Boiler start-up method to prevent scale formation and secondary combustion accidents in tail flue of 1000mw octagonal tangential boiler

An octagonal tangential boiler and tail flue technology, applied in steam generation, lighting and heating equipment, control systems, etc., can solve the problems of low fuel input, uneven distribution of heat load in the furnace, large furnace volume, etc., to prevent The effect of secondary combustion and prevention of furnace deflagration accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

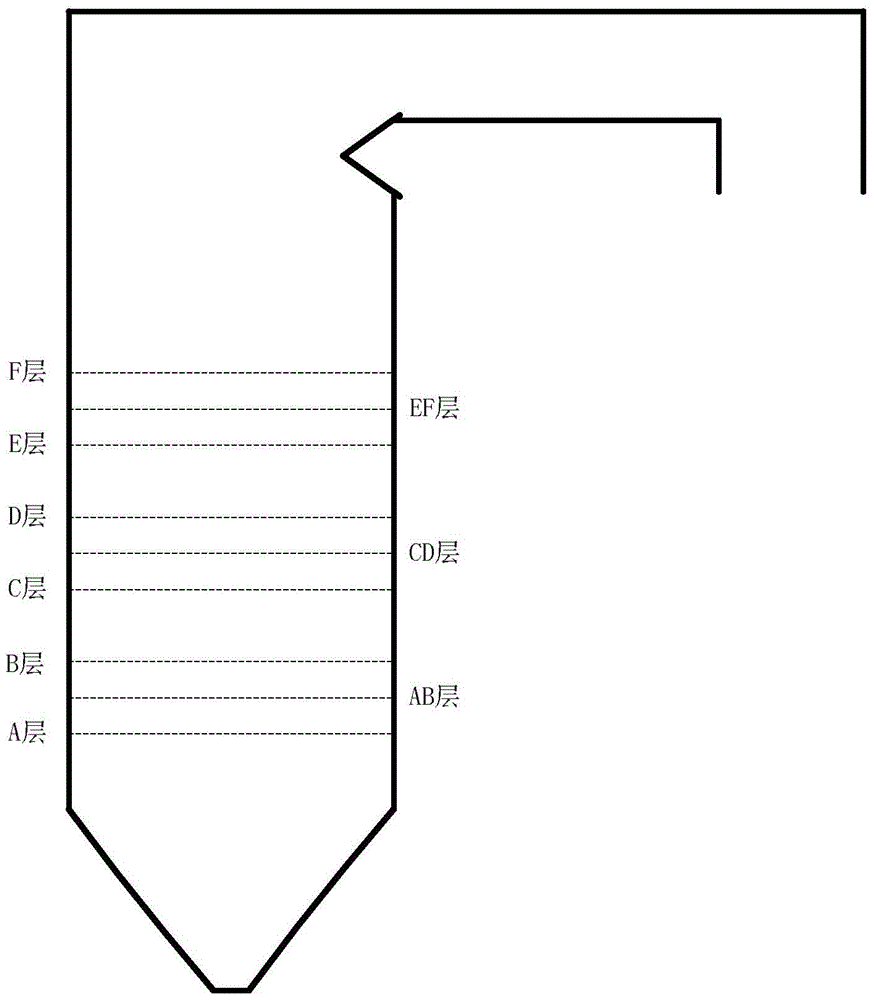

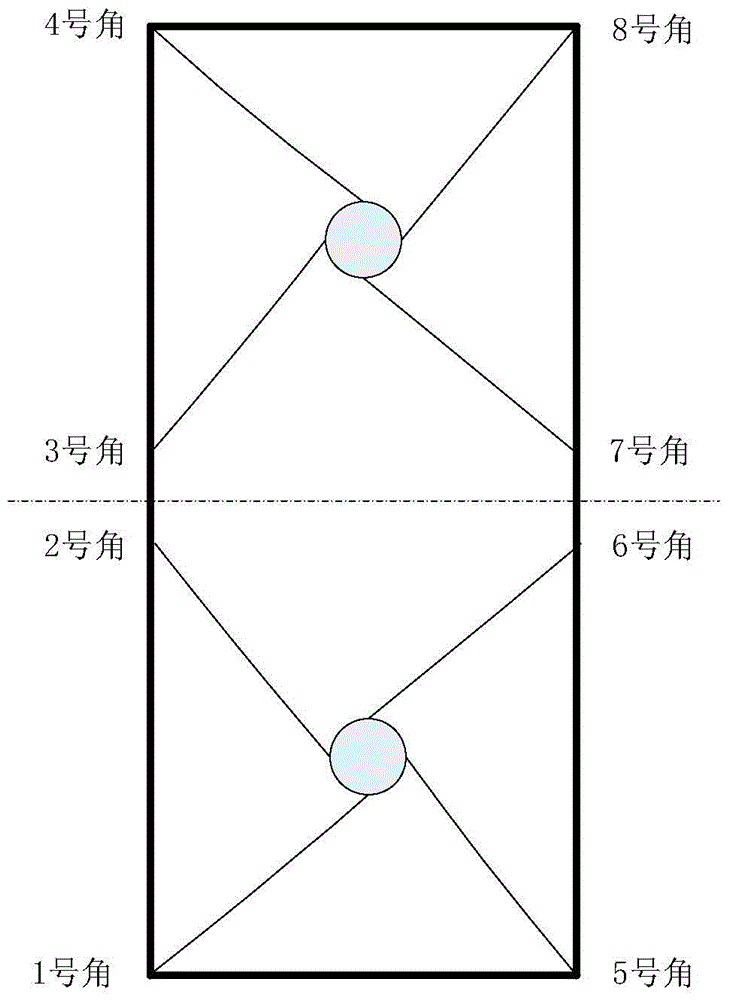

[0022] The boiler start-up method of the present invention to prevent the formation of oxide scales and secondary combustion accidents in the tail flue of a 1000MW octagonal tangential boiler, before the burner is put into operation, the steam source of the adjacent furnace is used to raise the temperature of the deaerator to above 100°C as much as possible for stove. After the heating is finished, the burner is put into operation. The burner is put into operation according to the following principles: first put all the large oil guns in the AB layer and some of the large oil guns in the CD layer one by one, until the outlet pressure of the steam-water separator of the boiler reaches 0.3MPa At this time, put all the micro-oil guns in layer A, and then put into operation the pulverizing system in layer A. The number of large oil guns put into operation is determined by the heating rate of the boiler. In the stage of hot flushing and temperature rise and pressure rise, part or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com