Direct reduction process for producing sponge iron by using converter gas

A converter gas and sponge iron technology, applied in furnaces, shaft furnaces, furnace types, etc., can solve the problems of long process route, low equipment investment, large equipment investment, etc., achieve low energy consumption and equipment investment, reduce dust content The effect of simple quantity and process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

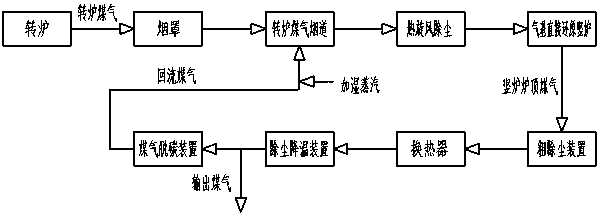

Image

Examples

no. 1 example

[0040] 1) The high-temperature converter gas discharged from the converter enters the converter gas flue through the fume hood, and mixes with the return gas after the shaft furnace top gas has been dedusted, cooled and decarburized, so that the temperature of the gas in the converter gas flue drops to 1050°C, from The 1050°C high-temperature gas coming out of the converter gas flue is dedusted by a hot cyclone and enters the gas-based direct reduction shaft furnace to reduce low-allocation carbon and cold-consolidate carbon-containing pellets to produce sponge iron and generate shaft furnace top gas.

[0041] 2) In the above step 1), the temperature of the high-temperature converter gas discharged from the converter is 1400°C.

[0042] 3) In the above step 1), after the top gas of the shaft furnace is dedusted and cooled by the coarse dedusting device, heat exchanger and dedusting and cooling device, part of it enters the gas decarbonization device to remove CO 2 Finally, it ...

no. 2 example

[0054] 1) The high-temperature converter gas discharged from the converter enters the converter gas flue through the fume hood, and mixes with the return gas after the shaft furnace top gas has been dedusted, cooled and decarburized, so that the temperature of the gas in the converter gas flue drops to 1075°C, from The high-temperature gas at 1075°C coming out of the converter gas flue is dedusted by a hot cyclone and enters the gas-based direct reduction shaft furnace to reduce low-allocation carbon and cold-consolidate carbon-containing pellets to produce sponge iron and generate shaft furnace top gas.

[0055] 2) In the above step 1), the temperature of the high-temperature converter gas discharged from the converter is 1550°C.

[0056] 3) In the above step 1), after the top gas of the shaft furnace is dedusted and cooled by the coarse dedusting device, heat exchanger and dedusting and cooling device, part of it enters the gas decarbonization device to remove CO 2 Finally, ...

no. 3 example

[0068] 1) The high-temperature converter gas discharged from the converter enters the converter gas flue through the fume hood, and mixes with the return gas after the shaft furnace top gas has been dedusted, cooled and decarburized, so that the temperature of the gas in the converter gas flue drops to 1100 ° C, from The 1100°C high-temperature gas coming out of the converter gas flue is dedusted by a hot cyclone and enters the gas-based direct reduction shaft furnace to reduce low-allocation carbon and cold-consolidate carbon-containing pellets to produce sponge iron and generate shaft furnace top gas.

[0069] 2) In the above step 1), the temperature of the high-temperature converter gas discharged from the converter is 1650°C.

[0070] 3) In the above step 1), after the top gas of the shaft furnace is dedusted and cooled by the coarse dedusting device, heat exchanger and dedusting and cooling device, part of it enters the gas decarbonization device to remove CO 2 Finally, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com