Winding-pipe production device

A technology of a winding device and a production device, which is applied in the direction of tubular articles, other household appliances, household appliances, etc., can solve the problems of high transportation cost of winding pipes, and achieve the effect of solving the high cost and flexible structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

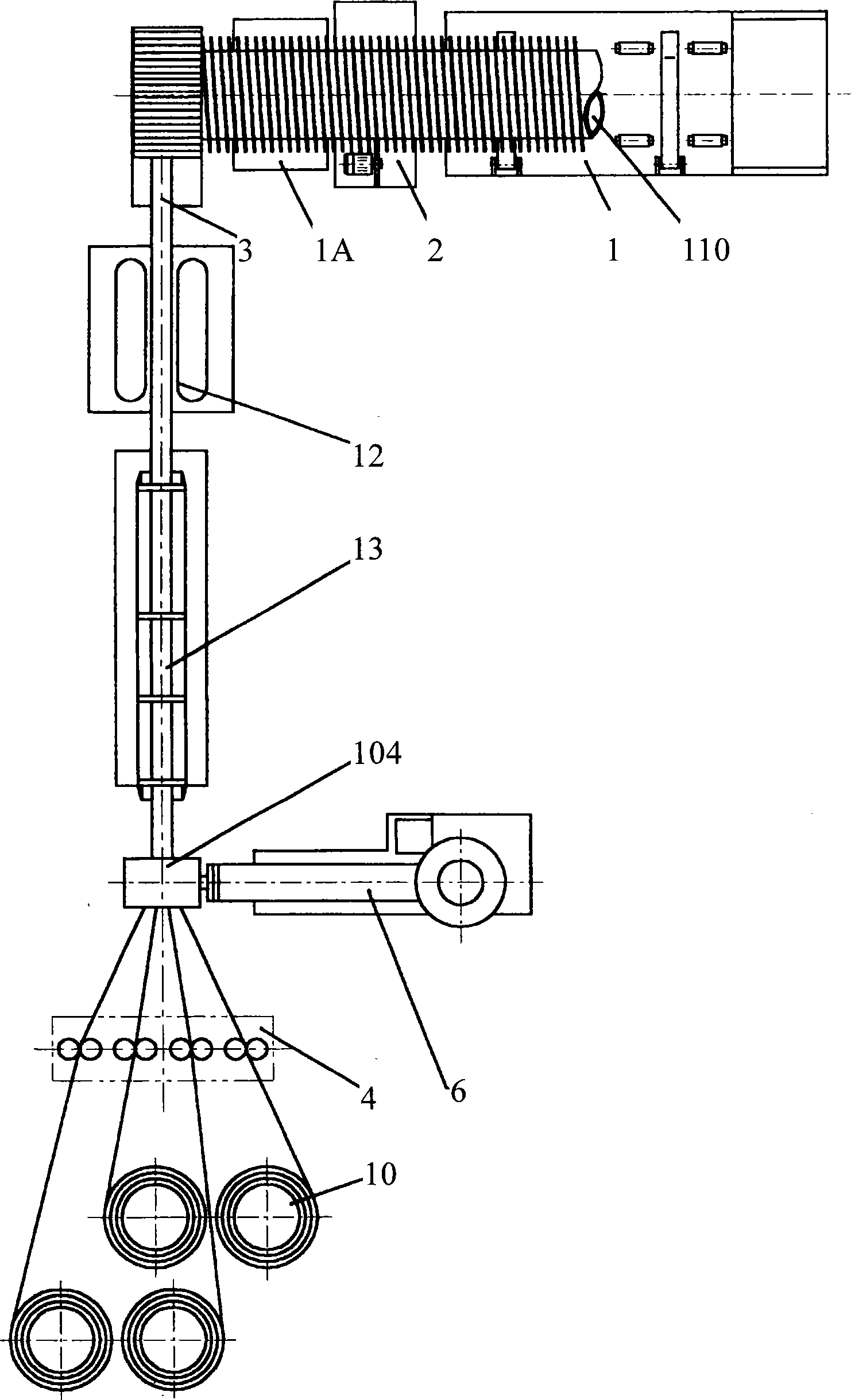

Embodiment 1

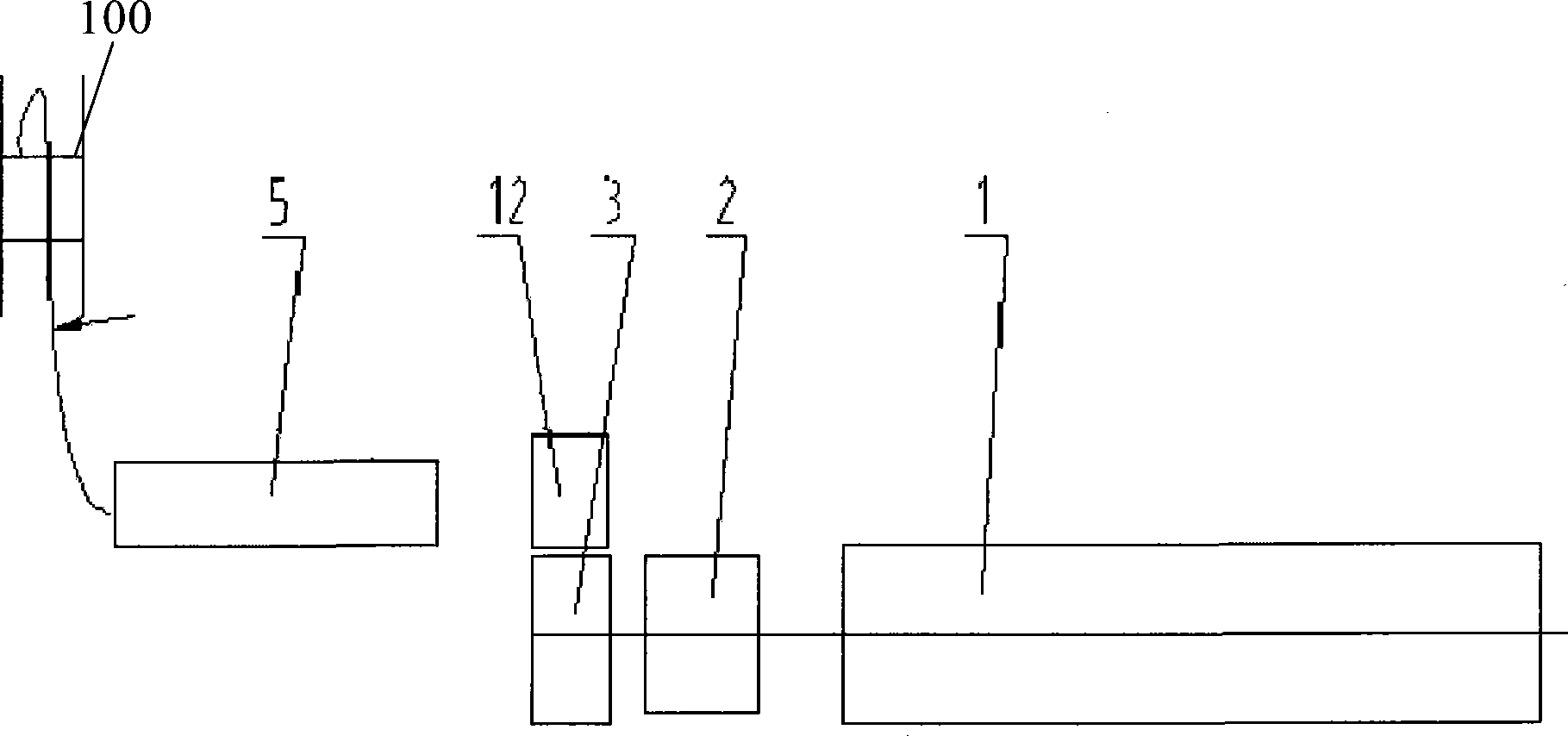

[0034] Such as image 3 As shown, in the present embodiment, the tape supply part includes an independent movable composite tape support 100 that cooperates with the feeding device, the feeding device is a tape feeding device 12, and the power supply end of the control system 8 is connected with the tape feeding device 12, winding The device 3 is connected with the driving mechanism of the pipe material cutting device 2 . The control system 8, the tape feeding device 12, the winding device 3 and the pipe material cutting device 2 are arranged on the same movable foundation 14, and the supporting frame 1 is arranged on another movable foundation (not shown in the figure).

Embodiment 2

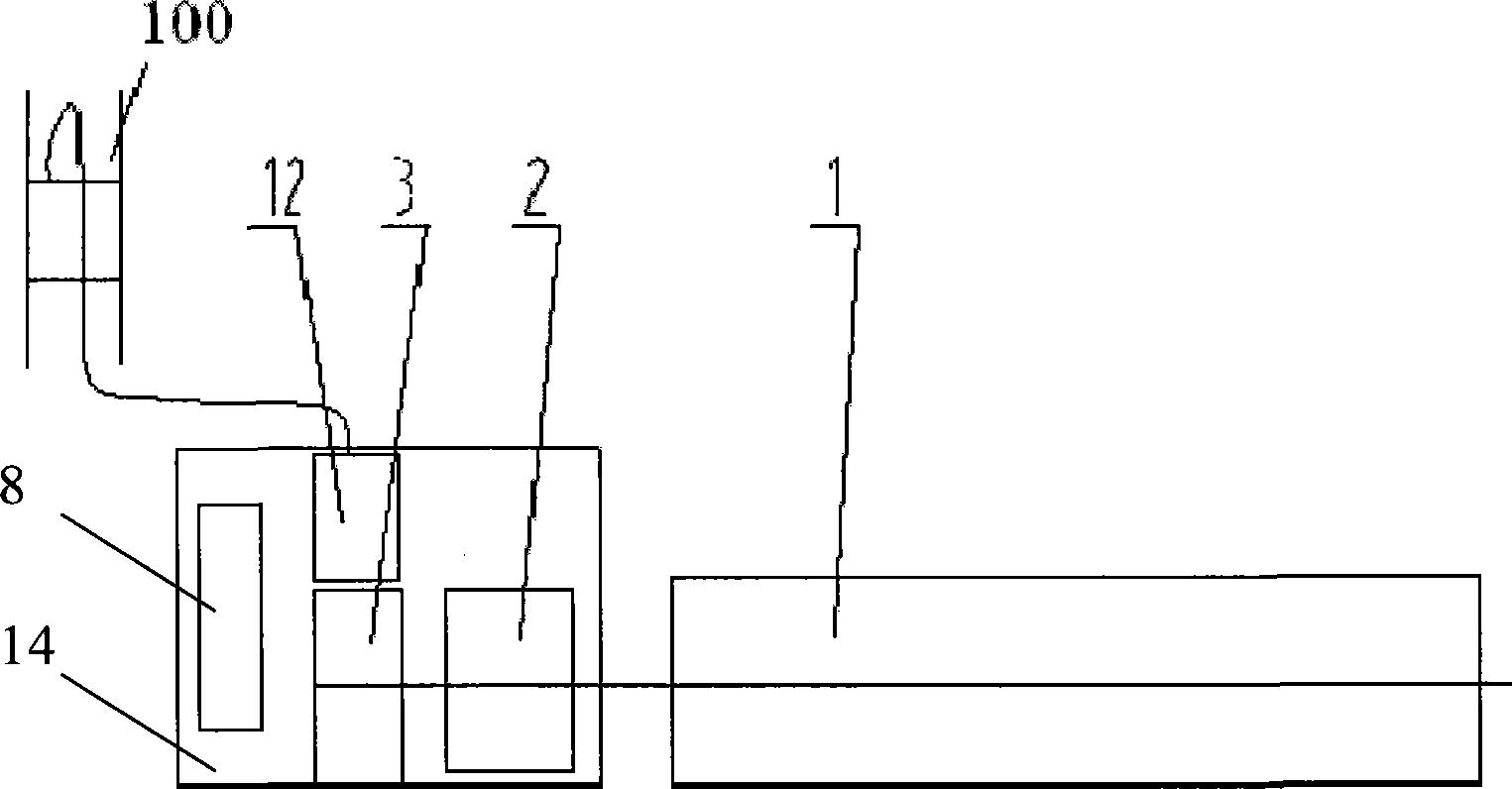

[0036] Such as Figure 4 As shown, the strip supply part in this embodiment includes a composite strip support 100 and a guide device 5 matched therewith. The discharge end of the guide device 5 is adjacent to the feed device 12, and the direction of its entry and exit is along the axis of the pipe production section. The direction (that is, the axial direction of the sequentially arranged winding device 3 , pipe material cutting device 2 and support frame 1 ) is set. The power supply end of the control system 8 is connected with the driving mechanism of the guiding device 5 , the feeding device 12 , the winding device 3 and the pipe cutting device 2 , and in this embodiment, the feeding device is the belt feeding device 12 . Control system 8, guiding device 5, belt feeding device 12, winding device 3 and pipe material cutting device 2 are arranged on the platform of special vehicle 11, and support frame 1 is arranged on another movable foundation (not shown in the figure).

Embodiment 3

[0038] Such as Figure 5 As shown, in the present embodiment, the strip supply part includes a steel strip material preparation section, a guide device 5, a sealing and welding plastic extruder 61 and an independent movable pure plastic semi-finished strip support 101 that cooperates with the feed device, and the feed device The straightening device 4 is used to flatten the steel strip and integrate the steel strip and the pure plastic semi-finished strip into one. The discharge end of the guide device 5 is adjacent to the straightening device 4, and the direction of the in-out belt of the guide device 5 is set along the axial direction of the pipe production part (that is, the axial direction of the sequentially arranged winding device 3, pipe cutting device 2 and support frame 1), The power supply end of the control system 8 is connected with the driving mechanism of the guiding device 5, the straightening device 4, the winding device 3, the pipe material cutting device 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com