Positive-pressure ash cooling system for biomass fluidized bed gasification furnace

A fluidized bed gasifier, biomass technology, applied in gasification process, granular/powder fuel gasification, chemical industry, etc., can solve the problem of not being able to discharge directly, prevent gas leakage and prevent deflagration accidents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

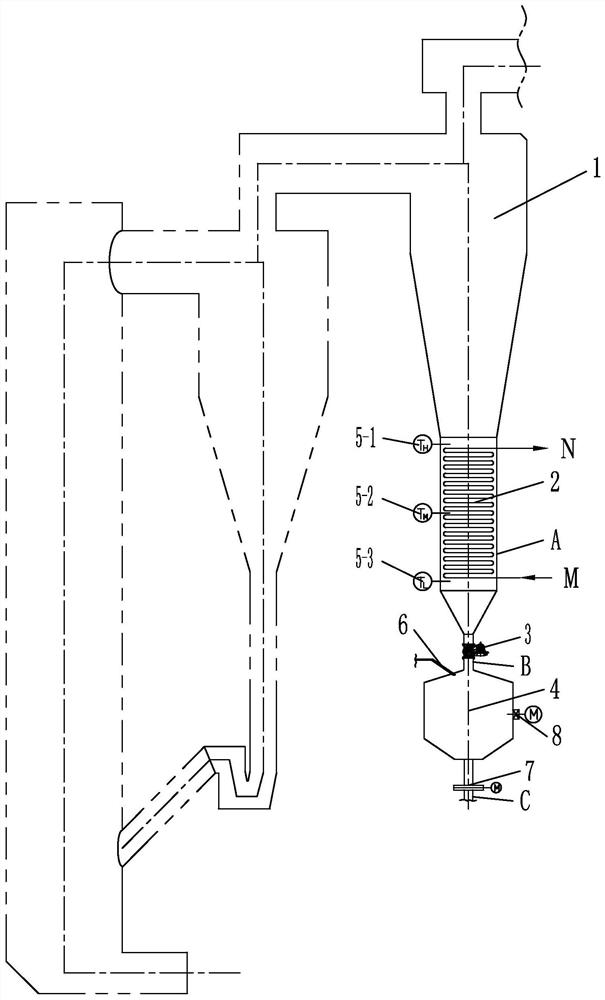

[0015] Specific implementation mode one: combine figure 1 Describe this embodiment, a positive pressure cold ash system for a biomass fluidized bed gasifier in this embodiment, which includes a fine ash separator 1, a cooling water heat exchanger 2, a rotary sealing valve 3, and an ash buffer The tank 4 and the electric gate 7, the standpipe A is arranged under the fine ash separator 1, the cooling water heat exchanger 2 is arranged in the standpipe A of the fine ash separator 1, and the ash buffer tank 4 is arranged in the fine ash separator 1, the ash buffer tank 4 is connected to the standpipe A of the fine ash separator 1 through the connecting pipe B, and the connecting pipe B between the ash buffer tank 4 and the fine ash separator 1 is provided with a rotary sealing valve 3, and the ash The ash discharge port below the buffer tank 4 is provided with an ash discharge pipe C, and the ash discharge pipe C is provided with an electric flashboard door 7 .

specific Embodiment approach 2

[0016] Specific implementation mode two: combination figure 1 Describe this embodiment, this embodiment also includes a material level gauge, the material level gauge is arranged on the inner wall of the riser A below the fine ash separator 1 . With such arrangement, the amount of ash in the vertical pipe A of the fine ash separator 1 is fed back through the temperature signal of the material level gauge. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0017] Specific implementation mode three: combination figure 1 Describe this embodiment, the material level meter of this embodiment comprises high material level meter 5-1, middle material level meter 5-2 and low material level meter 5-3, high material level meter 5-1, middle material level meter 5 -2 and the low material level meter 5-3 are sequentially arranged on the inner wall of the vertical pipe A below the fine ash separator 1 from top to bottom. So set, the high material level gauge 5-1, the middle material level gauge 5-2 and the low material level gauge 5-3 are used to measure the amount of ash in different positions of the riser A of the fine ash separator 1. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

[0018] Specific implementation mode four: combination figure 1 Describe this embodiment, the cooling water heat exchanger 2 of this embodiment is a serpentine tube heat exchanger, the cooling water of the serpentine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com