Method for biological production of hydroxytyrosol

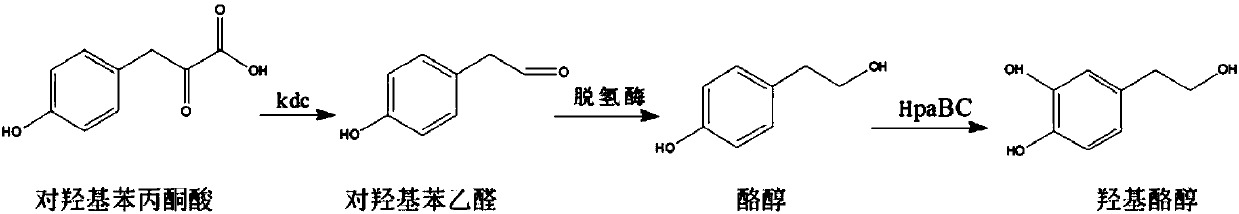

A technology for producing hydroxytyrosol and hydroxytyrosol, applied in the field of biomedicine, can solve the problems of unsuitability for industrial production, toxic chemical reagents, low yield and the like, and achieves the effects of reducing production costs, solving source problems, and being beneficial to industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 Design of keto-decarboxylase gene kdc and 4-hydroxyphenylacetic acid-3-monooxygenase gene hpaBC

[0034] Preferred Pichia pastoris GS115 keto decarboxylase gene, use JCAT online codon optimization software (http: / / www.jcat.de) in conjunction with OPTIMIZER online codon optimization tool (http: / / genomes.urv.es / OPTIMIZER / ) , optimize the codon preference of Escherichia coli, design the full-length kdc gene, and add the trc promoter before the gene.

[0035] Keto decarboxylase gene kdc with trc promoter, its nucleotide sequence is shown in SEQ ID No.1.

[0036] The 4-hydroxyphenylacetic acid-3-monooxygenase gene of preferred Escherichia coli uses JCAT online codon optimization software (http: / / www.jcat.de) in conjunction with OPTIMIZER online codon optimization tool (http: / / genomes.de). urv.es / OPTIMIZER / ), optimize the codon preference of Escherichia coli, design the full-length hpaBC gene, and add the tac promoter in front of the gene.

[0037] The nucleotide ...

Embodiment 2

[0038] Embodiment 2 Construction of recombinant expression vector pKB

[0039] The expression vector backbone pBPE004 was fully chemically synthesized, and its nucleotide sequence is shown in SEQ ID No.3.

[0040] The nucleotide sequence shown in SEQ ID No.1 and the nucleotide sequence shown in SEQ ID No.2 were connected to the nucleotide sequence shown in SEQ ID No.3 by enzyme-cut ligation, and positive clones were screened to obtain the recombinant vector pKB ;

[0041]The nucleotides shown in SEQ ID No.1 obtained by chemical total synthesis are respectively added with EcoRI and HindIII restriction sites at both ends of the fragment by PCR method, and FastDigest endonucleases EcoRI and HindIII are used for digestion. The reaction system It is: 5 μL 10*FD buffer, 2.5 μL EcoRI, 2.5 μL PstI, 30 μL nucleotides shown in SEQ ID No.1 with enzyme cutting sites and 10 μL ultrapure water. The reaction conditions are: 37°C, 2h. Using a PCR purification kit, add 250 μL of Bingding Bu...

Embodiment 3

[0043] Embodiment 3 Recombinant expression vector pKB is transformed into Escherichia coli chassis strain SyBE-002447

[0044] The detailed construction steps of recombinant vector pKB transformed into Escherichia coli SyBE-002447 are as follows:

[0045] 1. Inoculate 100 μL of activated Escherichia coli strain SyBE-002447 in 10 ml of LB medium, cultivate to OD at 37°C, 220 rpm 600 When the temperature is 0.8-1.0, transfer to a 10ml centrifuge tube, centrifuge at 4500rpm / min for 5min in a pre-cooled 4°C centrifuge, remove the supernatant, and collect the bacteria;

[0046] 2. Wash the cells with 5ml of pre-cooled sterilized 10% glycerin, centrifuge at 4500 rpm / min for 5 min in a pre-cooled 4°C centrifuge, remove the supernatant, collect the cells, and repeat washing three times;

[0047] 3. Pour off the supernatant as much as possible, add 100 μL of 10% glycerol to resuspend the bacteria, and make SyBE-002447 competent cells;

[0048] 4. Add 2.5 μL of the pKB plasmid constru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com