A blast furnace type design method for smelting vanadium-titanium magnetite

A blast furnace furnace type, vanadium-titanium ore technology, applied in the direction of the internal form, etc., can solve the problems of not being able to provide drop height, unfavorable blast furnace straight line, insufficient hearth heat, etc., to reduce the furnace body angle, pressure and friction Reduce and ensure the effect of metallurgical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

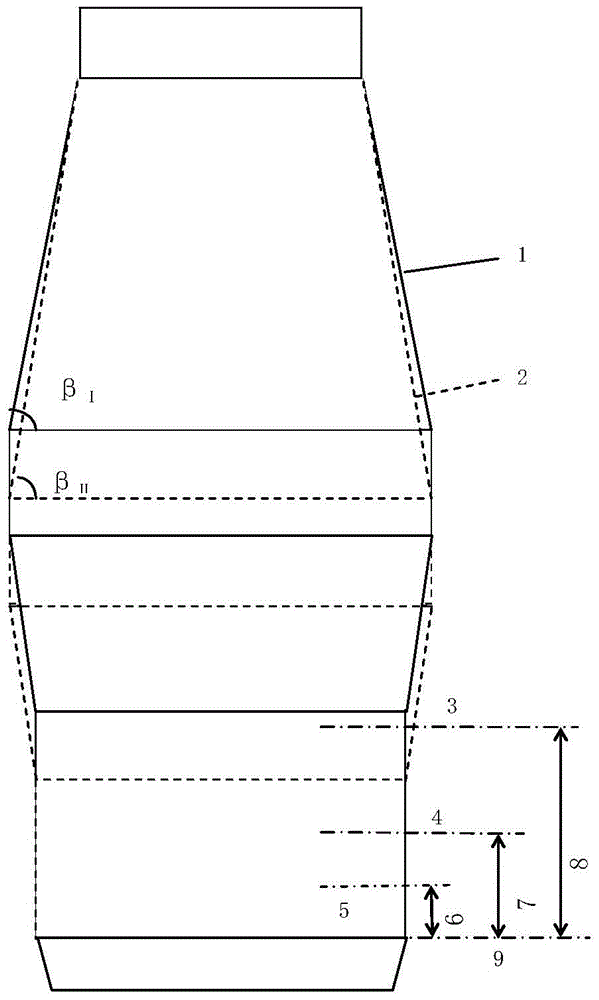

[0024] at 2500m 3 Taking vanadium-titanium magnetite smelting blast furnace as an example, the process steps of the blast furnace type design method applicable to vanadium-titanium magnetite smelting are as follows:

[0025] (1) Reduce the shaft angle β: β is reduced from 83.5° to 75.5°;

[0026] (2) Increase the tuyere height h f : Slag mouth height h z and tuyere height h f The ratio takes a value of 0.2.

[0027] By adopting the method of this embodiment, the utilization factor of the blast furnace is increased from 2.45 in the existing blast furnace type design to 2.60.

Embodiment 2

[0029] at 2000m 3 Taking vanadium-titanium magnetite smelting blast furnace as an example, the process steps of the blast furnace type design method applicable to vanadium-titanium magnetite smelting are as follows:

[0030] (1) Reduce the shaft angle β: β is reduced from 85.5° to 80.0°;

[0031] (2) Increase the tuyere height h f : Slag mouth height h z and tuyere height h f The value of the ratio is 0.4.

[0032] By adopting the method of this embodiment, the utilization factor of the blast furnace is increased from 2.50 in the existing blast furnace type design to 2.65.

Embodiment 3

[0034] at 2000m 3 Taking vanadium-titanium-magnetite smelting blast furnace as an example, the process steps of the blast furnace type design method applicable to vanadium-titanium-magnetite smelting are as follows:

[0035] (1) Reduce the shaft angle β: β is reduced from 85.5° to 78.5°;

[0036] (2) Increase the tuyere height h f : Slag mouth height h z and tuyere height h f The value of the ratio is 0.3.

[0037] By adopting the method of this embodiment, the utilization factor of the blast furnace is increased from 2.50 in the existing blast furnace type design to 2.62.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com