Positive-pressure slag cooling system for biomass fluidized bed gasifier

A technology of fluidized bed gasification furnace and biomass, applied in the field of positive pressure cold slag system, can solve the problems of leakage of harmful gas in ash slag, inability to ensure sealing, gasification furnace gas leakage, etc., to achieve convenient transportation slag, prevent leakage, and prevent deflagration accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

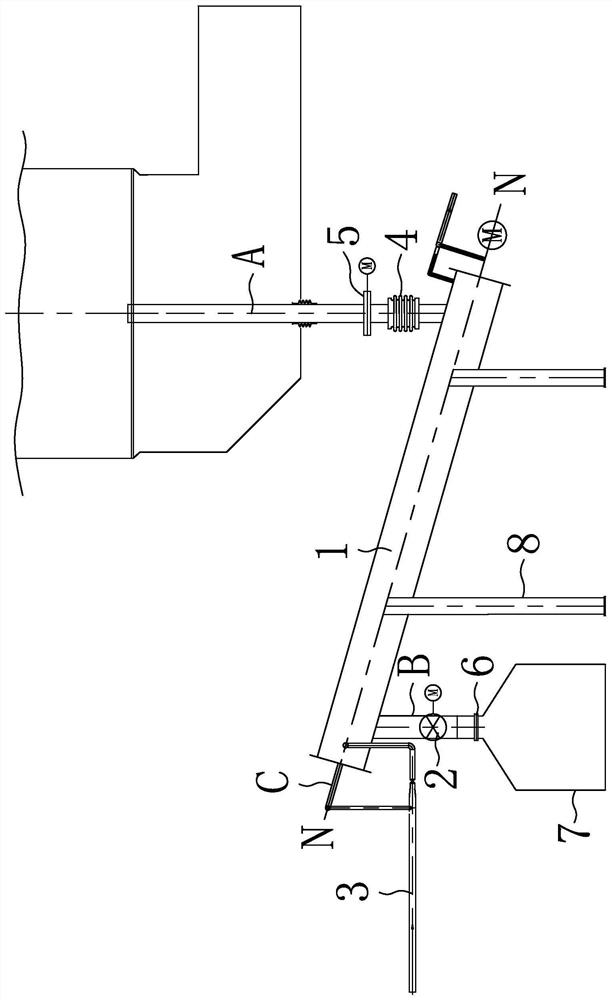

[0016] Specific implementation mode one: combine figure 1 Describe this embodiment, a positive pressure slag cooling system for a biomass fluidized bed gasifier in this embodiment, which includes a spiral slag cooler 1, a cooling water system 3, an electric ram door 5, a manual ram The door 6, the slag storage tank 7 and the support 8, the spiral slag cooler 1 are arranged obliquely, the support 8 is arranged under the spiral slag cooler 1, the spiral slag cooler 1 is connected to the upper end of the support 8, and the lower end of the spiral slag cooler 1 is connected to the gasification The lower end of the slag discharge pipe A of the furnace is connected, and an electric gate 5 is provided under the slag discharge pipe A. The upper end of the spiral slag cooler 1 is connected to the upper end of the ash outlet pipe B, and the lower end of the ash outlet pipe B is connected to the slag storage tank 7. The ash outlet pipe B is provided with a rotary sealing valve 2, and the...

specific Embodiment approach 2

[0018] Specific implementation mode two: combination figure 1 Describe this embodiment, this embodiment also includes a compensator 4, and the compensator 4 is arranged on the slag discharge pipeline A between the electric gate 5 and the spiral slag cooler 1 . So set, the expansion between the slag discharge pipe and the slag cooler 1 is absorbed by the compensator 4 . Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0019] Specific implementation mode three: combination figure 1 To describe this embodiment, the included angle between the axis N-N of the spiral slag cooler 1 of this embodiment and the horizontal plane is 10-25°. In this way, the spiral slag cooler 1 arranged obliquely can prevent the positive pressure gas in the furnace from going back and play a sealing effect. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

[0020] Specific implementation mode four: combination figure 1 To describe this embodiment, the included angle between the axis N-N of the spiral slag cooler 1 of this embodiment and the horizontal plane is 16°. In this way, the spiral slag cooler 1 arranged obliquely can prevent the positive pressure gas in the furnace from going back and play a sealing effect. Other compositions and connections are the same as those in Embodiment 1, 2 or 3.

[0021] Specific implementation mode five: combination figure 1 To illustrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com