Ice preventing and removing system for aircraft wing

A wing and anti-icing technology, which is applied in the field of anti-icing system of aircraft wings, can solve the problem of consuming aircraft air source or electric energy, etc., and achieve the effect of simple structure and remarkable anti-icing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

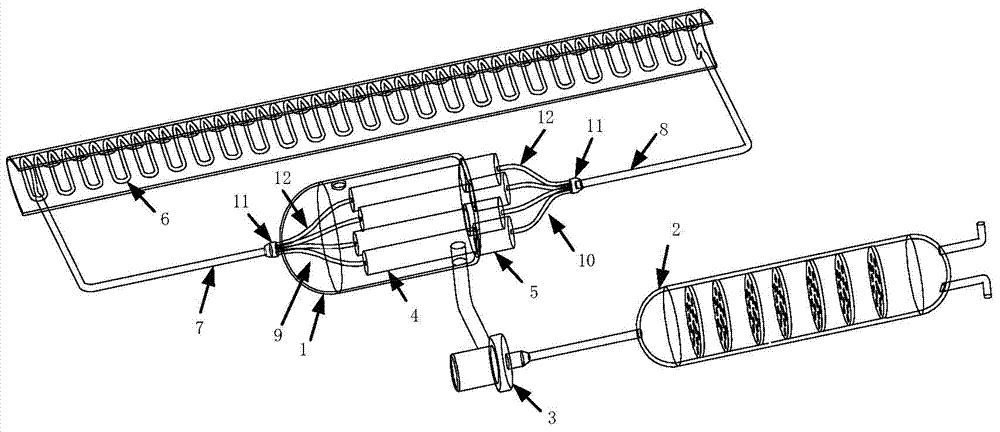

[0021] The anti-icing system of the present invention includes a heat source housing 1, an exhaust gas treatment device 2, an air pump 3, an evaporator 4, a liquid reservoir 5, a condenser 6, a steam line 7 and a liquid line 8, such as figure 1 shown.

[0022] Wherein, the heat source housing 1 adopts a cylindrical structure and is wrapped with heat-insulating material, which can reduce the heat dissipation of high-temperature gas to the outside and improve the utilization rate of heat. Let the two end faces of the heat source housing 1 be the end face A and the end face B respectively; resistance received. A waste gas inlet and a waste gas outlet are respectively opened on the side walls of the heat source housing 1 near the end surface A and the end surface B; and the waste gas inlet and the waste gas outlet are located on opposite sides of the heat source housing. The exhaust gas inlet is used to introduce engine exhaust gas; the engine exhaust gas is discharged into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com