Multifunctional glass crusher

A crusher and multi-functional technology, applied in dryers, heating devices, grain processing, etc., can solve the problems of difficult cleaning and destruction, easy accidental injury to operators, and reduced safety performance, so as to save glass transportation links and facilitate Subsequent processing, the effect of improving the crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

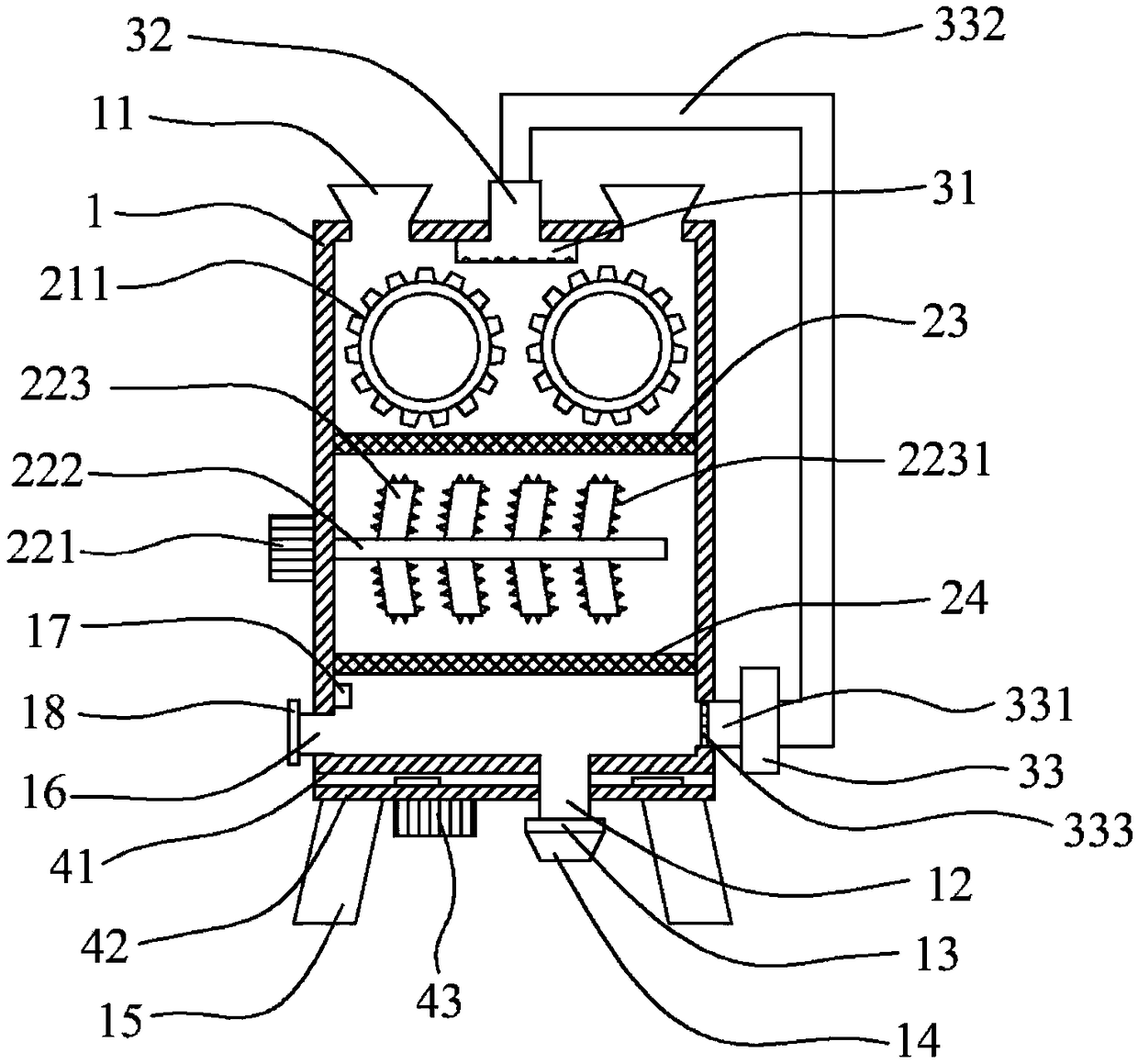

[0028] A multifunctional glass crusher, comprising a cavity 1, a crushing device, a cleaning device and a drying device are arranged in the cavity 1;

[0029] The top of the cavity 1 is provided with a feed port 11, and the bottom end of the cavity 1 is provided with a discharge port 12. In this embodiment, the number of feed ports 11 is 2, and the discharge port 12 is connected to an automatic discharge valve 13. One end of the discharge valve 13 away from the cavity 1 is connected to the weighing device 14, and the automatic discharge valve 13 and the weighing device 14 are respectively connected with a PLC controller (not shown in the figure), and the opening and closing of the automatic discharge valve 13 is controlled by the PLC controller. Closing and opening, so as to control the flow rate of the material in the glass pulverizer and realize automatic discharge; the lower end of the cavity 1 is provided with a bracket 15.

[0030] The crushing device includes a primary c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com