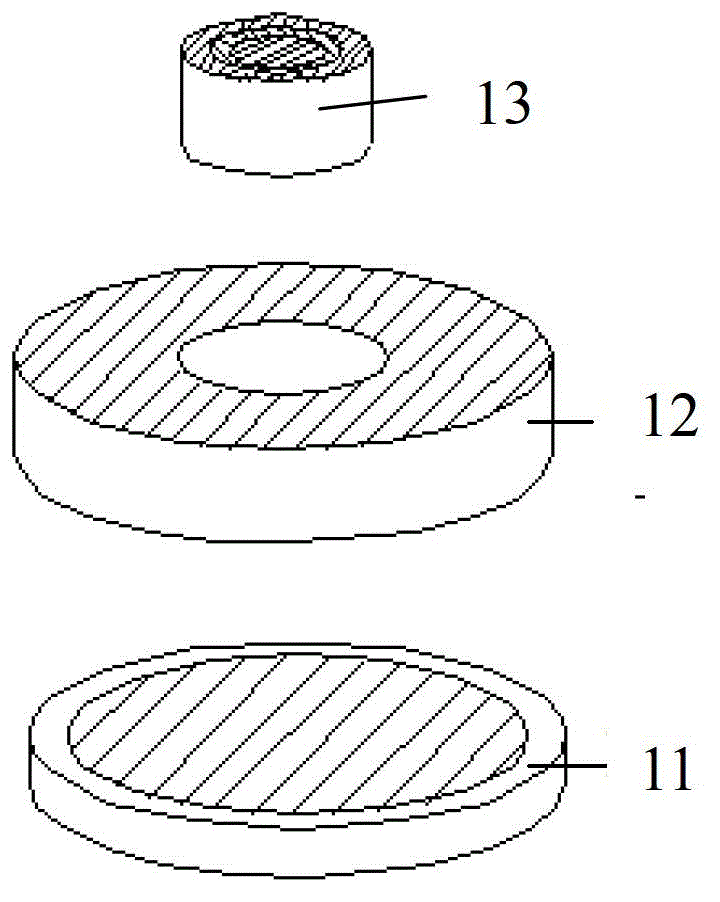

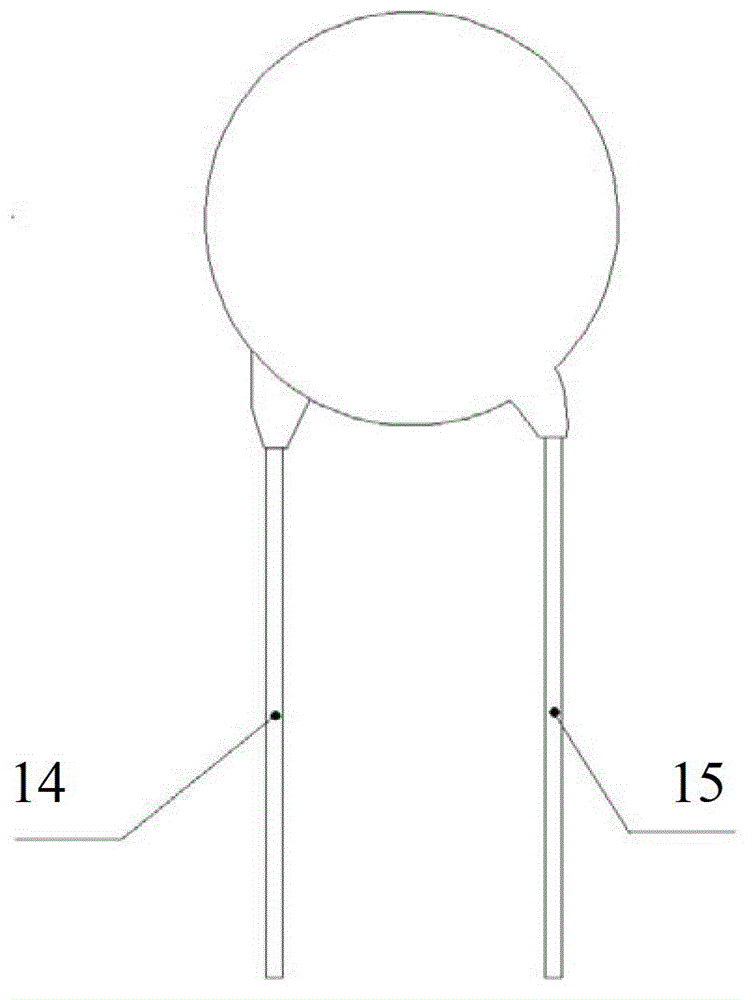

[0032] Such as Figure 1~2 As shown, the lightning protection and overvoltage protection assembly of the present embodiment includes a zinc oxide varistor sheet 11, a positive temperature coefficient ceramic thermistor sheet 12 and a gas discharge tube 13, and the positive temperature coefficient ceramic thermistor sheet 12 is made of In a ring structure, the size of the inner hole of the positive temperature coefficient ceramic thermistor sheet 12 matches the outer diameter of the gas discharge tube 13, and the gap between the two is 0.1 to 1mm; the thickness of the positive temperature coefficient ceramic thermistor sheet 12 is the same as The gas discharge tube 13 has the same height, and the outer diameters of the zinc oxide varistor sheet 11 and the positive temperature coefficient ceramic thermistor sheet 12 are consistent; The upper electrode surface of the gas discharge tube 13 is placed in the inner hole of the positive temperature coefficient ceramic thermistor sheet...

Embodiment 2

[0041] Such as Figure 5-6 As shown, the lightning protection overvoltage protection assembly of the present embodiment includes a zinc oxide varistor 21, a positive temperature coefficient ceramic thermistor 22 and a gas discharge tube 23, a zinc oxide varistor 21, a positive temperature coefficient thermal The varistor sheets 22 are all square, and the external dimensions of the varistor sheets, thermistor sheets and gas discharge tubes need to be properly matched: the gas discharge tube specifications adopted are the same as in Embodiment 1, and the size of the varistor sheets used is long* Width*height=15*15*3mm, the dimensions of the thermistor used are length*width*height=15*9*5mm. The lower electrode surface of the positive temperature coefficient thermistor sheet 22 is welded to the upper electrode surface of the zinc oxide varistor sheet 21 by soldering; the gas discharge tube 23 is located on one side of the zinc oxide varistor sheet 21, and its lower end surface is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie temperature | aaaaa | aaaaa |

| Curie temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com