Novel straw direct gasification and poly-cogeneration device and preparation process

A technology of polygeneration and straw, which is applied in fixed bed gasification, petroleum industry, and manufacture of combustible gas, etc. It can solve the problems of poor gasification effect of straw gasifier, low utilization rate of straw, and low operating cost. Achieve the effects of avoiding performance degradation, increasing calorific value and resource utilization, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

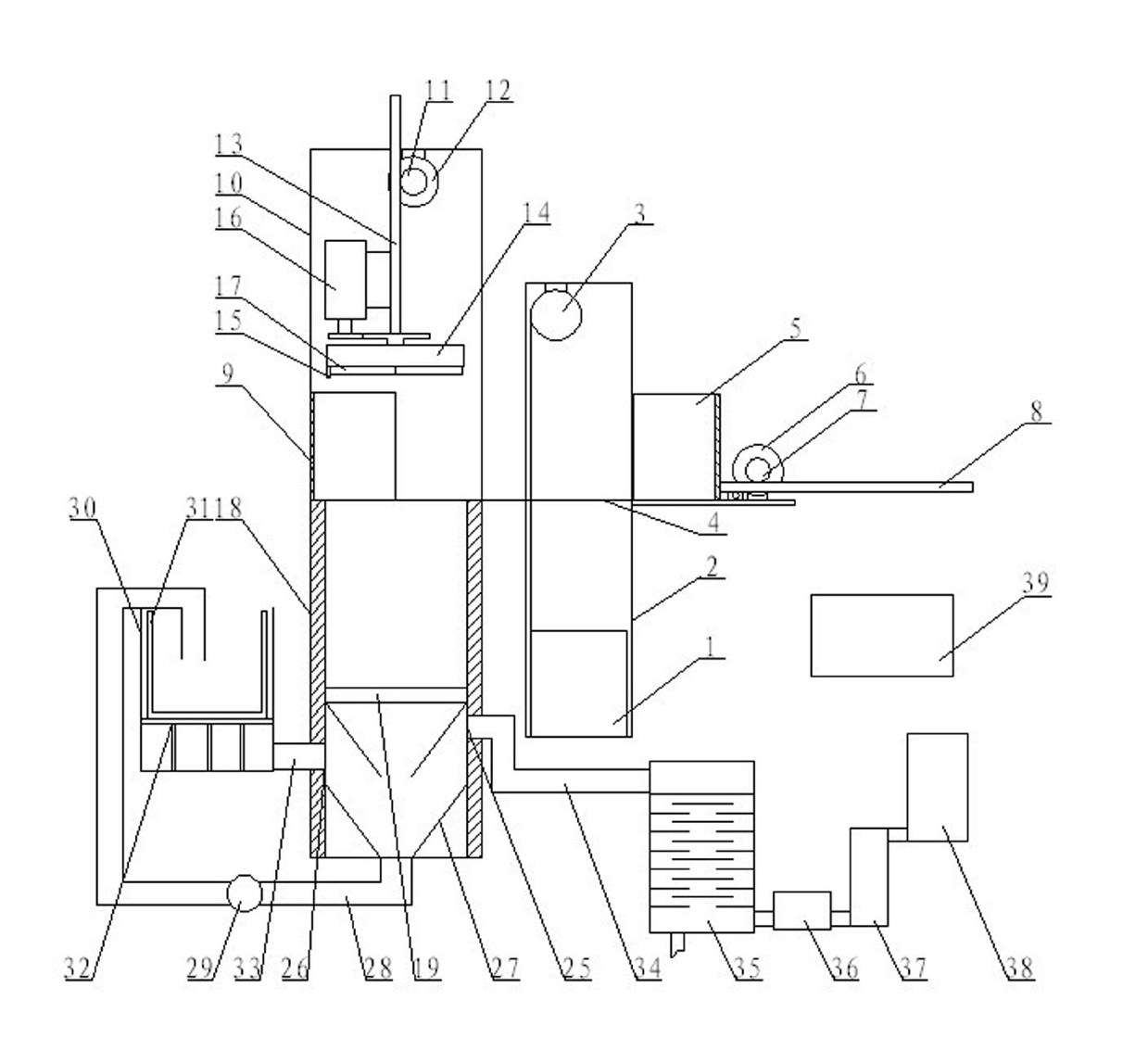

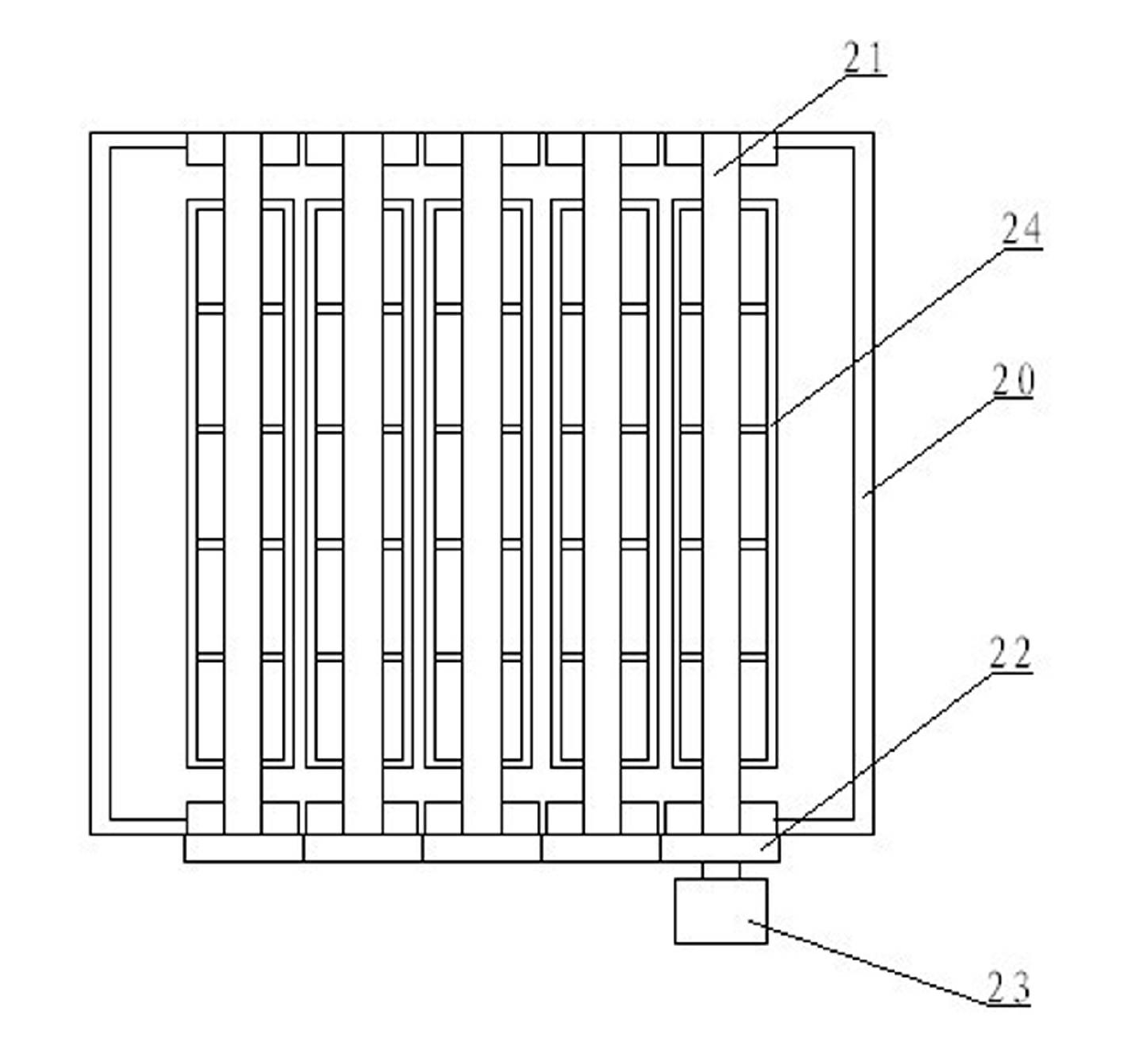

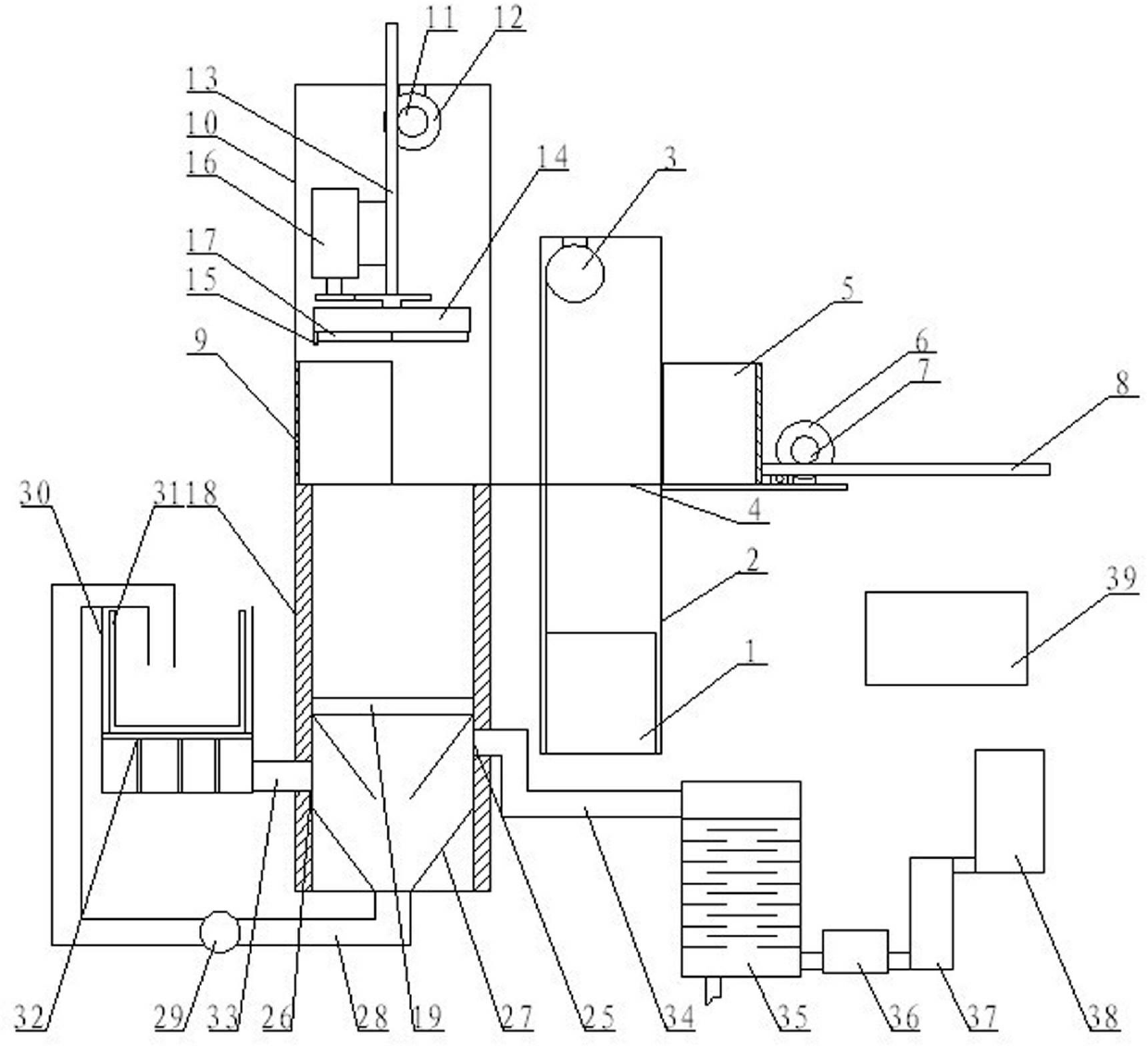

[0035] Figure 1-2 As shown, the new straw direct gasification polygeneration device includes a hopper 1, a feeding track 2, a feeding motor 3, a pushing track 4, a pushing plate 5, a pushing motor 6, a pushing gear 7, and a pushing tooth Strip 8, material pushing baffle 9, material pressing track 10, material pressing motor 11, material pressing gear 12, material pressing rack 13, material pressing cover 14, pressure sensor 15, material leveling motor 16, rice-shaped leveling material Device 17, gasifier 18, fire grate 19, charcoal pool 27, water outlet pipe 28, mud pump 29, charcoal outlet pool 30, non-woven fabric filter bag 31, mesh bracket 32, return pipe 33, air outlet pipe 34, Labyrinth spray washing device 35, blower fan 36, water seal filter device 37, gas storage cabinet 38 and control cabinet 39. The hopper 1 is arranged in the feeding track 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com