Mobile in-situ treatment apparatus for oil-containing sludge

An in-situ treatment and mobile technology, which is applied in the direction of pyrolysis treatment of sludge, petroleum industry, special form of dry distillation, etc., can solve the problem that oil sludge treatment equipment cannot be used in large-scale practical applications, and achieve reduced volume and heavy, high-efficiency pyrolysis , high purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be described in detail below in conjunction with the accompanying drawings.

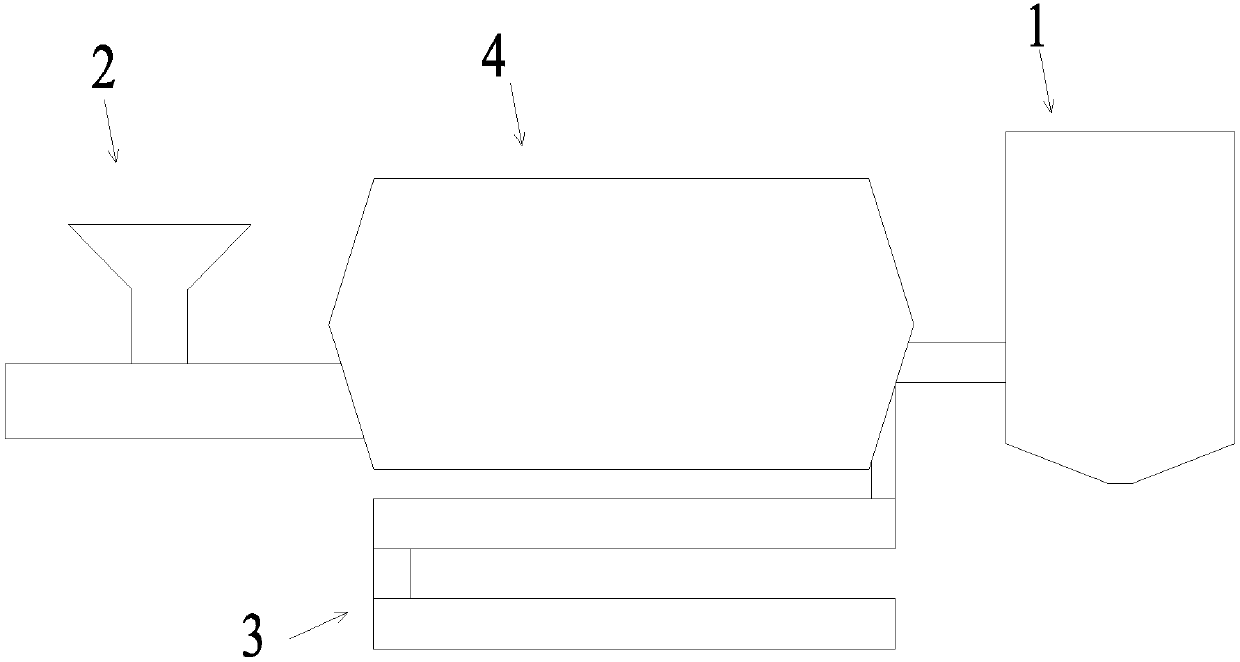

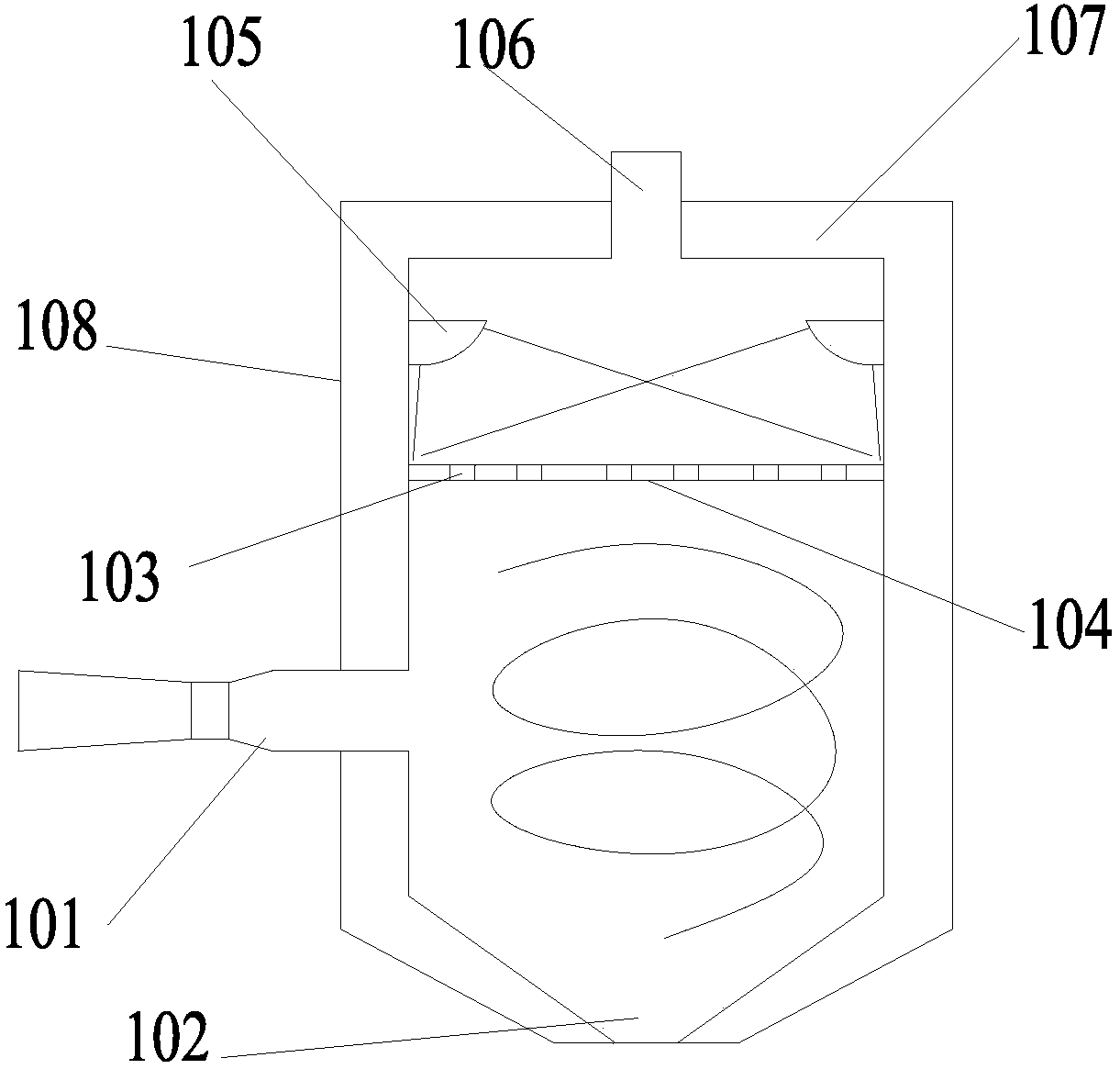

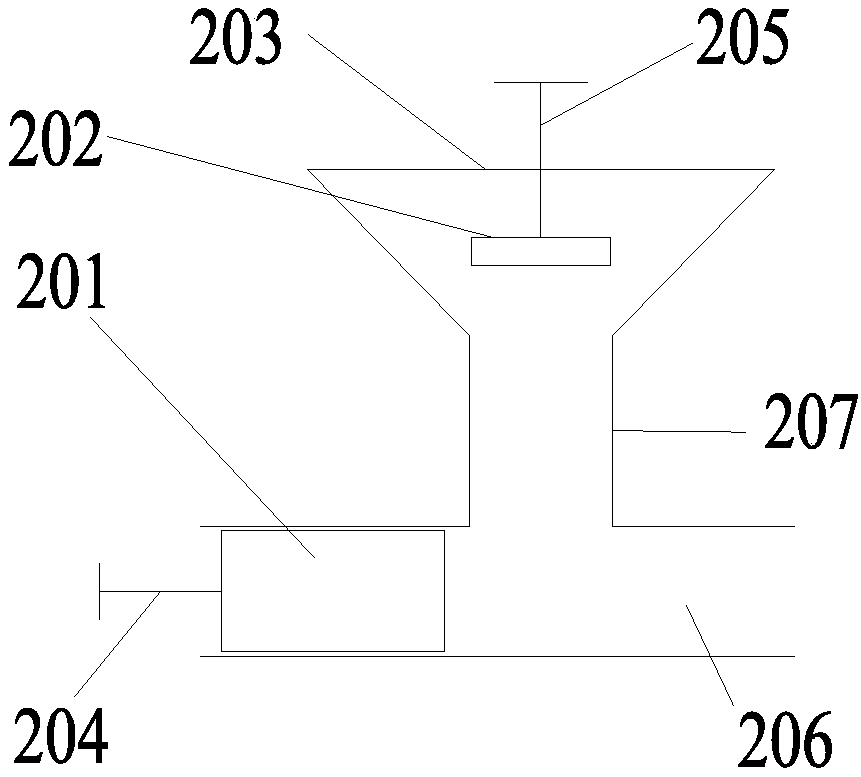

[0061] Such as figure 1 As shown, the mobile sludge in-situ treatment device of the present invention includes: a natural gas purification and separation device 1, a feeding device 2, a discharging device 3, and a pyrolysis device 4; the feeding device 2 is used to receive oily sludge and transport it to the pyrolysis device 4; the feed port of the pyrolysis device 4 is connected to the feeding device 2, the pyrolysis gas outlet is connected to the first air inlet 101 of the natural gas purification and separation device 1, and the slag outlet 303 is connected with the discharge device 3, the pyrolysis device 4 is used to heat and decompose the oily sludge; the discharge device 3 is used to cool and discharge the high-temperature slag; the natural gas purification and separation device 1 is used to decompose the pyrolysis gas The pyrolysis gas is discharged from the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com