Preparation method of hydrogenation catalyst and slurry bed hydrogenation technology using the catalyst

A hydrogenation catalyst and slurry bed technology, which is applied in the preparation of hydrogenation catalyst and slurry bed hydrogenation process, can solve the problems of poor catalytic performance and easy coking in the reactor, and achieve the advantages of reducing operation difficulty and significantly resisting coking. , the effect of improving the efficiency of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

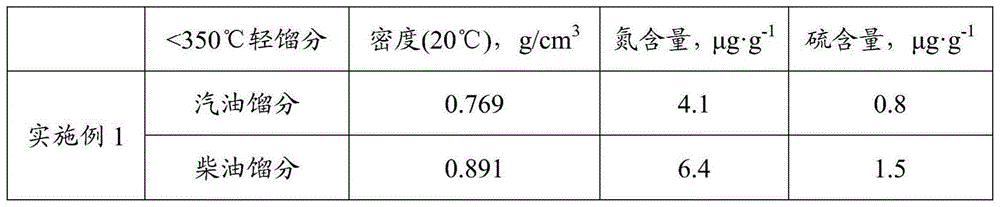

Embodiment 1

[0035] The preparation method of hydrogenation catalyst described in the present embodiment, comprises the steps:

[0036] (1) Iron oxyhydroxide desulfurizer is used as a desulfurizer in the petroleum refining process, at a temperature of 400-450°C, a pressure of 6.0MPa, and a gaseous space velocity of 1000-1200h -1 Desulfurization treatment is carried out under certain conditions, the desulfurization waste agent after desulfurization is collected, and the desulfurization waste agent with a mass ratio of 1:3 is mixed with 80°C low-temperature coal tar to form a mixture; wherein, the iron oxyhydroxide desulfurization agent is The iron content is 63wt%;

[0037] (2) Under the rotating speed of 15000r / min, the mixture of step (1) is subjected to beating treatment until the particle diameter of the solid particles in the mixture is less than 1 μm to obtain the hydrogenation catalyst slurry, which is designated as catalyst 1#.

[0038] The slurry bed hydrogenation process utilizin...

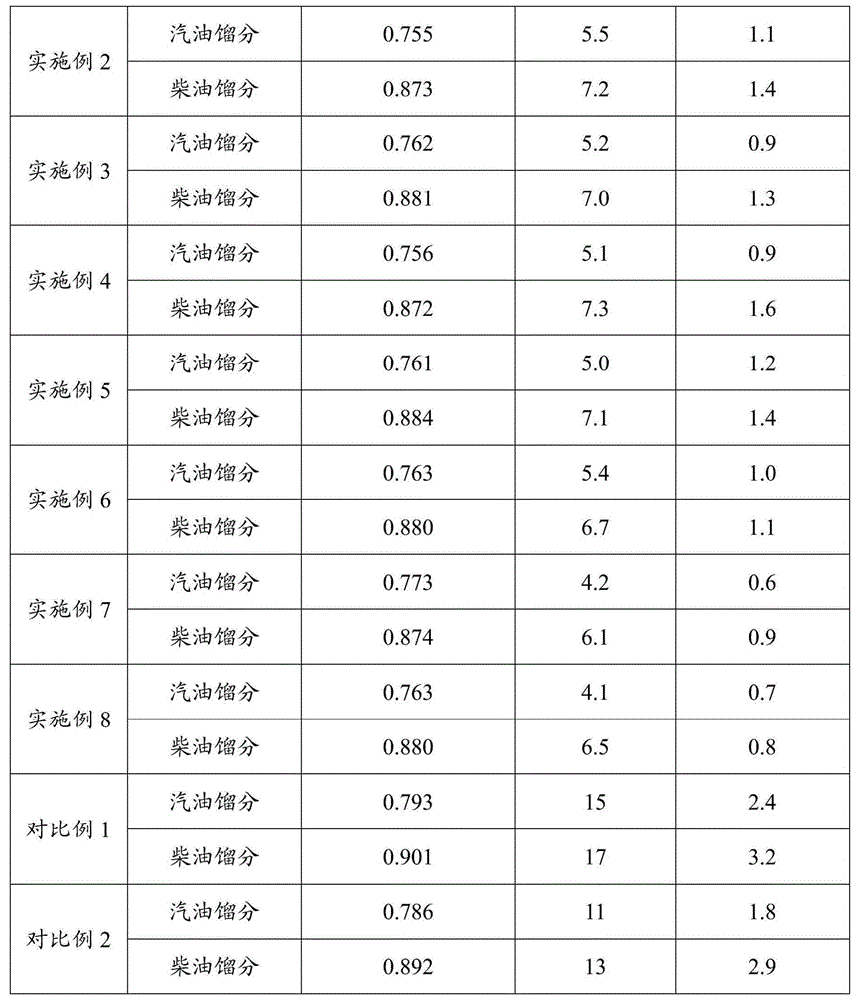

Embodiment 2

[0044] The preparation method of hydrogenation catalyst described in the present embodiment, comprises the steps:

[0045] (1) Iron oxyhydroxide desulfurizer is used as the desulfurizer in the gasoline hydrodesulfurization project, at a temperature of 280°C, a pressure of 1MPa, and a volume ratio of hydrogen to oil of 70Nm 3 Carry out desulfurization treatment under the condition of / kL, collect the desulfurized waste agent after desulfurization, and mix the desulfurized waste agent with a mass ratio of 1:1 and 120°C coal tar pitch to form a mixture; wherein, the iron oxyhydroxide desulfurizer The iron content in is 40wt%;

[0046] (2) Under the rotating speed of 10000r / min, the mixture of step (1) is subjected to beating treatment until the particle size of the solid particles in the mixture is less than 1 μm to obtain the hydrogenation catalyst slurry, which is designated as catalyst 2#.

[0047] Utilize the slurry bed hydrogenation process that catalyst 2# is carried out, ...

Embodiment 3

[0053] The preparation method of hydrogenation catalyst described in the present embodiment, comprises the steps:

[0054] (1) Iron oxyhydroxide desulfurizer is used as the desulfurizer in the kerosene hydrodesulfurization project, at a temperature of 400°C, a pressure of 15MPa, and a hydrogen-oil volume ratio of 700Nm 3 Carry out desulfurization treatment under the condition of 1 / kL, collect the desulfurized waste agent after desulfurization, and mix the desulfurized waste agent with a mass ratio of 1:2 and 150°C residue oil evenly to form a mixture; wherein, the iron oxyhydroxide desulfurizer The iron content in is 52wt%;

[0055] (2) Under the rotating speed of 20000r / min, the mixture of step (1) is subjected to beating treatment until the particle size of the solid particles in the mixture is less than 1 μm to obtain the hydrogenation catalyst slurry, which is designated as catalyst 3#.

[0056] Utilize the slurry bed hydrogenation process that catalyst 3# is carried out,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com