Automatic production line used for producing aluminum hot rolled plates or aluminum hot rolled coils

An automated production line and production line technology, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve problems such as high cost, low production efficiency, and potential safety hazards, so as to reduce production costs, improve production efficiency, and eliminate potential safety hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

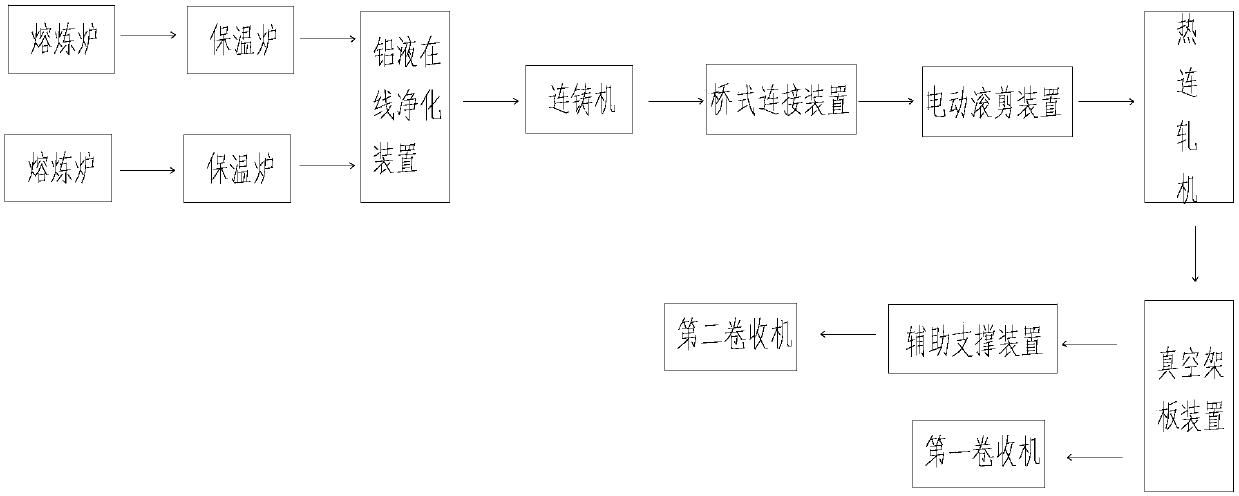

[0032] The automatic production line for producing hot-rolled aluminum plate or hot-rolled aluminum coil provided by the present invention includes:

[0033] Melting furnaces for melting aluminum ingots into molten aluminum;

[0034] Holding furnace for maintaining the temperature of molten aluminum;

[0035] On-line purification device, used to precipitate aluminum water and remove impurities in aluminum water;

[0036] Continuous casting machines for casting aluminum sheets;

[0037] The smelting furnace, the holding furnace, the on-line purification device, and the continuous casting machine are sequentially connected through pipelines; the production line also includes:

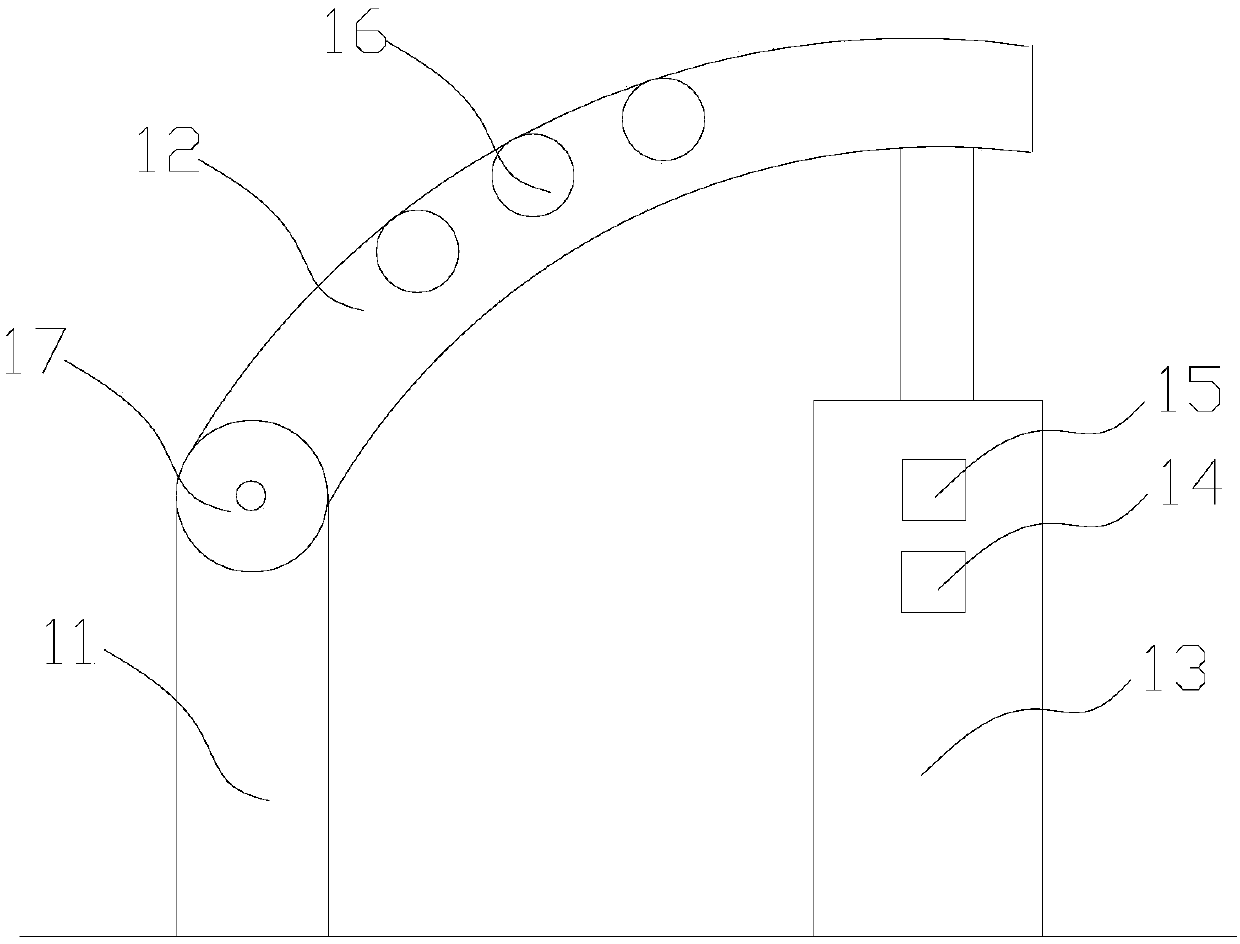

[0038] Bridge connection for conveying the aluminum sheet to the electric shear;

[0039] Electric roller shear device, used to cut the aluminum sheet and transfer the aluminum sheet to the hot rolling mill;

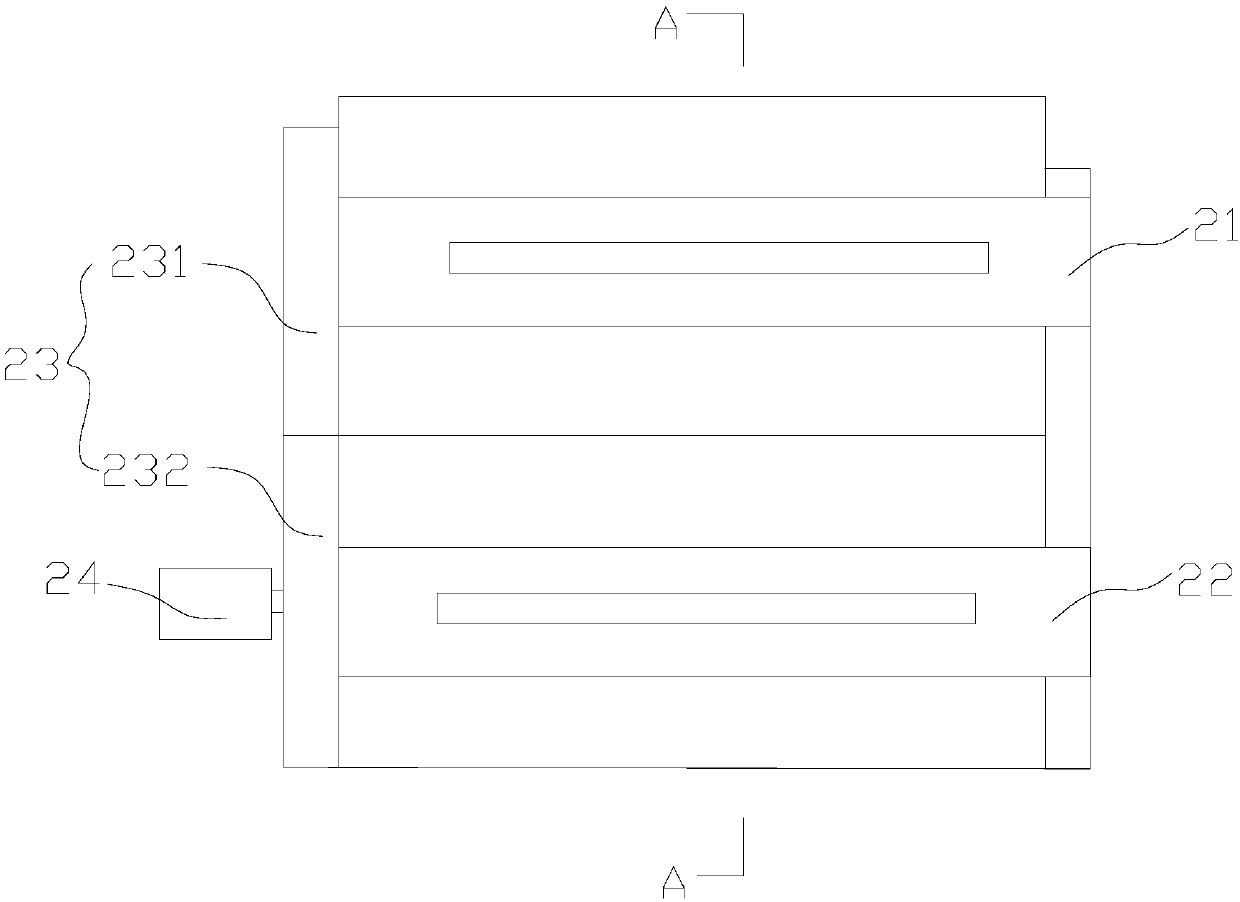

[0040] Hot tandem rolling mills for hot rolling of aluminum sheets to form hot-rolled sheets...

Embodiment 2

[0048] The automatic production line for producing hot-rolled aluminum plate or hot-rolled aluminum coil provided by the present invention includes:

[0049] Melting furnaces for melting aluminum ingots into molten aluminum;

[0050] Holding furnace for maintaining the temperature of molten aluminum;

[0051] On-line purification device, used to precipitate aluminum water and remove impurities in aluminum water;

[0052] Continuous casting machines for casting aluminum sheets;

[0053] The smelting furnace, the holding furnace, the on-line purification device, and the continuous casting machine are sequentially connected through pipelines; the production line also includes:

[0054] Bridge connection for conveying the aluminum sheet to the electric shear;

[0055] Electric roller shear device, used to cut the aluminum sheet and transfer the aluminum sheet to the hot rolling mill;

[0056] Hot tandem rolling mills for hot rolling of aluminum sheets to form hot-rolled sheets...

Embodiment 3

[0067] The automatic production line for producing hot-rolled aluminum plate or hot-rolled aluminum coil provided by the present invention includes:

[0068] Melting furnaces for melting aluminum ingots into molten aluminum;

[0069] Holding furnace for maintaining the temperature of molten aluminum;

[0070] On-line purification device, used to precipitate aluminum water and remove impurities in aluminum water;

[0071] Continuous casting machines for casting aluminum sheets;

[0072] The smelting furnace, the holding furnace, the on-line purification device, and the continuous casting machine are sequentially connected through pipelines; the production line also includes:

[0073] Bridge connection for conveying the aluminum sheet to the electric shear;

[0074] Electric roller shear device, used to cut the aluminum sheet and transfer the aluminum sheet to the hot rolling mill;

[0075] Hot tandem rolling mills for hot rolling of aluminum sheets to form hot-rolled sheets...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com