Patents

Literature

77results about How to "Reduce transportation links" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Support method for fully-mechanized coal mining face full-negative-pressure withdrawing channel

InactiveCN105134266AReasonable designGuaranteed ventilation section requirementsMining devicesUnderground chambersPre stressPre stressing

The invention relates to the technical field of mining engineering, in particular to a support method for a withdrawing channel. The support method achieves full-negative-pressure ventilation during highly gassy mine fully mechanized coal mining face support withdrawing. After lasting mining of a fully mechanized coal mining face is ended, the self-excavation withdrawing channel is formed through coal cutting of a coal cutter, high-strength anchor rod (cable) support is performed on the withdrawing channel, the roadway retaining mode of driving nogs behind a sheltering frame is omitted, and one-off support is utilized for achieving full-negative-pressure ventilation during support withdrawing. According to the top plate structure of the withdrawing channel, the method of high-pre-stress anchor rod (cable) support is adopted for surrounding rock control. Anchor rods (cables) are adopted for supporting the withdrawing channel in a cantilever mode, nog construction in a traditional support withdrawing mode is basically eliminated, and support strength can meet the requirement for a ventilation section in full-negative-pressure support withdrawing. Through innovating the full-negative-pressure withdrawing channel support mode, the labor intensity is lowered to the maximum degree, the support withdrawing efficiency is improved to the maximum degree, and finally the safe, efficient and economical support withdrawing mode is achieved.

Owner:TIANDI SCI & TECH CO LTD +2

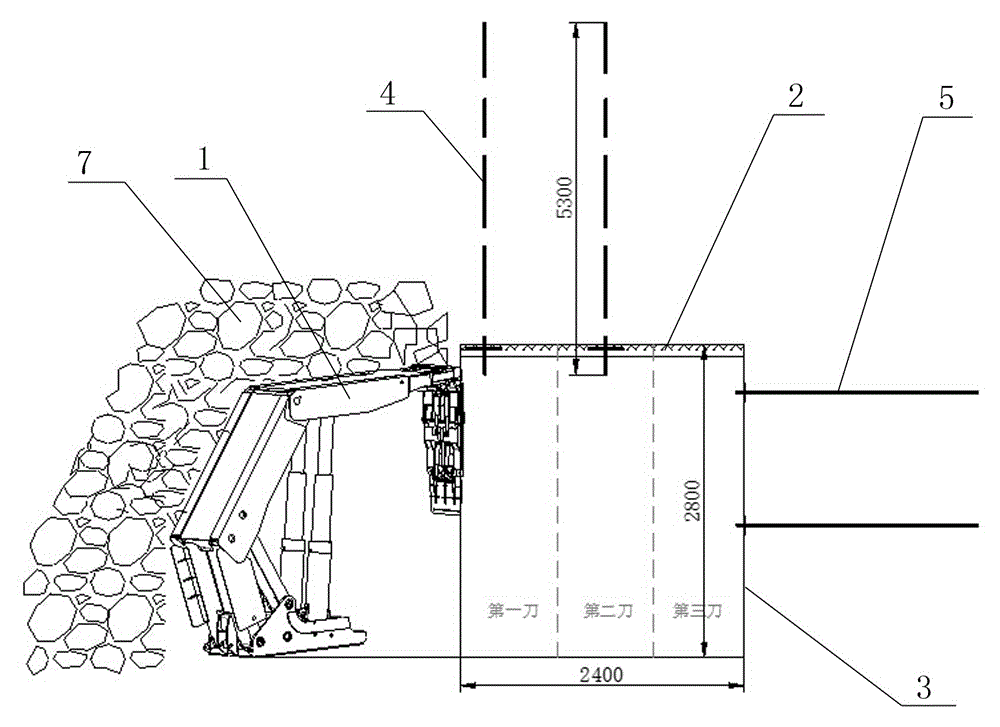

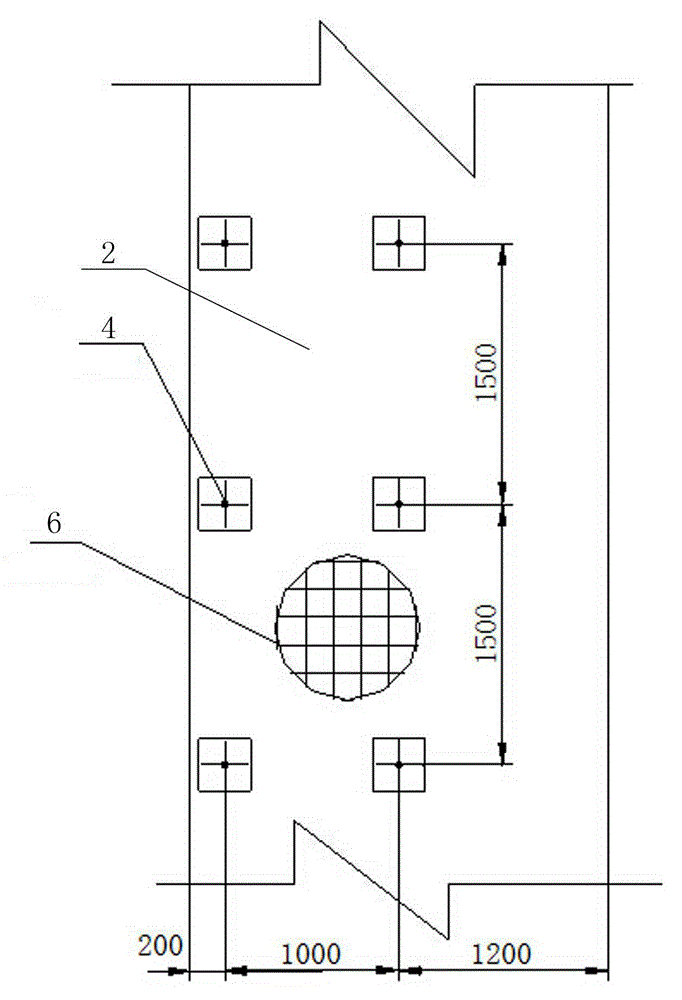

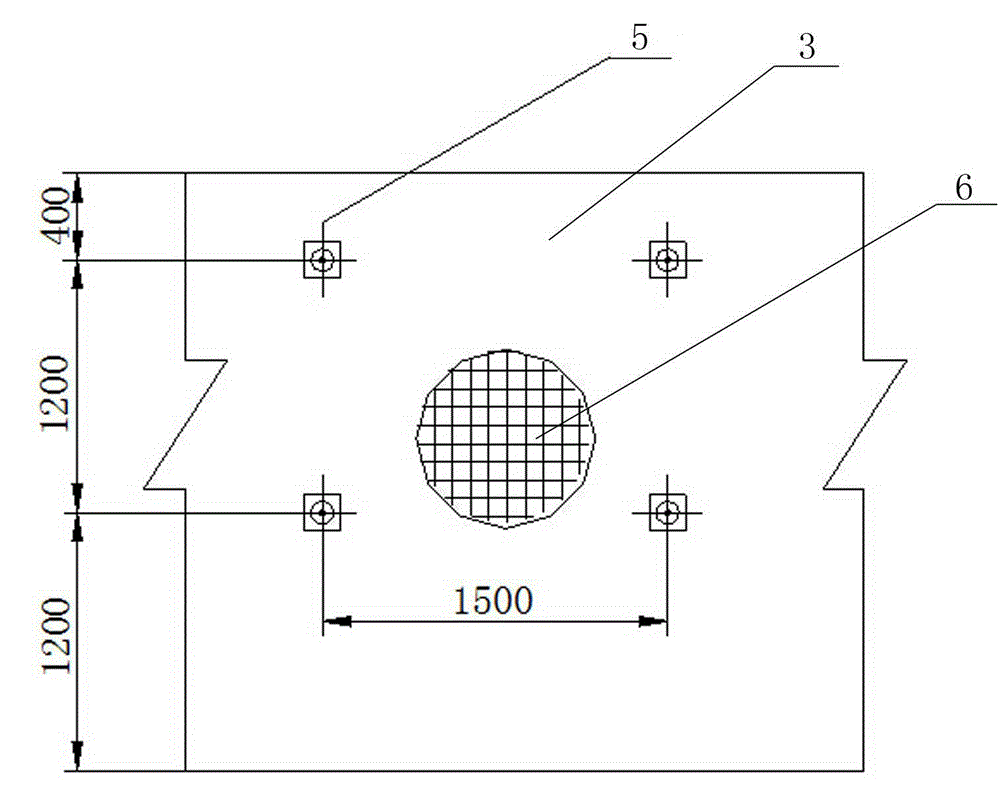

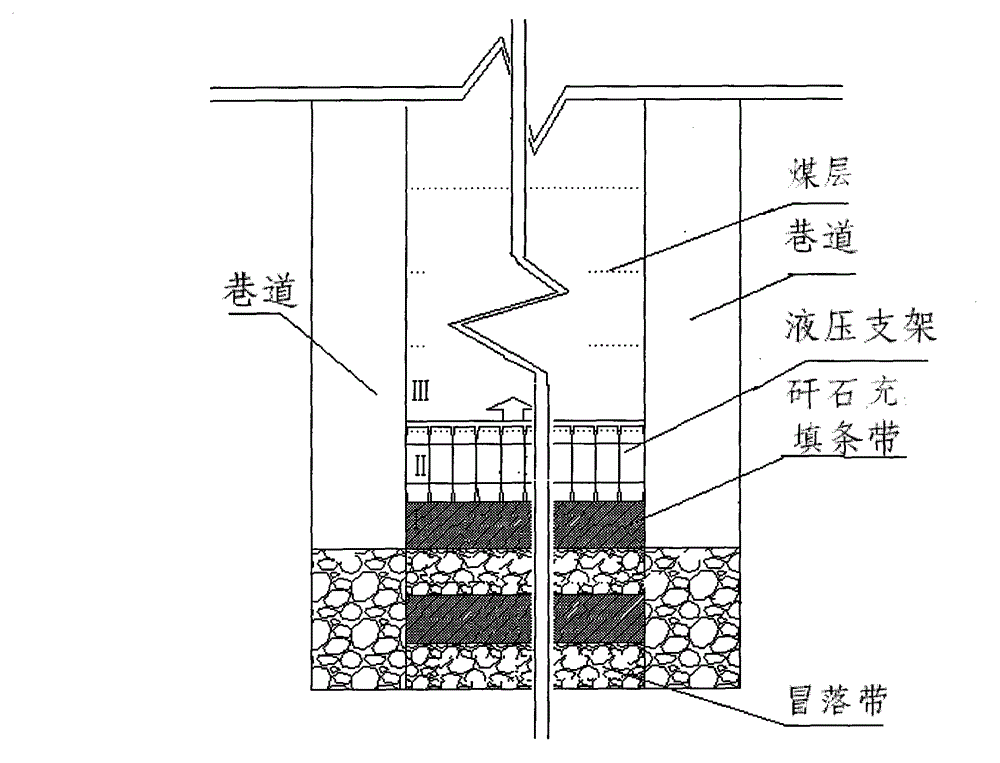

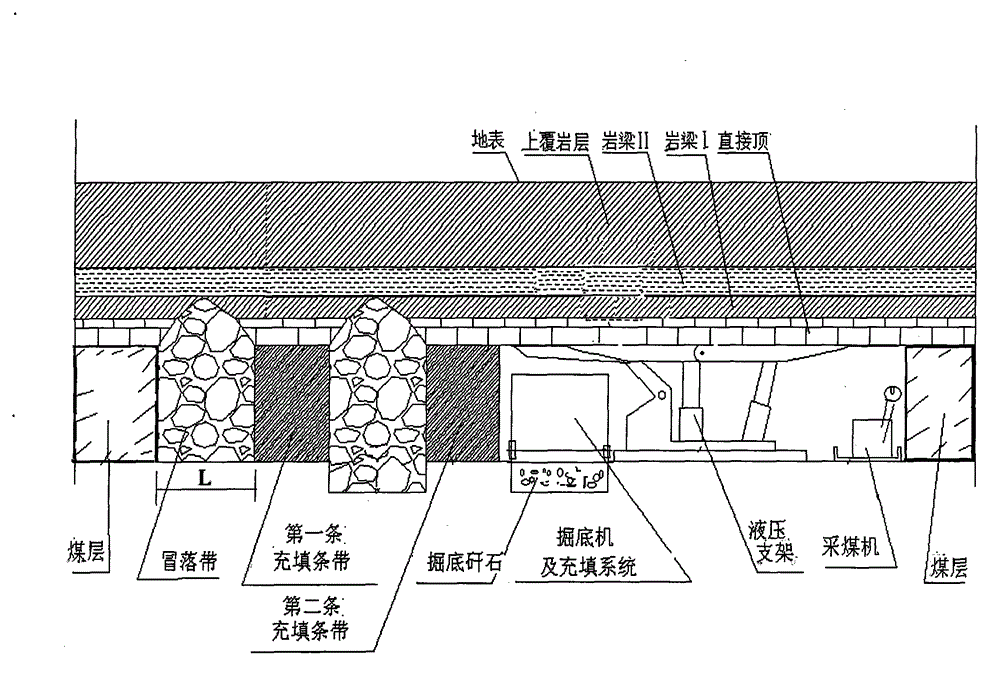

Method for performing coal mining and gangue cementation stripe filling simultaneously

ActiveCN102877848AImprove filling efficiencyWaiver of feesUnderground miningSurface miningFirst FillMining engineering

The invention discloses a method for performing coal mining and gangue cementation stripe filling simultaneously. When a working surface advances to a certain distance, an excavator and filling equipment are delivered under a filling support for assembly and adjustment; a bottom excavator excavates a bottom while coal mining machine mines coal, underlying strata excavated by the excavator are delivered to a filling bag through a filling system; the underlying strata form a first filling strip of a support goaf top plate after solidifying and sizing; and after filling of the first filling strip, the filling operation of a second filling strip is performed; and the steps are repeated accordingly, and coal mining and filling are performed simultaneously until a coal face is mined. According to the method, the filling mechanical equipment is transferred under a well, so that the ground site arrangement is reduced, gangue of down hole bottom excavating board is fully used, the problem of the filling material source is solved, transport links of filling materials are reduced, the filling system moving with the working surface simultaneously is formed, down hole filling is rapid and effective, and simultaneously, an efficient work flow of coal mining and filling simultaneously can be achieved.

Owner:SHANDONG UNIV OF SCI & TECH

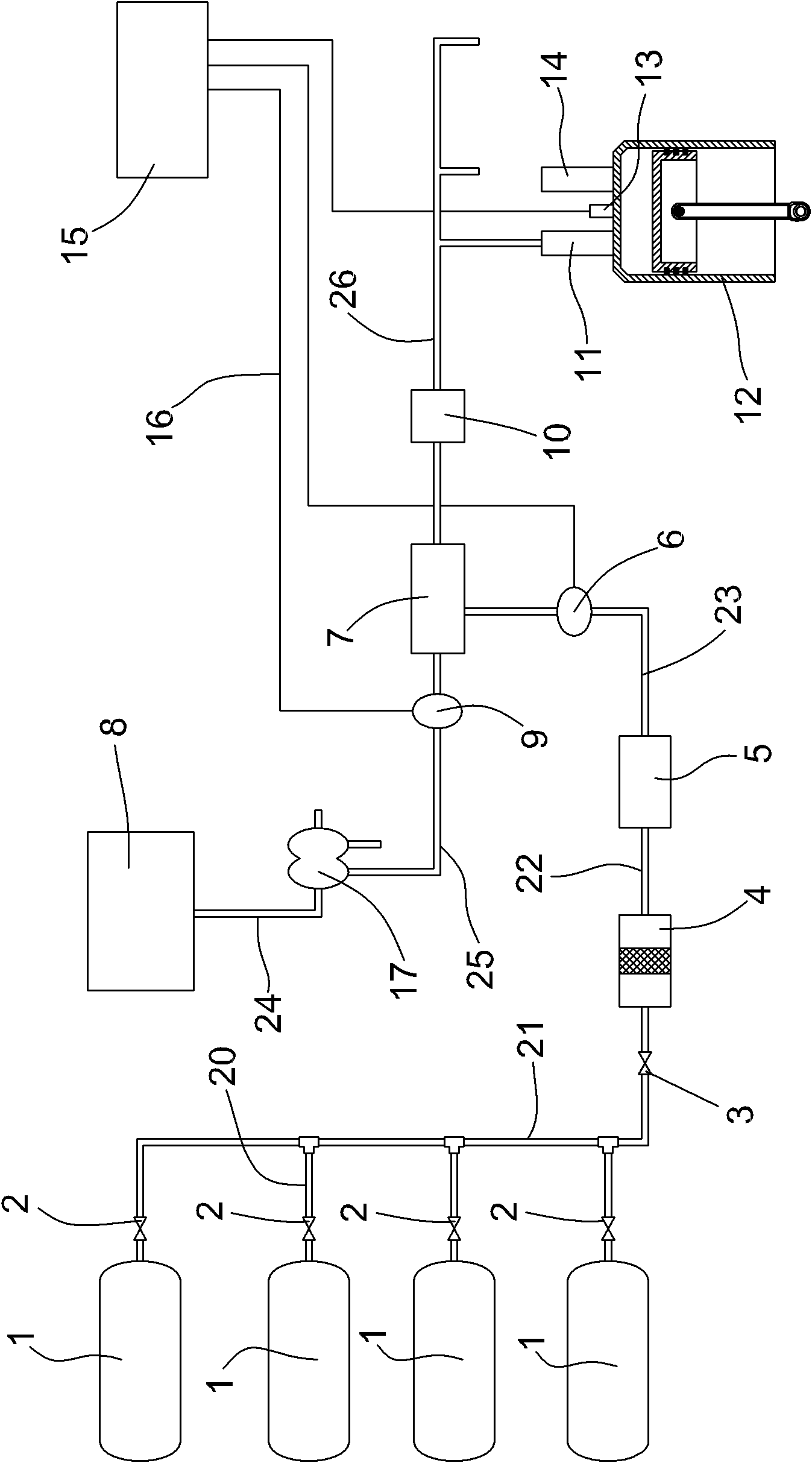

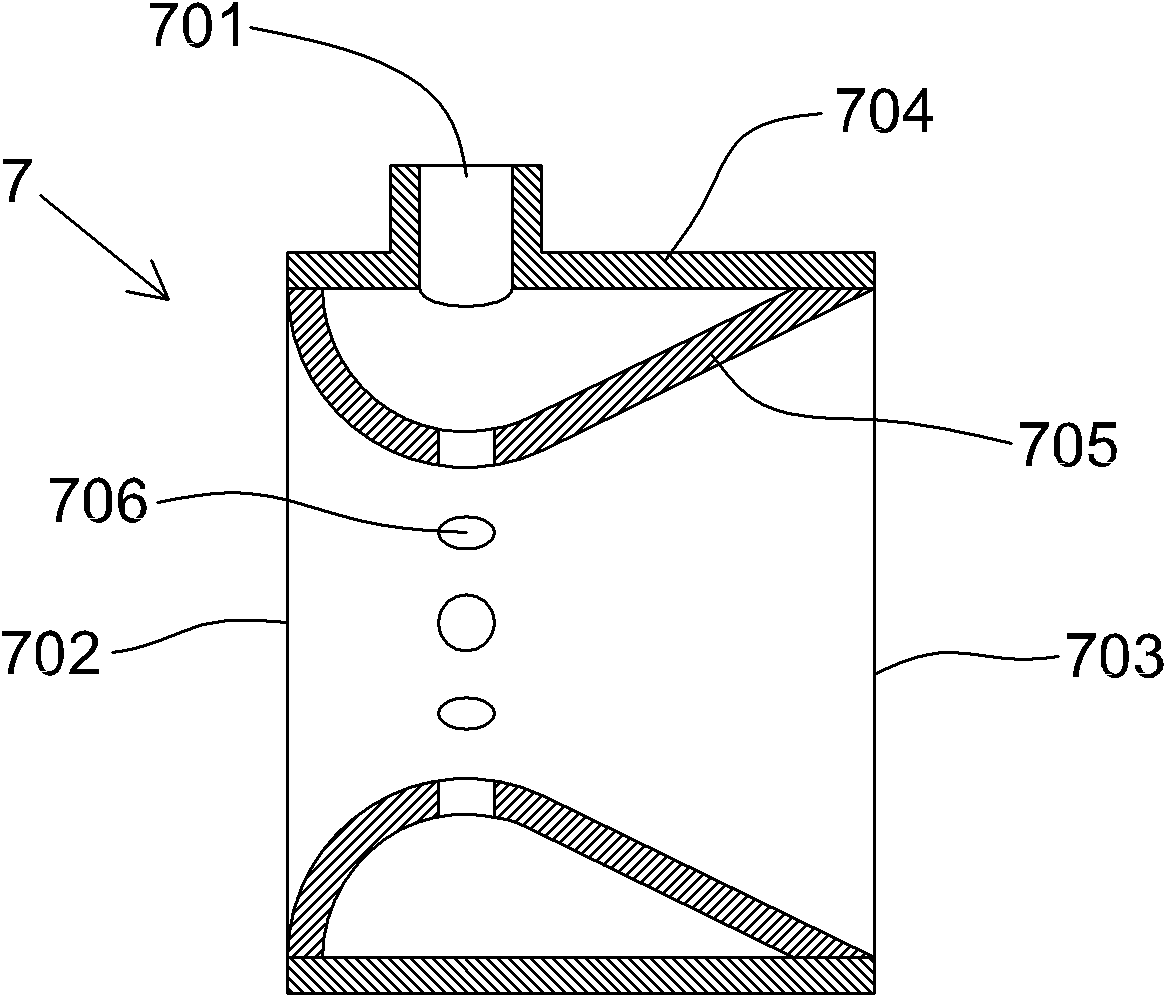

Methane-powered engine for farm vehicle

InactiveCN101858247ARealize multi-faceted utilizationReduce operating costsInternal combustion piston enginesFuel supply apparatusThrottleInlet valve

The invention discloses a methane-powered engine for a farm vehicle. The engine comprises a cylinder, a piston, a connecting rod, a crankshaft and a fuel supply system, wherein an air inlet valve, an air outlet valve and a spark plug are arranged on the cylinder; the fuel supply system consists of a fuel gas storage tank group, a fuel gas filter, a fuel gas pressure regulator, a fuel gas control electromagnetic valve, a fuel gas mixer, an air filter, an air control electromagnetic valve, an air throttle, an electronic control unit and a turbocharger; a fuel gas storage tank is connected with the fuel gas filter through a pipeline; the fuel gas filter is connected with the fuel gas pressure regulator through a pipeline; the fuel gas pressure regulator is connected with the fuel gas mixer through a pipeline; the air filter is connected with the turbocharger through a pipeline; the turbocharger is connected with the fuel gas mixer through a pipeline; and the fuel gas pressure regulator, the fuel gas control electromagnetic valve and the air control electromagnetic valve are connected with the electronic control unit. The engine of the invention takes methane obtained by purifying marsh gas as a fuel and is suitable for farm vehicles and farm equipment.

Owner:利华能源储运股份有限公司

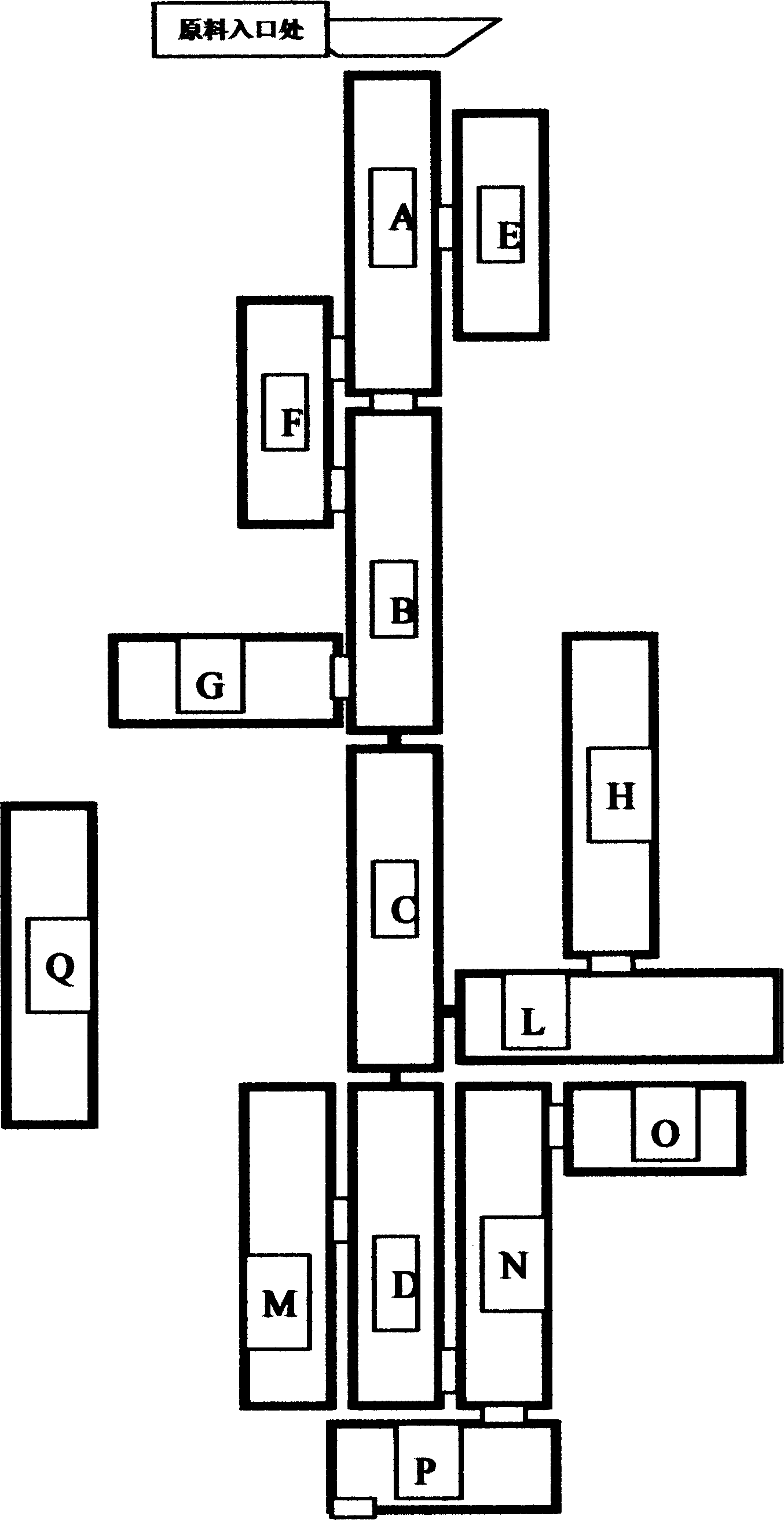

Layout method for underground dense-medium shallow-slot coal preparation in coal mine

InactiveCN102162364ACan't solve the problem of going to the wellSolve pollutionMaterial fill-upTunnelsWater treatment systemMining engineering

The invention discloses a layout method for underground dense-medium shallow-slot coal preparation in a coal mine. The method comprises the following steps: firstly exploiting a gangue bin in the mining-area rock formation around a coal bin, exploiting a first through-roadway between the coal bin and the gangue bin, and exploiting a second through-roadway from the gangue bin in the direction parallel to the mined-out area of a mining-area haulage roadway; and then exploiting a third through-roadway which is communicated with the mining-area haulage roadway, mounting a coal-gangue dense-mediumshallow-slot separator in the first through-roadway, mounting a coal slurry processing system and a gangue breaking system in the second through-roadway, and mounting a gangue storage and filling system in the third through-roadway. According to the invention, the coal-gangue dense-medium shallow-slot separator and the coal slurry processing system are mounted underground instead of on the ground, so that all the gangues are kept underground and the raw gangues and the sorted gangues are all re-filled to the mined-out area, which prevents the pollution of the gangue hill on the ground in the coal mine.

Owner:SHANDONG XINYANG ENERGY

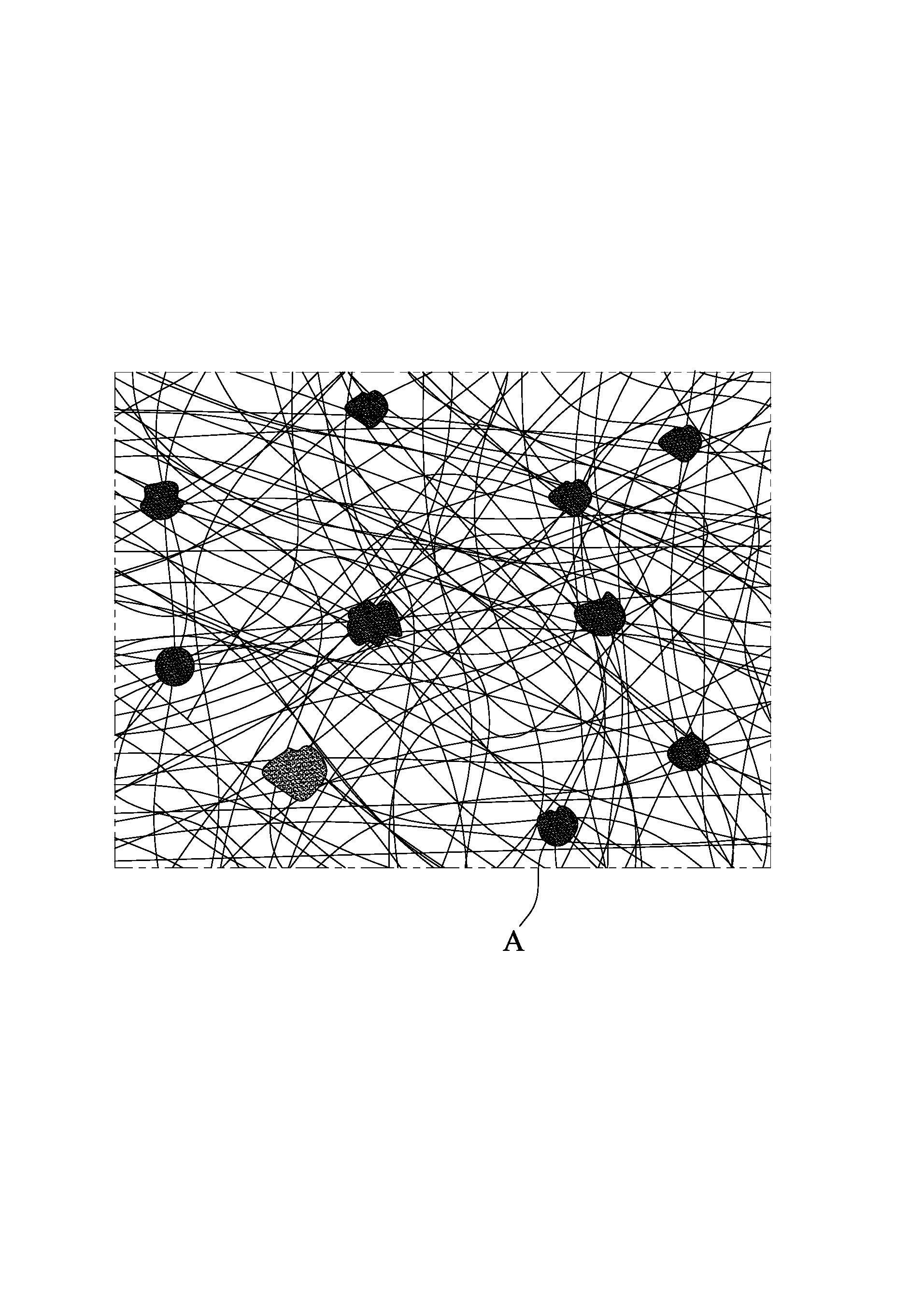

Filament nonwoven fabric and production process thereof

InactiveCN102587041AReduce transportation linksAvoid secondary pollutionNon-woven fabricsManufacturing cost reductionSquare Millimeter

Disclosed are a filament nonwoven fabric and a production process thereof. A nonwoven fabric coil is composed of filament fibers, the length of each filament fiber is equal to or larger than 1000mm, each filament fiber is made of low-melting-point thermoplastic polymer and high-melting-point thermoplastic polymer, the low-melting-point thermoplastic polymer with a melting point smaller than 150 DEG C is positioned on the surface of each filament fiber, the filament fibers are adhered together to form the nonwoven fabric coil by melting the low-melting-point thermoplastic polymer on the surfaces of the fibers, each adhesion point of the fibers is formed by low-melting-point thermoplastic polymer surfaces of two filament fibers, and average area of each adhesion point is smaller than 0.005 square millimeter. Therefore, the nonwoven fabric is bulky, soft and elastic, and has no warping fiber ends. The filaments are formed by one-step forming, the fabric is formed by hot air process, and compared with traditional procedures of fiber chopping, unpacking, chopped fiber carding and laying, a transport procedure is eliminated and production cost is lowered.

Owner:XIAMEN YANJAN NEW MATERIAL CO LTD

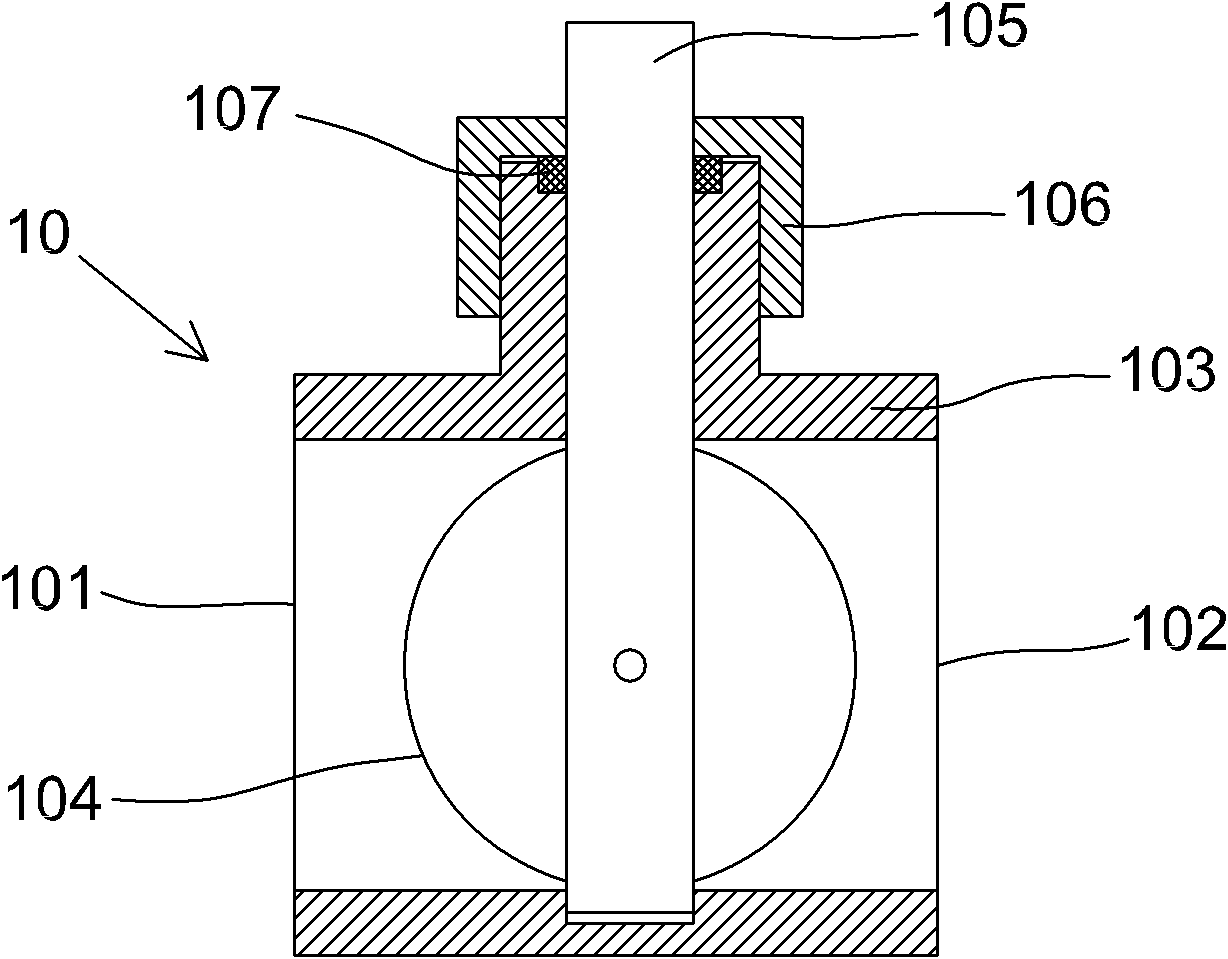

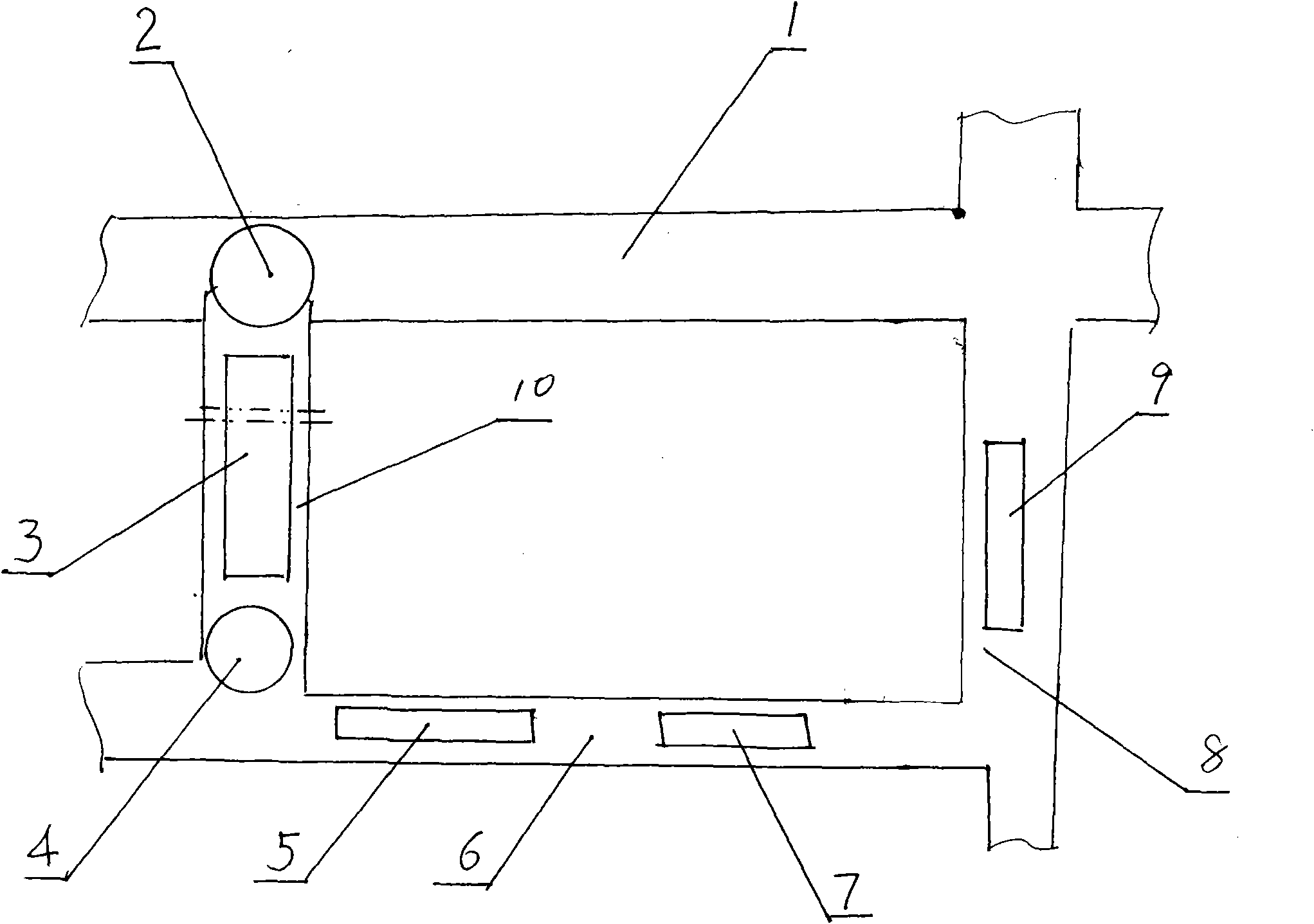

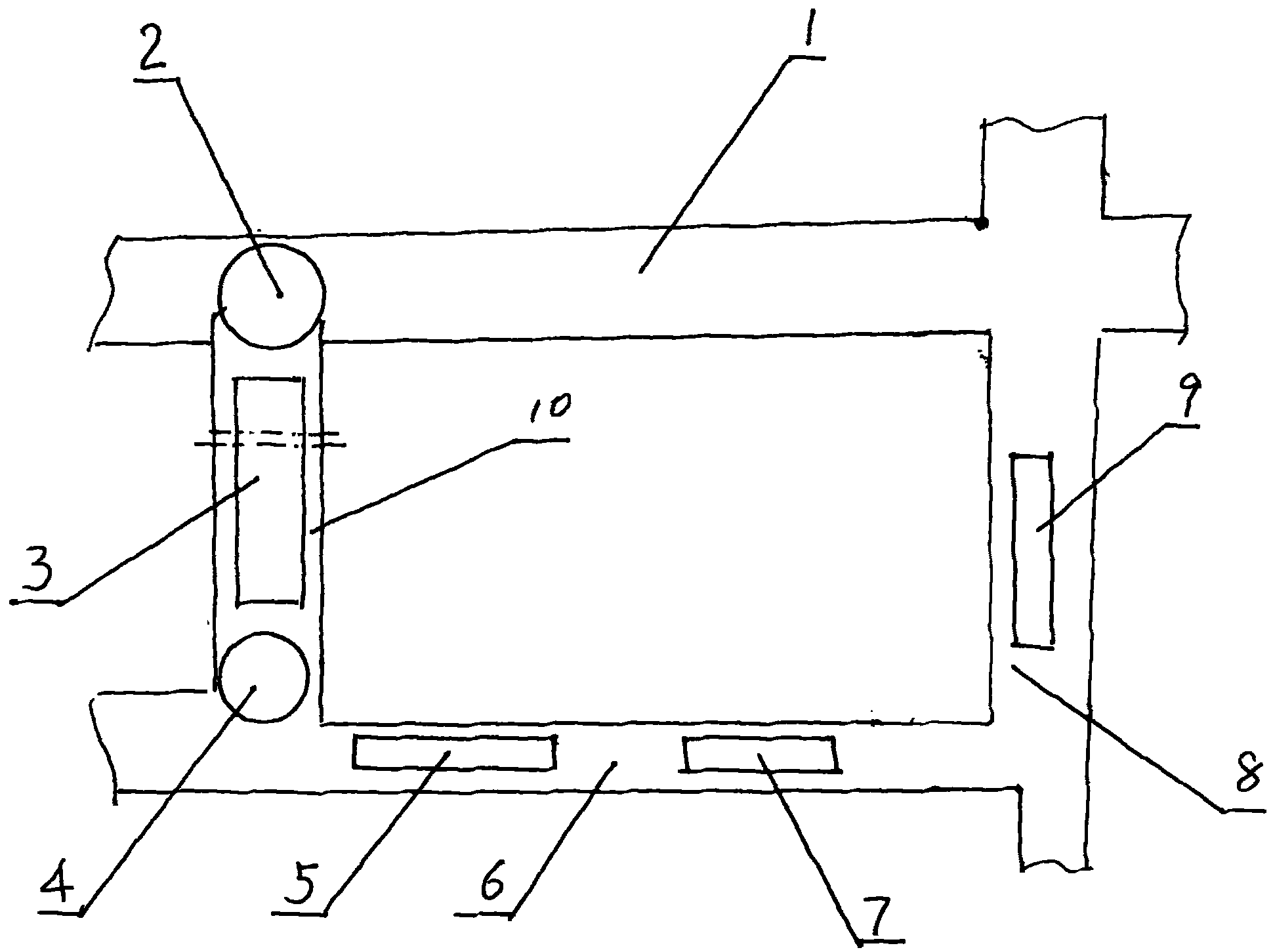

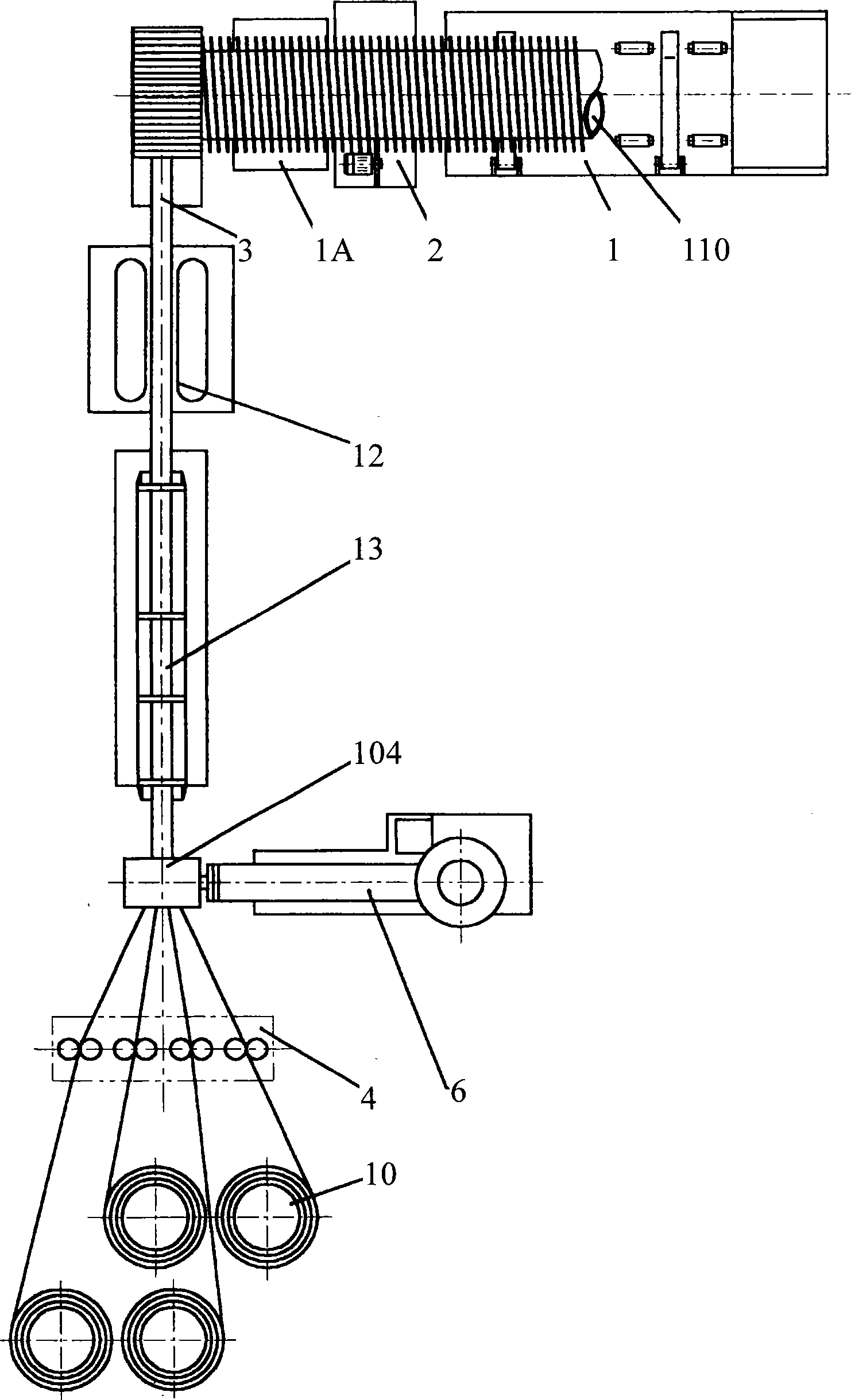

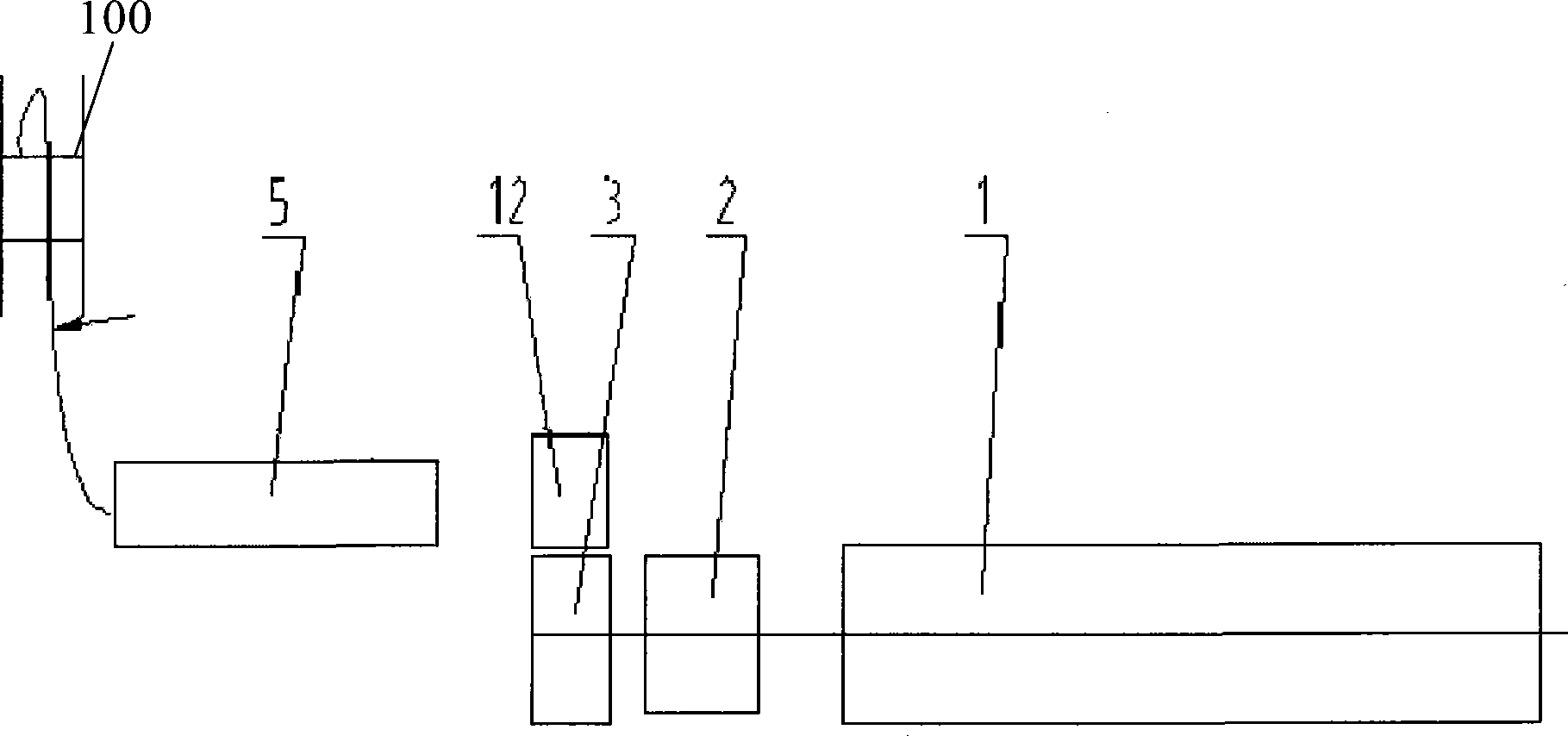

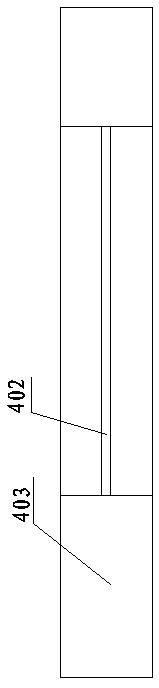

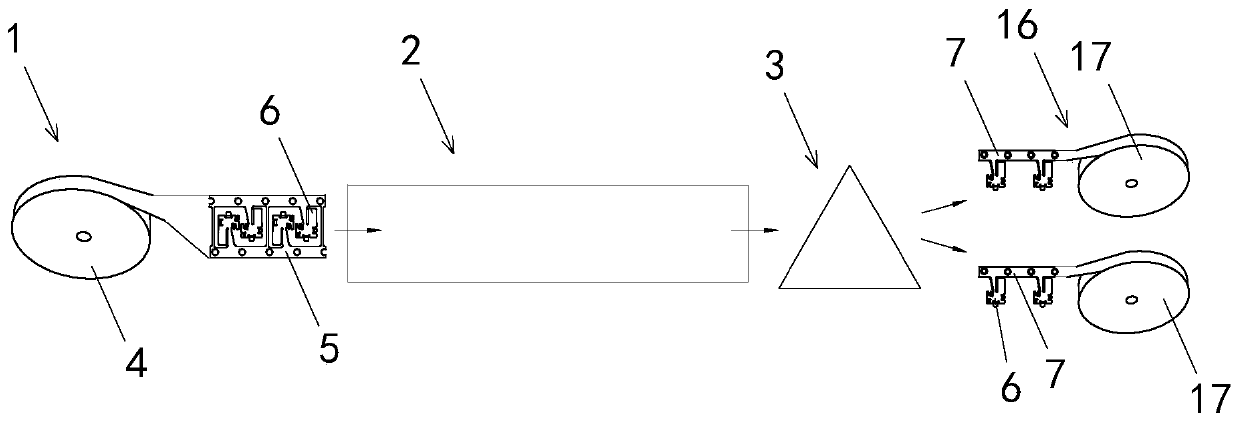

Winding-pipe production device

InactiveCN101456253AReduce transportation linksLow transportation costTubular articlesControl systemEngineering

The invention relates to a wound pipe production device. The production device comprises a belt supplying part, a pipe production part, a control system and a movable foundation, wherein the control system and the movable foundation are connected with a driving mechanism of the belt supplying part and the pipe production part. The pipe production part comprises a feeding device, a winding device, a pipe cutting device and a support, wherein the feeding device, the winding device, the pipe cutting device and the support are arranged on the movable foundation. The winding device, the pipe cutting device and the support are arranged sequentially in a matching mode. The feeding device and the winding device are arranged in a matching mode to realize feeding along a cutting direction. The wound pipe production device can be delivered to a site where pipes are used for on-site production, thereby saving pipe transpiration and pipe transportation cost. The wound pipe production device is flexible in structure, can use compound belts as raw material to product pipes, carry out complete belt production and pipe production, use steel strips and plastic raw materials to produce pipes and produce wound pipes of various pipe diameters.

Owner:HUAHAN SCI & TECH

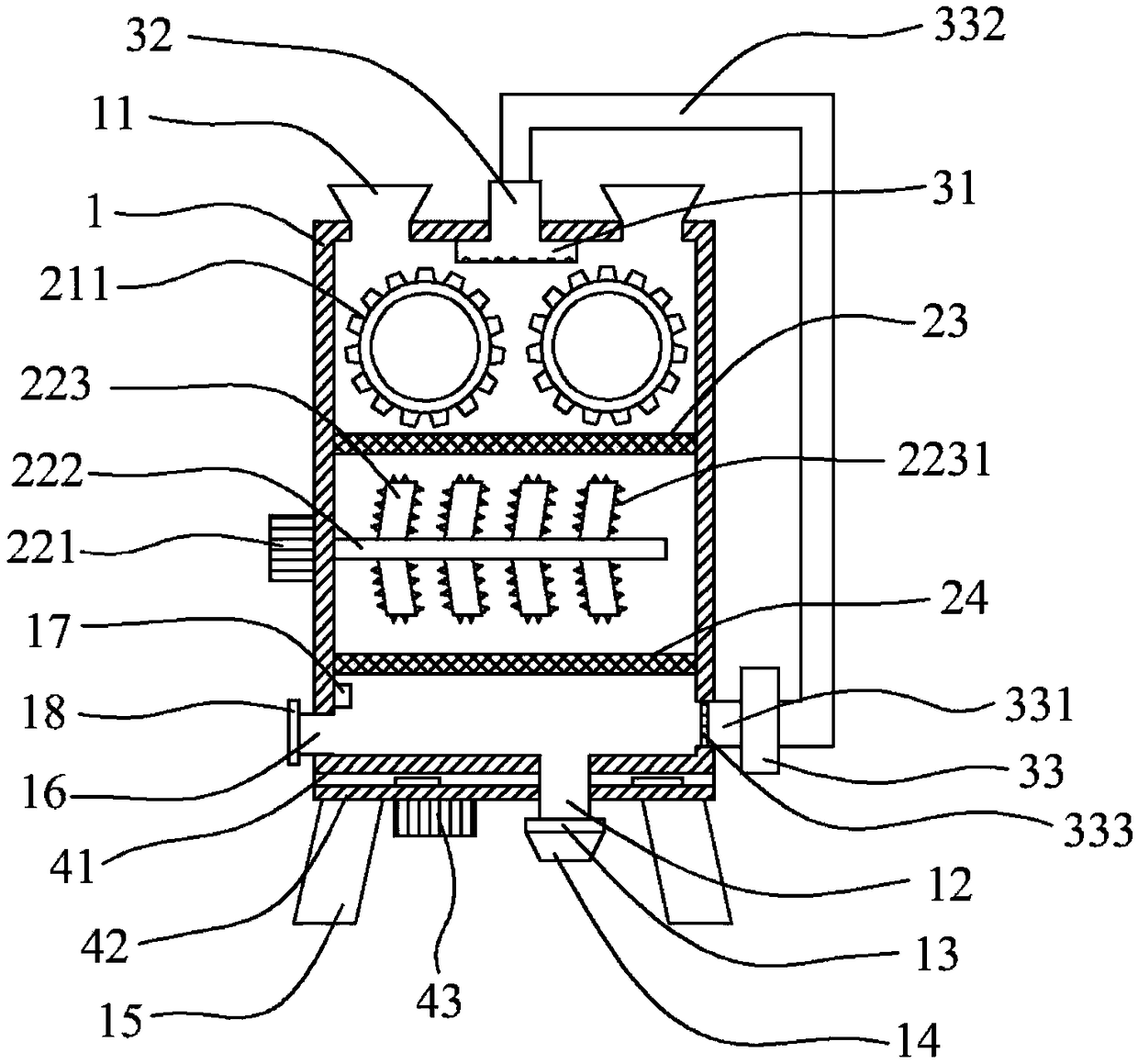

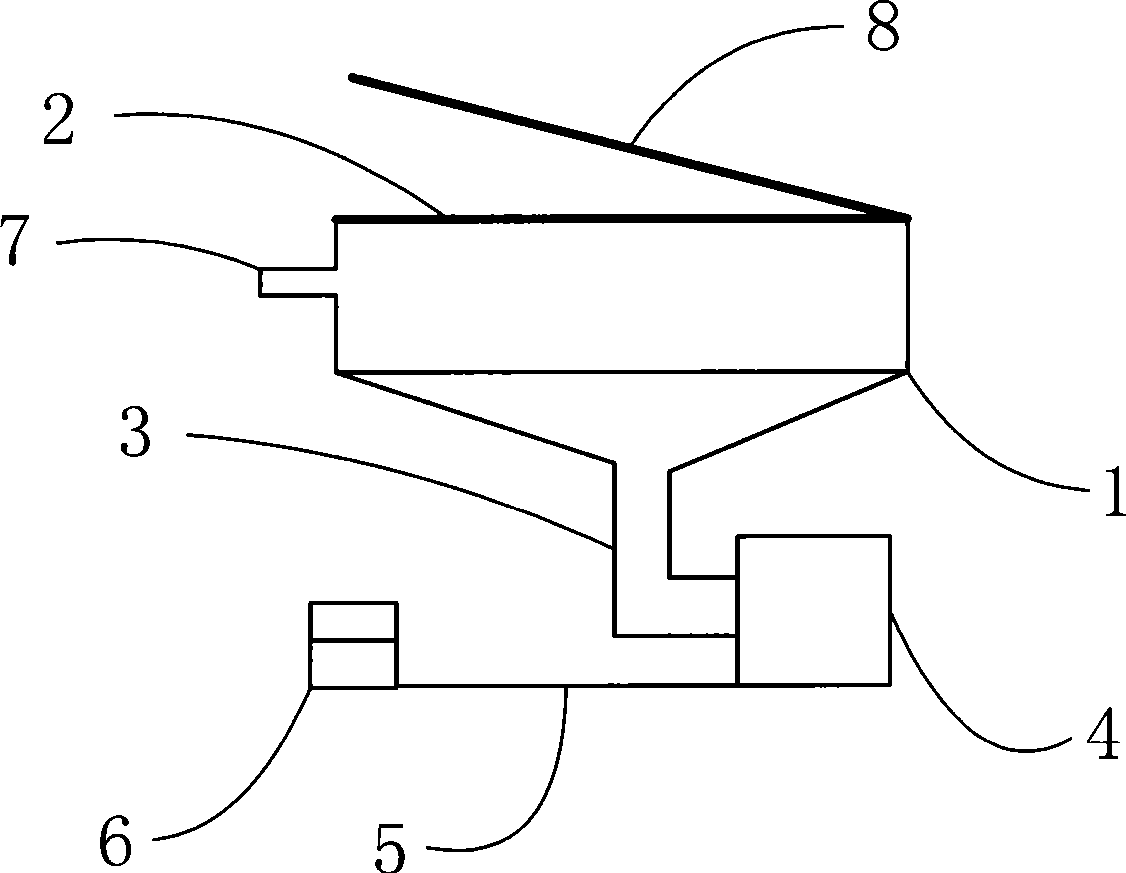

Multifunctional glass crusher

InactiveCN109201273AReduce transportation linksReduce splashCleaning using liquidsGrain treatmentsCrusherGlass manufacturing

The invention discloses a multifunctional glass crusher, and relates to the technical and mechanical field of glass manufacturing. The multifunctional glass crusher solves the problems that glass splash, accidental injury to operators and increased operation cost are prone to causing when waste glass is transported into a glass crusher after being cleaned and dried. The multifunctional glass crusher comprises a cavity, wherein a crushing device, a cleaning device and a drying device are arranged in the cavity; the crushing device comprises a primary crushing device and a secondary crushing device, wherein the primary crushing device is positioned above the secondary crushing device, and a first sieve plate is arranged between the primary crushing device and the secondary crushing device; the cleaning device comprises a spray head arranged on the inner wall of the cavity and a liquid inlet connected to the upper end of the spray head; and the drying device is positioned below the secondary crushing mechanism. The multifunctional glass crusher has the beneficial effects that the waste glass can be cleaned, crushed and dried at the same time, glass transportation links are omitted, glass splashing is reduced, and operation cost is reduced.

Owner:TG ANHUI GLASS

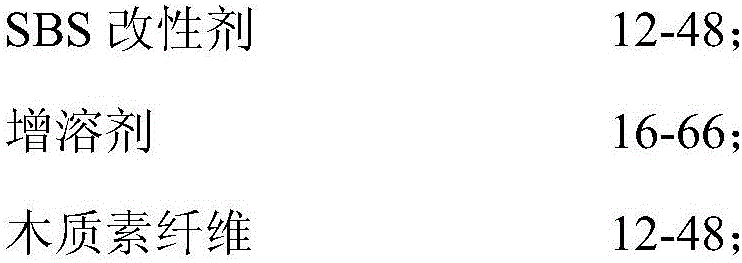

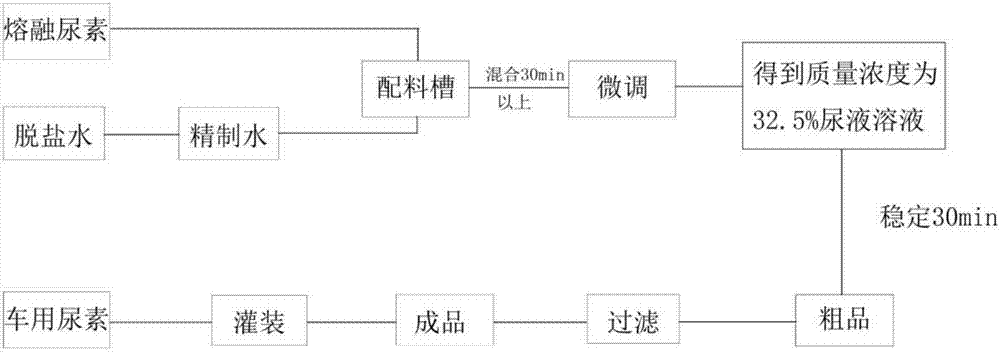

SMA asphalt concrete modifier and preparation method thereof

The invention discloses an SMA asphalt concrete modifier and a preparation method thereof, and relates to the field of road engineering materials. The SMA asphalt concrete modifier comprises a modifier basic material composed of an SBS modifier, a cosolvent and a solubilizer, lignin fibers, a crosslinking agent and an accelerator. The preparation method comprises the steps: mixing the SBS modifier, cosolvent and solubilizer at high temperature to obtain the uniformly mixed modifier basic material; carrying out primary cooling treatment on the modified asphalt basic material, adding the lignin fibers and stirring to obtain the modifier basic material mixed with the lignin fibers; carrying out secondary cooling treatment on the modifier basic material mixed with the lignin fibers, adding the crosslinking agent and accelerator, and after uniformly mixing, granulating to obtain the SMA asphalt concrete modifier. The modifier prepared according to the preparation method can be directly added on site, solves the problems of segregation in storage and property attenuation of SBS modified asphalt, and also solves the construction deficiency of ununiform dispersion of added fibers and probable appearance of oil stain.

Owner:BEIJING ZHONGLU PAVING TECH +4

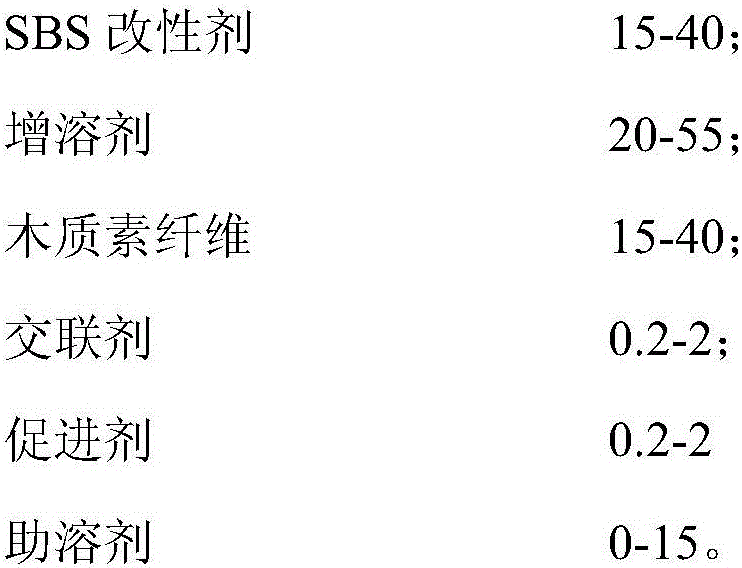

Composite modifier and high-scattering-resistance drainage asphalt concrete prepared through same

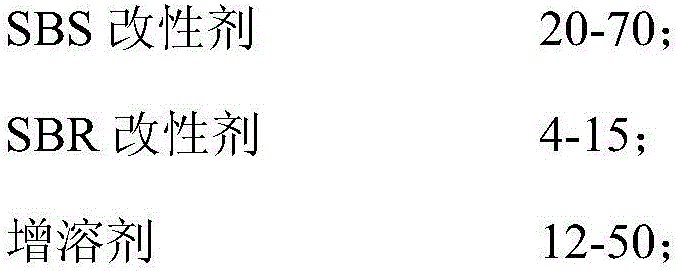

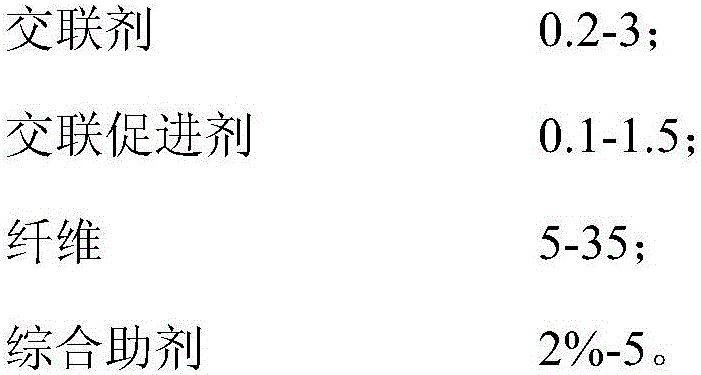

ActiveCN106630731AImprove adhesionImprove heat aging resistanceClimate change adaptationCeramicwareFiberCross-link

The invention discloses a composite modifier and a high-scattering-resistance drainage asphalt concrete prepared through the same and relates to the field of road engineering materials. The composite modifier is composed of base materials, fiber, comprehensive additives, cross-linking agent and cross-linking promoter, wherein the base materials are composed of SBS (styrene-butadiene-styrene) modifier, SBR (styrene butadiene rubber) modifier and solubilizer. The drainage asphalt concrete prepared through the composite modifier is high in scattering resistance. Through field deployment of conventional asphalt, aggregate, mineral powder and the composite modifier, a high-performance and stable-performance drainage mixture can obtained and meanwhile is more stable in properties compared with those applying modified asphalt, so that worries on storage segregation and performance degradation of the modified asphalt can be saved, and meanwhile construction deficiencies of dispersing non-uniformity of fiber deployment and grease spots can be completely avoided.

Owner:BEIJING ZHONGLU PAVING TECH +2

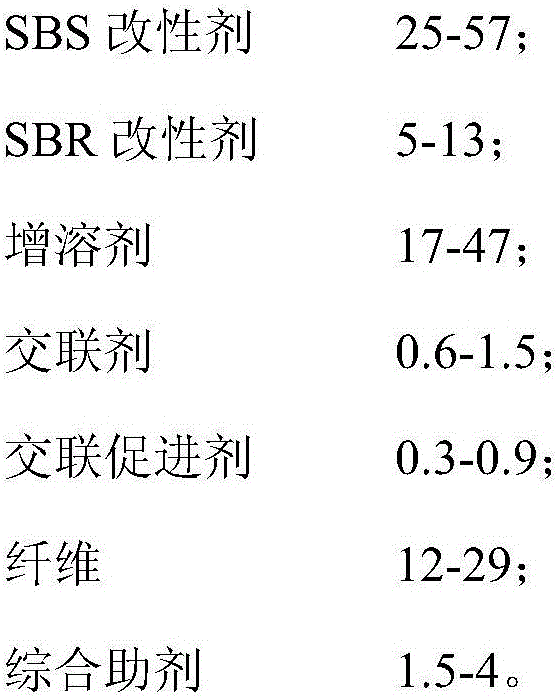

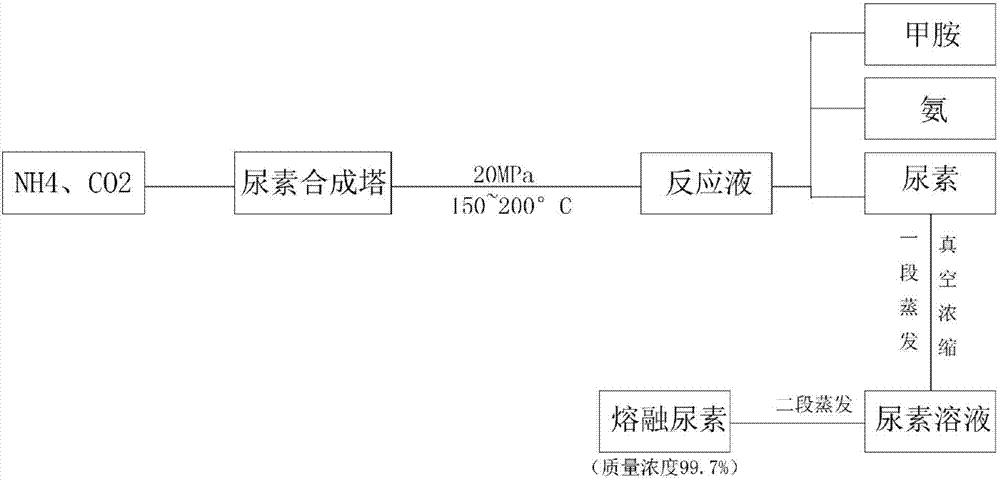

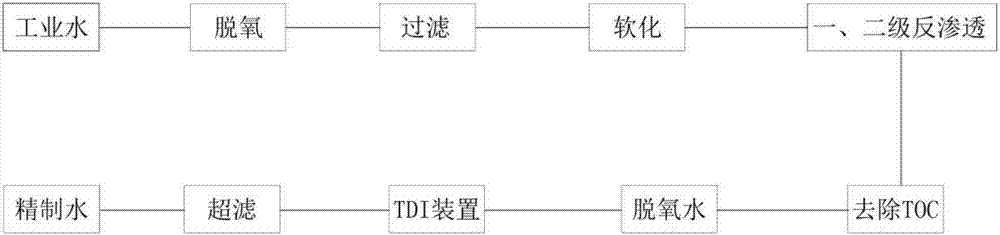

Preparation method of vehicle urea

InactiveCN107417576ASimple production processImprove yieldUrea derivatives preparationProductsUreaChemistry

The invention discloses a preparation method of vehicle urea. The preparation method comprises the following steps: (S1) synthesizing ammonia and carbon dioxide so as to obtain fused urea, wherein the mass concentration of the fused urea is 80%, and the mass percentage of biuret is less than or equal to 0.25%; (S2) treating desalted water by virtue of water refining equipment, so as to obtain refined water with a resistivity of 18Mohm.cm-20Mohm.cm; (S3) simultaneously adding the fused urea obtained in the step (S1) and the refined water obtained in the step (S2) into a batching tank in a proportion of 1 to 1.5, stirring for 30 minutes or longer, so as to obtain a urea solution with a mass concentration of 31.5%-32%; (S4) finely adjusting the amount of the fused urea or the refined water, so as to obtain the urea solution with a mass concentration of 32.5%, namely crude urea; (S5) filtering the crude urea so as to obtain vehicle urea; and (S6) conveying the vehicle urea into a finished product tank, and pumping the vehicle urea into a filling machine by virtue of a finished product pump, so as to obtain the finished vehicle urea. By utilizing the fused urea as the raw material, the vehicle urea with relatively high quality is obtained.

Owner:四川金素环保科技有限公司

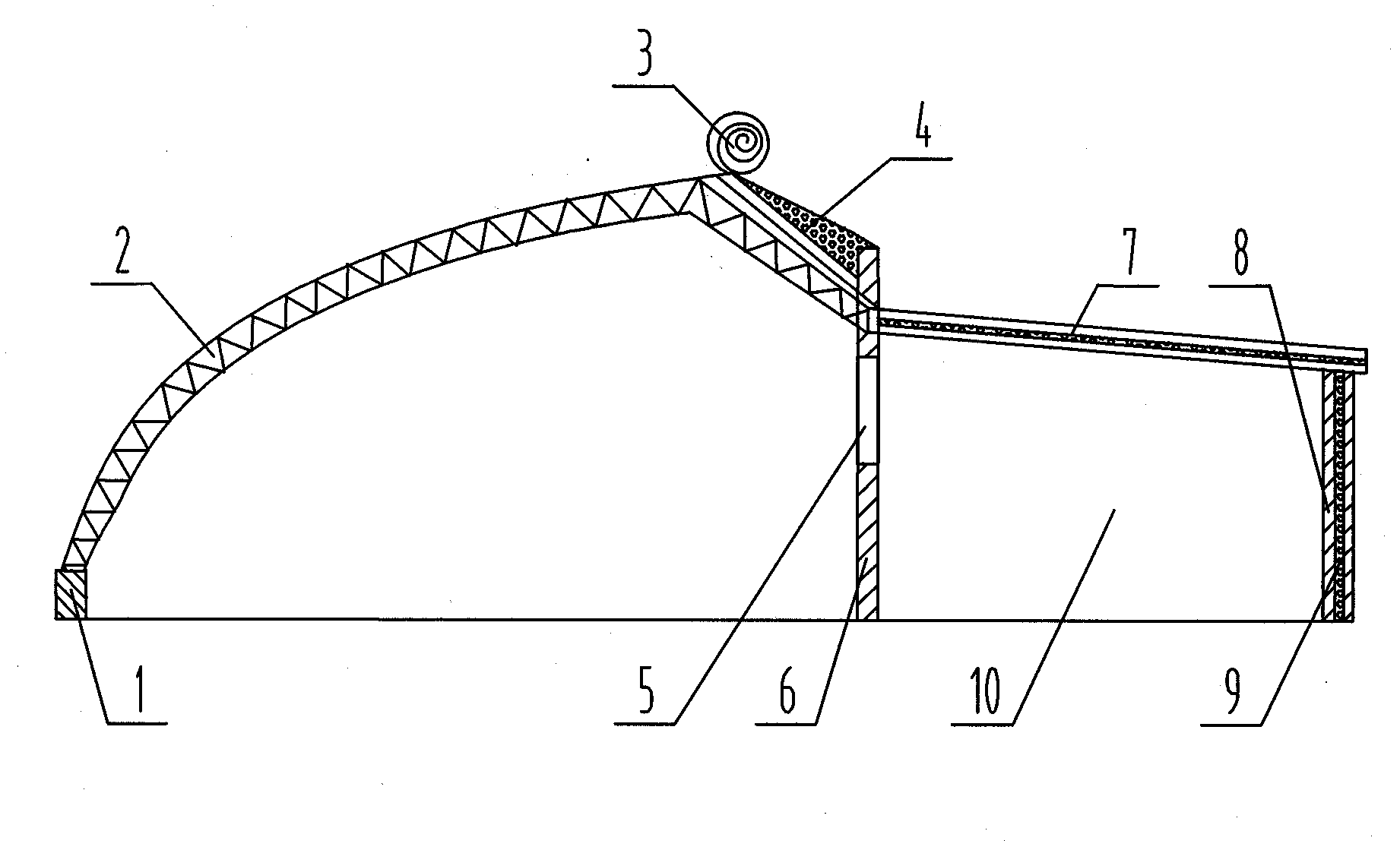

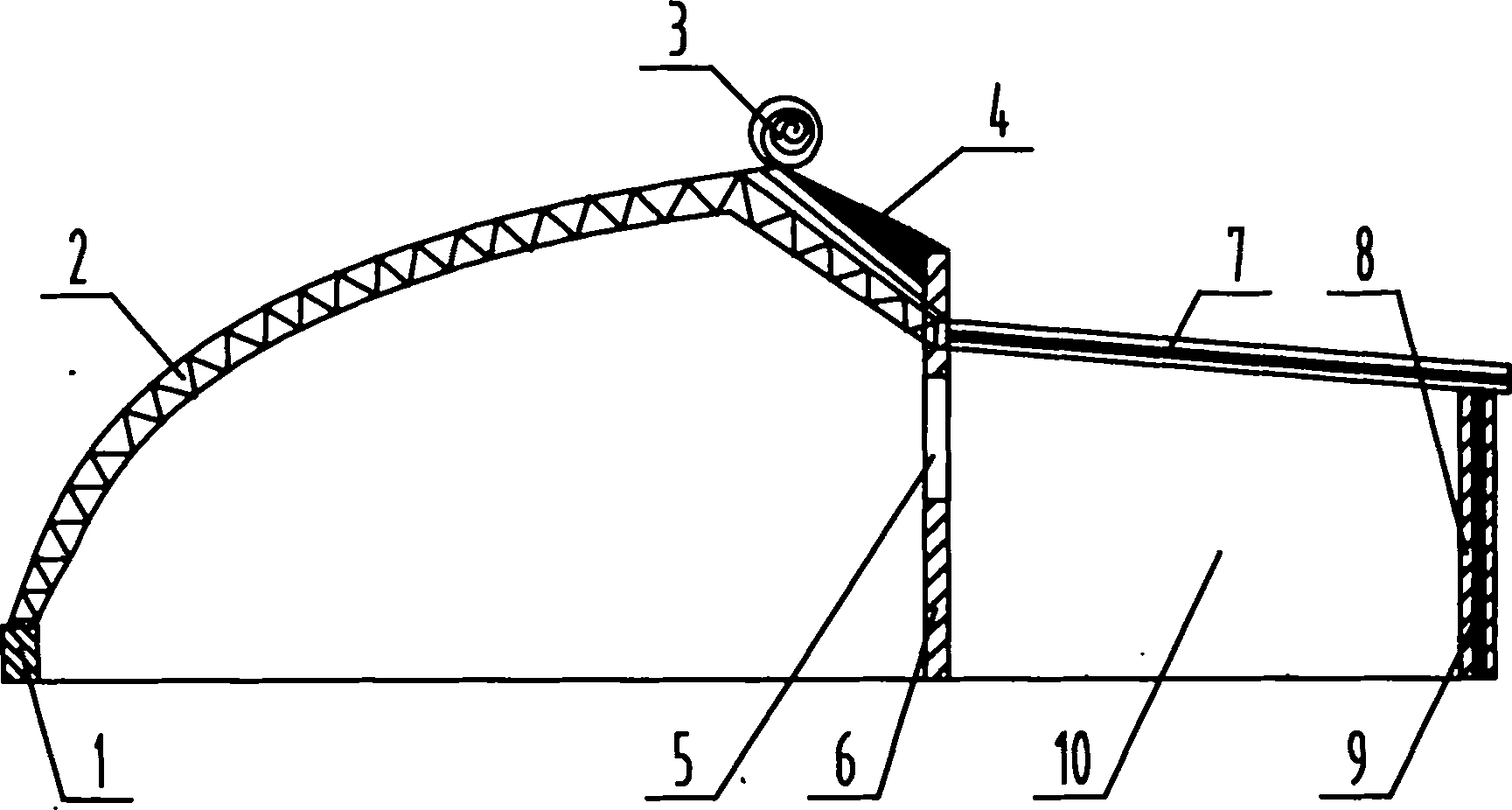

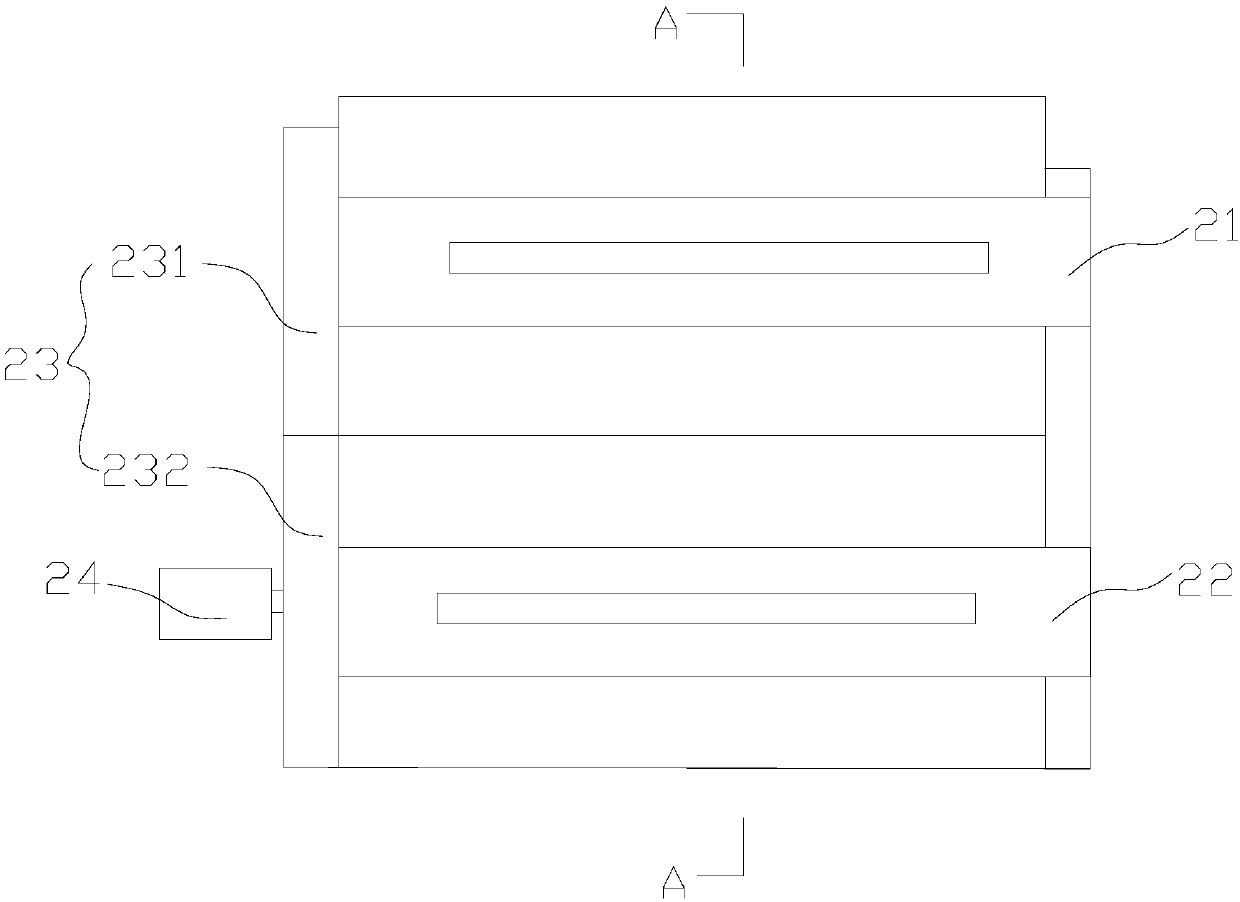

Tissue culture and seedling raising integration energy-saving sunlight conjoined greenhouse

InactiveCN102657045AReach exchangeStable temperatureClimate change adaptationGreenhouse cultivationBrickDaylight

The invention discloses a tissue culture and seedling raising integration energy-saving sunlight conjoined greenhouse which has good thermal insulating properties and energy conservation effects, saves cost and reduces the risks in tissue culture and seedling transportation. The tissue culture and seedling raising integration energy-saving sunlight conjoined greenhouse comprises a solar greenhouse consisting of a sleeper wall, a framework, a rear slope, a bearing wall and gable walls, as well as a roller shutter arranged on the roof of the framework, wherein a rear house is connected with the rear side of the solar greenhouse to form the conjoined greenhouse, the rear house and the solar greenhouse shares the bearing wall, a protective wall body of the conjoined greenhouse consists of the sleeper wall at the front bottom corner of the solar greenhouse, the gable walls at the two ends of the solar greenhouse, the bearing wall in the middle of the solar greenhouse and brick walls of the rear house, a row of tissue culture rooms is arranged in the rear house in uniform intervals along the longitudinal direction, and each tissue culture room is provided with a door and window on the bearing wall. The conjoined greenhouse is applicable to the integral energy-saving production for tissue culture and seed raising.

Owner:SHENYANG AGRI UNIV

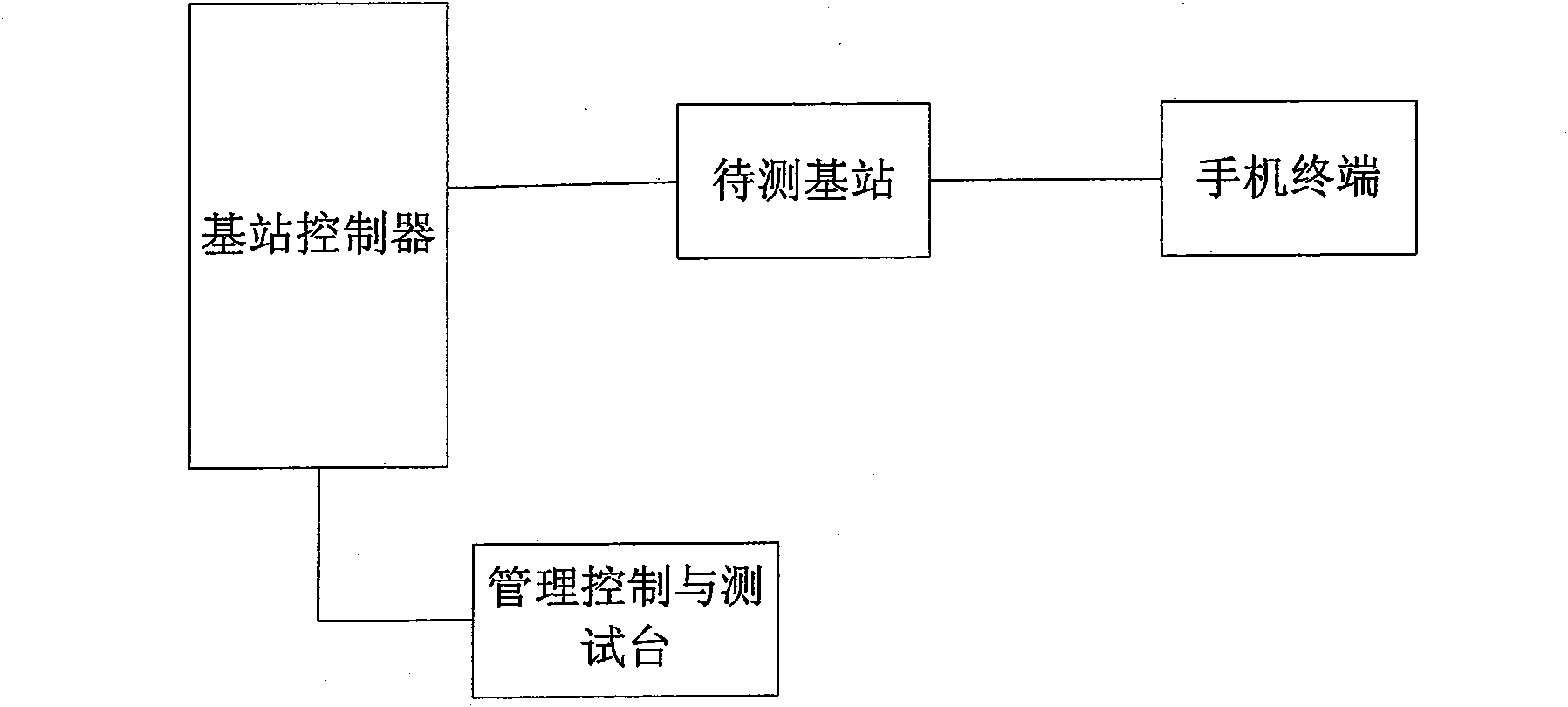

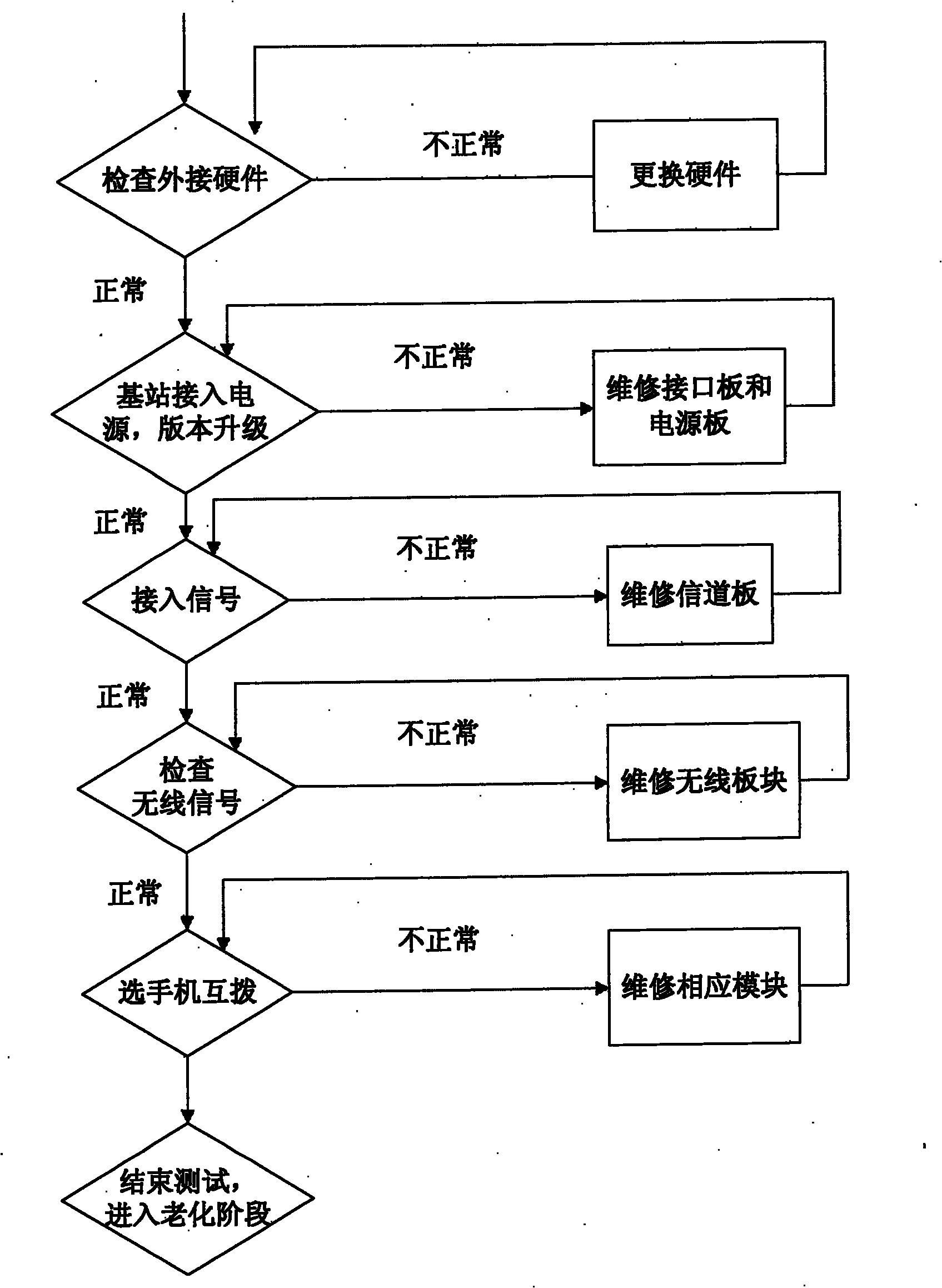

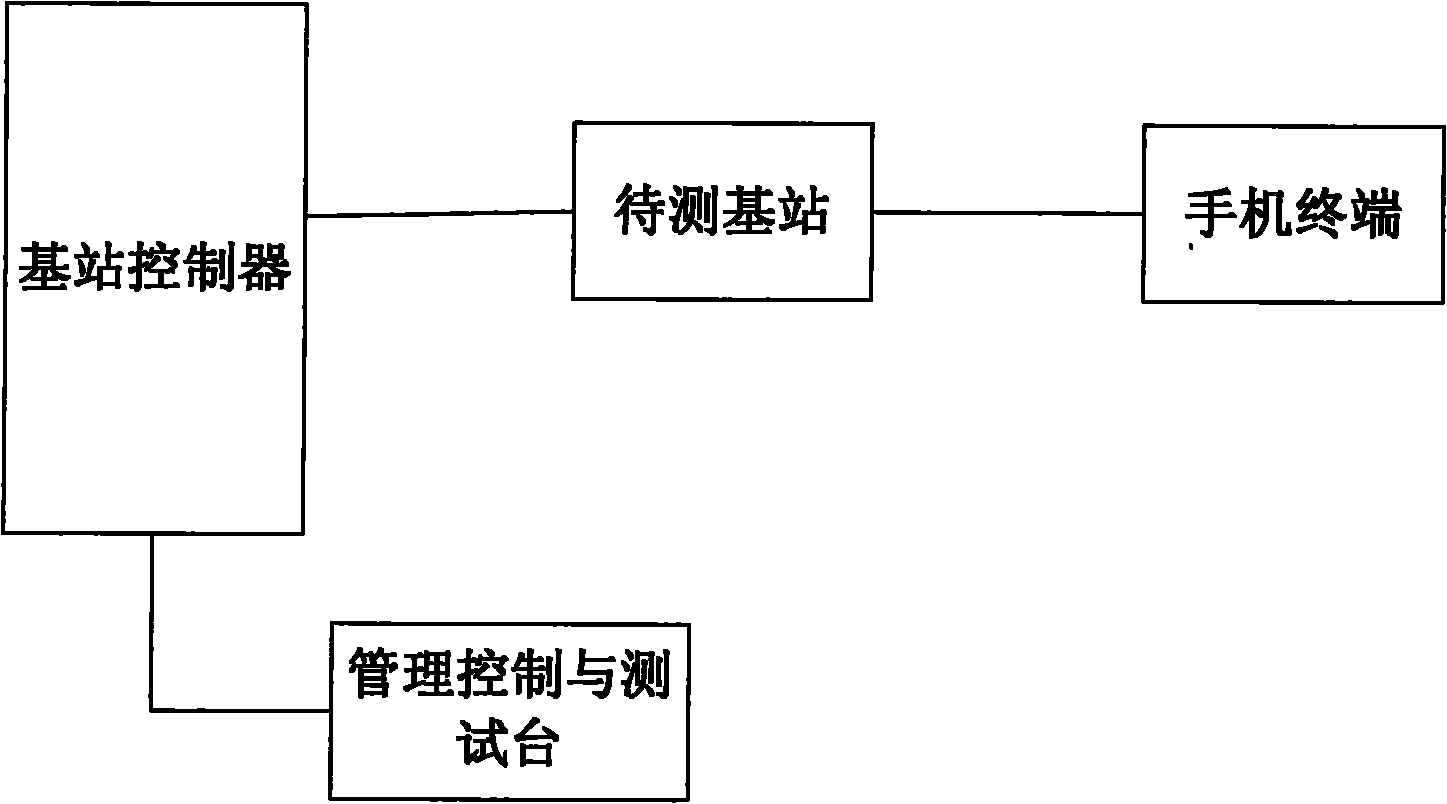

Maintenance system for personal handy-phone system base station

InactiveCN101909309ATimely repairImprove operation and maintenance response timeWireless communicationEngineeringLarge size

The invention relates to a maintenance system for a personal handy-phone system base station. The maintenance system comprises a base station controller, a management control and test board, a base station to be tested and a phone terminal, wherein one end of the base station controller is connected with the management control and test board, and the other end of the base station controller is connected with the base station to be tested; and the base station to be tested is communicated with the phone terminal through a channel. Compared with the prior art, the maintenance system performs repair timely, improves the operation and maintenance response time and is favorable for local maintenance test; because the base station has a large size and weights dozens of jin, the labor consumption is reduced by reducing the transportation process; and the system lowers the operation and maintenance cost and reduces the number of spare parts.

Owner:SHANGHAI GONGLIAN COMM INFORMATION DEV

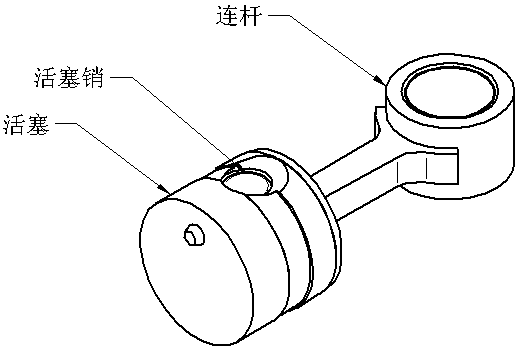

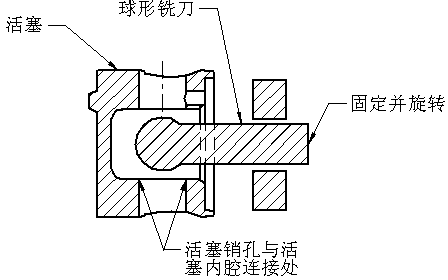

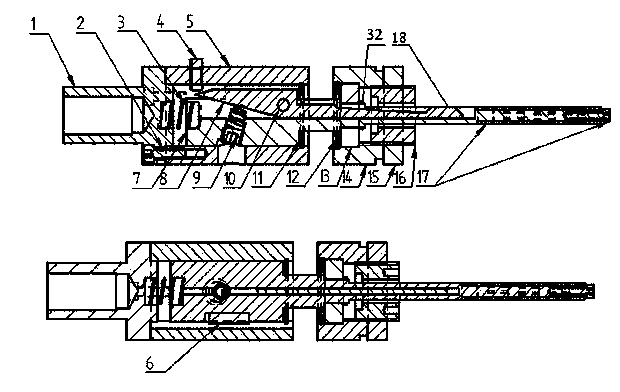

Refrigerator compressor piston pin hole combination processing method

ActiveCN104227342AReduce bumpsImprove manufacturing precisionPositive displacement pump componentsPositive-displacement liquid enginesIceboxStructural engineering

The invention provides a refrigerator compressor piston pin hole combination processing method. A combination processing cutter is adopted, and the method comprises a processing step. The combination processing cutter consists of a flange cutter handle assembly, a sliding sleeve assembly, a sliding cutter rod shaft assembly and a bearing assembly. The processing step comprises the following processes that the first roll finishing is sequentially carried out on pin holes, the chamfering is carried out at a connecting part of a piston pin hole and an inner cavity, and the piston pin hole is subjected to the roll finishing again. The combination processing method has the advantages that the production rhythm is reduced, the oil tank processing quality is improved, and the use range of the cutter is expanded. Compared with the single-cutter-blade processing and cutting, the processing by the combined cutter has the advantages that the processing efficiency is improved by 20 percent, and the production and work efficiency is improved by 18.8 percent, so wide market prospects are realized.

Owner:CHANGHONG HUAYI COMPRESSOR CO LTD

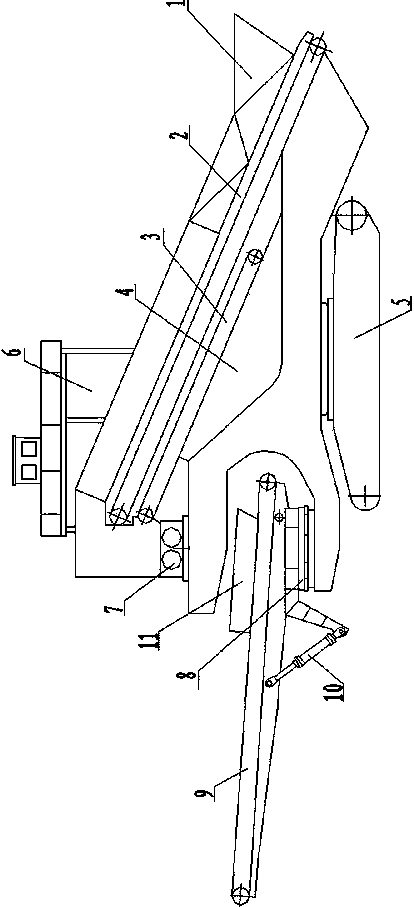

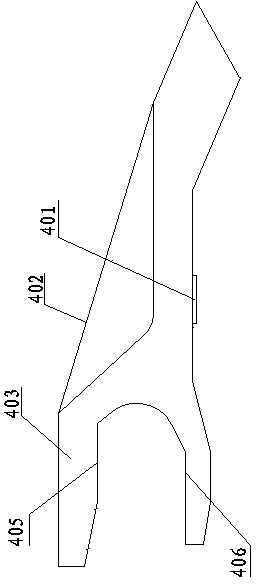

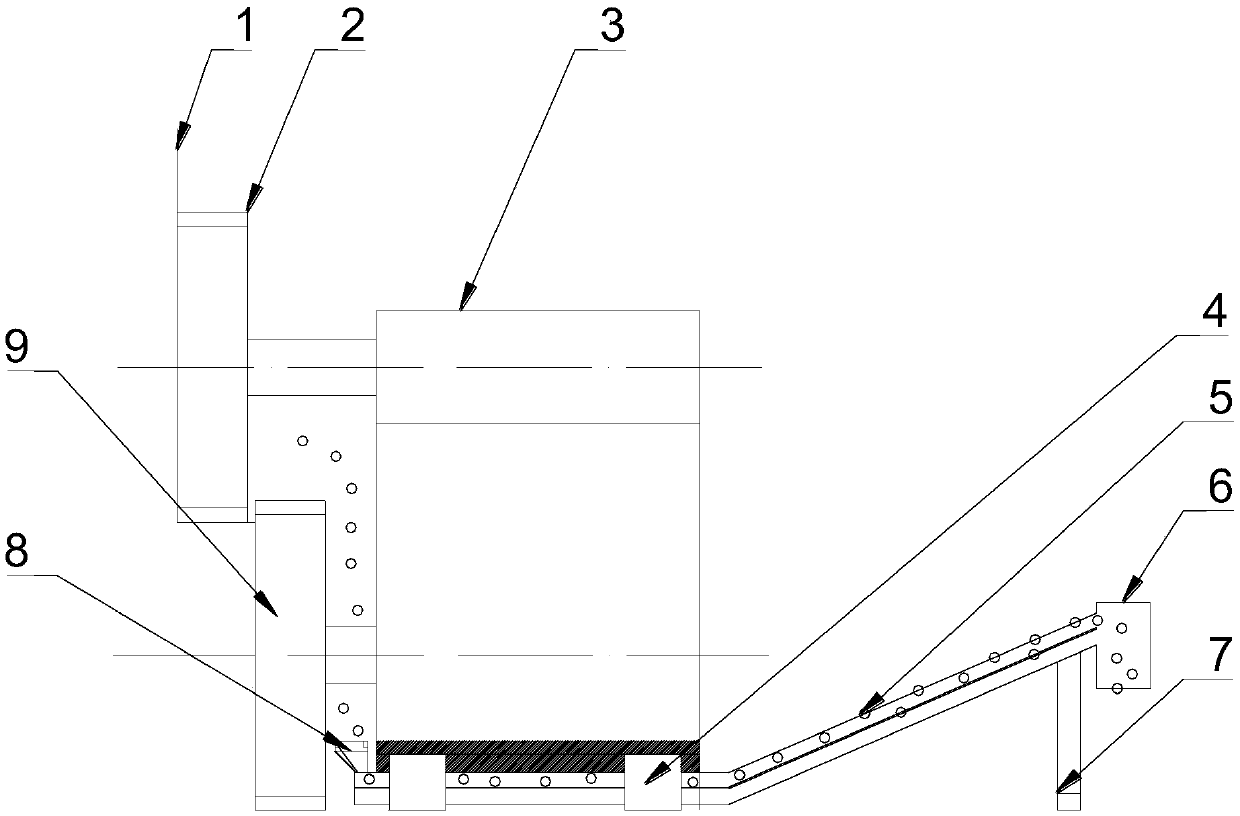

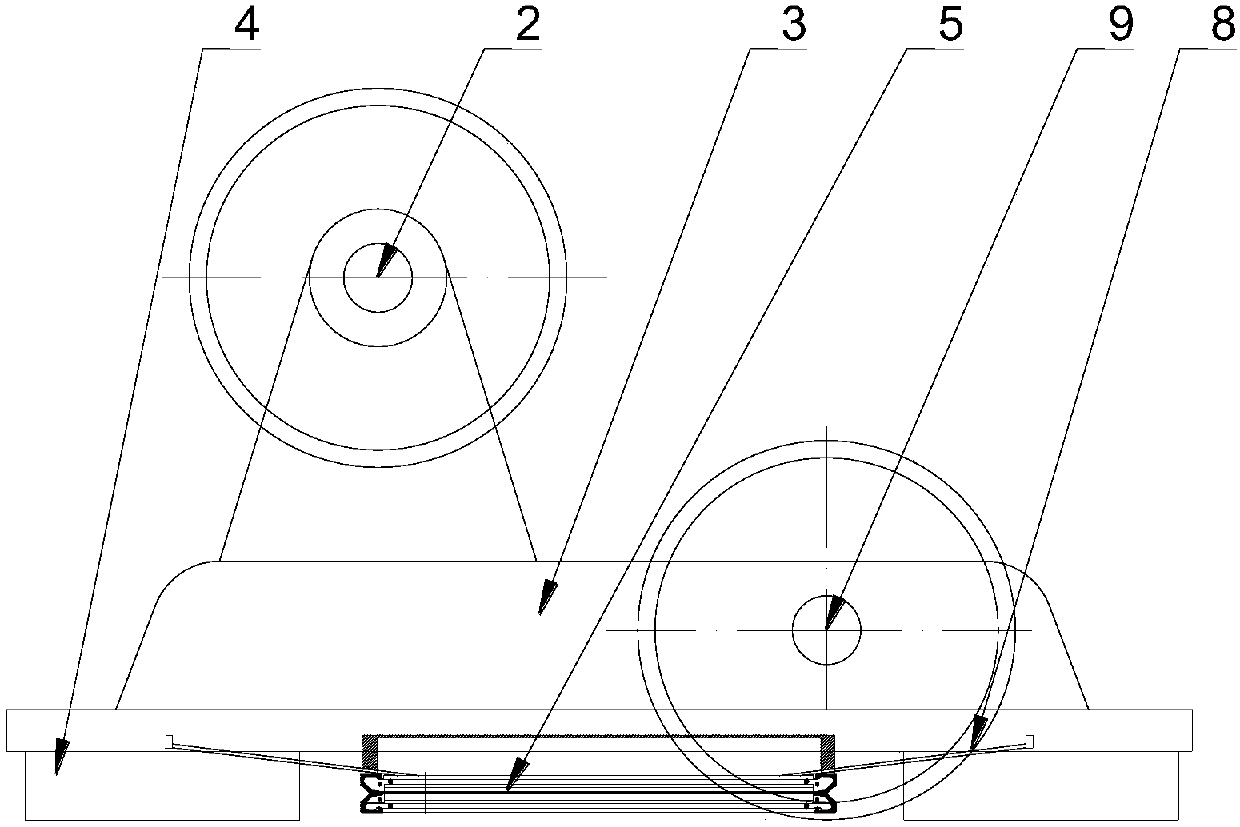

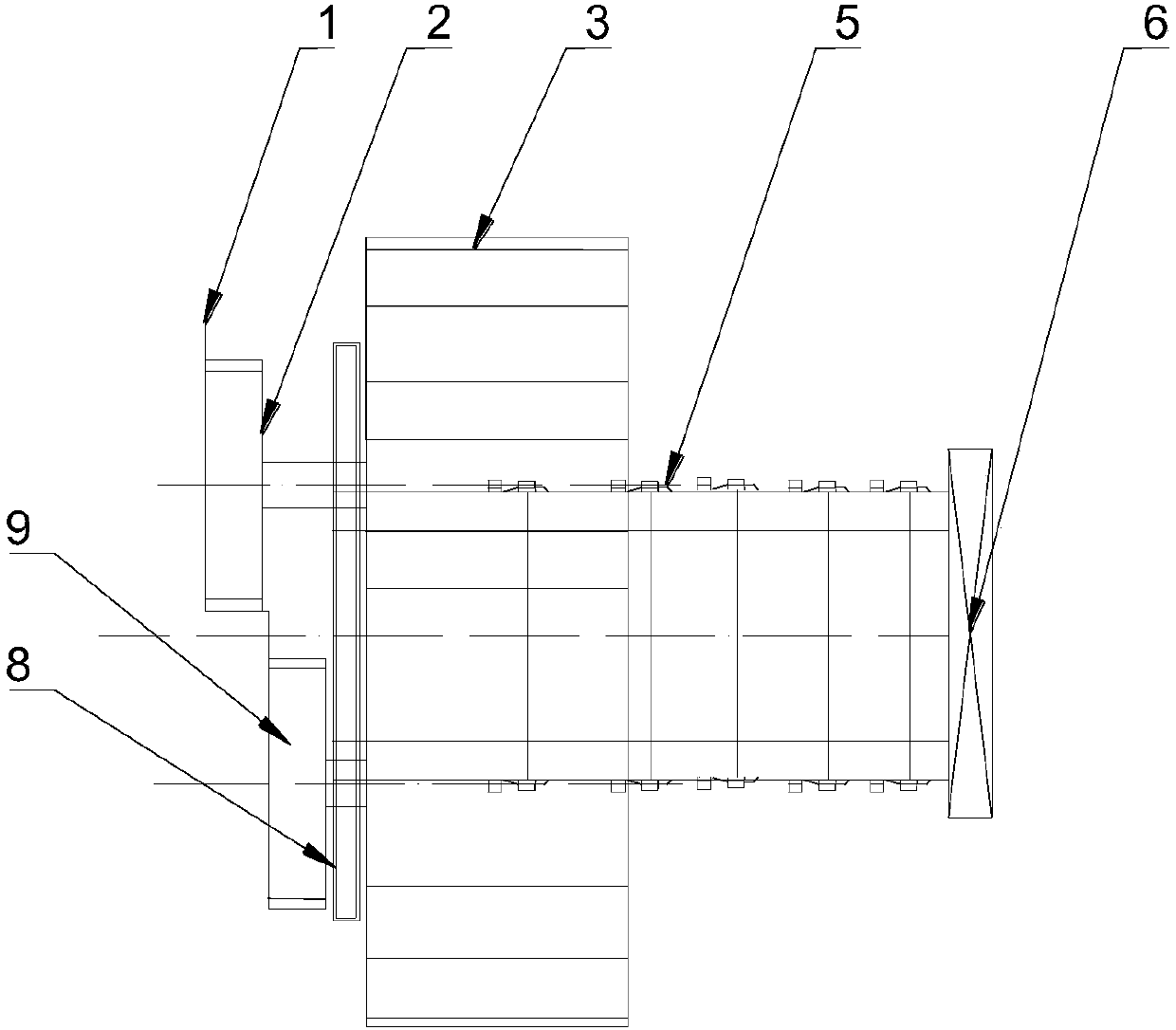

Self-moving crusher

InactiveCN103433111AEasy to operateContinuous operationGrain treatmentsCrusherIndustrial engineering

The invention relates to a crusher for a strip mine, and in particular relates to a self-moving crusher. The self-moving crusher comprises a carrying framework, a stock bin, a feeding conveying device, a collection conveying device, a caterpillar traveling device, a crushing device, a rotating supporting device, a discharging conveying device and a lifting device, wherein the carrying framework is in a wrench-shaped structure, the carrying framework is respectively provided with a traveling platform, a feeding platform, a crushing platform and a discharging platform, the collection conveying device is supported on the feeding platform, the feeding conveying device is supported on the collection conveying device, and the stock bin is supported on the feeding conveying device; the bottom of the traveling platform is connected with the caterpillar traveling device, the crushing device is installed on the crushing platform, and the discharging conveying device is installed on the discharging platform. Compared with the prior art, for the self-moving crusher, the automobile transportation link can be reduced, the collection function, the crushing function and the conveying function are integrated, the advantages of cleanliness, energy conservation, high efficiency and safety can be achieved, the stable and continuous operation can be realized, the extraction efficiency can be improved, the links of a production process can be reduced, and the production cost can be reduced.

Owner:TIANDI TANGSHAN MINING TECH

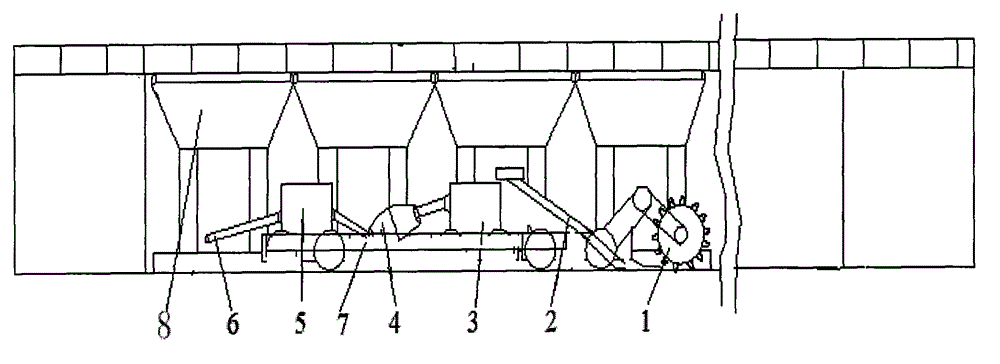

Open pit coal mine self-moving-type continuous coal mining and loading equipment and arrangement method thereof

InactiveCN108071399ARealize one-time miningAchieve continuous loadingOpen-pit miningCutting machinesHardnessEngineering

The invention discloses open pit coal mine self-moving-type continuous coal mining and loading equipment and an arrangement method thereof. The open pit coal mine self-moving-type continuous coal mining and loading equipment is characterized in that the open pit coal mine self-moving-type continuous coal mining and loading equipment comprises a caterpillar truck, a coal falling machine, two cutting rollers and a transporting chain; the two cutting rollers are concentratedly arranged in the middle of the coal falling machine, connected with the coal falling machine, and arranged in a vertical mode; a certain distance is formed between the end faces, close to the coal wall side, of the two cutting rollers, and a mined coal wall is divided into a step shape; the coal falling machine is located on the caterpillar truck and is in rigid connection with the caterpillar truck. The transporting chain is located on the lower portion of the coal falling machine and is in rigid connection with thecoal falling machine. A working face is mainly formed by arranging a self-moving-type mining and loading machine, a working face transferring belt and a working face rubber belt conveyor. The open pit mine self-moving-type mining and loading machine can achieve continuous mining and loading work of coal seams of different hardness. Technological arrangement is conducted in single-step arrangementand multi-step arrangement modes according to the thicknesses of the coal seams, and the equipment and the arrangement method can adapt to the coal seams of different thicknesses and meanwhile have high adaptability to different complex environments under open pits.

Owner:CHINA UNIV OF MINING & TECH

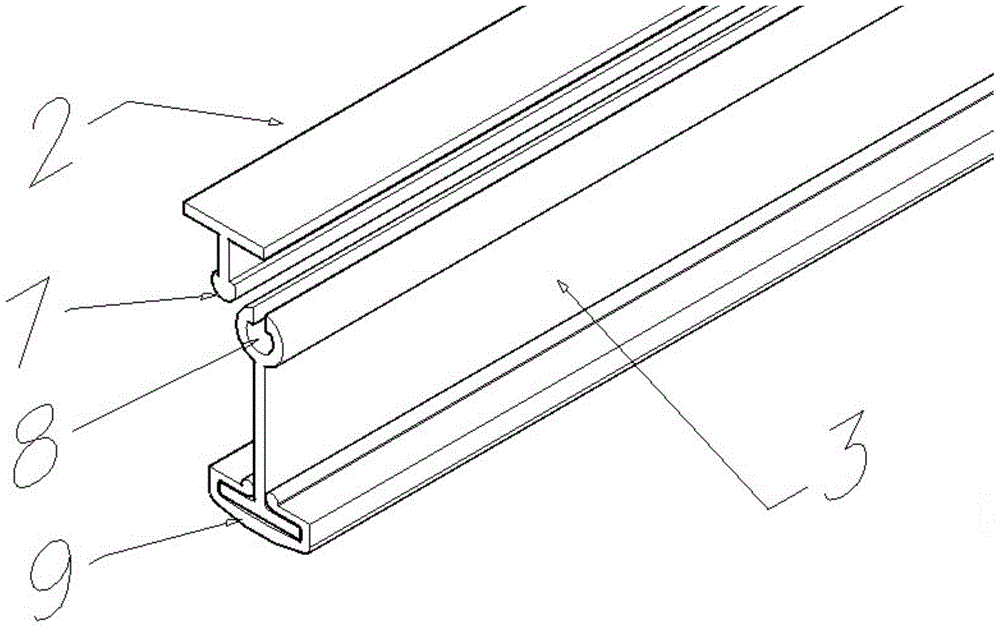

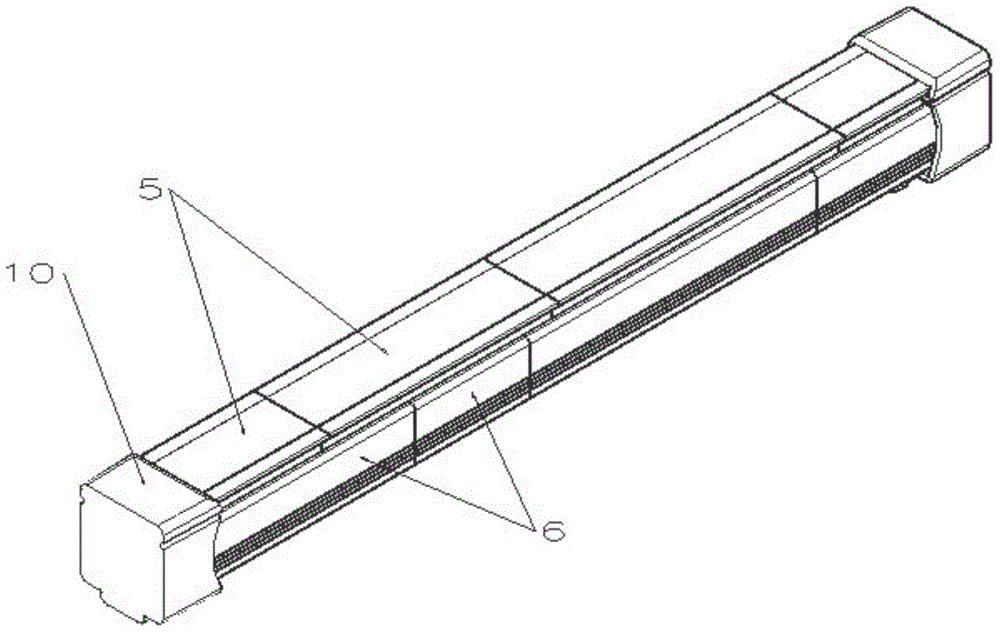

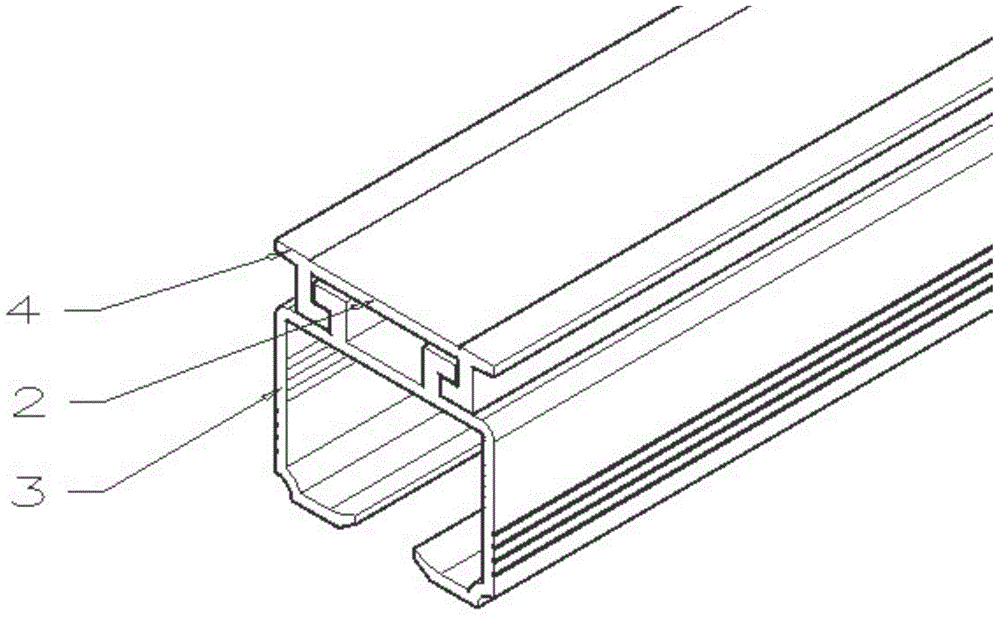

Split section staggered insertion type curtain track

ActiveCN105054748AGood flexibilityEasy to transportCurtain suspension devicesEngineeringEdge matching

The invention provides a split section staggered insertion type curtain track which comprises a main track body matched with a paw type clamping groove of an installation kit to be fixed to a wall of a window. The main track body comprises an upper paw buckling strip and a lower track strip which are equal in length. The two side edges of the top of the upper paw buckling strip protrude out and form clamping edges matched with the paw type clamping groove of the installation kit, and assembling mechanisms inserted longitudinally and fixed vertically are formed by the bottom of the upper paw buckling strip and the top of the lower track strip. The upper paw buckling strip is formed by sequentially connecting at least two sections of paw buckling bodies, the lower track strip is formed by sequentially connecting at least two sections of track bodies, and a connecting strap of every two adjacent sections of paw buckling bodies and a connecting strap of the corresponding adjacent track bodies are staggered. The main track body can be disassembled into two assemblies capable of being assembled in an insertion mode, each assembly is further disassembled into a plurality of sections, so that the track body is disassembled into a plurality of parts which can be independently manufactured and are convenient to transport and assemble, and the assembled track is attractive as a whole, good in flexibility and capable of being bent for a second time.

Owner:广州市并驰电子商务有限公司

Combined mobile temperature control closed sterile soft drinks and foods processing technique and application thereof

InactiveCN1631260AAdvanced technologyImprove performanceVehicle arrangementsFood scienceTemperature controlPesticide residue

The invention relates to a combined mobile temperature control closed sterile soft drinks and foods processing technique and application, wherein the differences of raw material maturation period and growth place can be taken into consideration, the beverage and food production can be carried out at different place of raw material origin at different time, thus substantially shortening manufacture time and saving a large amount of expense of transportation for raw material and waste slag.

Owner:沈军

Gold blocking paper printing method

InactiveCN101474932AEasy to flattenReduce transportation linksMonocarboxylic acid ester polymer adhesivesLabelling deformable materialsHigh volume manufacturingPulp and paper industry

The invention provides a method for printing bronzing paper. The method comprises that: a glue material pattern taking ethylene and ethylene-vinlacetate copolymer as a main body is printed on the bronzing paper on a glue-printing device; and the bronzing paper printed with the glue material is transferred and attached to an object. Compared with the prior method for printing glue and then bronzing on the object, the method has the advantages of high speed, time conservation, labor conservation and convenient batch production. Because the pattern is printed on the bronzing paper, the bronzing paper printed with the pattern can be directly transferred to the object for bronzing so as to reduce transportation link, be convenient for batch production, and improve production efficiency and printing quality. When the glue material is printed on the bronzing paper, negative pressure is adopted to adsorb the bronzing paper so as to be favorable for unfolding the bronzing paper, make the printed pattern not deformed and not to damage the printing surface. The method is applicable to bronzing on the object.

Owner:史占海

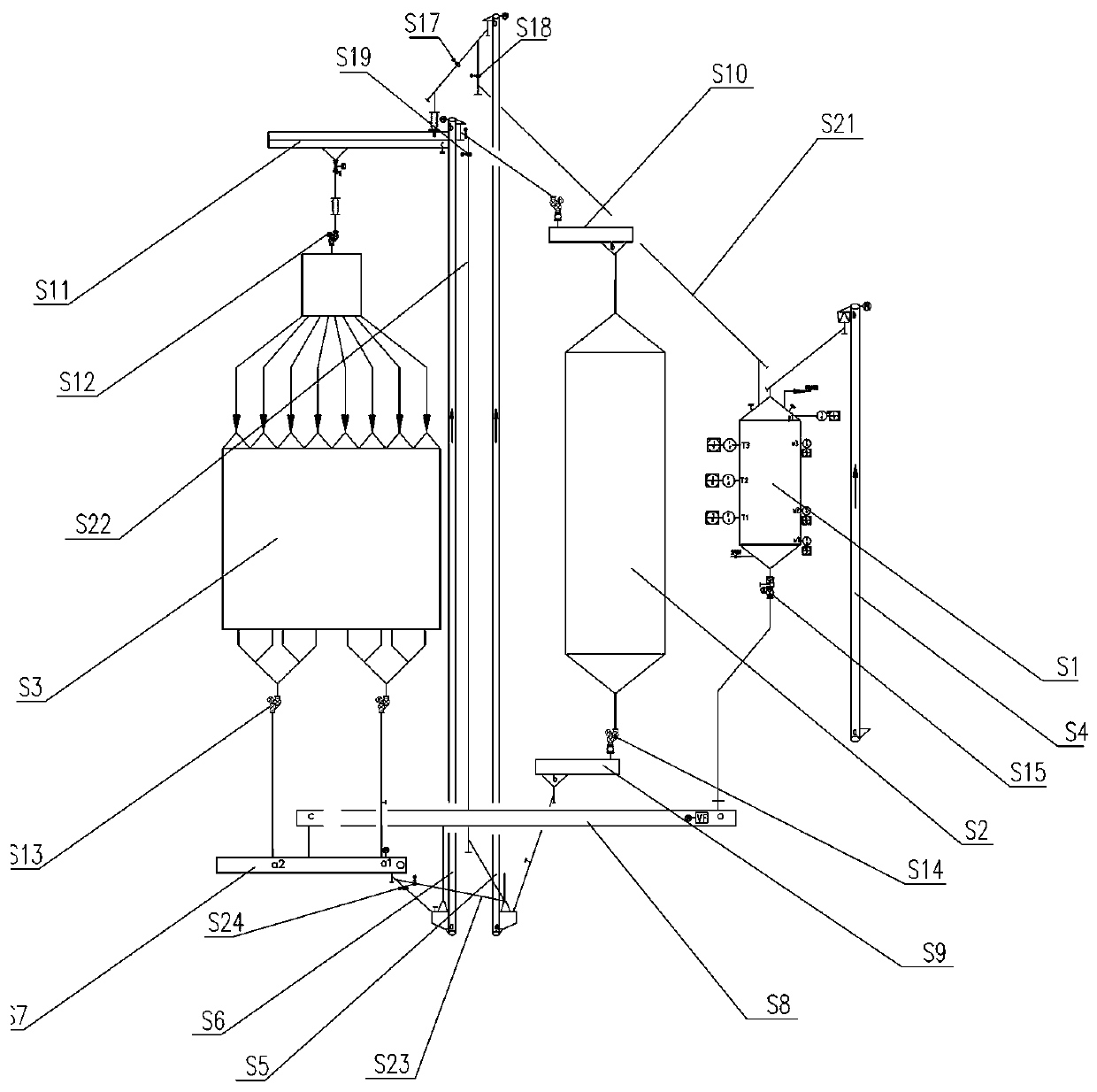

Active coke flue gas purification material conveying system with storage bin also functioning as accident bin

PendingCN110652836ASmall footprintLow costGas treatmentDispersed particle separationThermodynamicsFlue gas

The invention belongs to the technical field of flue gas purification and especially relates to an active coke flue gas purification material conveying system with a storage bin also functioning as anaccident bin. The active coke flue gas purification material conveying system comprises adsorption system tower top-tower bottom horizontal material conveying equipment, adsorption system-regeneration system vertical section material conveying equipment, adsorption system-regeneration system material distribution equipment, unloading equipment, screening equipment, storage bin and storage bin feeding equipment, and a material conveying chute. The system is characterized by further comprising the storage bin, wherein a bypass a is arranged at the adsorption system-regeneration system verticalsection material conveying equipment; a valve I is arranged on the bypass a; a bypass b is arranged at the regeneration system vertical section material conveying equipment; a valve II is arranged onthe bypass b; a valve III is arranged on the material conveying chute; a bypass chute is arranged at the bottom of the adsorption tower; and a valve IV is arranged on the bypass chute. The active cokeflue gas purification material conveying system of the invention provides the accident bin; and the storage bin of the system also serves as the accident bin, so occupied space is saved, and manufacturing cost is reduced.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

Wet garbage treatment device for residential districts

PendingCN110862924AReduce transportation linksHarmlessBioreactor/fermenter combinationsBiological substance pretreatmentsBiogasRefuse Disposals

The invention discloses a wet garbage treatment device for residential districts. The device comprises a biogas reaction tank, a first infusion pump and a heating kettle, a wet garbage throwing opening is formed in the biogas reaction tank, a sealing cover is screwed on the wet garbage throwing opening, a drain outlet is formed in the lower side of the biogas reaction tank, the first infusion pumpis arranged beside the biogas reaction tank, the first infusion pump is connected to the biogas reaction tank through a first infusion pipe, the heating kettle is arranged beside the biogas reactiontank, a biogas combustor is arranged below the heating kettle, a liquid inlet pipe and a liquid outlet pipe are arranged on the heating kettle, the liquid inlet pipe is connected to the lower side ofthe biogas reaction tank, a second infusion pump is arranged on the liquid outlet pipe, the liquid outlet pipe is connected to the upper part of the biogas reaction tank, two biogas outlets are formedin the upper part of the biogas reaction tank, one biogas outlet is connected to the biogas combustor through a first gas pipe, and the other biogas outlet is connected to the biogas storage tank through a second gas pipe. The device is simple in structure and integrates collection and treatment, wet garbage and excrement in a septic tank are used as raw materials to produce biogas, and waste isturned into wealth.

Owner:刘睿哲

Preparation method of denatured methyl alcohol and denatured ethyl alcohol

InactiveCN1824633AQuality improvementGood way to mix on siteHydroxy compound separation/purificationGasolineMethanol

The present invention relates to a preparation method of modified methyl alcohol and modified ethyl alcohol. It is characterized by adding modifier to obtain modified methyl alcohol and modified ethyl alcohol which can be mutually solved with gasoline so as to make them be changed into methyl alcohol gasoline and ethyl alcohol gasoline.

Owner:HEILONGJIANG JIANYE FUEL

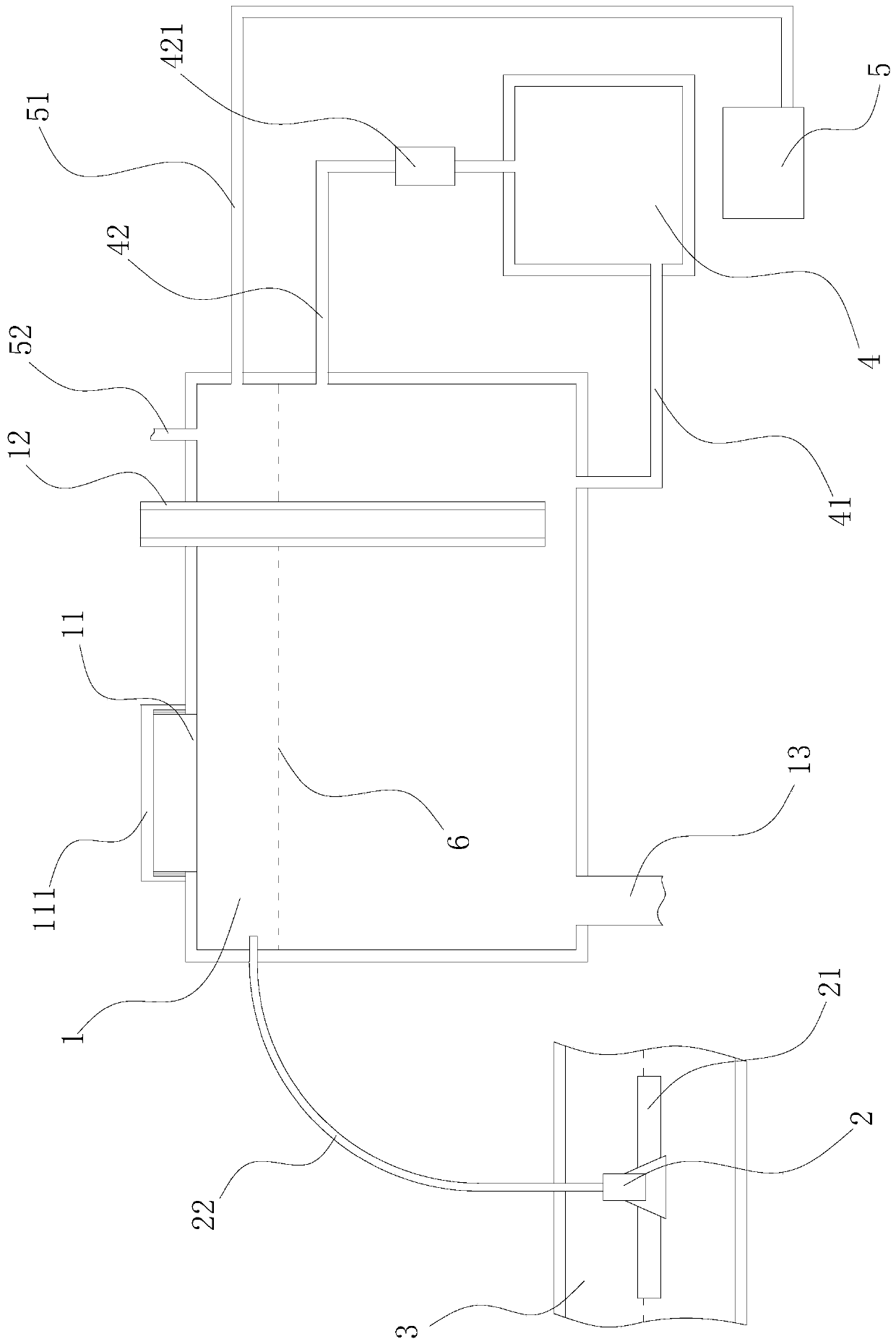

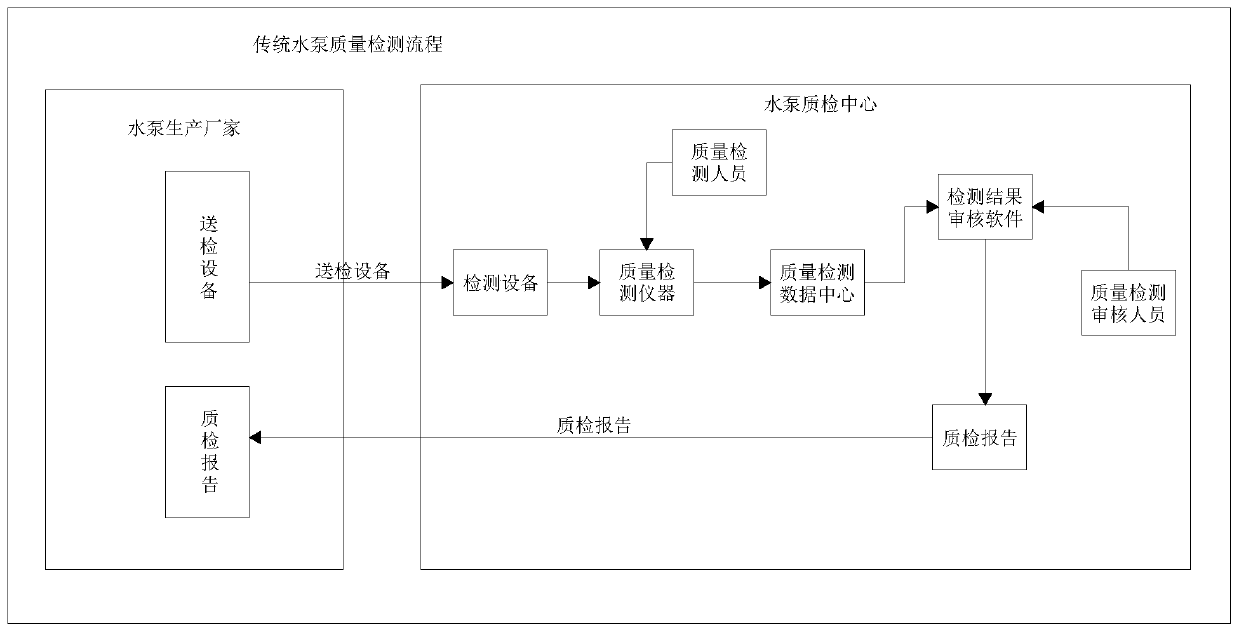

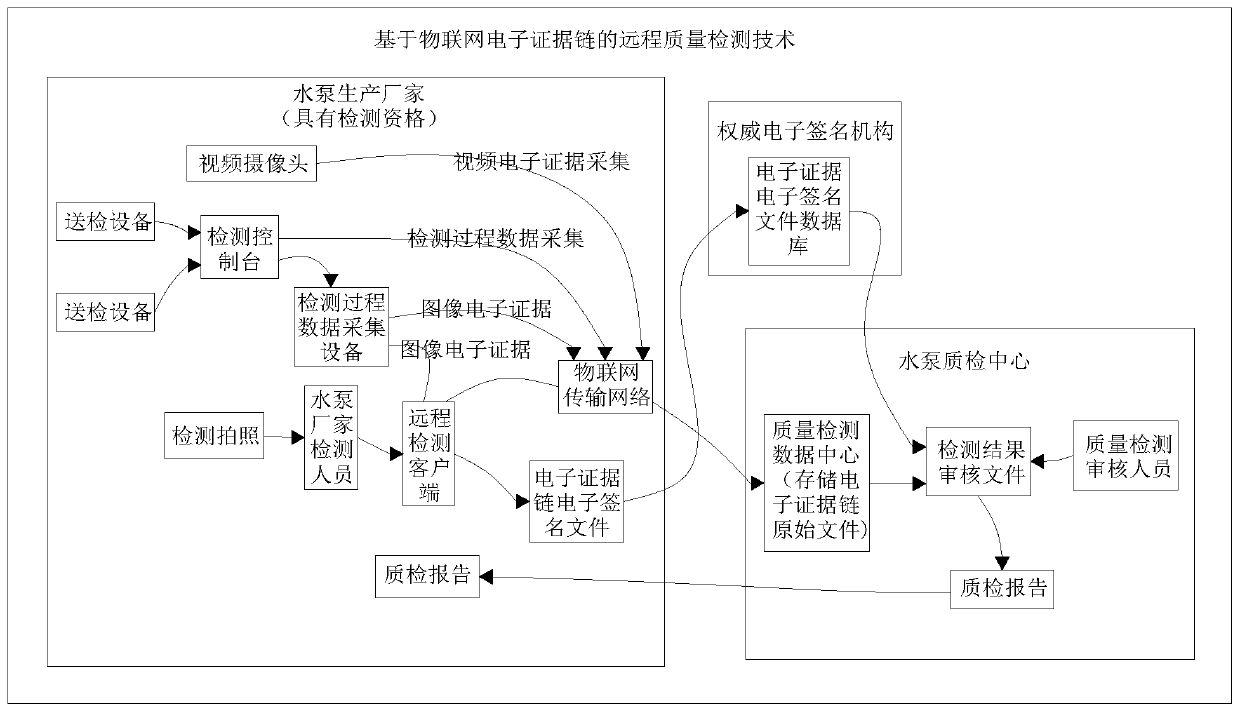

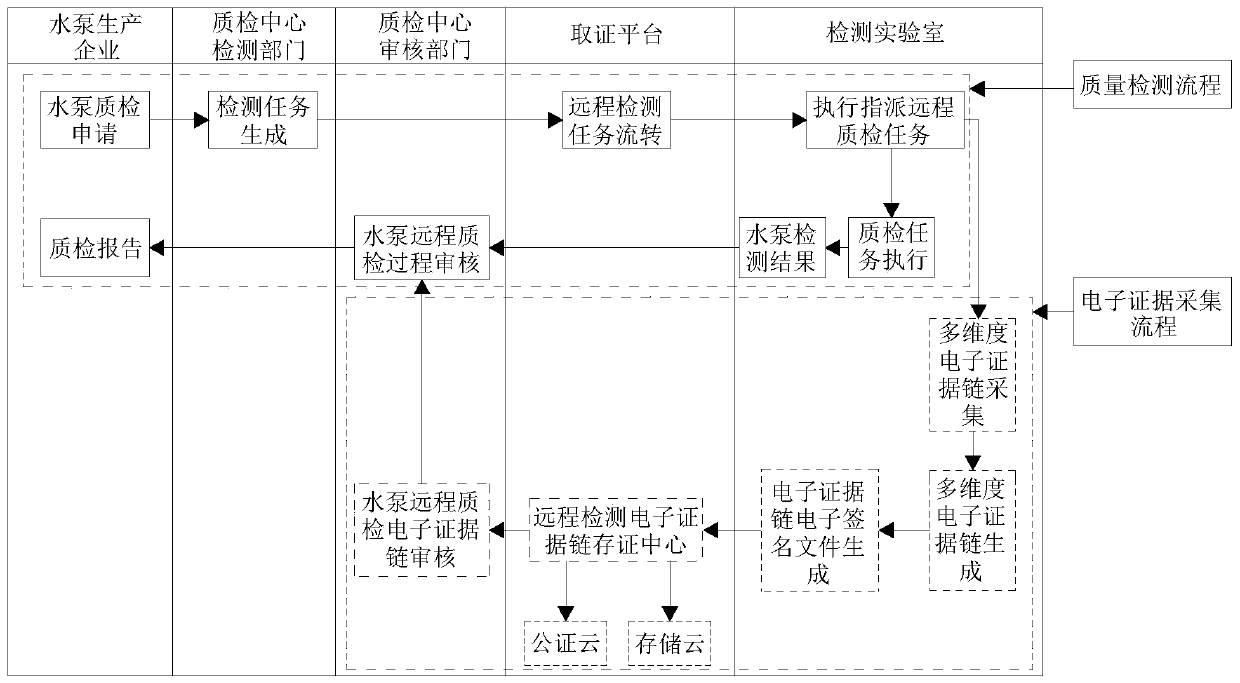

Remote quality detection technology based on Internet of Things electronic evidence chain

InactiveCN110674534AIncrease costEliminate quality inspection fraud incidentsDigital data protectionResourcesInternet of ThingsEngineering

The invention discloses a remote quality detection technology based on an Internet of Things electronic evidence chain, and the detection method guarantees that a quality detection result is more fairand public because of the separation of detection and auditing. The newly added collection process of the electronic evidence chain also ensures that the whole quality detection process can be tracedback and verified. Remote quality detection can be realized, and rapid quality detection service is provided for enterprises: when an enterprise detection laboratory has local detection capability, remote quality detection Internet of Things equipment is additionally built, and the remote quality detection service can be completed together with a quality detection center. Manufacturers can reducethe transportation links of submission equipment, and the submission cost is saved. In addition, the existing working environment of a manufacturer can be directly utilized to directly perform onlineremote quality detection, so that the tedious process of setting up a detection environment and debugging equipment from the beginning in a quality inspection center is avoided. According to the system and the method, effective sharing and maximum utilization of expensive special quality detection equipment can be realized, and repeated investment and construction of the country and enterprises are reduced.

Owner:温岭市产品质量检验所温岭市计量检定所 +2

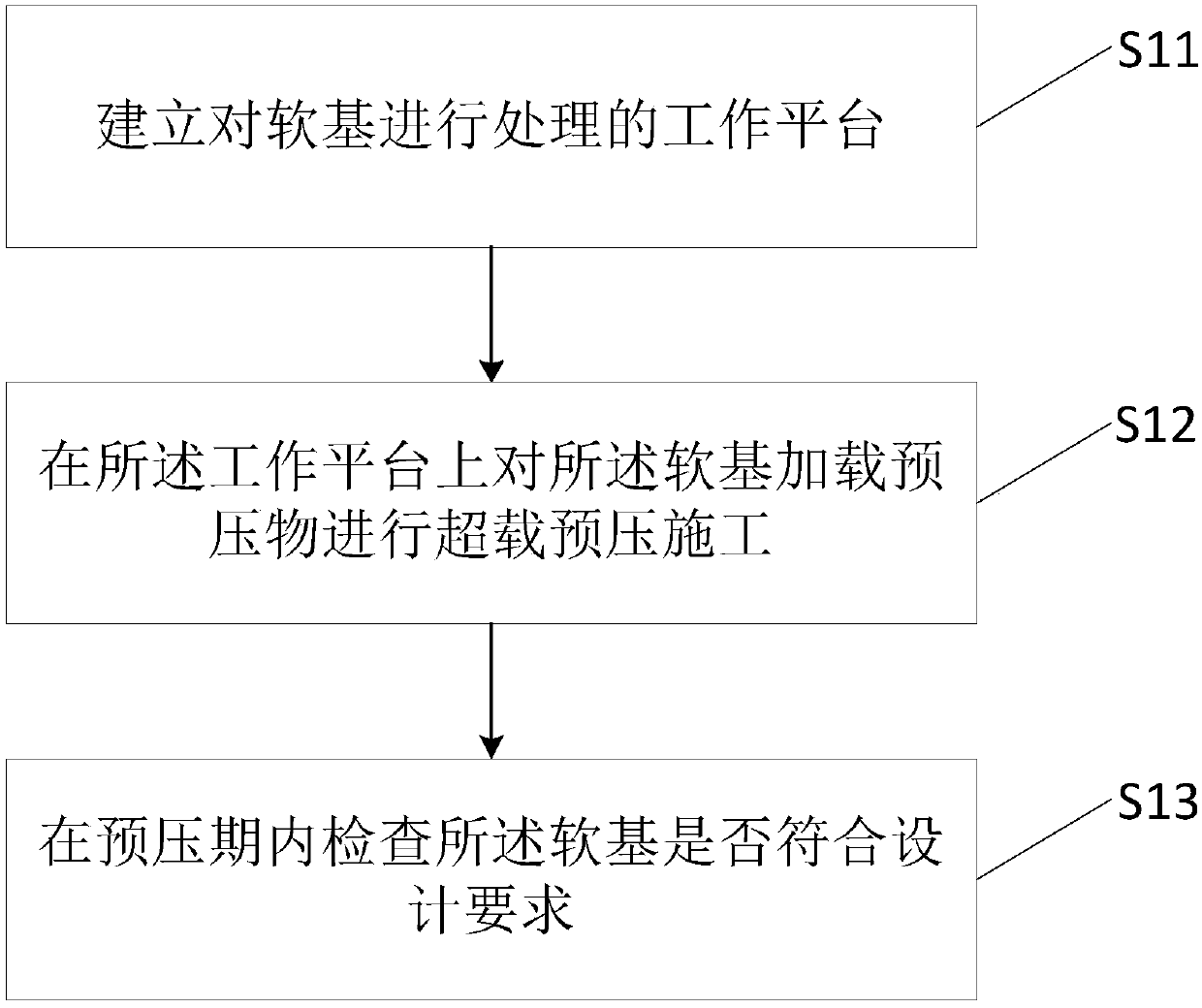

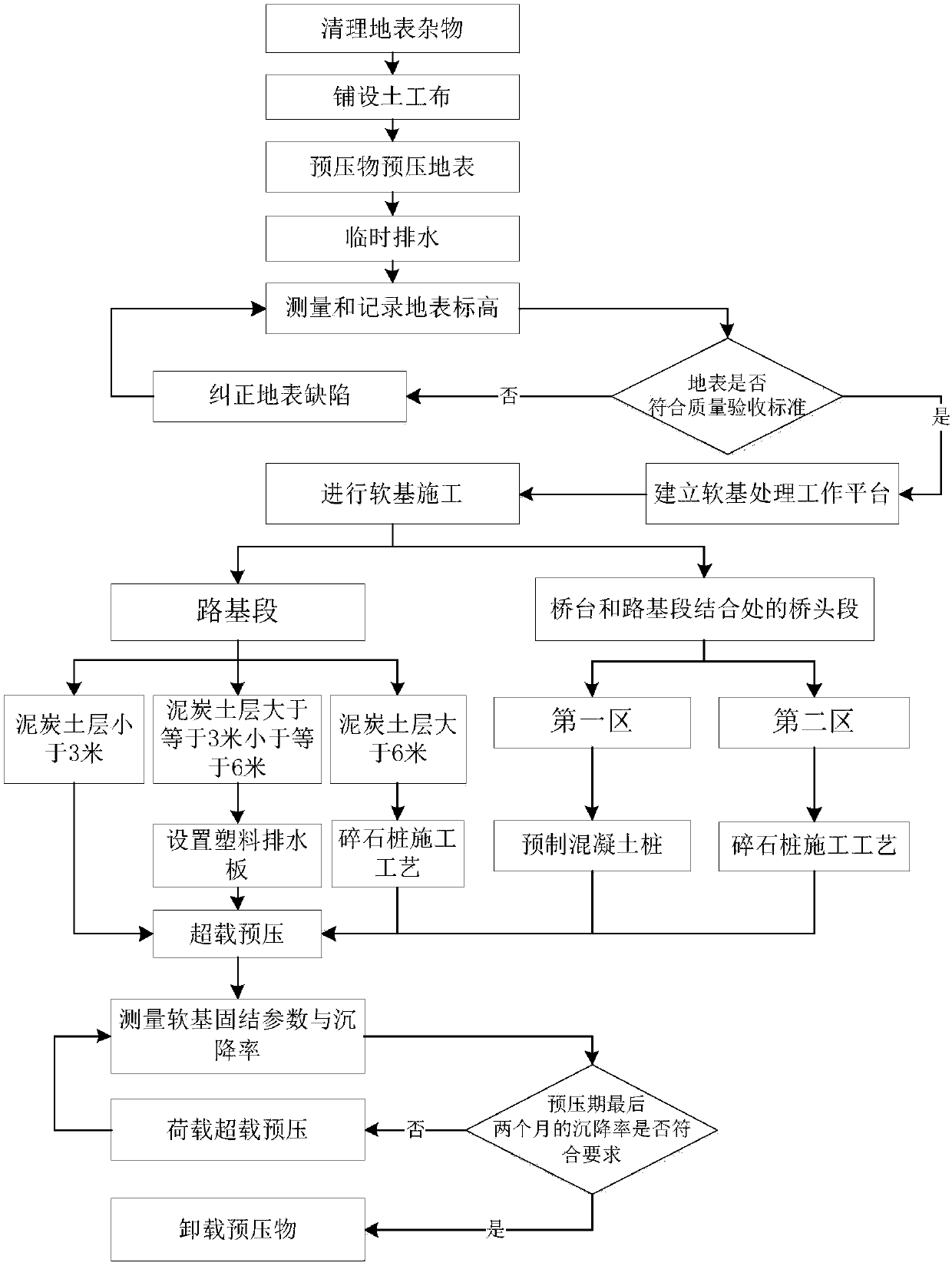

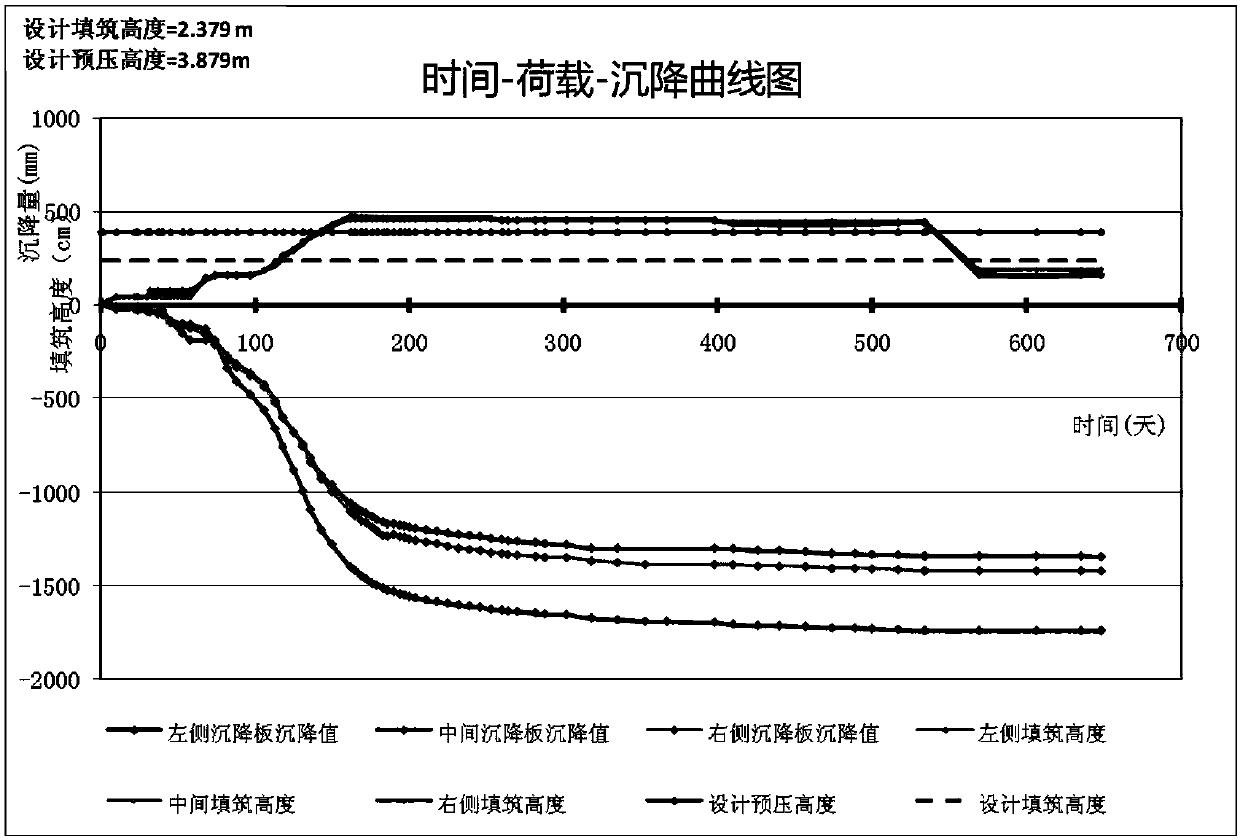

Road peat soil soft foundation comprehensive treatment method

InactiveCN107675693AShorten the consolidation cycleReduce transportation linksSoil preservationPeatSedimentation

The invention provides a road peat soil soft foundation comprehensive treatment method. The road peat soil soft foundation comprehensive treatment method comprises the steps that a work platform for treatment of a soft foundation is built; on the work platform, pre-pressing objects are loaded on the soft foundation for overload pre-pressing construction; and in the pre-pressing period, whether thesoft foundation meets the design requirement or not is checked. According to the road peat soil soft foundation comprehensive treatment method, the pre-pressing objects are used for overload pre-pressing treatment of the soft foundation, construction is conducted by adoption of the subarea and classified construction mode, the sedimentation rate of the pre-pressing objects is detected in the pre-pressing period, and the pre-pressing objects are unloaded after the sedimentation rate meets the design requirement. Through the method, the problems that deep and thick peat soil serves as a road bed, so that the bearing capacity is insufficient and sedimentation is uneven are effectively solved, before main consolidation sedimentation and partial residual sedimentation are completed, the soft foundation consolidation cycle is shortened, and the probabilities of large uneven sedimentation difference and sedimentation rate sudden change are decreased. Local materials are used for the pre-pressing objects, under the premise that the engineering quality is ensured, the construction efficiency is improved, and the overall construction cost is further reduced.

Owner:CHINA MCC20 GRP CORP

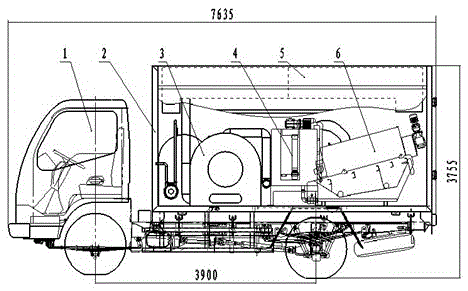

Movable dirt-sucking and purifying vehicle

InactiveCN105523661AReduce manufacturing costEasy to separateSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentFlocculationSludge

The invention provides a movable dirt-sucking and purifying vehicle, comprising a chassis and a vehicle box. The floor of the vehicle box is provided with an integrated residue-sucking and filtering machine, a flocculation tank, a sewage settling tank and a sludge concentration machine; the integrated residue-sucking and filtering machine is connected with the sewage settling tank via a pipeline and a valve, and filtered sewage is delivered to the sewage settling tank; the sewage settling tank is connected with the flocculation tank through a pipeline, sewage flows into the flocculation tank through the pipeline under the action of gravity, and through reagent addition, stirring and full flocculation, water and residues in domestic sewage are layered in the flocculation tank; and the flocculation tank is connected with the sludge concentration machine through a pipeline, layered sewage overflows to the sludge concentration machine through the pipeline under the action of gravity, water flows out from slits after concentration, extrusion and dehydration by the sludge concentration machine, and residues are continuously discharged from a residue discharging outlet of the sludge concentration machine. The movable dirt-sucking and purifying vehicle is prepared through comprehensive integration of conventional domestic sewage treatment equipment and optimization of configuration, and realizes mobile treatment.

Owner:CHONGQING DAJIANG IND

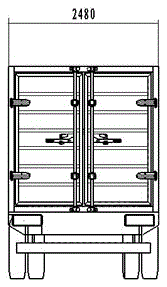

Continuous material belt type metal part efficient electroplating and cutting integrated flow line

PendingCN109968036AShorten the timeImprove processing efficiencyOther manufacturing equipments/toolsEngineeringMechanical engineering

The invention discloses a continuous material belt type metal part efficient electroplating and cutting integrated flow line. The continuous material belt type metal part efficient electroplating andcutting integrated flow line comprises a discharging unit, an electroplating unit and a cutting unit. The discharging unit comprises a first material roll which performs horizontal discharging in a material belt mode through rotation, and a material belt enters the electroplating unit for electroplating; the electroplating unit delivers the material belt into the cutting unit for cutting after finishing electroplating of the material belt, and thus electroplated metal parts are cut out from the material belt, or the electroplated material belt is divided into at least two branch material belts; the flow line further comprises a material belt conveying control unit which corresponds to the electroplating unit and the cutting unit; and the control unit comprises at least one pulling mechanism, and the material belt is driven by the pulling mechanisms to perform displacement from the electroplating unit into the cutting unit. The electroplating unit is connected with the cutting unit in series through the material belt conveying control unit, the conveying speed of the portions, in the electroplating unit and the cutting unit, of the material belt is balanced, and thus stable and reliable production of the flow line can be guaranteed after integration.

Owner:LEOCO SUZHOU PRECISE IND

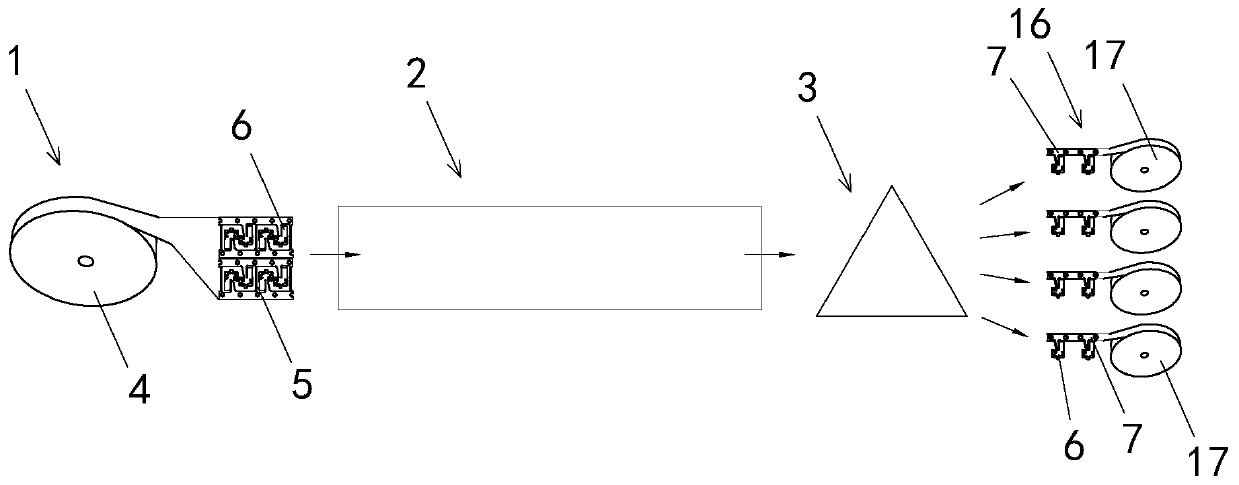

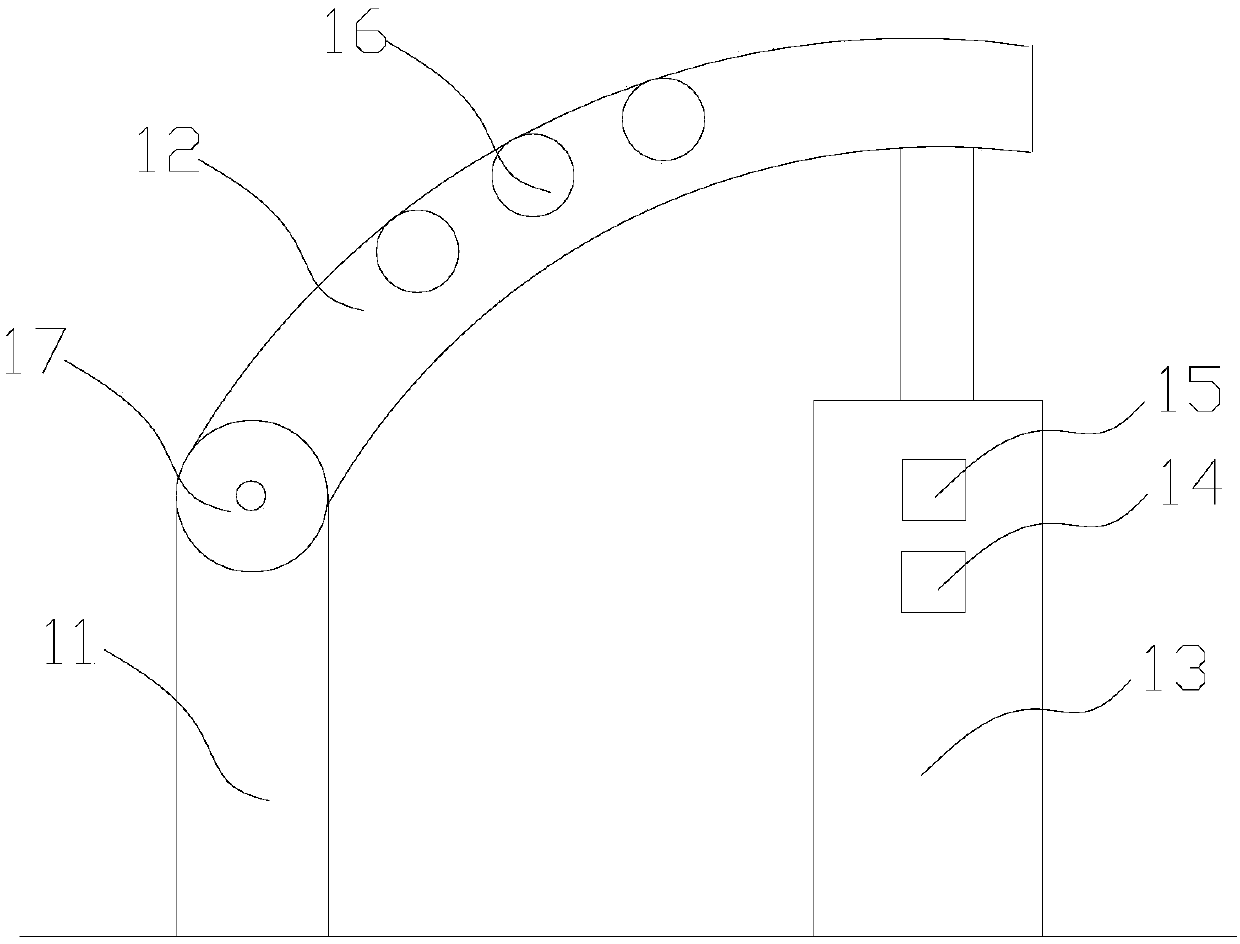

Automatic production line used for producing aluminum hot rolled plates or aluminum hot rolled coils

InactiveCN107791034ARealize automated productionMechanizationOther manufacturing equipments/toolsProduction lineContinuous rolling

The invention belongs to the technical field of production lines of aluminum sheets or aluminum coils, and mainly designs an automatic production line used for producing aluminum hot rolled plates oraluminum hot rolled coils. The automatic production line aims to realize the beneficial effects that the production cost is reduced, the production efficiency is improved, and potential safety hazardsare eliminated to the maximum extent. According to the technical scheme, the automatic production line used for producing the aluminum hot rolled plates or the aluminum hot rolled coils comprises smelting furnaces, holding furnaces, an online purification device, a continuous casting machine, a bridging connection device, an electric roller shear device, a hot continuous rolling mill, a vacuum frame plate device and a first coiling machine. The automatic production line has the beneficial effects that 1, automatic production of aluminum products is realized, and the production efficiency is improved; 2, compared with a traditional production line, a lot of transportation links between production processes are reduced, and the production cost is reduced; 3, compared with the traditional production line, mechanization is achieved to a greater extent, and the potential safety hazards are effectively eliminated.

Owner:惠州市金世纪铝业有限公司

Ultrahigh molecular weight polyethylene filament nonwoven fabric based on film-splitting method and production process thereof

InactiveCN106637682ACut offReduce transportation linksNon-woven fabricsFinenessUltra-high-molecular-weight polyethylene

The invention discloses an ultrahigh molecular weight polyethylene filament nonwoven fabric based on film-splitting method, comprising filament fiber mesh made by laying ultrahigh molecular weight polyethylene fiber filaments 0.5-20 dtex in average fineness, the filament fiber mesh is compressed by means of repeated needle-punching reinforcing and drawing to form the ultrahigh molecular weight polyethylene filament nonwoven fabric based on film-splitting method. The production process comprises: (1) preparing materials; (2) splitting; (3) lapping; (4) needle-punching; (5) rolling. The ultrahigh molecular weight polyethylene filament nonwoven fabric based on film-splitting method and the production process thereof have the advantages that the fabric is produced by one-time forming, the defects of the prior art such as poor firmness of nonwoven fabric and complexity of the preparation process can be overcome, overall strength of the filament nonwoven fabric is enhanced, and the nonwoven fabric has good water permeability and air permeability and is widely applicable.

Owner:QINGDAO UNIV

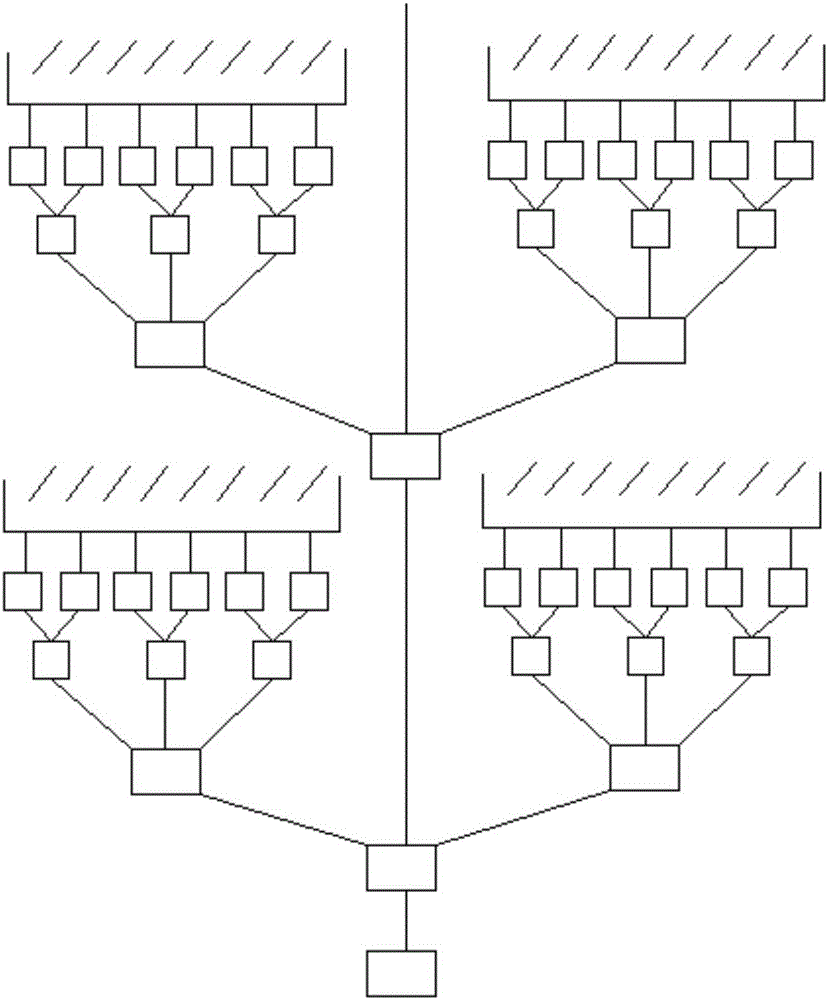

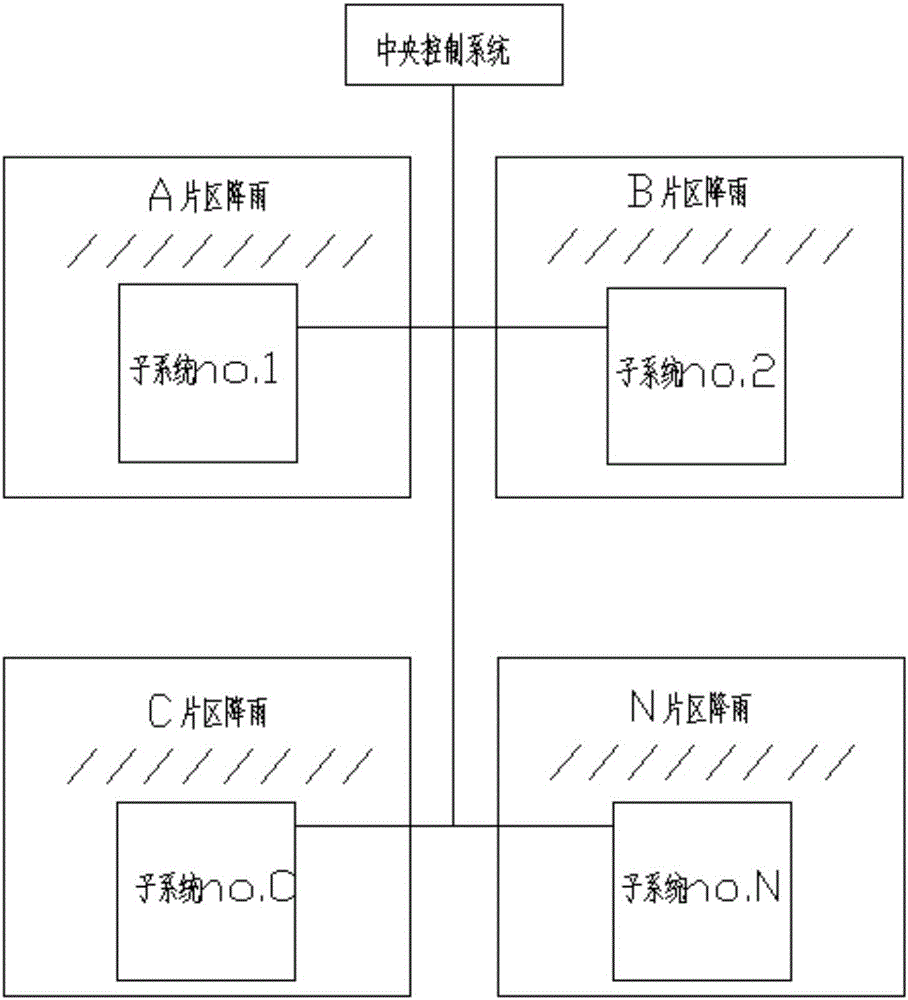

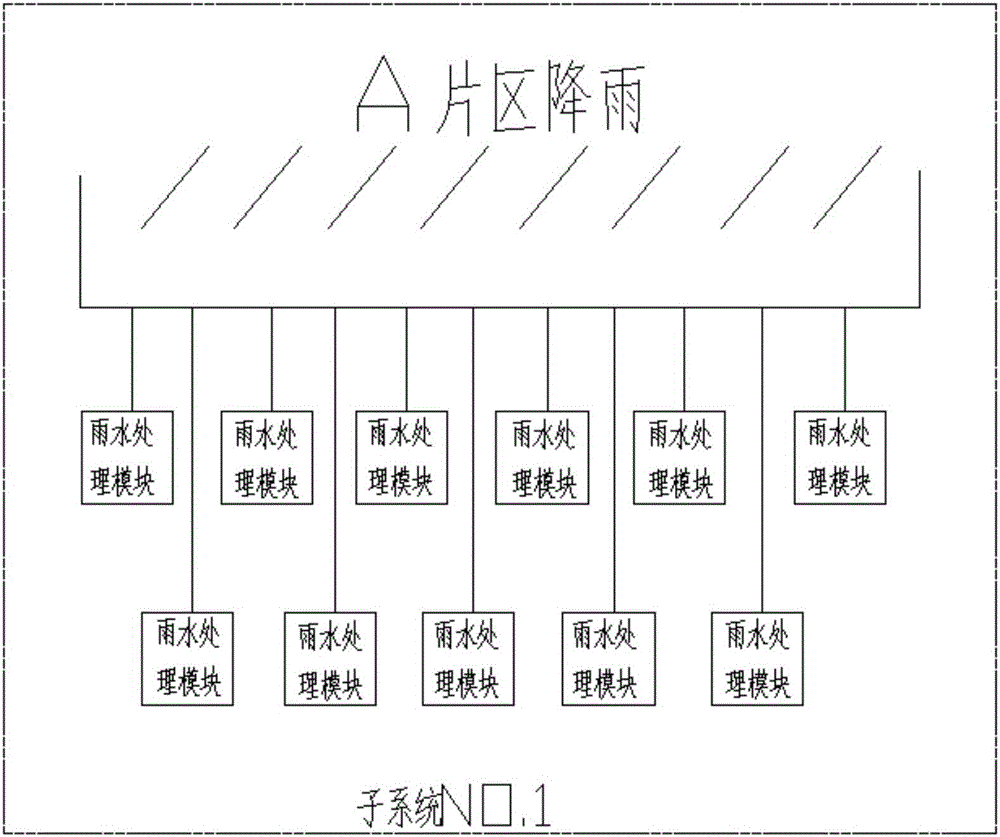

Novel intelligent grid stormwater and flood management system

ActiveCN105804201AImprove the ecological environmentRealize the effect of environmental protection and energy savingFatty/oily/floating substances removal devicesSewerage structuresEcological environmentEngineering

The invention discloses a novel intelligent grid stormwater and flood management system. The system comprises a plurality of subsystems. Each subsystem comprises a plurality of rainwater treatment modules. Each rainwater treatment module is composed of a collection device, a rainwater discarding device, a filtering and purifying device and a storage and leakage device which are arranged on the ground or on the lower portion of the kerb, wherein the rainwater discarding device and the filtering and purifying device are arranged on the storage device, the collection device is connected with a water inlet of the rainwater discarding device through a pipeline, the rainwater discarding device is communicated with the filtering and purifying device through a liquid guide opening, and the filtering and purifying device is communicated with the inside of the storage and leakage device through a rainwater collection pipe. According to planned initial rainwater discarding values of cities, the functions of rainwater collection, precise discarding, filtering, storage and leakage can be precisely achieved under any rainfall condition, flood drainage safety can be effectively guaranteed, the structure is reliable, and maintenance is convenient. Meanwhile, rainwater treatment conditions in an implementation area can be monitored as a whole, big data management of sponge city planning is achieved, and the ecological environment in the area is improved.

Owner:SICHUAN MUYU ENVIRONMENTAL PROTECTION TECH CO LTD

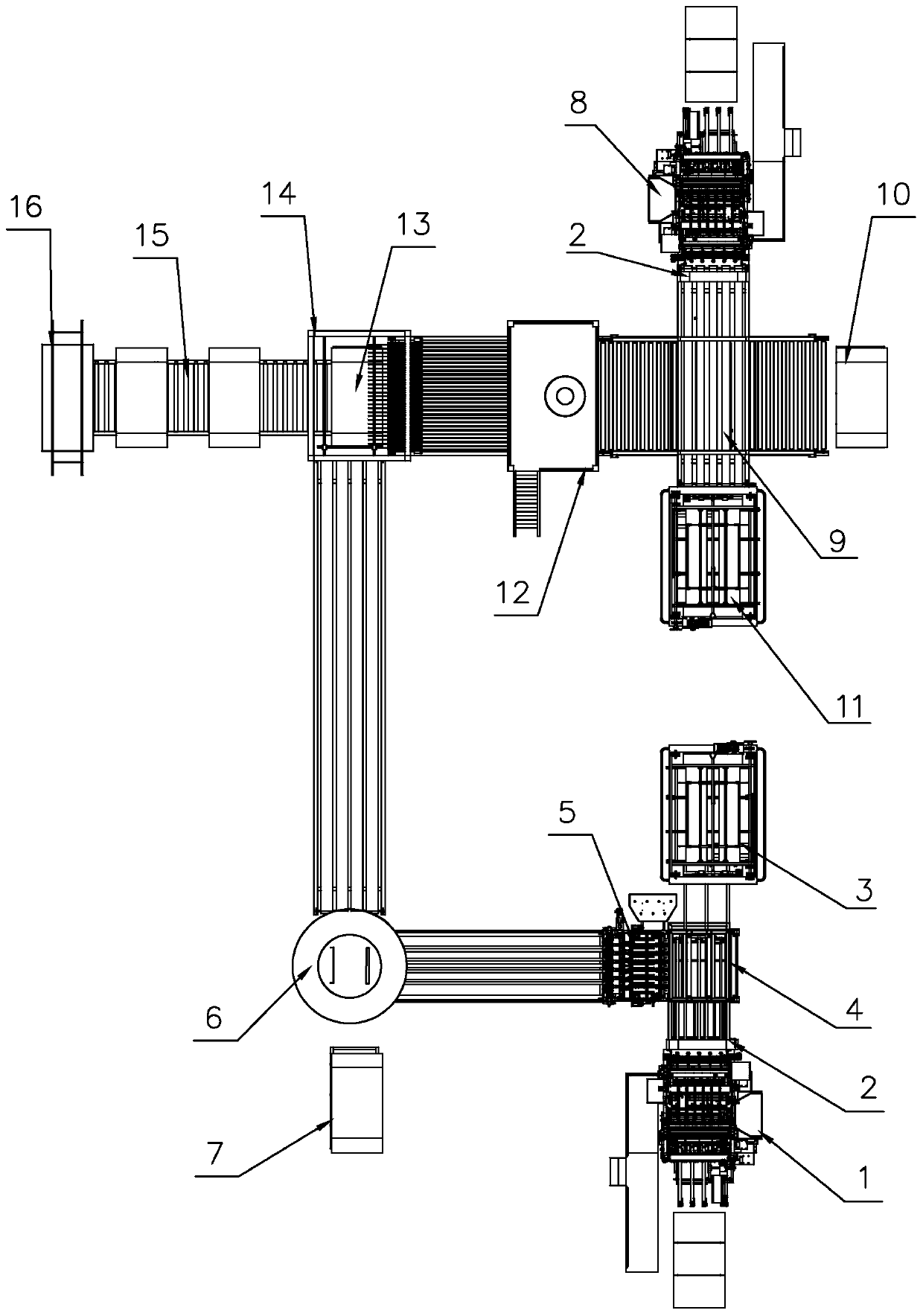

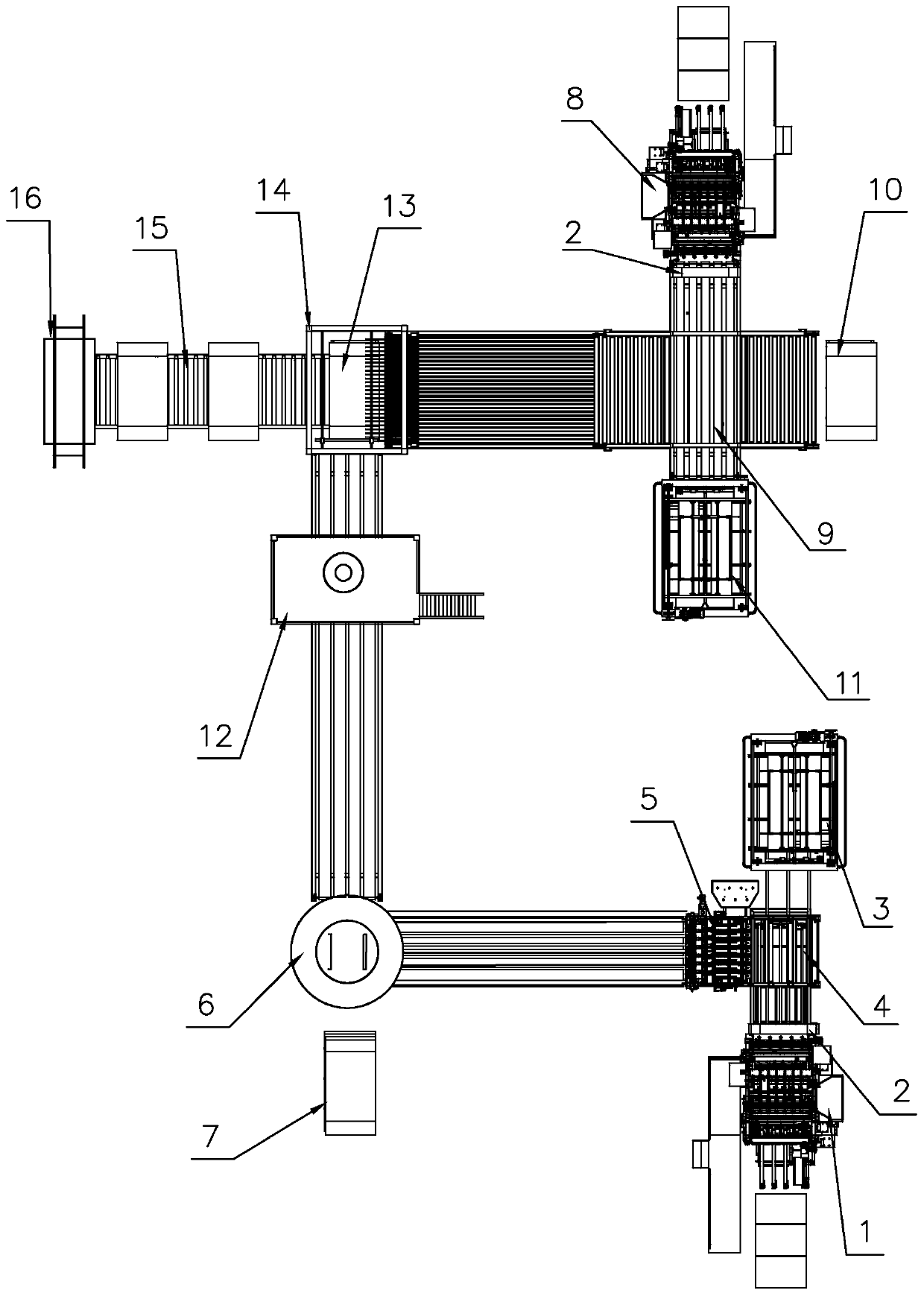

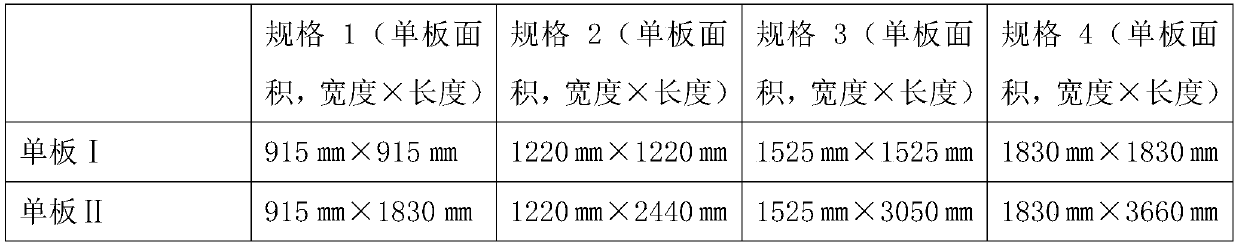

Full-automatic multi-layer board double machine production line

PendingCN111300560ASimplify the traditional production processReduce labor intensityOther plywood/veneer working apparatusPlywood pressesPalletizerProcess engineering

The invention discloses a full-automatic multi-layer board double machine production line. The full-automatic multi-layer board double machine production line comprises a single board I vertical splicing and horizontal splicing mechanism, a finished product viewing angle detection mechanism, a single board I defective product separation mechanism, a 90-degree steering mechanism III, a single boardII vertical splicing mechanism, a 90-degree steering assembly mechanism, a single board II horizontal splicing mechanism, a 90-degree steering mechanism IV, a single board II defective product separation mechanism, a single board automatic gluing mechanism, a glue board assembly mechanism, a stacking mechanism, an automatic conveying mechanism and a full-automatic cold pressing mechanism. According to the full-automatic multi-layer board double machine production line, the flow line production from single board finishing to assembly cold pressing is achieved, a traditional production technology process of a multi-layer board is greatly simplified, intermediate links are reduced to achieve the flow production, the product quality of single board production is improved, the problems of cavity, sticking, color difference and the like existing in single board production are solved, meanwhile the needs of assembly speed can be met, the supplement amount of a supplement mechanism is avoided, the intermediate conveying link is greatly reduced, and the working efficiency is improved.

Owner:山东昶兴智能科技有限公司

Method for smelting ash iron by using cupola furnace

The invention discloses a method for smelting ash iron by using a cupola furnace, and belongs to reduction of iron ore and manganese ore. The raw materials comprise the following materials in percentage by mass: 0-70 percent of iron ore powder, 0-60 percent of manganese ore powder, 0-10 percent of silicon carbide, 5-15 percent of reducing agent, 0-10 percent of limestone powder, 5-15 percent of dolomite powder, 1-5 percent of fluorite, 0-5 percent of adhesive, 0-5 percent of water and 0-35 percent of scrap steel. According to the method, a technological line is shortened, so that the aims of reducing transportation steps, saving power, keeping coke energy greater than 35 percent, reducing production cost per tone by over 30 percent and reducing greenhouse gas and pollutant emission by over 30 percent are fulfilled.

Owner:乔永刚

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com