Patents

Literature

205results about How to "Resolve source issues" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

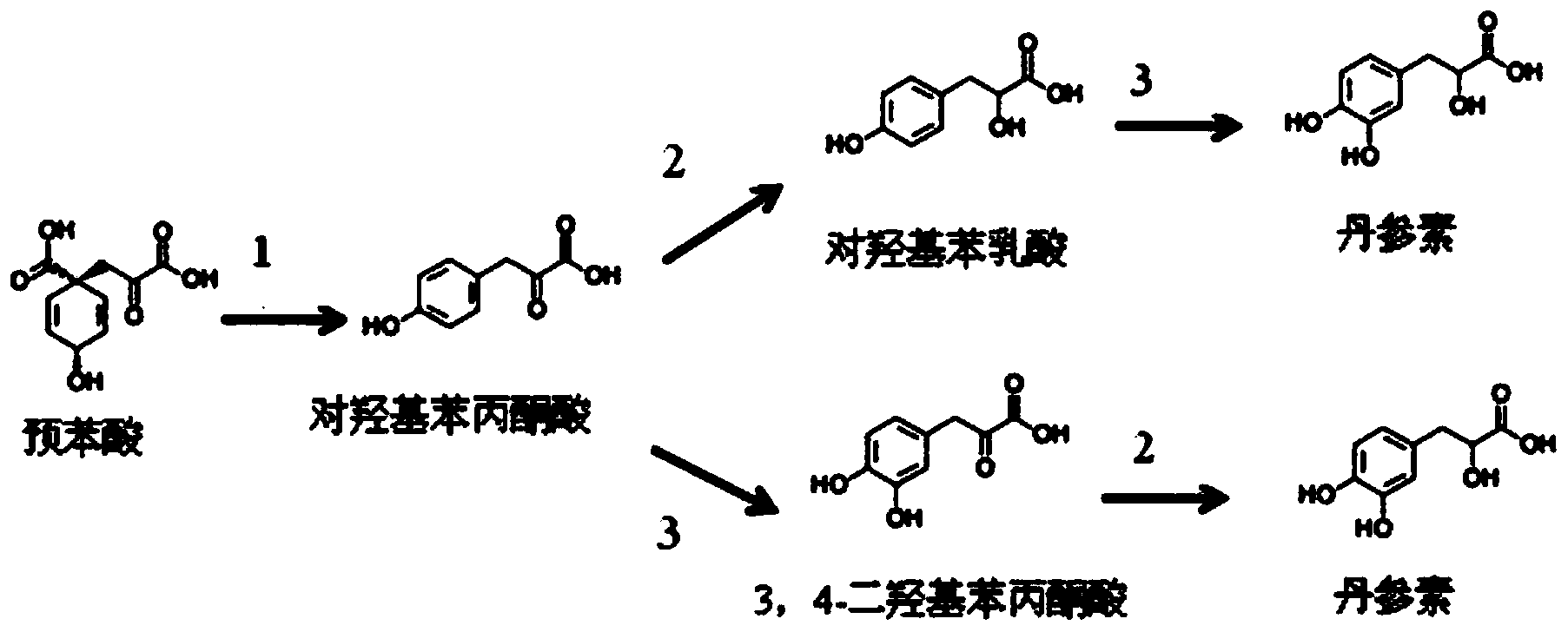

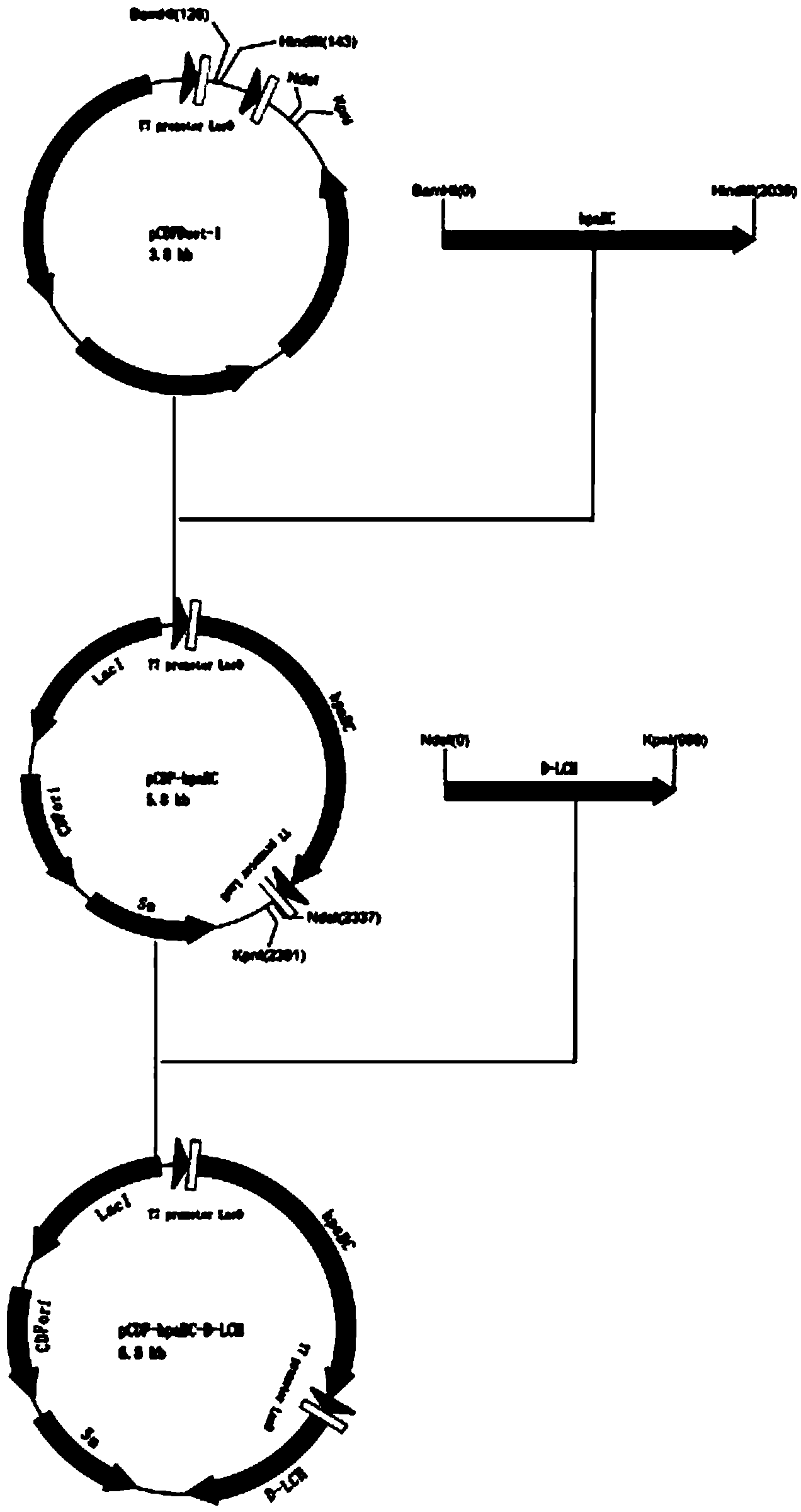

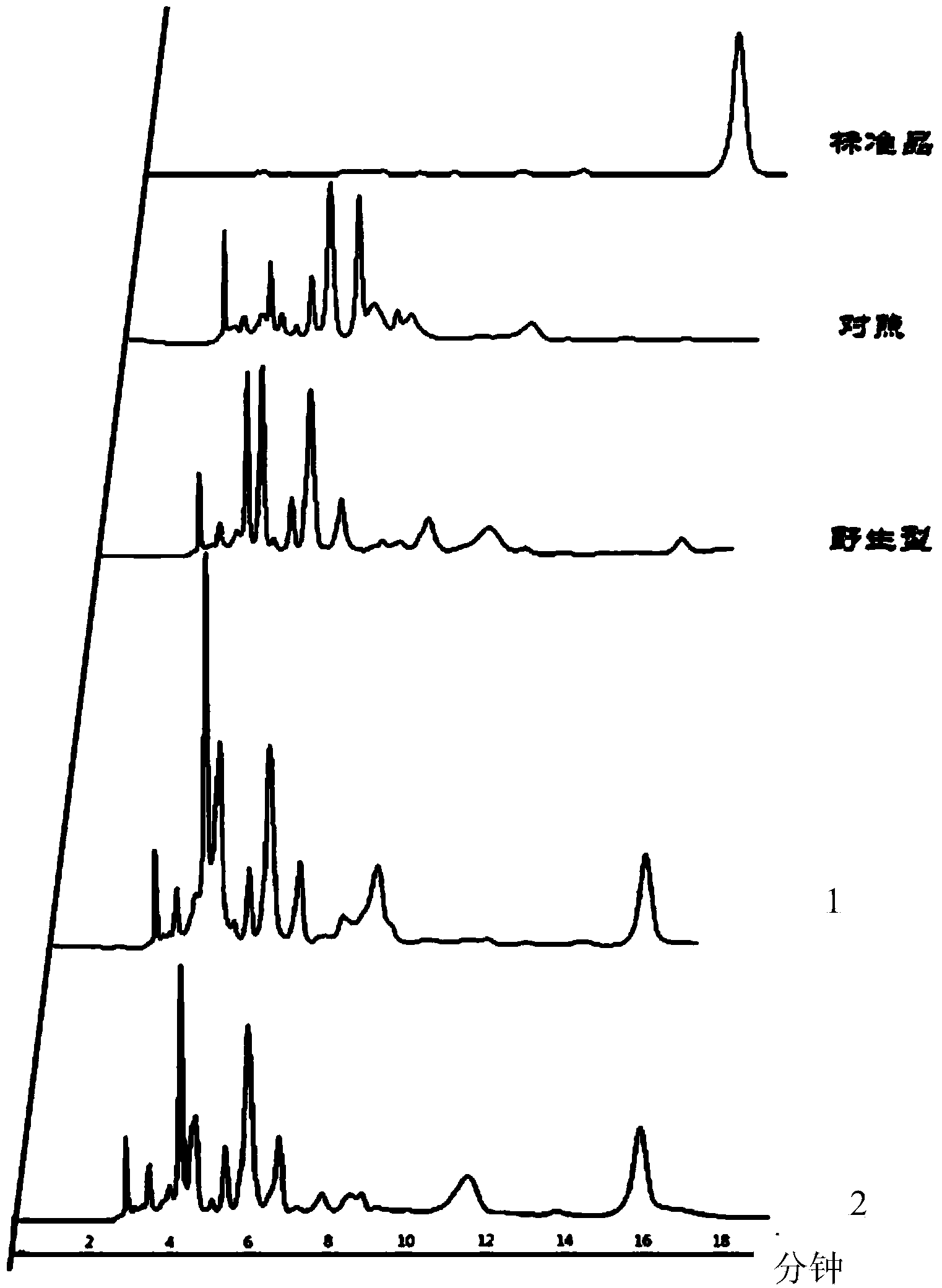

Biological production method of tanshinol

ActiveCN103667371ADe novo synthesisResolve source issuesBacteriaMicroorganism based processesSalvia miltiorrhizaEscherichia coli

The invention discloses a biological production method of tanshinol, which comprises the following steps: synthesizing p-hydroxyphenylpyruvic acid into 3,4-dihydroxyphenylpyruvic acid under the catalytic action of a p-hydroxyphenylacetic acid meta-position hydroxylation enzyme, and then, synthesizing to obtain the tanshinol under the catalytic action of a D-lactate dehydrogenase; or synthesizing p-hydroxyphenylpyruvic acid into p-hydroxyphenyllactic acid under the catalytic action of a D-lactate dehydrogenase, and then, synthesizing to obtain the tanshinol under the catalytic action of a p-hydroxyphenylacetic acid meta-position hydroxylation enzyme. According to the invention, gene engineering glutamic acid corynebacteria and Escherichia coli are used to produce the tanshinol through fermentation, and the tanshinol can be synthesized without adding a substrate, thereby realizing de novo synthesis of the tanshinol and solving the problem on the source of the tanshinol; and meanwhile, the production cost is lowered to the greatest extent. Thus, the biological production method is beneficial to industrial production.

Owner:TIANJIN UNIV

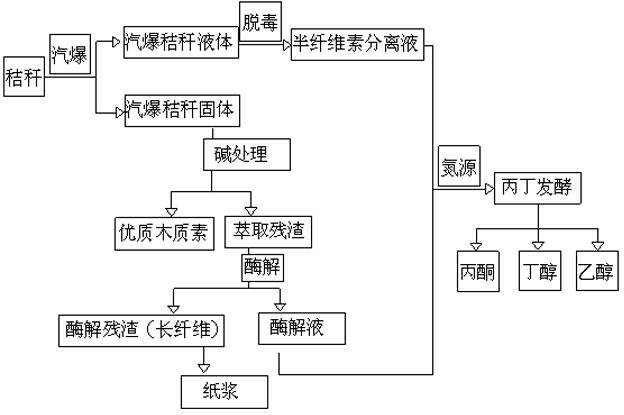

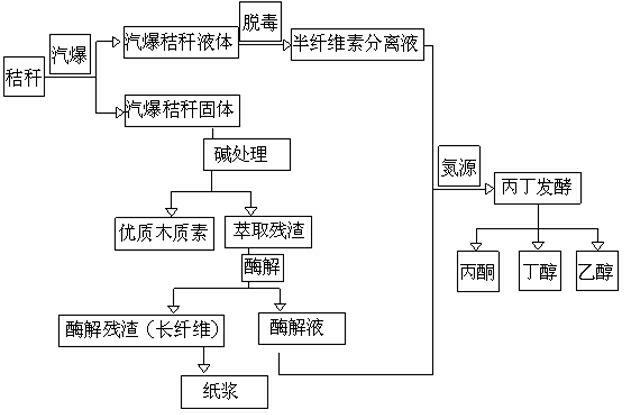

A method for comprehensive utilization of straw raw materials

ActiveCN102277391AImprove use valueWide variety of sourcesMicroorganism based processesFermentationFiberCellulase

The invention relates to a comprehensive utilization method of straw raw materials. The method is characterized by comprising the following steps: a, carrying out solid-liquid separation on steam-exploded straws, using an alkaline cooking method to process solid bodies of the steam-exploded straws, and extracting good xylogens from an alkaline extract liquor by an acid-out method; b, carrying out enzymolysis on the extracted residues in the step a to obtain zymolytic residues and a zymolytic liquid, wherein the zymolytic residues are used for preparing pulps; and c, after the steam-exploded straws in the step a are detoxificated, mixing a zymolytic liquid with the zymolytic liquid in the step b and adding nitrogen sources to butylicum fermentation. The method has the advantages that sources of raw materials are wide; the separation of celluloses (continuous fibers and staple fibers), hemicelluloses, xylogens and the like in the straws is realized, thus sufficiently realizing the value of each component; and the celluloses are divided into the continuous fibers which are difficult to realize enzymolysis and the staple fibers which are easy to realize enzymolysis, thus reducing the usage amount and cost of the cellulase, improving the comprehensive utilization value of the straws and solving the source problem of raw materials in industrialization production of the butylicum fermentation.

Owner:NANTONG HEBAO BIOTECH

Method for culturing mushroom using swine waste

ActiveCN101336598ARealize resource utilizationImprove use valueBio-organic fraction processingOrganic fertiliser preparationBiotechnologyResource utilization

The invention provides a method for culturing mushroom using pig nightsoil comprising culturing the mushroom using pig nightsoil instead of the cow dung in the conventional mushroom culture medium. The cultivation steps are as follows: culture medium preparation- stacking prewet- primary fermentation- post fermentation- cooling- sowing- fungi growth and soil cover- management of producing mushroom- mushroom picking- mushroom product. By using the pig nightsoil instead of cow dung to culture mushroom, the method of the invention solves the raw material source problem of the mushroom scale production, reduces the production cost of the mushroom, is useful for the sustainable development of the edible fungi industry, improves the production efficiency of the edible fungi, further more achieves the resource utilization of the pig nightsoil, improves the utilization value of the pig nightsoil, reduces the pollution discharge in the pig industry and is useful for quantitative reduction and resource reutilization in the pig industry.

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI +1

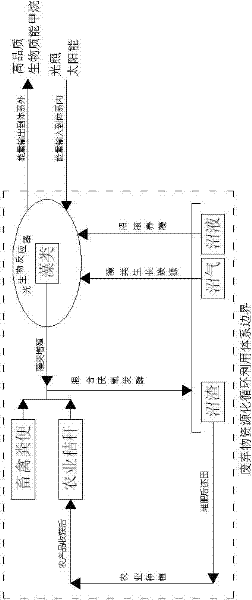

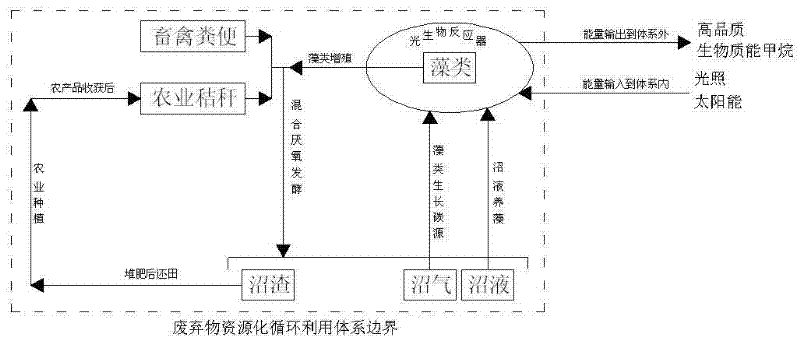

Method for biologically purifying marsh gas and recycling waste of marsh gas

InactiveCN102337302APromote growthAvoid harmBio-organic fraction processingUnicellular algaeSocial benefitsPhotobioreactor

The invention belongs to the technical field of recycling of resources, and in particular relates to a method for biologically purifying marsh gas and recycling waste of the marsh gas. The method comprises the following steps of: purifying carbon dioxide in the marsh gas by using a photo-bioreactor constructed by algae to obtain high-quality biomass energy methane; simultaneously, combining fermented liquid and residues which are residual after fermentation, and comprehensively recycling the algae proliferated in the photo-bioreactor to fulfill the aim of zero emission of the waste. By the method, the marsh gas has an obvious purification effect, the concentration of the methane in the marsh gas can be improved from the range of between 30 and 40 percent to 90 percent, the energy flow of solar energy from the algae to high-quality marsh gas and the matter cycle of nutrient elements such as C, N, P and the like are realized, and economic and social benefits are obvious.

Owner:FUDAN UNIV

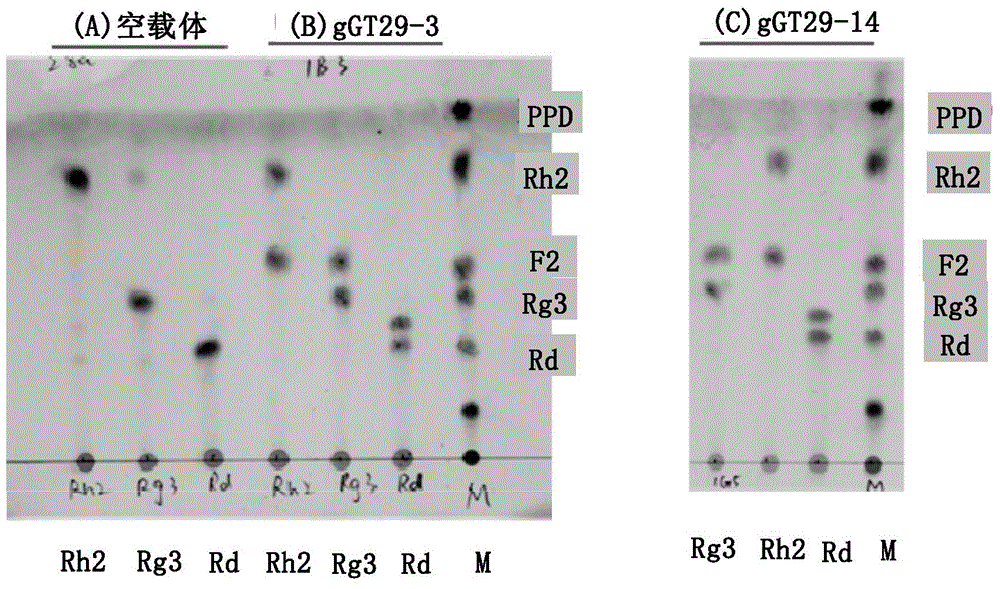

A group of glycosyl transferase, and applications thereof

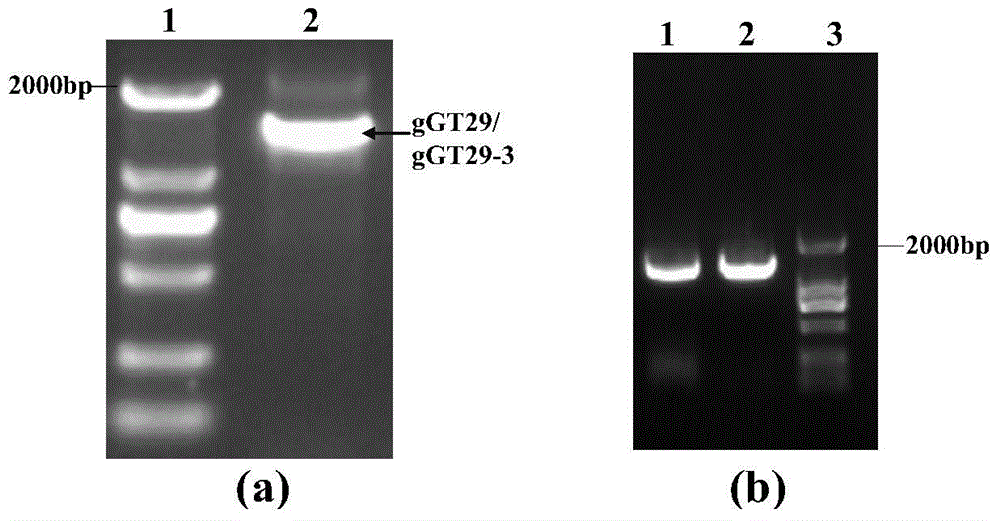

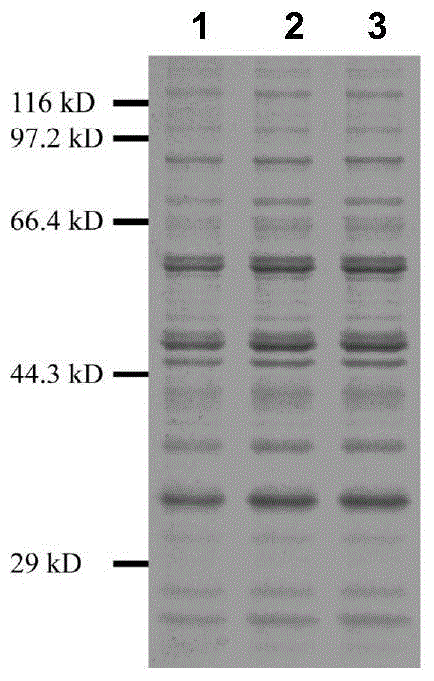

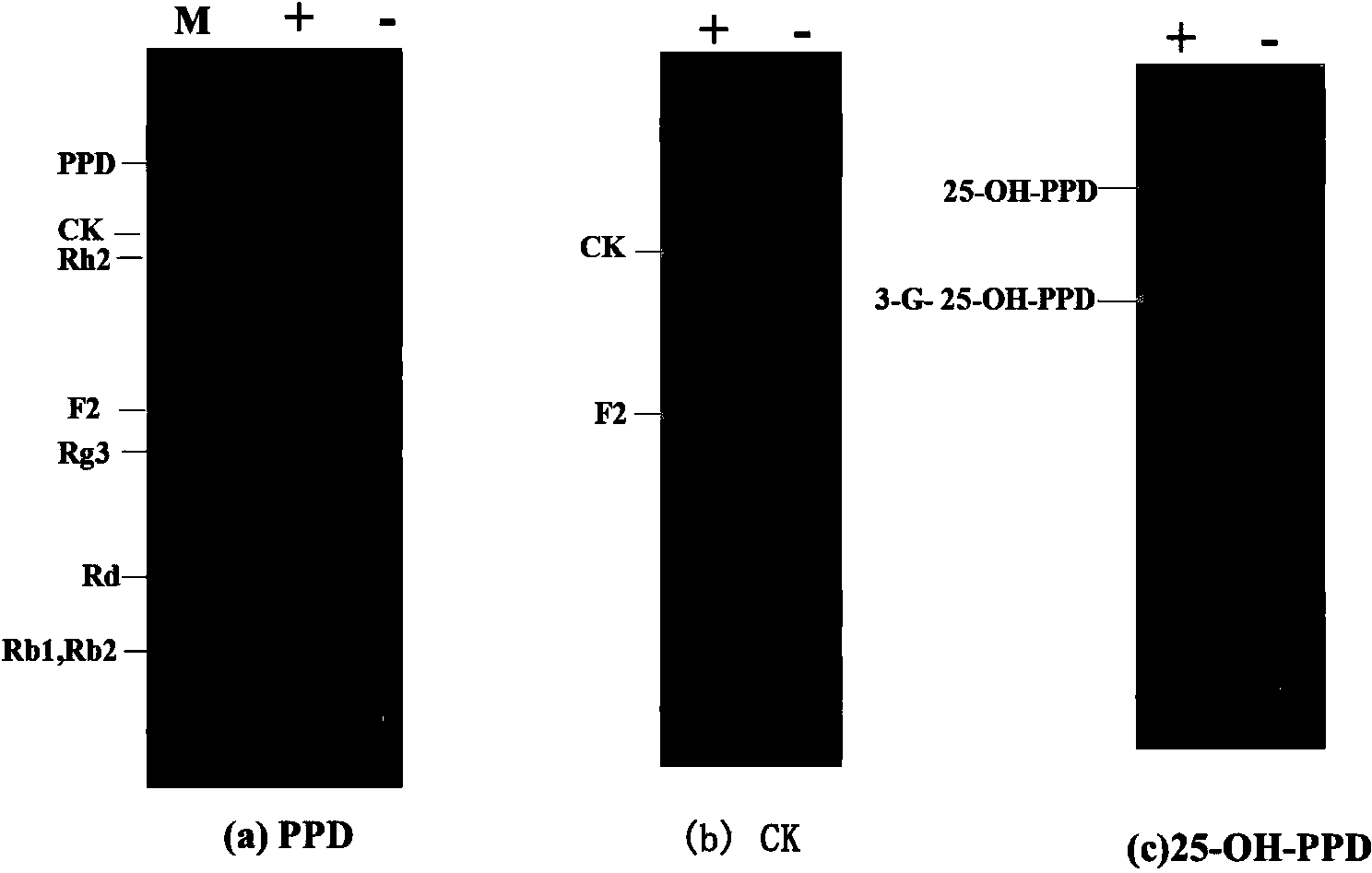

InactiveCN105177100AHigh anticancer activityResolve source issuesTransferasesPlant peptidesTriterpeneTriterpenoid

The present invention relates to a group of glycosyl transferase and applications thereof, and specifically provides applications of the glycosyl transferase gGT29-7 and a derived polypeptide thereof in terpene compound glycosylation catalysis and new saponin synthesis, wherein the glycosyl transferase can specifically and efficiently transfer the glycosyl from a glycosyl donor to the first glycosyl on C-3 site and / or C-6 site of a tetracyclic triterpene compound so as to extend the sugar chain. The glycosyl transferase of the present invention can further be used for constructing artificial ly-synthesized rare ginsenosides and a variety of new ginsenosides and derivatives thereof.

Owner:周志华

Glycosyl transferases and applications of glycosyl transferases

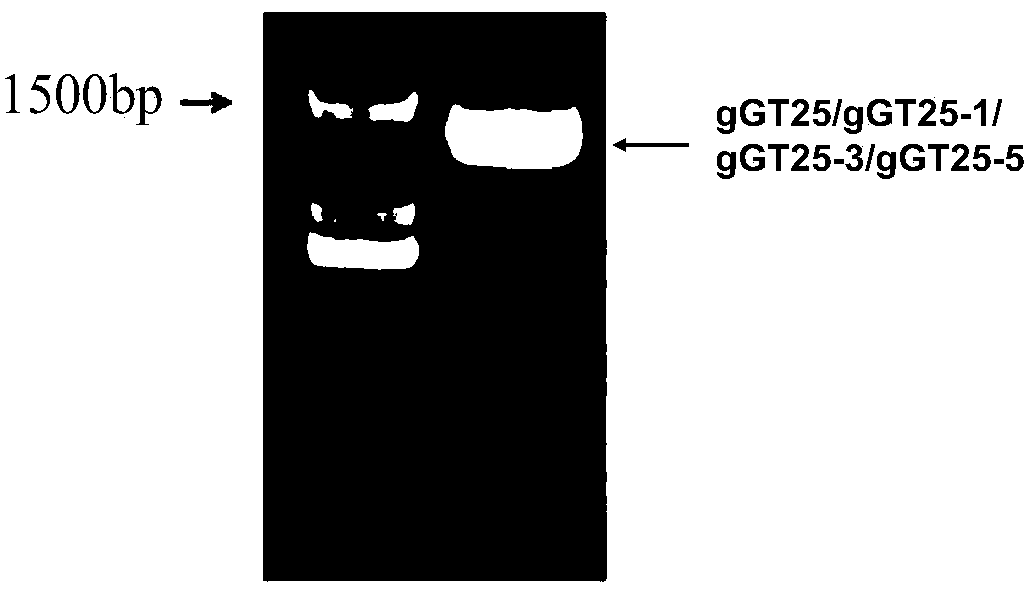

ActiveCN104232723ASpecific and efficient transferHas anticancer activityTransferasesFermentationTriterpeneCoa transferase

The invention relates to a group of glycosyl transferases and applications of the glycosyl transferases. Particularly, the invention provides applications of glycosyl transferases gGT25, gGT13, gGT30, gGT25-1, gGT25-3, gGT25-5, gGT29, gGT29-3, gGT29-4, gGT29-5, gGT29-6, gGT29-7, 3GT1, 3GT2, 3GT3 and 3GT4, and derived peptides of the glycosyl transferases in glycosylation catalysis and new saponin synthesis of terpenoids. The glycosyl transferases can specifically and efficiently catalyze hydroxyl glycosylation of C-20 bit and / or C-6 bit and / or C-3 of a tetracyclic triterpenoid compound substrate, and / or transfers the glycosyl groups from glycosyl donors to the first glycosyl groups of the C-3 bit and C-6 bit of the tetracyclic triterpenoid compound to extend a carbohydrate chain. The glycosyl transferases disclosed by the invention can also be applied to building synthetic rare ginsenosides and a plurality of novel ginsenosides and derivatives of the ginsenosides.

Owner:SYNBIOTECH (SUZHOU) CO LTD

Rice field breeding method for crayfish procambrarus clarkii

InactiveCN101011039AImprove survival rateSolve fishing problemsAnimal reproductionClimate change adaptationProcambarus clarkiiPrawn

The invention relates to a method for cultivating the Krause's crayfish, comprising that cleaning the field, cultivating the parental crayfish, cultivating the seed and taking off, cultivating the rice. The invention is characterized in that the cultivation of parental crayfish is processed in the surrounded groove, which has an anti-jump device and near the ground arranges seed holes at 0.8-1.2cm diameter; the crayfish seed can pass through the holes into the field. The invention can pre-cultivate the parental crayfish to avoid damaging the rice. And the invention can obtain many benthic fauna as the bait of parental crayfish, seed, or the like.

Owner:JIANGSU BAOLONG GROUP +1

Biological method for producing resveratrol

InactiveCN102605006ADe novo synthesisResolve source issuesBacteriaMicroorganism based processesBiotechnologyPhenylalanine hydroxylase

The invention discloses a biological method for producing resveratrol, which comprises the following steps: ligating target genes obtained by restriction enzyme digestion to an expression vector, wherein the target genes include the sequences of phenylalanine hydroxylase (PAH), tyrosine ammonia lyase (TAL) 4-coumarate:coenzyme A ligase (4CL) and resveratrol synthase (RS); transforming the constructed expression vector into a strain to obtain a recombinant engineered strain; and fermenting the recombined engineered strain. Compared with the prior art, the technical scheme provided by the invention uses the genetically engineered strain for fermentation to produce resveratrol, so as to realize denovo synthesis of resveratrol with no need of adding substrates. The method disclosed by the invention solves the source problem of resveratrol, and at the same time, reduces the production cost in a maximum extent, and is beneficial for industrial production.

Owner:TIANJIN UNIV

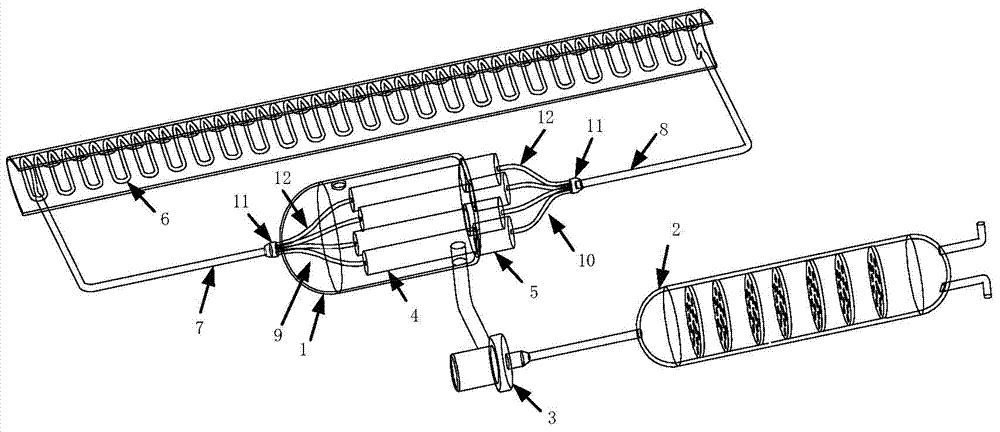

Ice preventing and removing system for aircraft wing

The invention discloses an ice preventing and removing system for an aircraft wing. The system comprises a waste gas treatment device, an air pump, a shell, an evaporator, a condenser, an air line and a liquid line, wherein engine waste gas treated by the waste gas treatment device is introduced into the shell to heat the evaporator, working media are vaporized after being heated in the evaporator and then led out through the air line, and then the working media are cooled into liquid in the condenser located on the skin and give out heat, and finally flow back to the evaporator through the liquid line to finish the whole circulation. According to the system, the vapor-liquid two-phase flow phase change heat transfer design concept is adopted, vapor-liquid phase conversion of the working media is utilized to transmit heat, and then the purpose of preventing and removing ice on the aircraft wing is achieved; engine waste gas of an airplane is utilized as the heat source to increase the comprehensive utilization rate of airplane energy.

Owner:BEIHANG UNIV

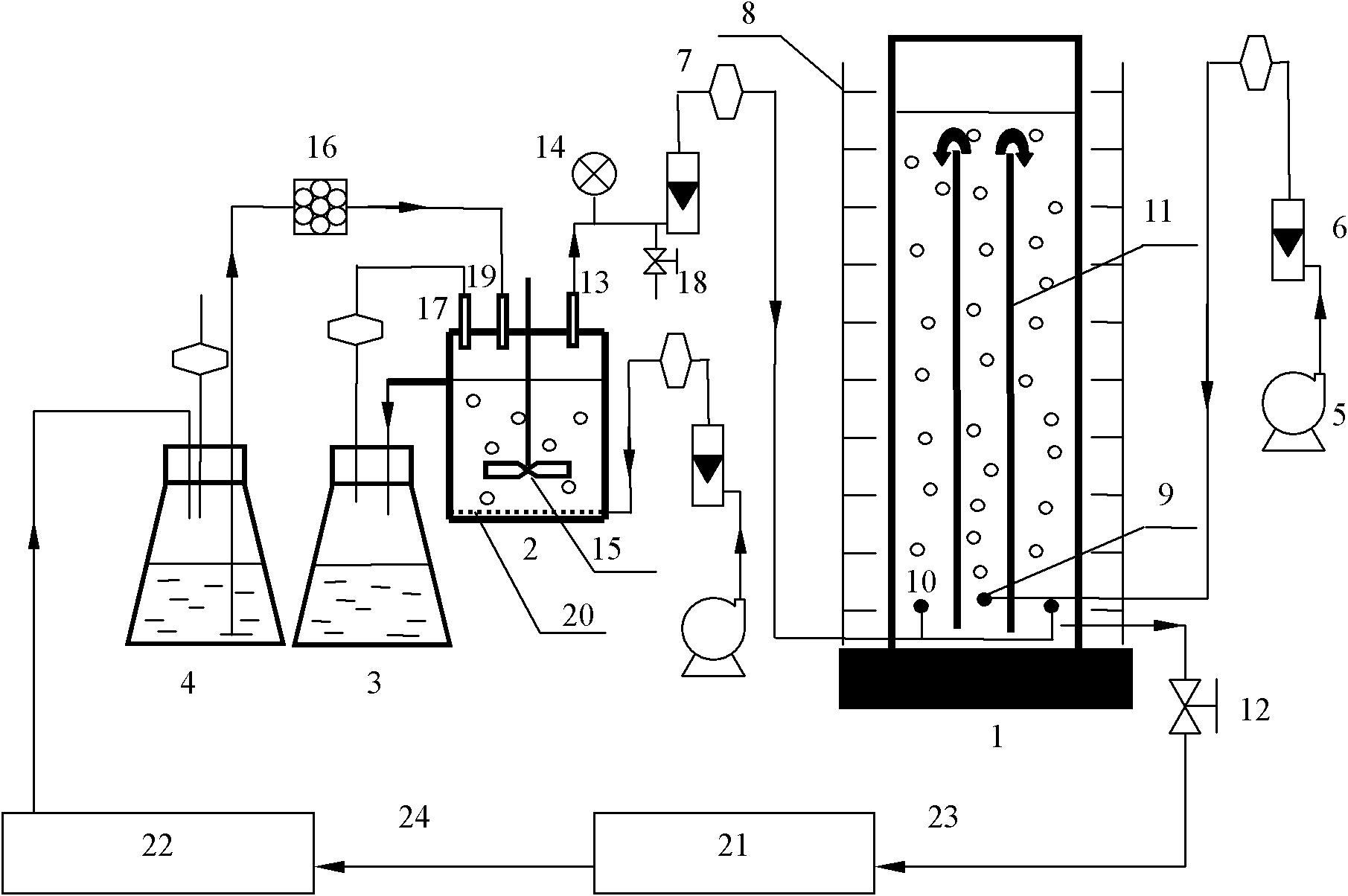

Method for supplementing fermentation raw material by microbial fermentation tail gas CO2 immobilized by microalgae culture

InactiveCN102827775AEnvironmentally friendlyAchieve CO2 emission reductionBioreactor/fermenter combinationsBiological substance pretreatmentsBiomassNitrogen source

The invention relates to CO2 emission reduction and recycling technologies, and discloses a method for adopting microalgae culture immobilized microbe fermentation tail gas CO2 as a supplementation fermentation raw material. According to the invention, tail gas in a microbe fermentation tank is directly introduced into a microalgae culture illumination bioreactor; conditions such as illumination, temperature, and ventilation are controlled; proper inorganic nutrient salts are added; CO2 in microbe fermentation tail gas is adopted as a carbon source for culturing microalgae; biomasses such as carbohydrates and proteins are accumulated; the biomasses are converted into raw materials such as carbon and nitrogen sources needed by fermentation through pretreatment; and the raw materials are delivered back to the microbe fermentation system to be utilized as a fermentation supplementation raw material. With the method provided by the invention, emission reduction and recycling of the microbe fermentation tail gas CO2 are realized; grain raw material consumption of microbe fermentation is reduced; and good environmental and social benefits are provided.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

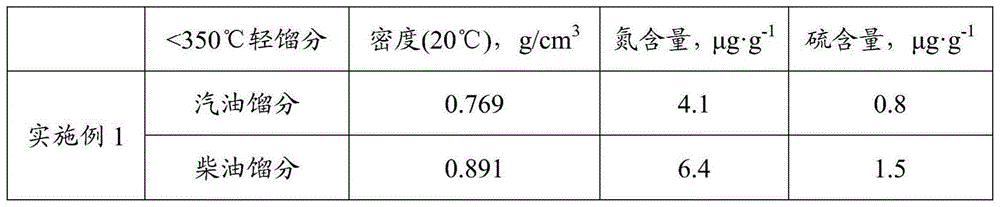

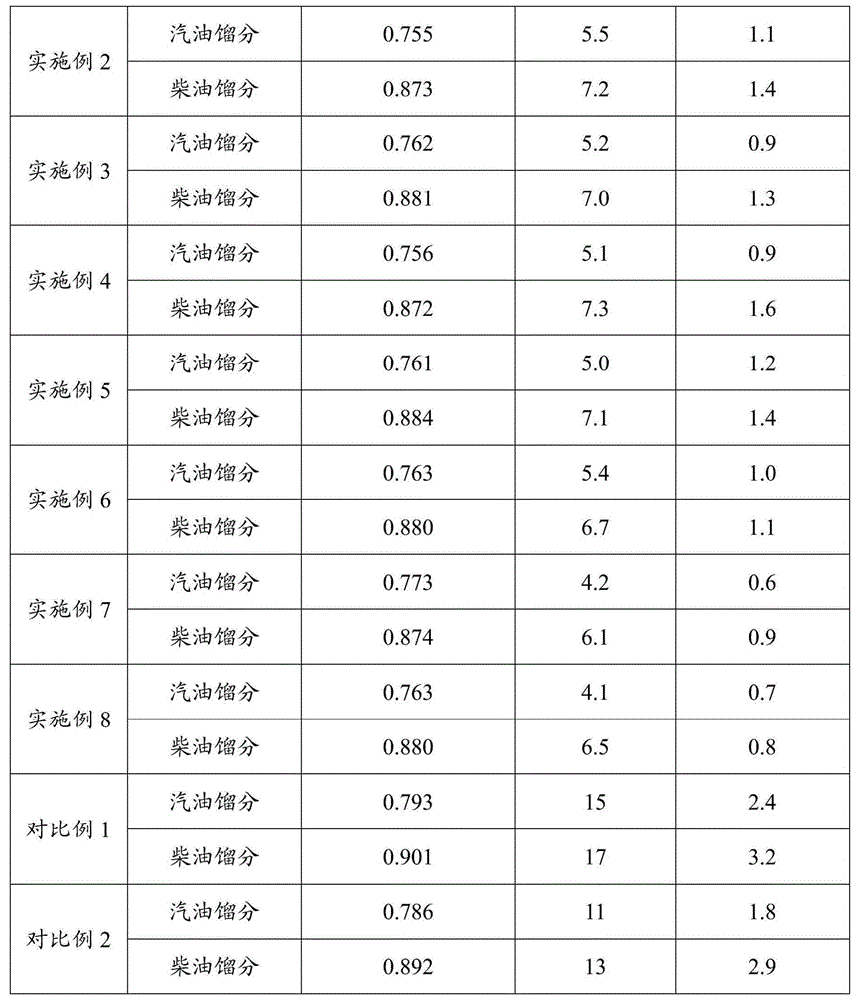

Preparation method of hydrogenation catalyst and slurry bed hydrogenation technology using the catalyst

ActiveCN105126933ALarge specific surface areaGood dispersionCatalyst regeneration/reactivationHydrocarbon oil crackingHydrogenation reactionHydrogenation process

The invention provides a preparation method of hydrogenation catalyst and a slurry bed hydrogenation technology using the catalyst. The preparation method comprises the following steps: a desulphurization waste agent and / or a waste catalyst is placed in a solvent oil at 80-150 DEG C for beating, and a hydrogenation catalyst slurry is obtained. The preparation method of the present invention can increase dispersibility of the catalyst in raw oil and is good for improving activity of the catalyst, and simultaneously can effectively reduce even inhibite the coking problem of slurry bed. According to the slurry bed hydrogenation technology provided by the invention, the desulphurization waste agent generated in the process of slurry bed tail gas desulphurization is prepared into the hydrogenation catalyst, and the hydrogenation catalyst is calculatedly used in the hydrogenation reaction of heavy raw oil, thereby realizing cyclic utilization of catalysts with different functions in the whole slurry bed hydrogenation process flow, solving the coking problem easily generated in the slurry bed hydrogenation technology, and simultaneously developing a low-cost new approach for safety recovery of the desulphurization waste agent, the waste catalyst or the like.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

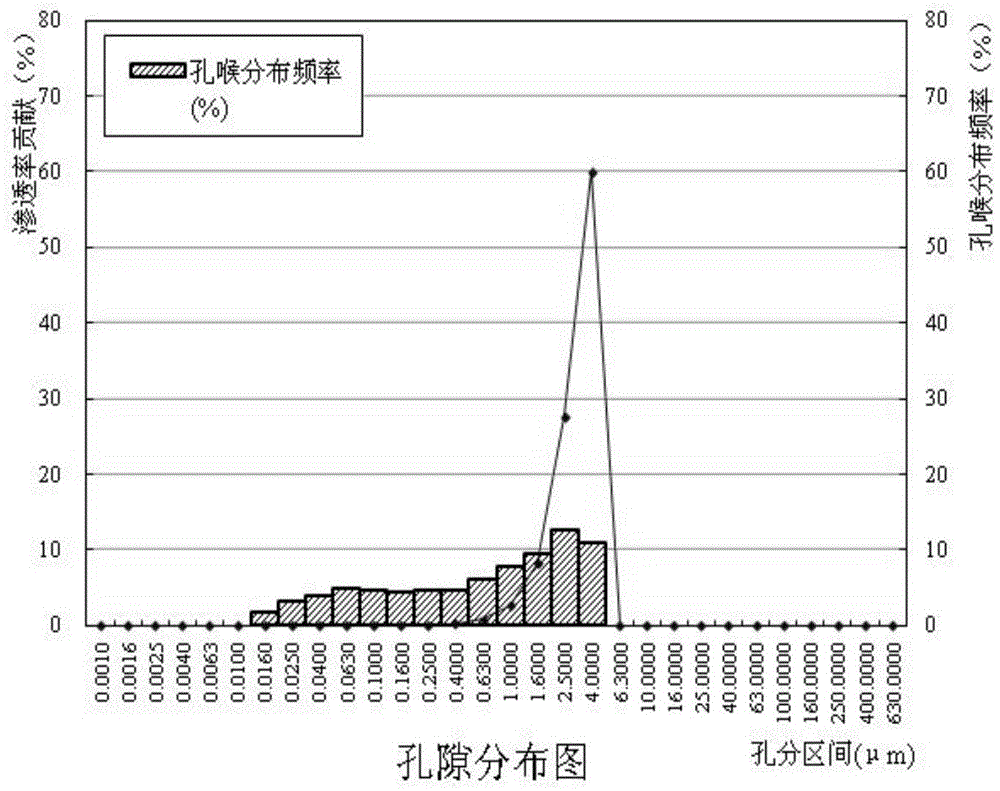

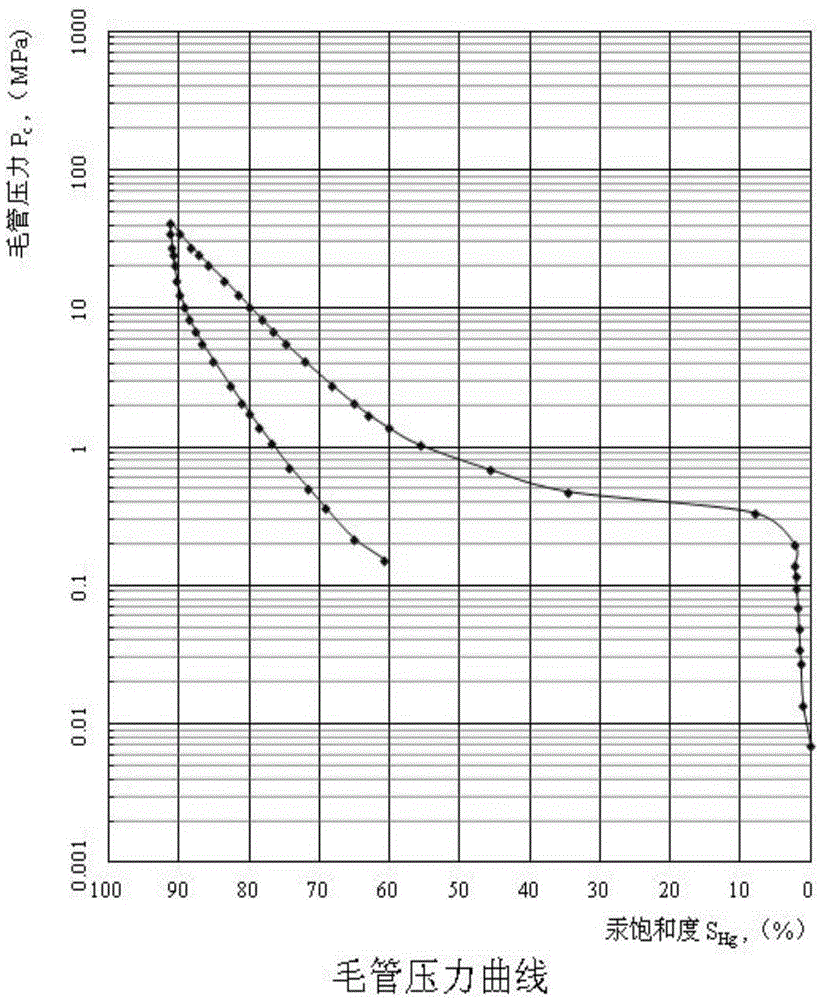

Artificial conglomerate core as well as preparation method and application thereof

The invention discloses an artificial conglomerate core which is used an indoor physical simulation experiment, and belongs to the technical field of oil-gas field development physical simulation. The artificial conglomerate core is mainly prepared from the following raw materials in percentage by weight: 2-15% of clay, 5-25% of cementing matter, 20-50% of river sand and 30-60% of quartz sand. The artificial conglomerate core has the advantages that the source problem of the conglomerate core in physical simulation is solved, the obtained artificial conglomerate core is stable in structure, complicated in pore throat structure and diverse in core components, has the characteristics of simple structure and stable property and can replace natural core to be used in physical simulation, and the shortcomings that the pore throat disposition, wetting property and the like of the synthetic core have great difference from those of the natural core are effectively overcome.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for preparing environment-friendly thermal-insulation building block from construction waste

ActiveCN104193263AImproved long-term mechanical properties and durabilityResolve source issuesSolid waste managementThermal insulationC constant

The invention relates to a method for preparing an environment-friendly thermal-insulation building block from construction waste, which comprises the following steps: uniformly mixing cement, active mineral admixture, haydite and construction waste in a weight ratio of (8-25):(20-60):(20-45):(8-15), adding water, pulping and stirring for 5-10 minutes, adding a special additive which accounts for 0.8-1.5 wt% of the dry powder, and stirring for 0.5-1 minute; and preparing a slurry, injecting into a specimen mold, standing in a 55 DEG C constant-temperature steam curing chamber, curing for 4 hours, demolding, cutting with a steel wire, sending into an autoclave, heating and pressurizing for 8 hours, and discharging to obtain the thermal-insulation building block. The density of the thermal-insulation building block is 500-700 kg / m<3>, the heat conductivity coefficient is less than or equal to 0.16 W / m.K, and the compression strength is greater than or equal to 5 MPa. By using the construction waste instead of part of the active mineral admixture and the haydite as the component, the method achieves the effects of protecting the environment, enhancing the cyclic utilization efficiency of resources and lowering the cost.

Owner:广西壮族自治区建筑科学研究设计院

A kind of Pleurotus eryngii culture material

The invention relates to a Pleurotus eryngii culture medium which is prepared from the following raw materials in parts by mass: 40-60 parts of bacterial dreg, 30-40 parts of corn cob, 10-15 parts of bran and 0.9-1.1 parts of lime. By using the bacterial dreg instead of wood dust and cottonseed hull, the bacterial dreg is recycled, thereby enhancing the bioavailability of the effective constituents in the bacterial dreg; and thus, the invention solves the problem of raw material resources, effectively utilizes the agricultural leftovers, changes wastes into valuable substances and lowers the raw material cost and transportation expenses, thereby lowering the production cost of the Pleurotus eryngii and having favorable economical and ecological effects.

Owner:广西中农食品有限公司

Preparation method and applications of antibacterial peptide

ActiveCN103468673ALow costSimplified purification stepsAntibacterial agentsCosmetic preparationsBiopesticideCosmetics

Owner:GENLOCI BIOTECH

Tailings disposing and filling method

The invention discloses a tailings disposing and filling method and belongs to the field of tailings utilization and disposal. The method includes: grading tailing pulp to obtain fine-particle tailings pulp and coarse-particle tailings; dewatering the fine-particle tailings pulp and the coarse-particle tailings pulp respectively according to application to obtain fine-particle tailings and fine aggregate and coarse-particle tailings for granulation, mortar and dry-mixed mortar; sintering the fine-particle tailings at high temperature, and adding a binding material into the coarse-particle tailings for granulation, mortar and dry-mixed mortar to obtain coarse aggregate, a mortar material and a dry-mixed mortar material; mixing the coarse aggregate and the fine aggregate, conveying the samedown into a well through a filling well, conveying the mortar material down into the well through a filling pipe, mixing, and then filling; conveying the dry-mixed mortar material down into the well to be mixed with pipe flushing water to prepare a dry-mixed mortar material mixture, mixing the mixture with the aggregate, and filling. By the method, treating and hardening time of the filling material can be shortened, strength of a filled body can be enhanced, downhole operation conditions can be improved, and pollution of underground environment can be reduced.

Owner:LIAONING TECHNICAL UNIVERSITY +1

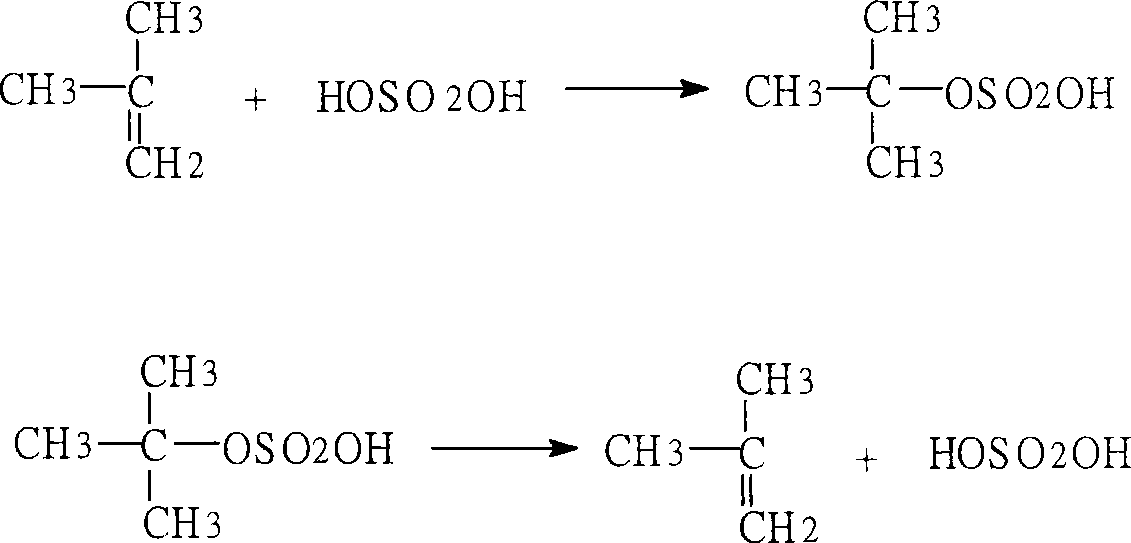

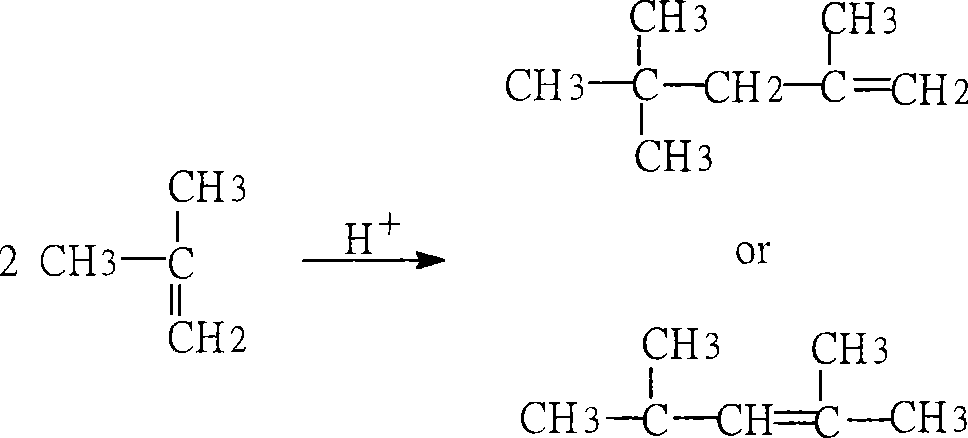

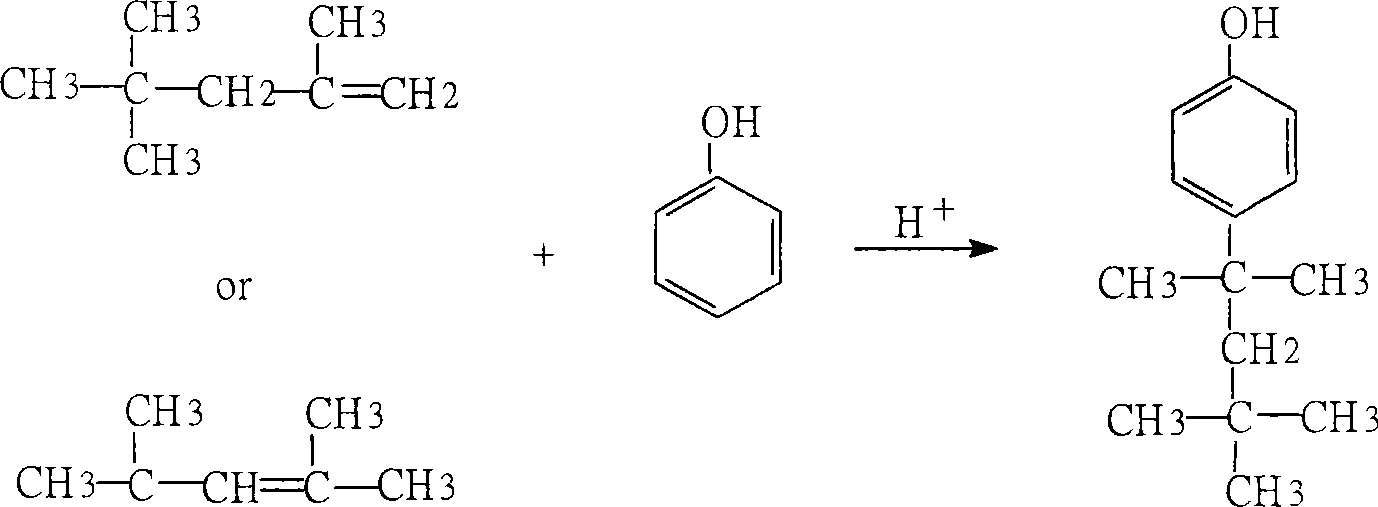

Method for preparing p-tert octyl phenol

ActiveCN101161616AOvercome high costLow cost of preparationOrganic chemistryOrganic compound preparation4-tert-octylphenolStrong acids

The invention provides a method for preparing 4-tert-octylphenol. The C4 fraction addition mixture with 80 percent of isobutene dimer remained by esterification-degasification of sulfuric acid is taken as the raw material ; after the raw material is braized and cut under the temperature between 75 DEG C and 105 DEG C, the isobutene dimmer that the content of the target distillate is more than 98 percent is obtained to be taken as the alkylating agent; Na-type sulfonated styrol-butadiene polymer strong base anion-exchange resin with 50 percent of water is acidified to a H-type sulfonated styrol-butadiene polymer strong acid cation-exchange resin as the alkylation catalyst; the target distillate isobutene dimmer and the phenol are made a alkylation reaction under the temperature between 90 DEG C and 100 DEG C with the H-type sulfonated styrol-butadiene polymer strong acid cation-exchange resin as the catalyst to produce the 4-tert-octylphenol alkylation mixing liquid; the alkylation mixing liquid is braized and cut under the temperature between 220 DEG C and 270 DEG C to produce the 4-tert-octylphenol.

Owner:RACHEM CHINA CO LTD

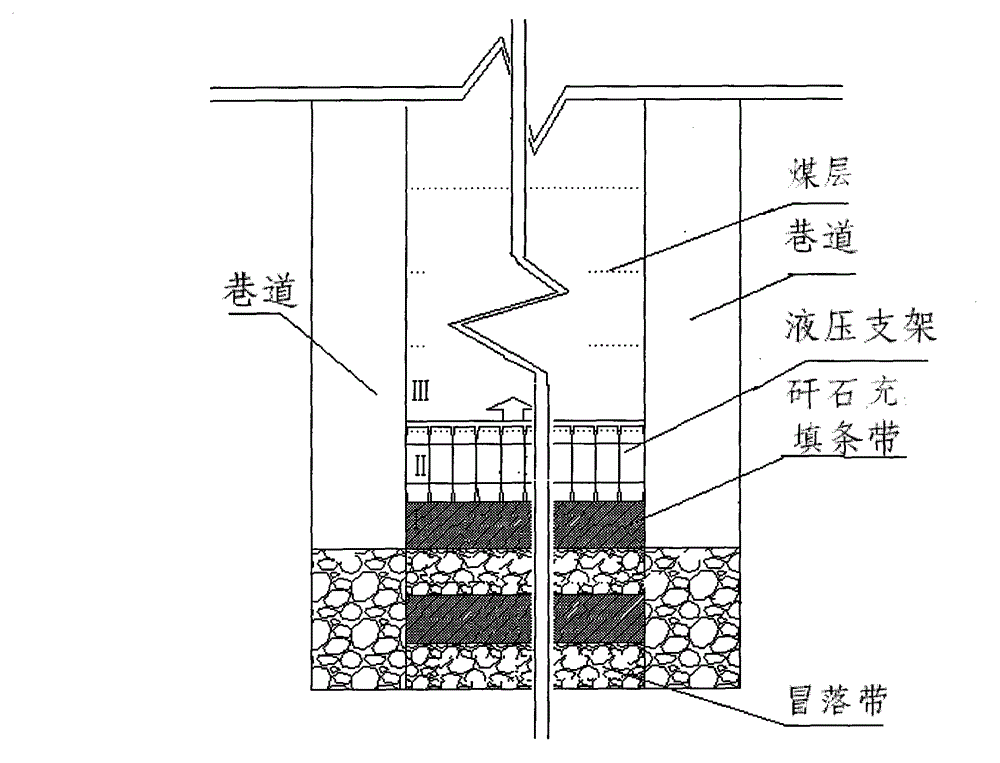

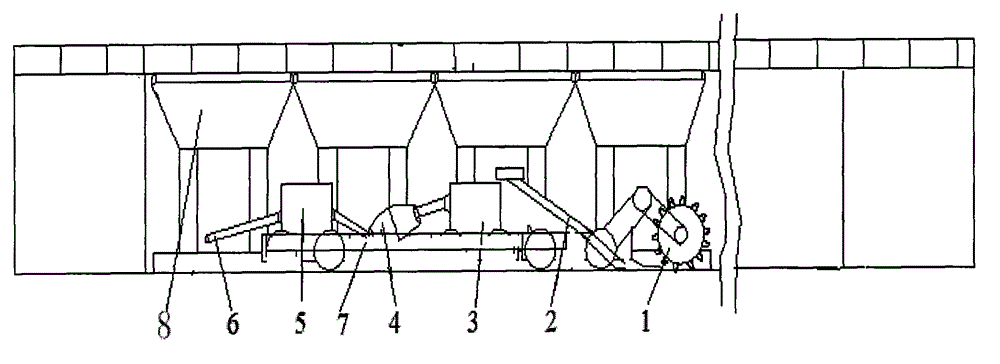

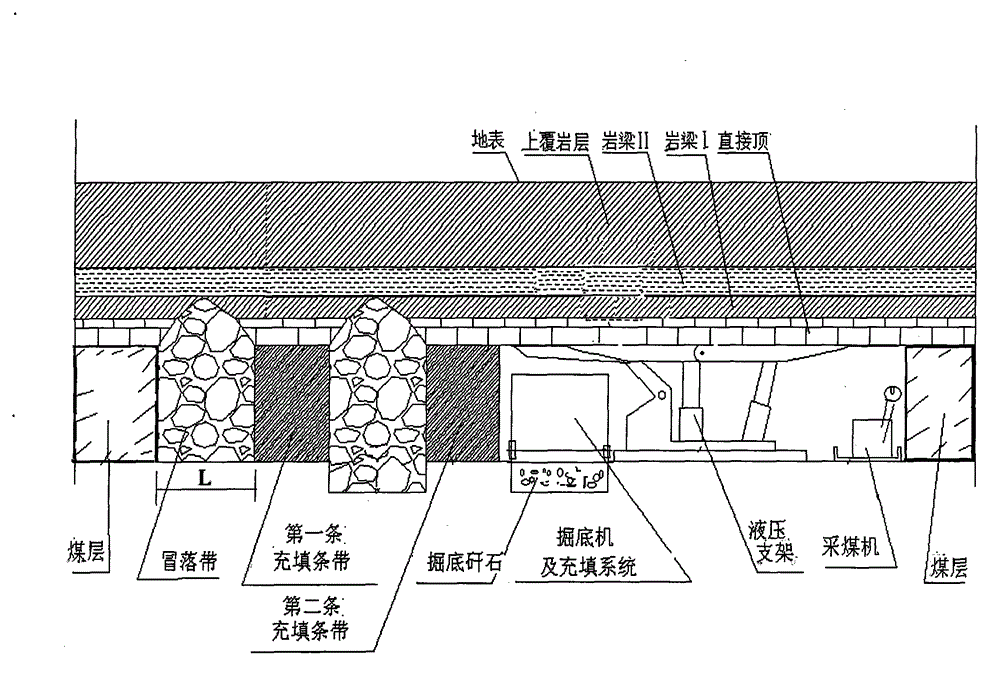

Method for performing coal mining and gangue cementation stripe filling simultaneously

ActiveCN102877848AImprove filling efficiencyWaiver of feesUnderground miningSurface miningFirst FillMining engineering

The invention discloses a method for performing coal mining and gangue cementation stripe filling simultaneously. When a working surface advances to a certain distance, an excavator and filling equipment are delivered under a filling support for assembly and adjustment; a bottom excavator excavates a bottom while coal mining machine mines coal, underlying strata excavated by the excavator are delivered to a filling bag through a filling system; the underlying strata form a first filling strip of a support goaf top plate after solidifying and sizing; and after filling of the first filling strip, the filling operation of a second filling strip is performed; and the steps are repeated accordingly, and coal mining and filling are performed simultaneously until a coal face is mined. According to the method, the filling mechanical equipment is transferred under a well, so that the ground site arrangement is reduced, gangue of down hole bottom excavating board is fully used, the problem of the filling material source is solved, transport links of filling materials are reduced, the filling system moving with the working surface simultaneously is formed, down hole filling is rapid and effective, and simultaneously, an efficient work flow of coal mining and filling simultaneously can be achieved.

Owner:SHANDONG UNIV OF SCI & TECH

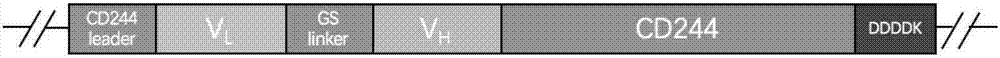

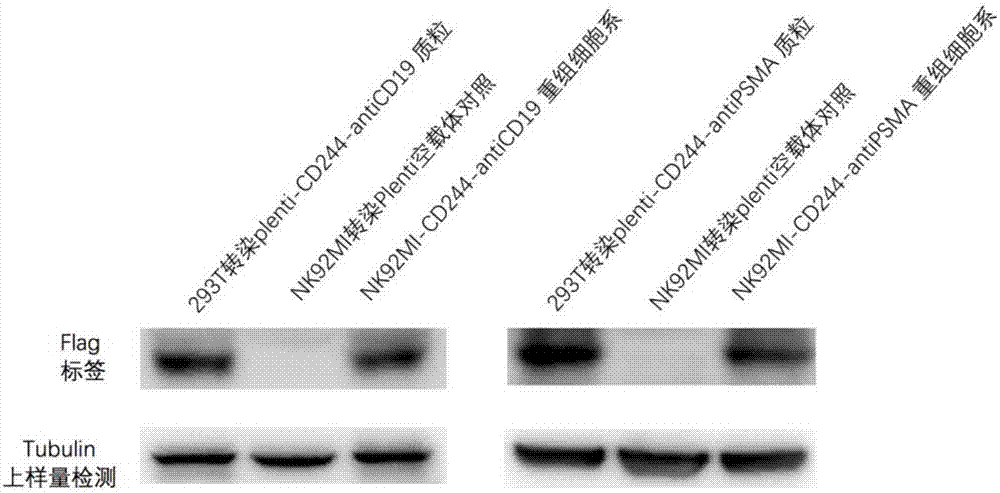

CAR-NK cell as well as preparation method and application thereof

ActiveCN107034237AInduced lysisReduce manufacturing costMammal material medical ingredientsNucleic acid vectorCAR PROTEINLentivirus

The invention relates to a CAR-NK cell as well as a preparation method and an application thereof. The method comprises the following steps: S1, linking a specific antibody coding gene into a cloning site region of a modified CAR skeleton so as to obtain a CAR gene, wherein the modified CAR skeleton comprises a CD244 episporium signal region, the cloning site region, a CD244 extracellular hinge region, a CD244 transmembrane part region and a CD244 intracellular part region which are sequentially connected; and S2, infecting the CAR gene with NK cell through lentivirus, so that the NK cell expressing the CAR protein is obtained, namely the CAR-NK cell. The prepared tumor immnuotherapy cell, namely the CAR-NK cell, of the invention, besides a patient with cancer, is also applicable to allosome infusion; therefore, the prepared tumor immnuotherapy cell, in comparison with existing CAR-T, is wider in application scope and is lower in preparation cost.

Owner:国健亦诺生物科技(北京)有限公司

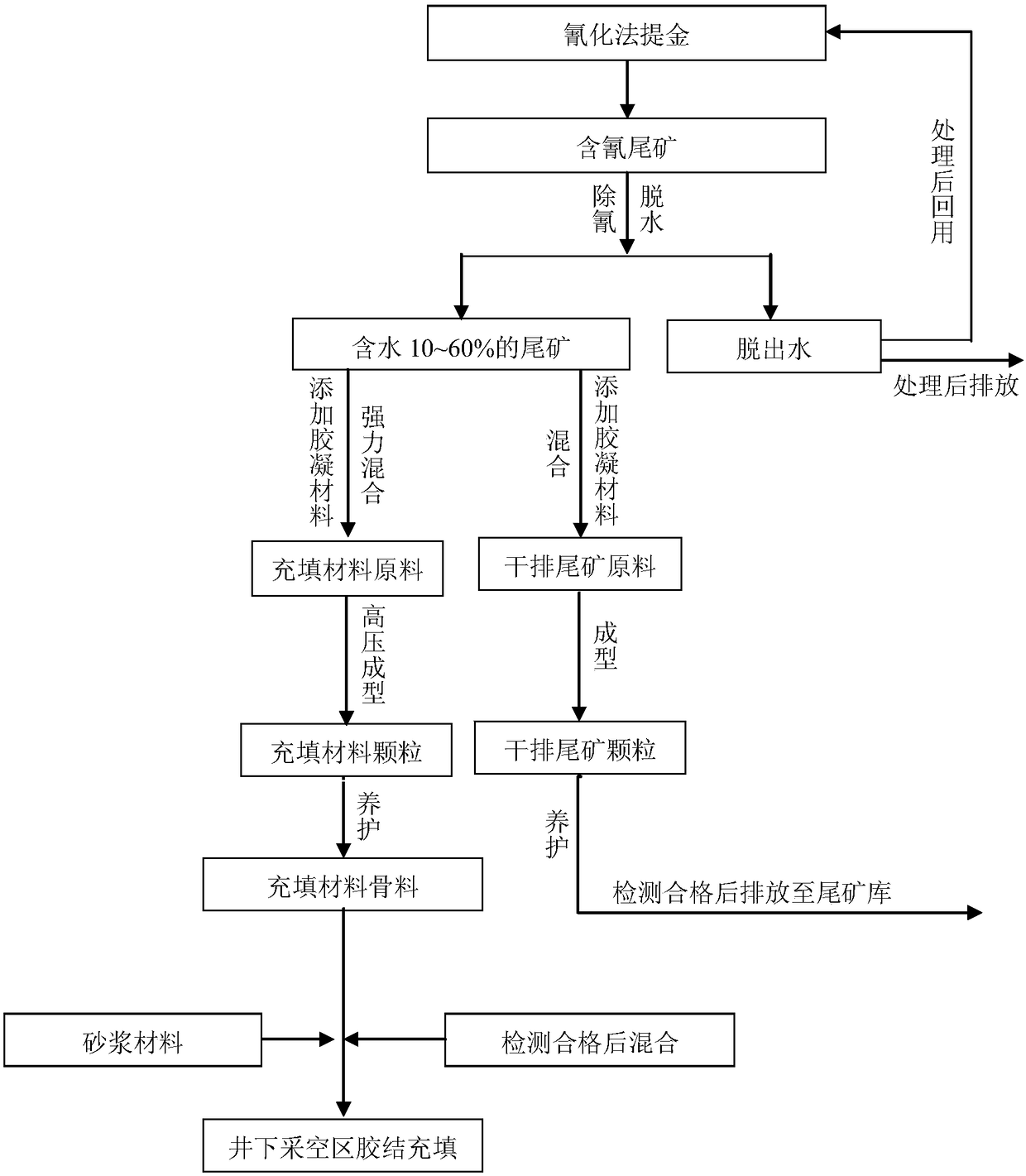

Comprehensive treatment method for cyanogens-containing tailing pulp

ActiveCN108298718AEmission reductionHigh strengthSludge treatmentWater contaminantsFilling materialsUltimate tensile strength

The invention provides a comprehensive treatment method for cyanogens-containing tailing pulp. The method comprises the following steps: performing dehydration cyanogens removal treatment on cyanogens-containing tailing pulp so as to obtain water-containing tailings of corresponding parameter requirements; treating the water-containing tailings in one of the following modes: a mode I: putting a cementing material into the water-containing tailings according to a ratio, uniformly mixing, preparing granules, and maintaining as filling material aggregate, adding a mortar material, uniformly mixing, fully filling pores of the aggregate with the mortar material, forming a flowing entity, filling an under-wall gob area, and forming a filling body of certain strength and good overall properties;a mode II: putting the cementing material or sticky soil into the water-containing tailings according to a ratio, uniformly mixing, pelletizing, curing, conveying to a tailing warehouse, and discharging. The treatment method provided by the invention has the advantages of large-scale application, flexible treatment modes, adjustable and controllable process indexes, safe treatment processing and results, environment protection, and the like, and meanwhile economic requirements can be met.

Owner:LIAONING TECHNICAL UNIVERSITY +1

Combined-blowing converter bottom gas supply element blocking-preventing device and method

ActiveCN1743466AGuaranteed metallurgical effectExtend your lifeManufacturing convertersComputer control systemSlag

This invention blow-stop ventilation device of a bottom blow gas supply element of a multi-blow converter is composed of an air dehydrator, a pneumatic fast cut valve, a pneumatic regulation valve, a gas flowmeter, a pressure tester, a computer control system, a blow-step gas source and gas transportation pipe lines interconnected by the gas transportation pipe lines. Said method takes air as the gas supply element and utilizes 20% oxygen in the air to oxidize the blockage-slag-metal mushroom head continuously to keep it at reasonable state to ensure the life time of the supply element the same with the converter lining.

Owner:CENT IRON & STEEL RES INST

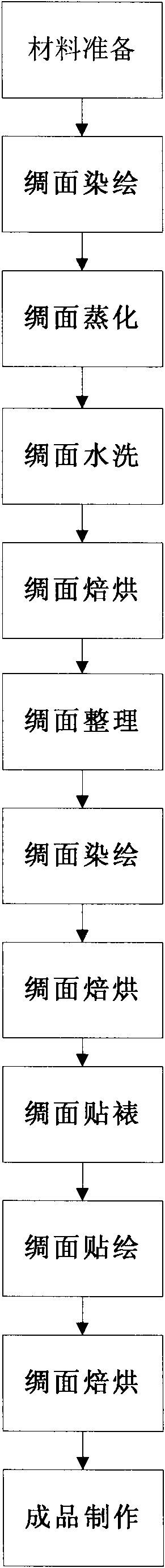

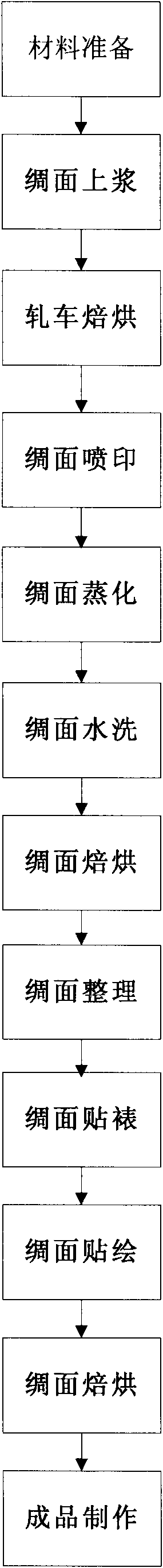

Silk polished lacquer painting and preparation method thereof

InactiveCN102085773AReduce manufacturing costBroad prospects for market development and applicationSpecial artistic techniquesArtistic surface treatmentPolymer scienceLacquer

The invention discloses a silk polished lacquer painting and a preparation method thereof. The silk polished lacquer painting is prepared by the following steps: (1) firstly dyeing, drawing, inlaying, embedding, pasting and etching on a silk surface with polished lacquer painting materials or carrying out digital jet-printing on the silk surface to form an initial product; (2) fixing and drying the initial product on the silk surface and then adjusting a picture; and (3) carrying out lacquering, polishing and refining on the dried initial product to obtain the required silk polished lacquer painting finished product. By preparing the silk polished lacquer painting in the invention, the range of used materials of the polished lacquer painting is expanded, the manufacturing period of the product can be reduced, and the silk polished lacquer preparation and industrialization production in inlaying, embedding, pasting and carving materials are realized.

Owner:SUZHOU UNIV

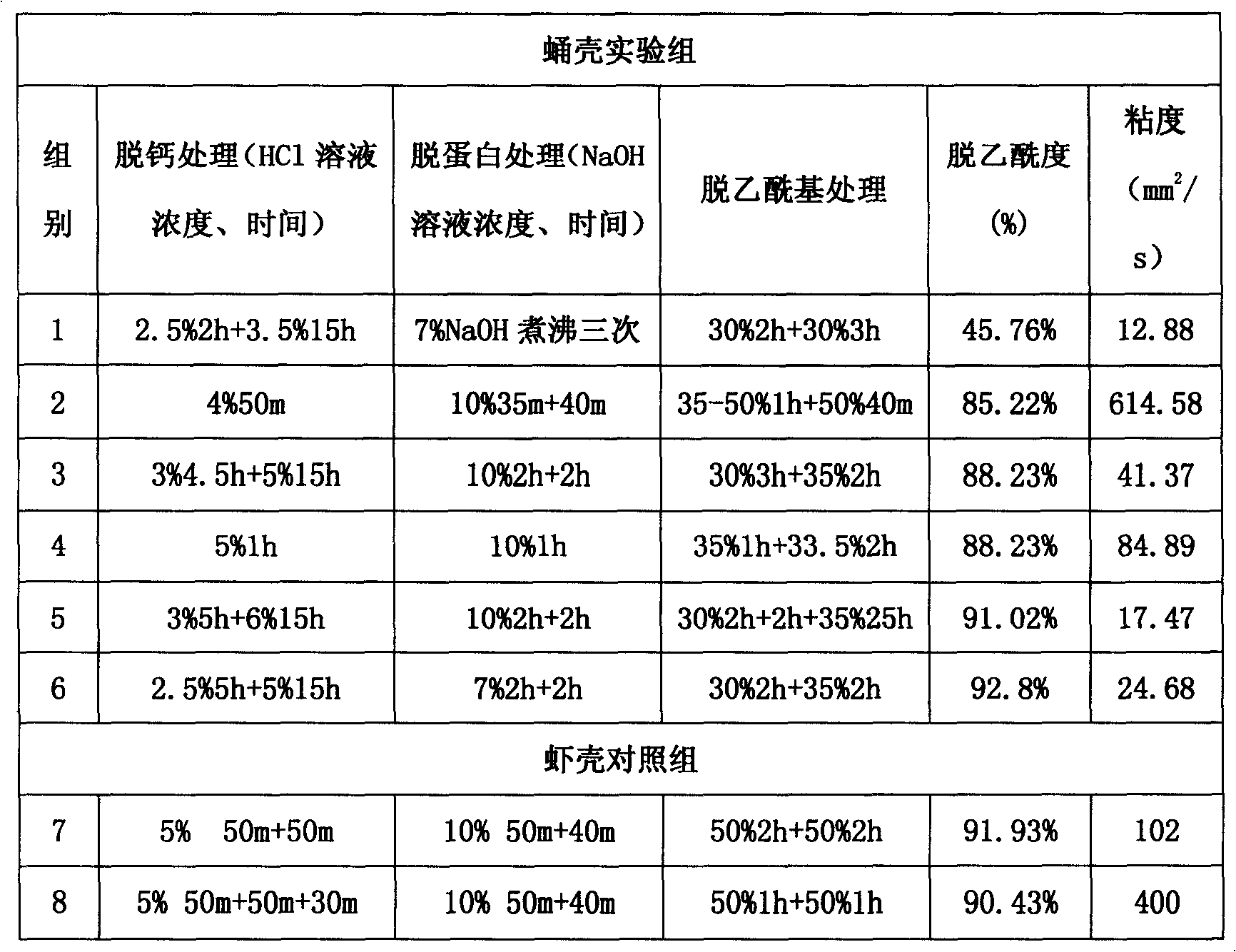

Method for extracting chitosan by employing flies

The invention relates to a method for extracting chitosan using fly, characterized in that the fly puparium is treated by acid alkaline process to obtain raw material. The raw material is subjected to decalcifying, deproteinizing, deacetylating, and then filtering, cleaning to be neutral to obtain the chitosan end product. The method can produce chitosan in enormous quantities using the high breeding property of fly, therefore the production rate of chitosan is increased. A product center combining raw material production and chitosan production together can avoid the inconvenience of raw material collection, therefore the production scale is greatly increased and the cost is reduced. During feeding the fly, the fly can be used for extract of protein feedstuff and antibiotic fly protein.

Owner:THE AFFILIATED HIGH SCHOOL OF SHANGHAI UNIV

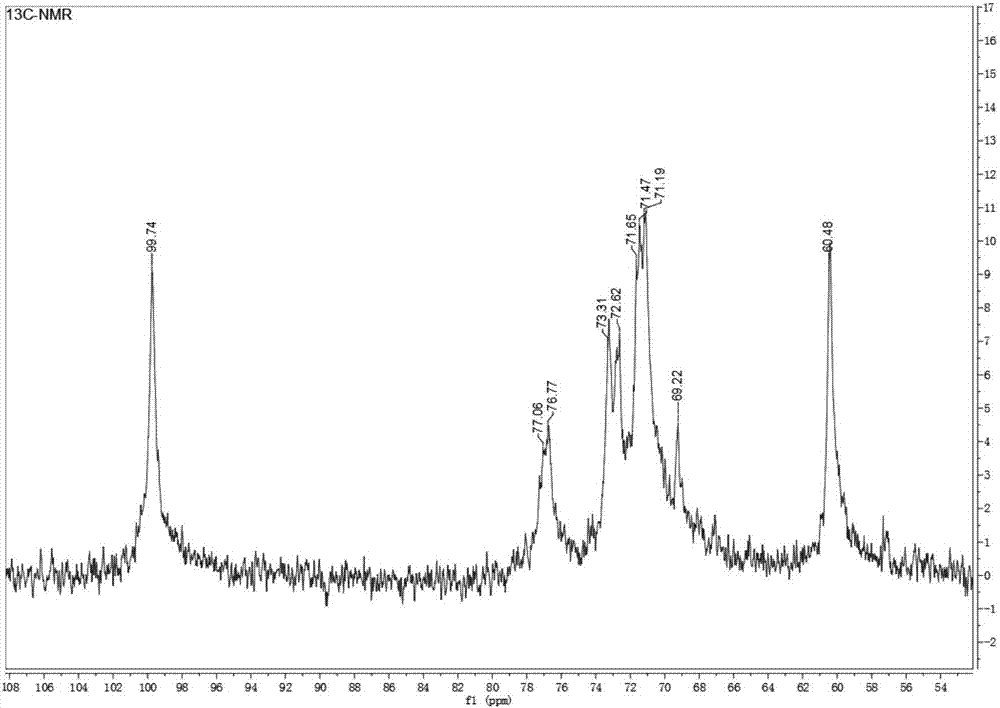

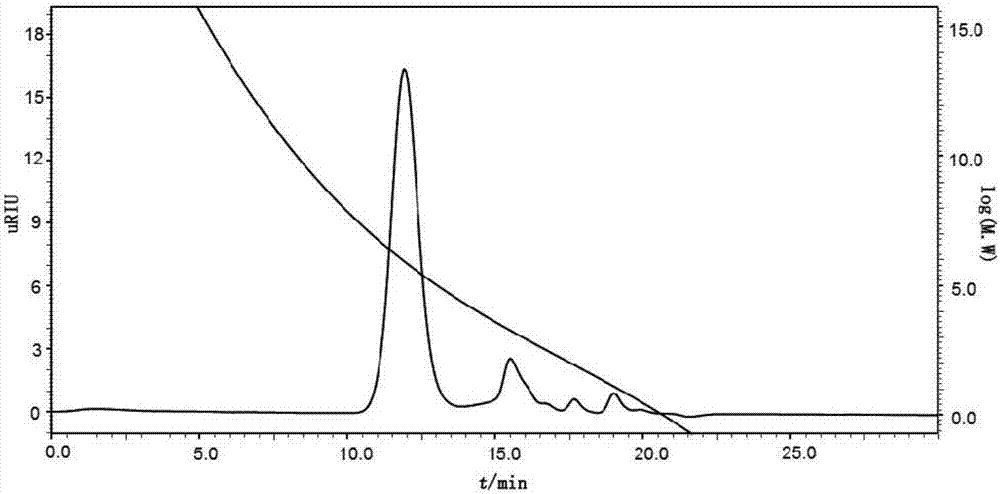

Mytilus edulis polysaccharide, and preparation method and application of mytilus edulis polysaccharide

ActiveCN107056962AResolve source issuesImprove securityMetabolism disorderFood ingredient functionsLow density lipoprotein cholesterolGlucose polymers

The invention provides mytilus edulis polysaccharide extracted from mytilus sp., an industrial extraction method of the mytilus edulis polysaccharide, and an application of the mytilus edulis polysaccharide in preparation of antilipemic and antiatherosclerotic drugs and health food. The mytilus edulis polysaccharide takes (1-4)-alpha-D-Glc as main chains, contains (1-2)-alpha-D-Glc branches, and has a configuration of alpha-pyranoid glucan; every 12 glucose main chains averagely contain one (1-2) glucose branch; and the relative molecular weight is 800-8000KDa. The mytilus edulis polysaccharide is extracted from boiled and dried mytilus sp. by coarse extraction, enzymolysis, purification, drying and the like, and is mild in extraction condition and high in purity. The mytilus edulis polysaccharide can significantly reduce triglyceride, total cholesterol and low-density lipoprotein cholesterol, has an effect of reducing lipid, and is widely applied to preparation of drugs for treating or preventing hyperlipoidemia and atherosclerosis and preparation of antilipemic health products or special medical formula food.

Owner:SHANDONG ACADEMY OF PHARMACEUTICAL SCIENCES +1

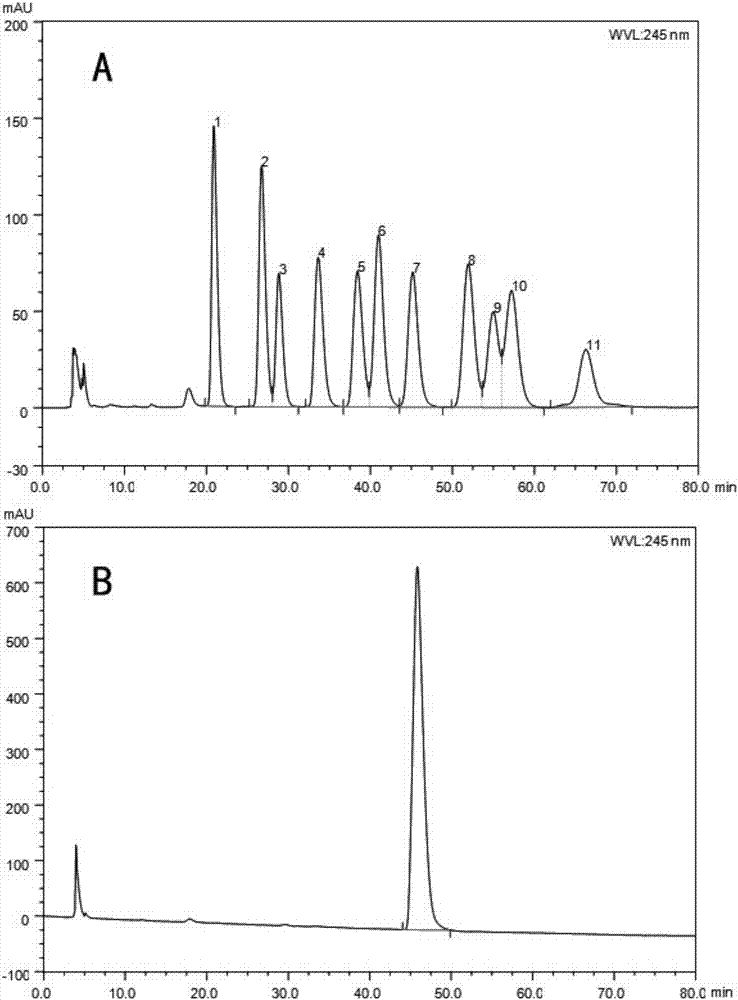

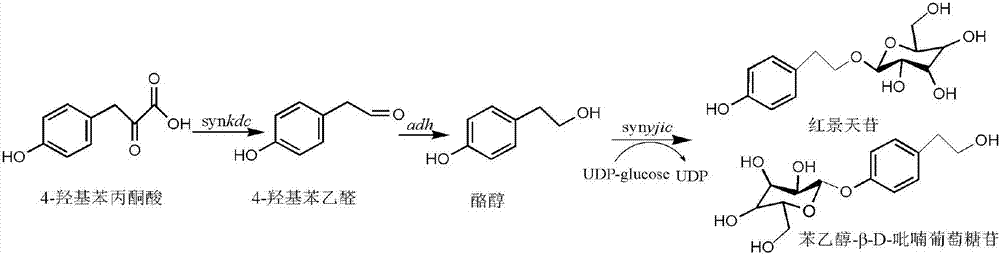

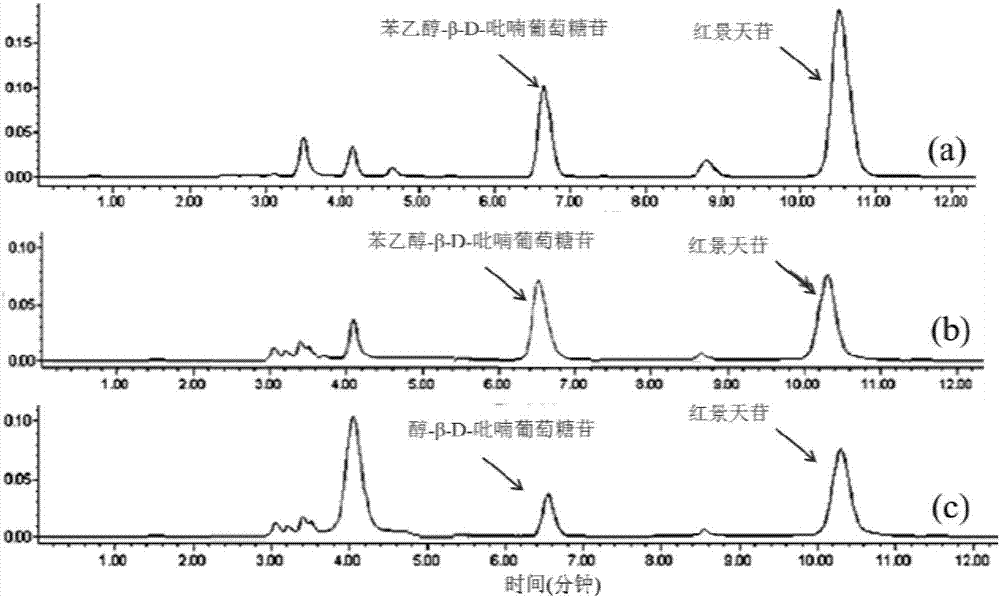

Recombinant bacteria for producing salidroside and analogue thereof, and construction method and use

InactiveCN107460203AResolve source issuesReduce manufacturing costBacteriaMicroorganism based processesSalidrosideMicrobiology

The invention discloses recombinant bacteria for producing salidroside and analogue thereof, and a construction method and use. The construction method comprises the steps of synthesizing keto-decarboxylase gene synkdc and glycosyl transferase gene synyjic, and connecting to a vector pRSFDuet-1 to construct a recombinant vector pSynkdc1-yjic; enabling T7RNA polymerase gene to be free or integrated to SyBE-002447 base bacterial strain, and introducing pSynkdc1-yjic to obtain SyBE-218011 and SyBE-218013 bacterial stains; and directly integrating synkdc and synyjic to SyBE-002447 chromosome, and removing feaB and ushA in a knockout manner to obtain a SyBE-218015 bacterial strain. The bacterial strain disclosed in the invention can be used for producing salidroside and analogue thereof through fermentation, so that the problem existing in source of the salidroside and analogue thereof can be solved, and cost can be lowered.

Owner:TIANJIN UNIV

Electronic lock system with electronic lock being supplied electric energy and key information by mobile

InactiveCN103114771AEasy to useImprove confidentialityElectromagnetic wave systemTransmission systemsWireless transmissionMobile phone

The invention provides an electronic lock system with an electronic lock (2) being supplied electric energy and key information by a mobile (1). A battery (2) which is arranged in the mobile phone (1) is utilized to supply the electric energy to a wired or wireless electronic lock (2). A keyboard of the mobile phone (1), a touch screen of the mobile phone (1) or equipment which stores the key information of the mobile phone (1) are utilized to supply the key information to the electronic lock (2). The equipment of the mobile phone (1) generates or stores the key information and transmits the key information to the electronic lock (2) through a mode of wired contact or wireless transmission. Therefore, the same mobile phone (1) not only can solve the problem of electric energy supply to the electronic lock (2), but also supply the key information of unlocking to the electronic lock (2), roles of the mobile phone are further played, and the electronic lock is enabled to be further utilized conveniently. The electronic lock system with the electronic lock being supplied the electric energy and the key information by the mobile is beneficial to popularization of the electronic lock, and provides a great convenience for life of people.

Owner:孙勃

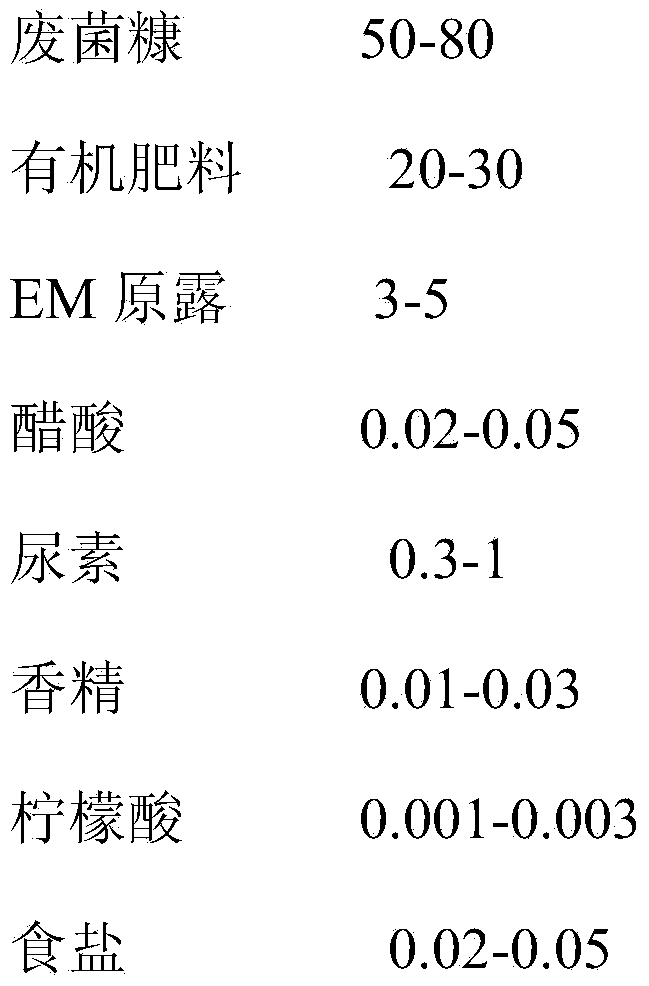

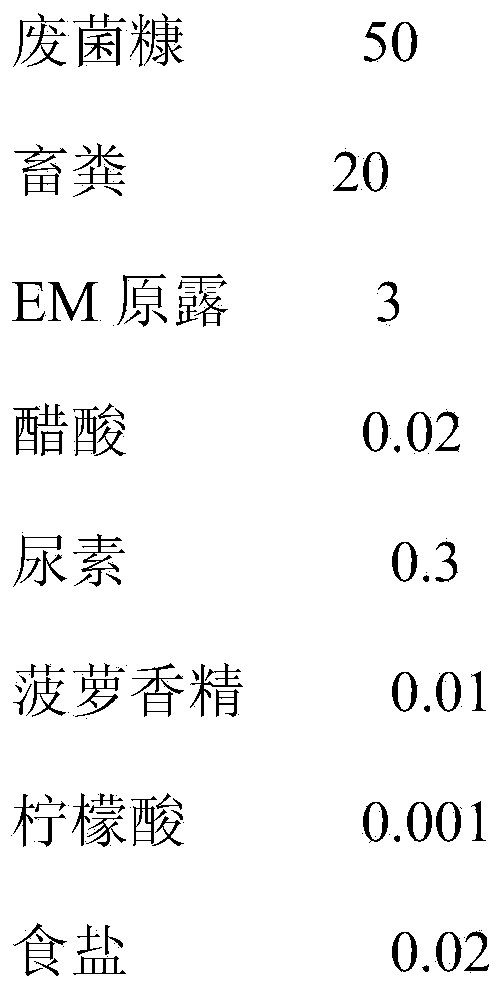

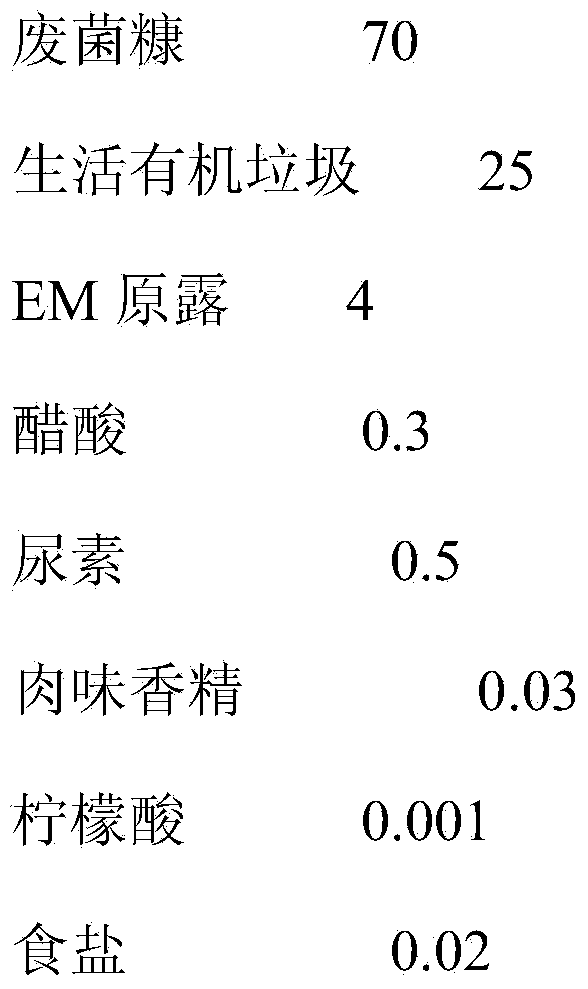

Earthworm feed and preparation method thereof

InactiveCN103859229ASolve processing problemsIncrease growth rateFood processingAnimal feeding stuffAcetic acidEffective microorganism

The invention discloses an earthworm feed and a preparation method thereof. The earthworm feed comprises the following components in parts by weight: 50-80 parts of waste mushroom bran, 20-30 parts of organic fertilizer, 3-5 parts of EM (Effective Microorganisms), 0.02-0.05 part of acetic acid, 0.3-1 part of urea, 0.01-0.03 part of essence, 0.001-0.003 part of citric acid and 0.02-0.05 part of table salt. The materials are fermented to prepare the earthworm feed. The waste mushroom bran and the organic fertilizer are used as materials to prepare the earthworm feed, the source problem of animal protein is solved, as the waste mushroom bran and the organic fertilizer are cheap and easily available, and the treatment problem of the waste mushroom bran and the organic fertilizer is solved. Meanwhile, as the acetic acid and the essence are added into the earthworm feed, earthworms like staying in the feed, and the growth speed and yield of earthworms are greatly increased.

Owner:安徽利海新城镇开发有限公司

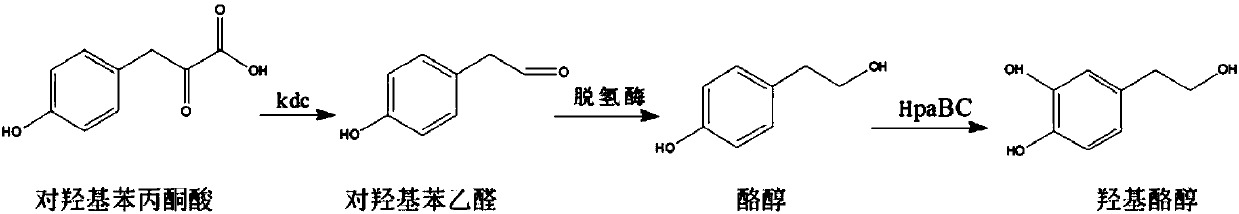

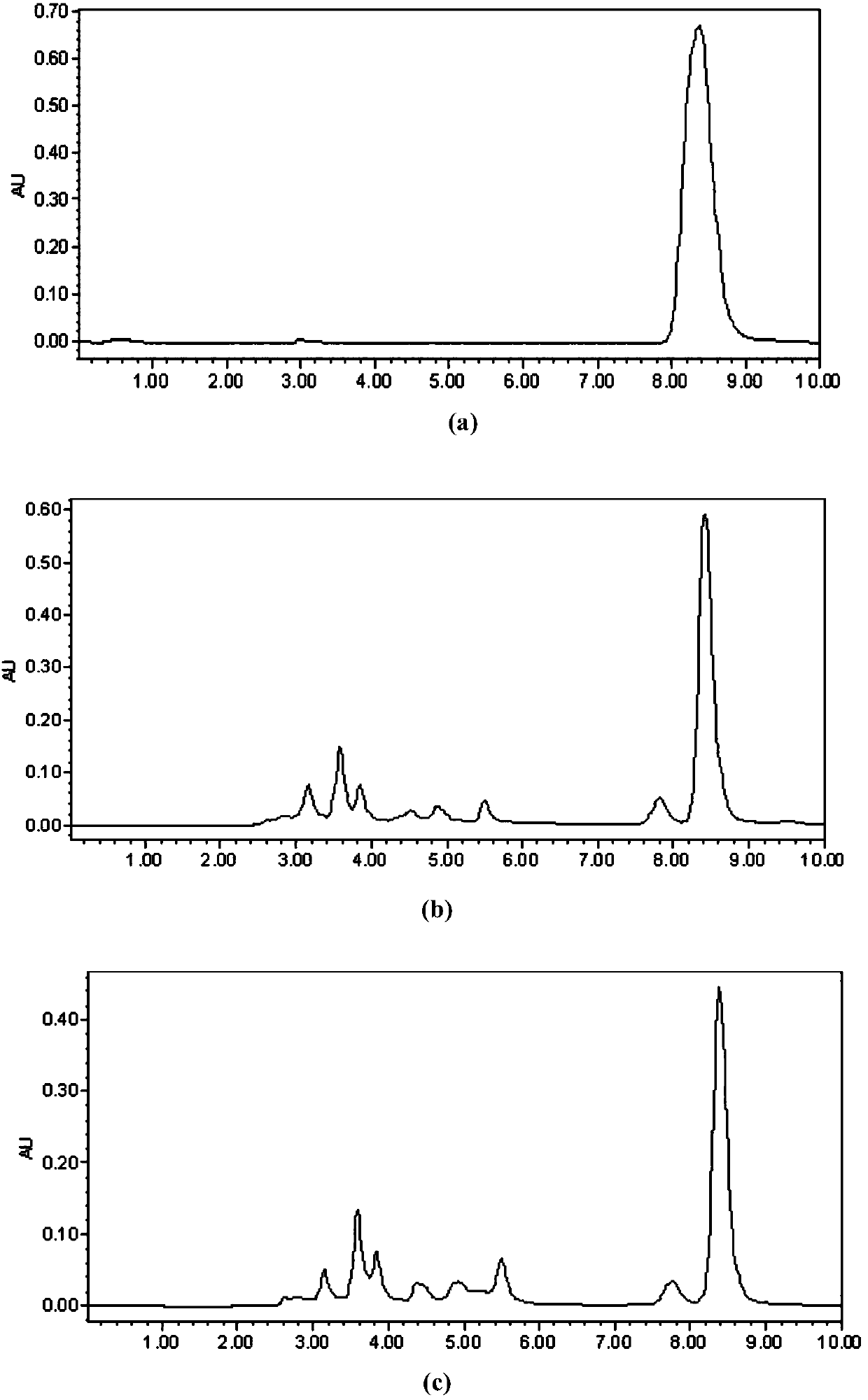

Method for biological production of hydroxytyrosol

InactiveCN107723306AResolve source issuesReduce manufacturing costBacteriaMicroorganism based processesEscherichia coliChemical synthesis

The invention discloses a method for biological production of hydroxytyrosol. The method comprises the following steps: performing complete chemical synthesis of a ketone group decarboxylase gene kdcwith a trc promoter and a 4-hydroxyphenylacetic acid-3-monooxygenase gene hpaBC with a tac promoter, performing complete chemical synthesis of a carrier skeleton pBPE004, connecting the kdc and the hpaBC onto pBPE004 to obtain a recombinant vector pKB by using an enzyme digestion connection method, shifting the pKB into a base tray strain SyBE-002447 to obtain a SyBE-KB1 strain; integrating the kdc gene and the hpaBC gene onto a SyBE-002447 chromosome to obtain an SyBE-KB2 strain. Glucose is used as a precursor, and the SyBE-KB1 and SyBE-KB2 strains are fermented to produce the hydroxytyrosol.According to the method, engineering escherichia coli is used for producing the hydroxytyrosol, the source problem of the hydroxytyrosol can be solved, and the cost can be reduced.

Owner:TIANJIN UNIV

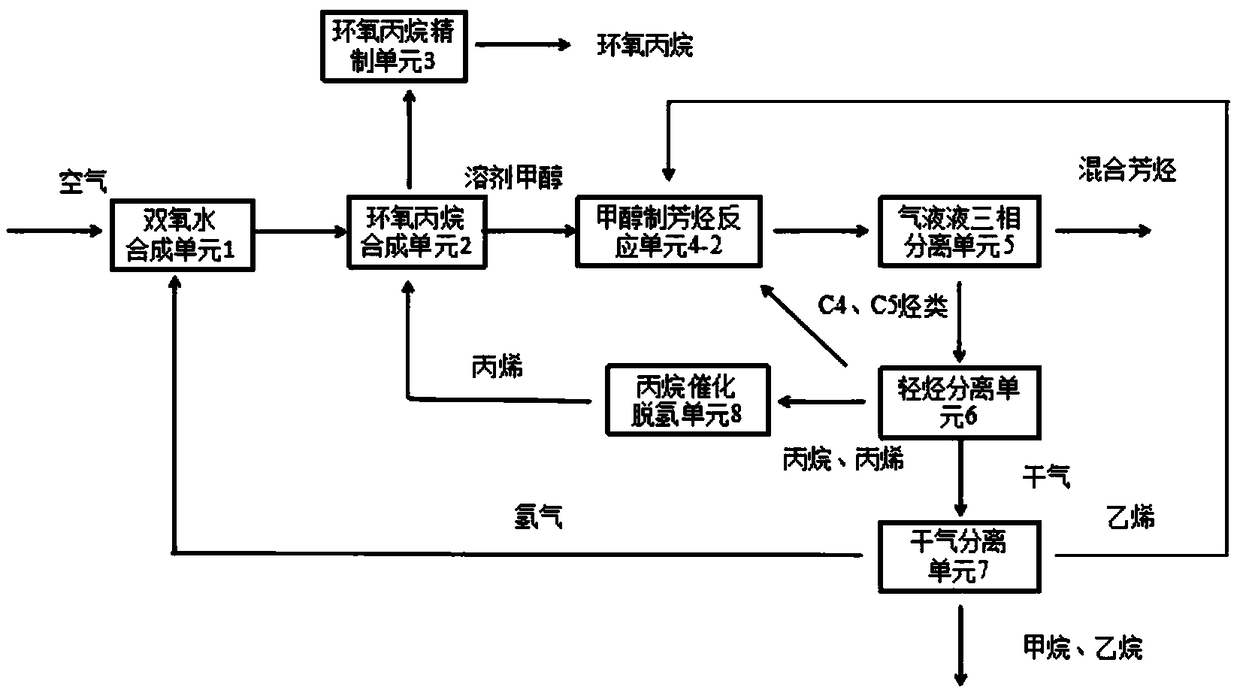

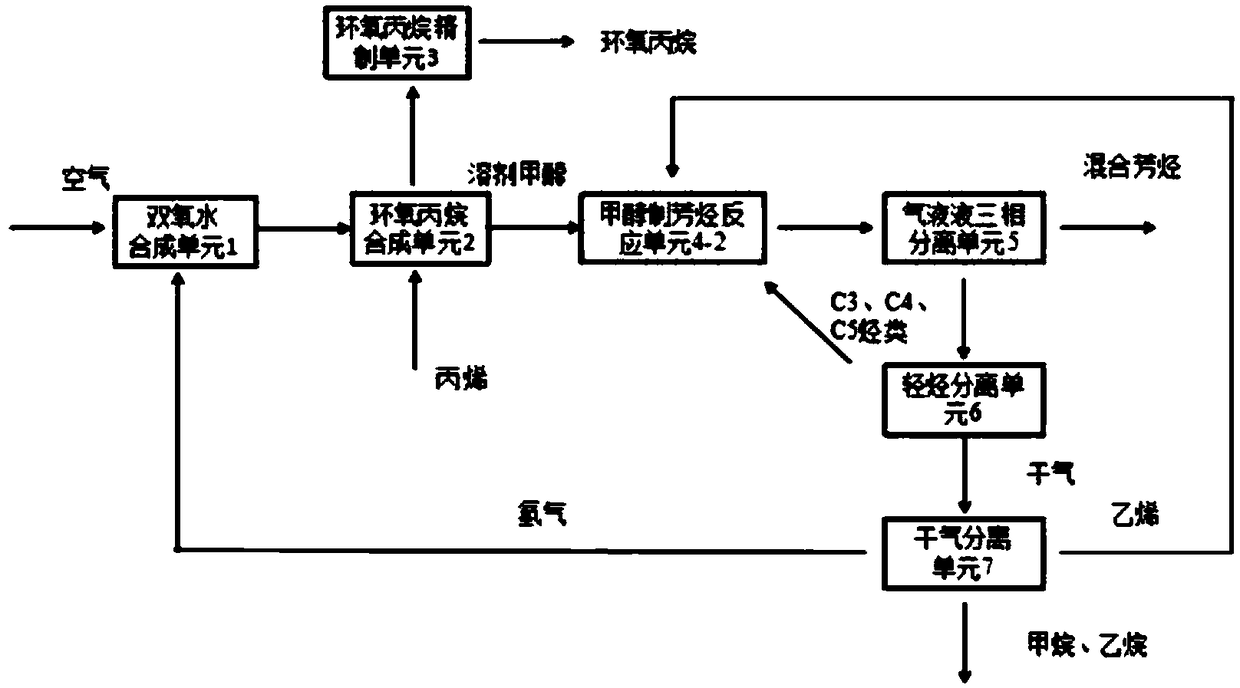

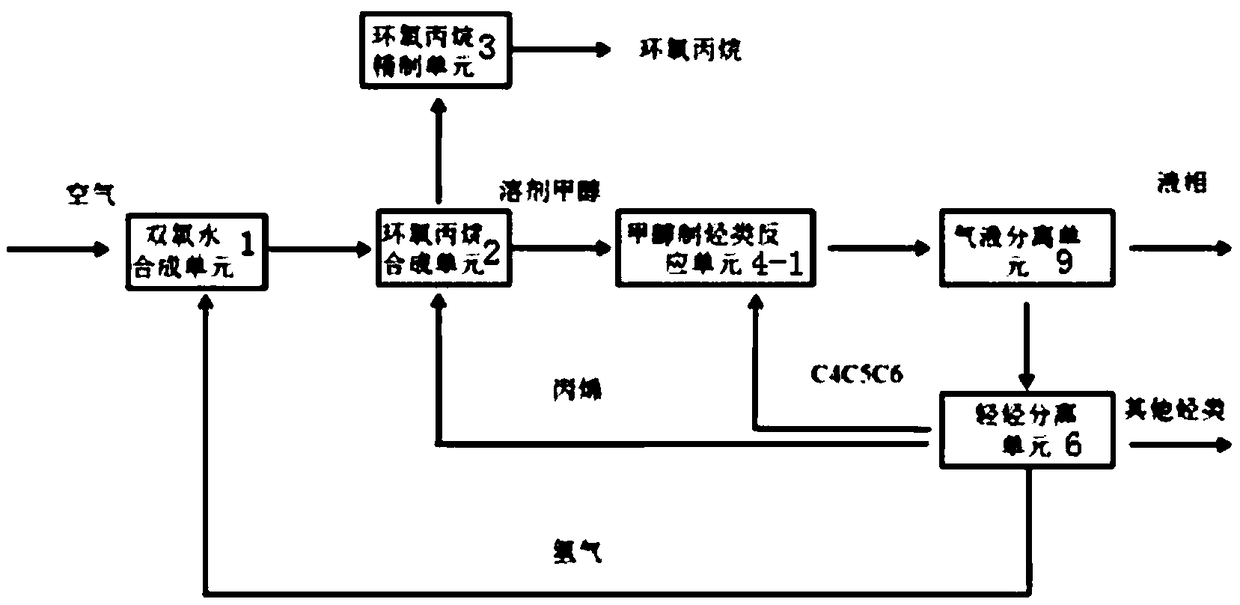

System and method of coproduction of propylene oxide and arene

ActiveCN108997263ASolve the problem of recovering energy consumptionReduce consumptionHydrocarbon from oxygen organic compoundsHydrogenSolvent

The invention relates to a system and method of coproduction of propylene oxide and arene. A solvent namely methanol in the production course of the propylene oxide is used for the course of preparinghydrocarbon with the methanol, and besides, byproducts of hydrogen gas and propylene in the course of preparing the hydrocarbon with the methanol are used for preparing a hydrogen peroxide solution,so that the source problem of the hydrogen peroxide solution is solved; and a product byproduct namely the propylene is used as the raw material of the propylene oxide, so that the production technology and the energy consumption of the propylene oxide are reduced. Through the adoption of the system and method disclosed by the invention, steam consumption of production of the propylene oxide is substantially reduced, and the reduction of the steam consumption quantity reaches 50% or above.

Owner:HUADIAN COAL IND GRP +1

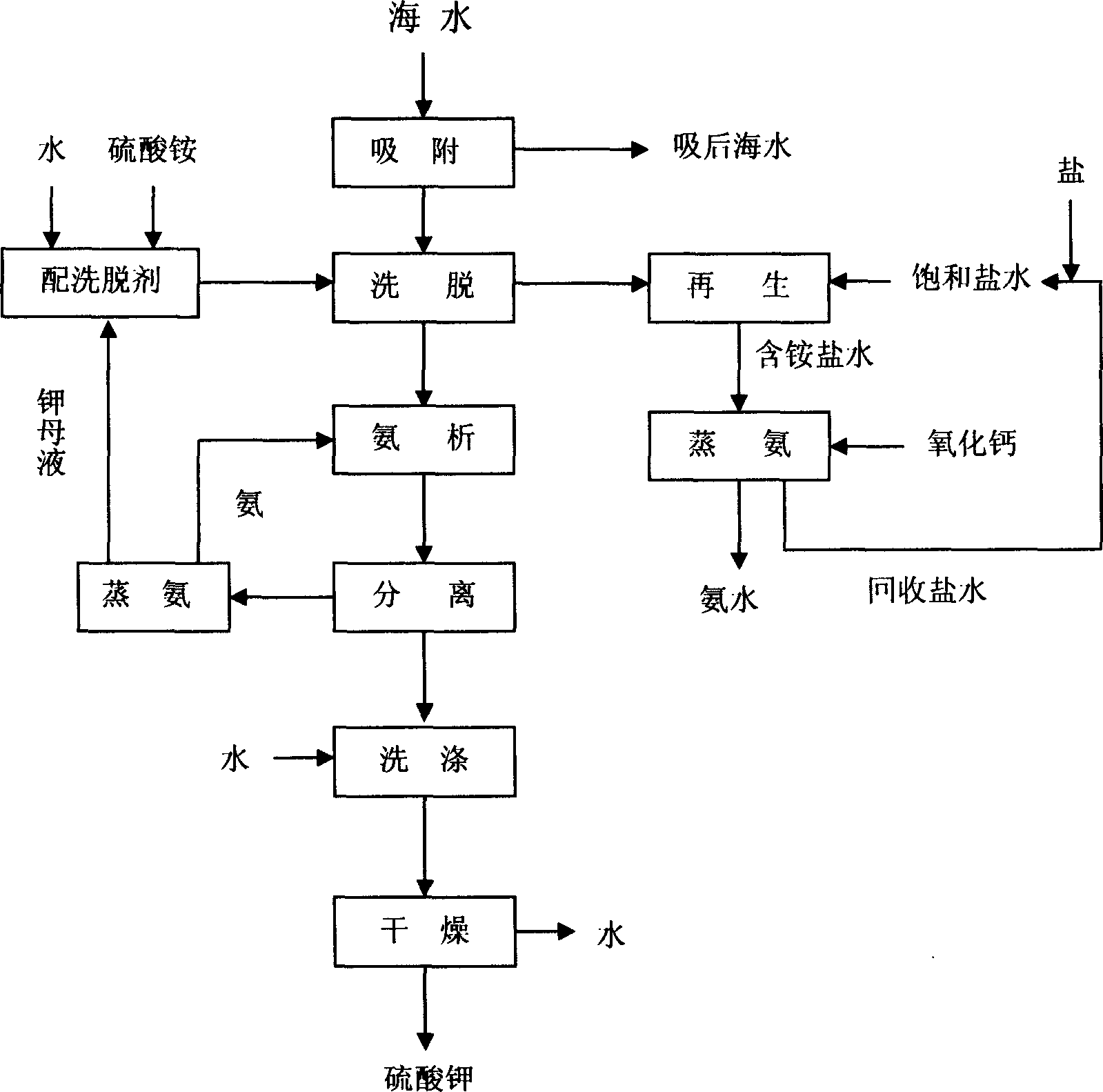

Process for preparing potassium sulfate by sea water

InactiveCN1792797AQuality improvementResolve source issuesAlkali metal sulfites/sulfatesIon exchangeAmmonium sulfate

A process for preparing potassium sulfate from seawater includes preparing the K-enriched liquid, in which the ammonium sulfate solution is used to elute out the K ions adsorbed by the clinoptilolite in ion exchange column, and preparing potassium sulfate, in which the ammonia is filled in said K-enriched liquid for educing out potassium sulfate. It features no pollution to environment.

Owner:HEBEI UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com