Self-moving crusher

A crusher, self-moving technology, applied in grain processing and other directions, can solve the problems of large environmental pollution and high maintenance costs of trucks, and achieve the effect of improving economic benefits, reducing production costs and continuous operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

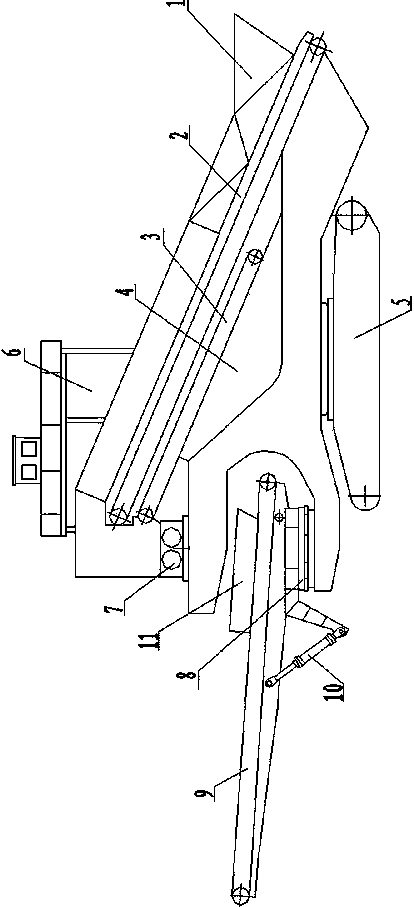

[0034] A self-moving crusher, see Figure 1 to Figure 5 , Figure 7 to Figure 12 , in the figure: silo 1, feeding conveying device 2, aggregate conveying device 3, bearing frame 4, crawler walking device 5, operating room 6, crushing device 7, slewing support device 8, discharge conveying device 9, lifting device 10. Collection hopper 11.

[0035] Main shaft 201, chain plate 202, supporting roller 203, frame 204, tensioning device 205, supporting roller 6, supporting sprocket 207, driving motor 208, supporting body 209.

[0036] Driving wheel 301, scraper chain 302, chute 303, guide wheel 304, tensioning device 305.

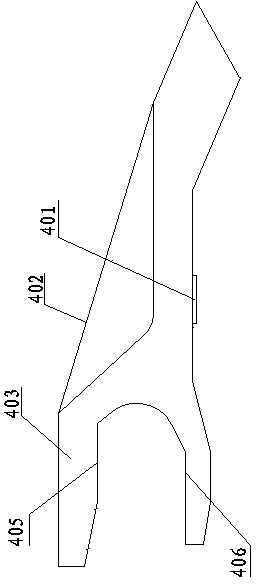

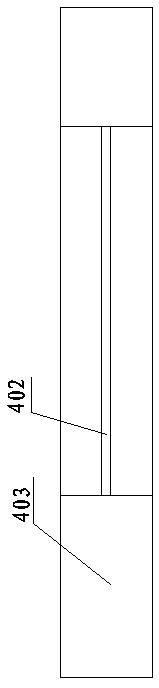

[0037] Walking platform 401, feeding platform 402, crushing platform 403, discharging platform 404; upper fork 405, lower fork 406.

[0038] Track driving motor 501, driving wheel 502, track shoe 503, bearing wheel 504, connection platform 505, tensioner wheel 506.

[0039] Crushing motor 701, hydraulic coupling 702, reducer 703, coupling 704, cr...

Embodiment 2

[0057] See attached Image 6 , the difference from Embodiment 1 is: the discharge platform 404 is located on the lower surface of the upper fork 405 in the wrench head, the lower surface of the upper fork 405 is provided with a rotary support device 8, and the rotary support device 8 is connected to the row Material conveying device 9 and lifting device 10. This structure is suitable for self-moving crushers with small processing capacity, and the collection hopper 11 can be omitted to make the structure more compact and reduce the height of the whole machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com