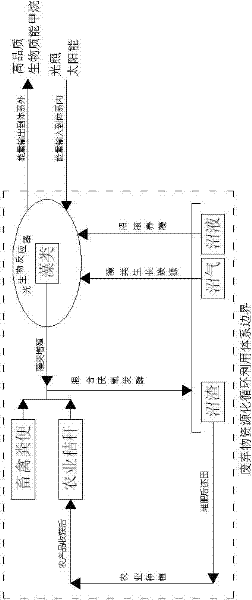

Method for biologically purifying marsh gas and recycling waste of marsh gas

A waste and recycling technology, applied in the direction of biochemical equipment and methods, methods based on microorganisms, fertilizers made from biological waste, etc., can solve problems such as being in the blank, and achieve the effects of cost saving, good economy and growth promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

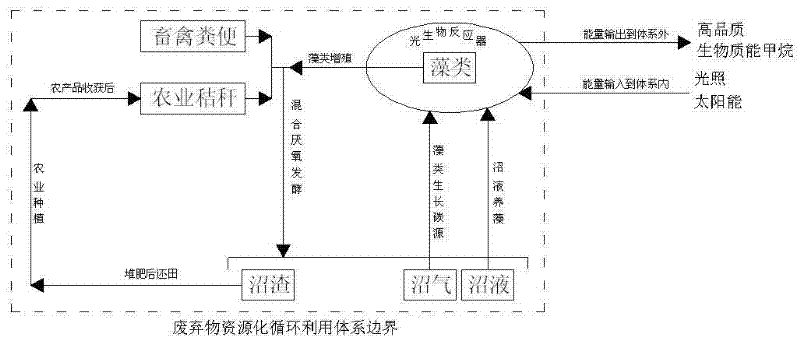

[0027] The present invention is described in detail below by embodiment:

[0028] The photobioreactor in this example adopts a multi-stage serial plate type, and the culture medium is chlorella purchased from the Institute of Hydrophytic Botany, Chinese Academy of Sciences (Wuhan), and BG11 medium is used for expansion. The biogas and biogas slurry produced by mixed anaerobic fermentation were used as the carbon source and culture fluid of Chlorella, respectively. The specific steps are:

[0029] 1. Mixed anaerobic fermentation

[0030] After the straw is crushed, it is mixed with livestock and poultry manure, and inoculated from well-fermented biogas according to the mass ratio of 5:1.

[0031]The anaerobic activated sludge obtained in the air tank is finally added with water to adjust the solid concentration TS to 30%, and the temperature of the fermenter is maintained at 35°C.

[0032] 2. Biogas slurry to grow algae

[0033] The biogas slurry produced by anaerobic ferme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com