Combined-blowing converter bottom gas supply element blocking-preventing device and method

A gas supply element and converter bottom blowing technology, which is applied in the field of iron and steel metallurgy, can solve the problems of poor operability of the oxygen blowing and plugging system, difficulty in mastering the operating process, and missing the best time for blowing and plugging, so as to reduce the design difficulty and Project cost, prolong life, remarkable effect of economic benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

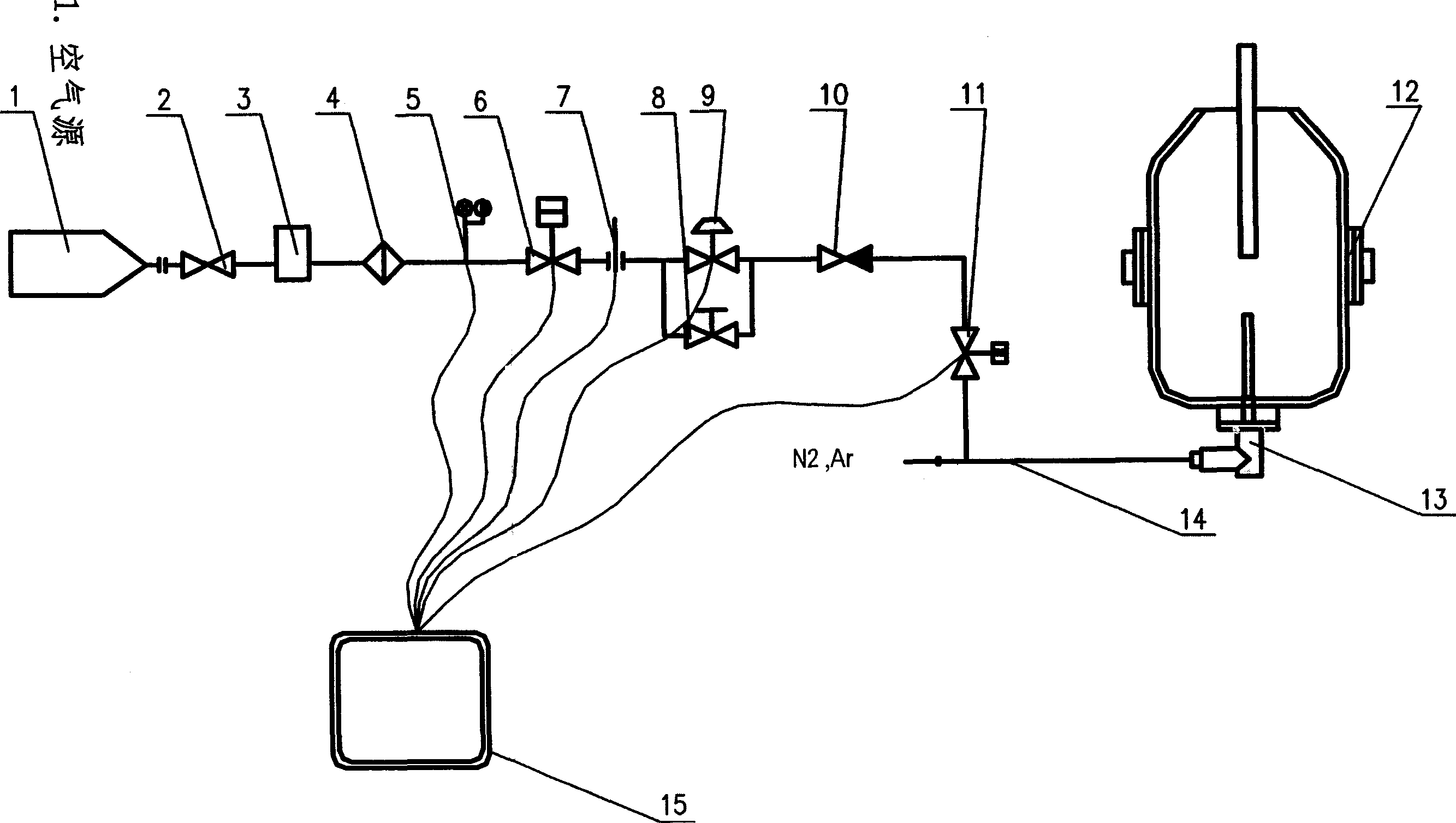

Method used

Image

Examples

Embodiment

[0027] By adopting the device and method for blowing, plugging and re-opening of the bottom-blowing air supply element of the complex-blowing converter of the present invention, the application of blowing, blocking and re-opening of the bottom-blowing gas supply element has been carried out on three complex-blowing converters. Usually, the bottoms of large and medium-sized complex-blowing converters are equipped with 4 Up to 8 ring-slit bottom-blowing gas supply components, one of the 3 compound-blown converters tested has been blocked successively. Although it is not completely blocked, the gas supply flow rate has been greatly reduced, which has affected the entire For the re-blowing effect of the converter, it is necessary to implement blowing and re-blowing. The tonnage of the combined blowing converter in the test, the service life of the bottom blowing gas supply components before blowing and plugging, and the parameters of the bottom blowing gas supply are listed in Tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com