Process method for continuous safe discharge of dry tailings subsidence subsidence area

A technology of safe discharge and process method, applied in the direction of conveyor, mechanical conveyor, transportation and packaging, etc., can solve the problems of continuous discharge and natural discharge of subsidence subsidence areas, etc., and achieve high production efficiency and simple and reliable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

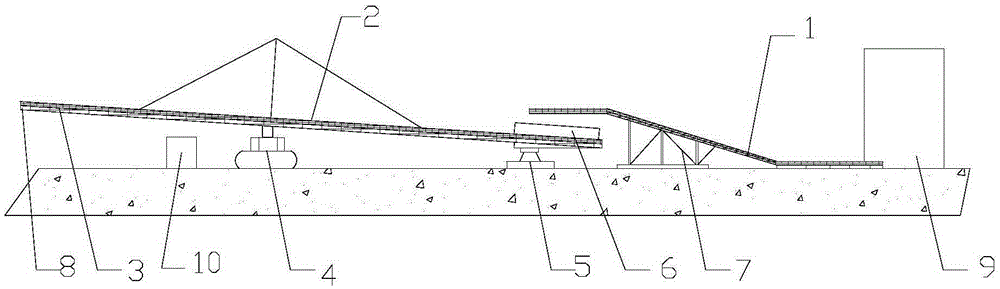

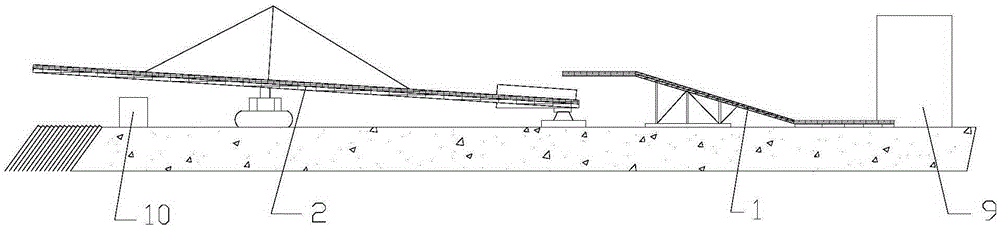

[0024] Embodiment: the equipment selected has ordinary belt conveyor 1, tailings discharge machine 2, bulldozer or loader 10;

[0025] Specifically follow the steps below:

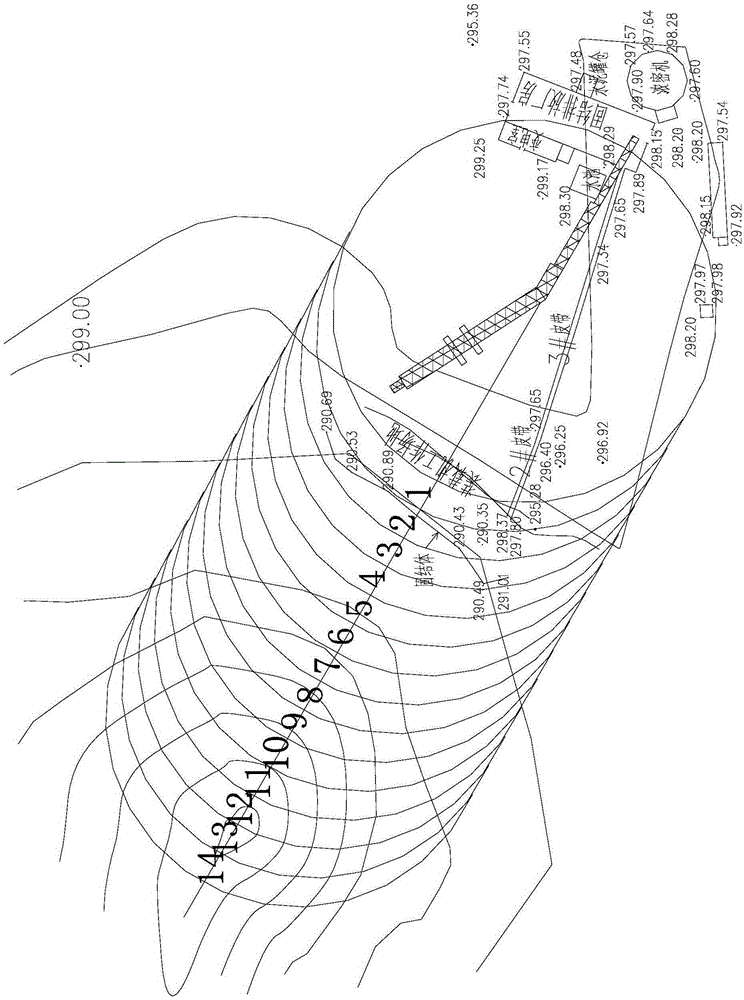

[0026] 1) Level the site for equipment installation see figure 1 The length of the ordinary belt conveyor 1 is determined according to the distance between the subsidence zone and the filter press workshop 9 and the length of the tailings discharge machine 2 . Ordinary belt conveyor 1 is laid out from the filter press workshop 9 from the horizontal section to the upward slope and then to the horizontal section. The length of the horizontal section after the inclination of the ordinary belt conveyor 1 is determined according to the step distance of the tailings discharge machine, and is connected with the rear of the tailings discharge machine 2. The sloped segments coincide by on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com