Patents

Literature

42results about How to "Life Synchronization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

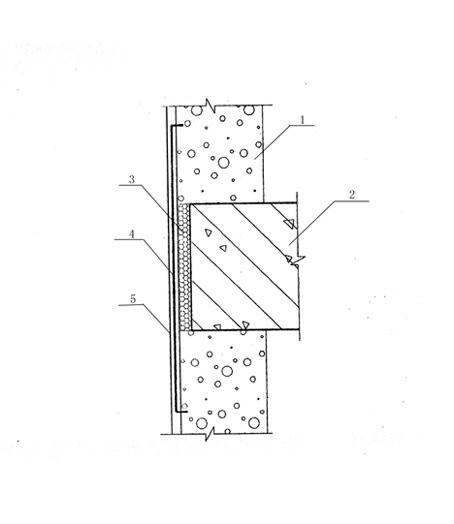

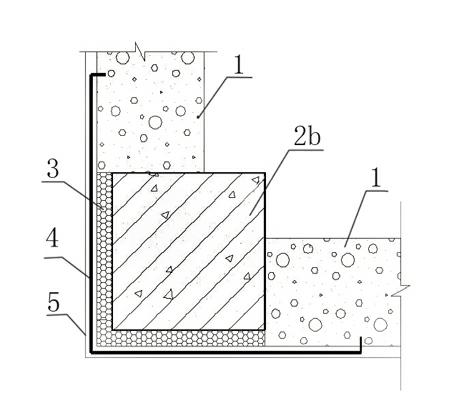

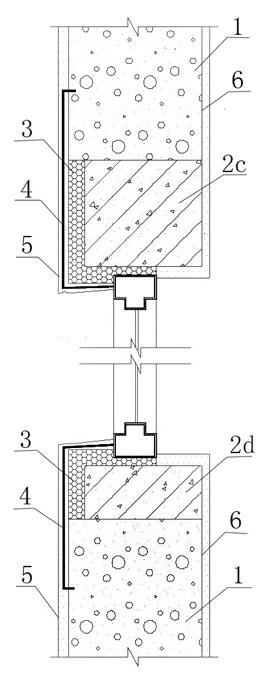

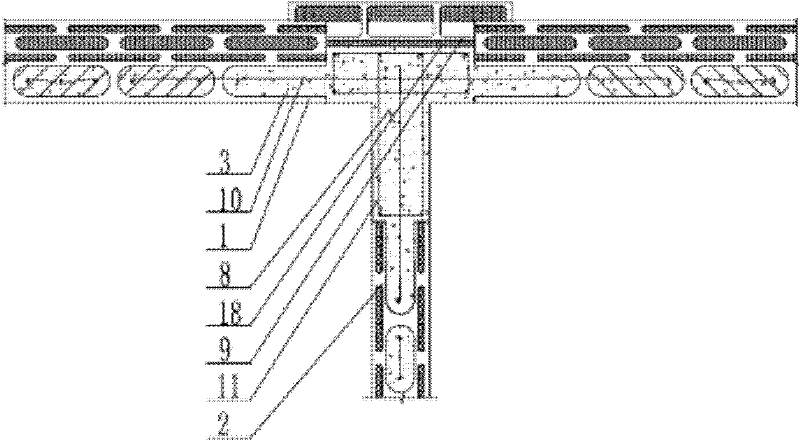

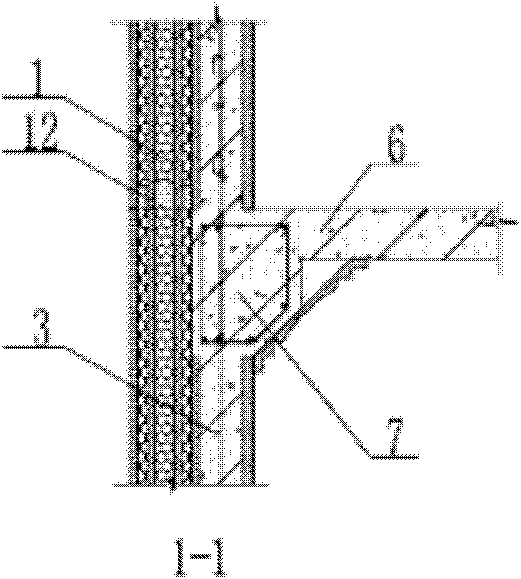

Automatic heat preservation, energy saving and air-entrapping concrete brick wall and manufacturing method thereof

InactiveCN102162282AImprove performanceMeet the requirements of the outer protective structureConstruction materialSolid waste managementInsulation layerThermal bridge

The invention relates to an automatic heat preservation, energy saving and air-entrapping concrete brick wall and a manufacturing method thereof. The invention is characterized that: a heat preservation wall plate is protruded, relative to the outer surfaces of a beam and a stand column or a concrete plate, 20 to 50 millimeters or flatly bricked; beam and column part heat preservation layers are bonded on the outer surfaces of the beam and the stand column or the concrete plate; and alkali-proof grids or steel mesh sheets are paved on the surfaces of the heat preservation layers. During bricking of the wall, the comprehensive performance of the heat preservation wall can be enhanced under the condition of no addition of the heat preservation layers on the whole wall by using energy saving and air-entrapping concrete bricks and heat preservation bricking mortar as well as heat preservation processing measures taken on hot bridge parts such as the beam, the column and the like, so the requirement of a periphery protective structure of a building wall can be met, and heat energy loss due to the hot bridges formed in mortar joints of the wall can be avoided effectively; therefore, the design standard requirement of China on heat preservation and energy saving of a building is met, and the manufacturing cost of the wall and the comprehensive cost of the building are reduced greatly.

Owner:徐振飞

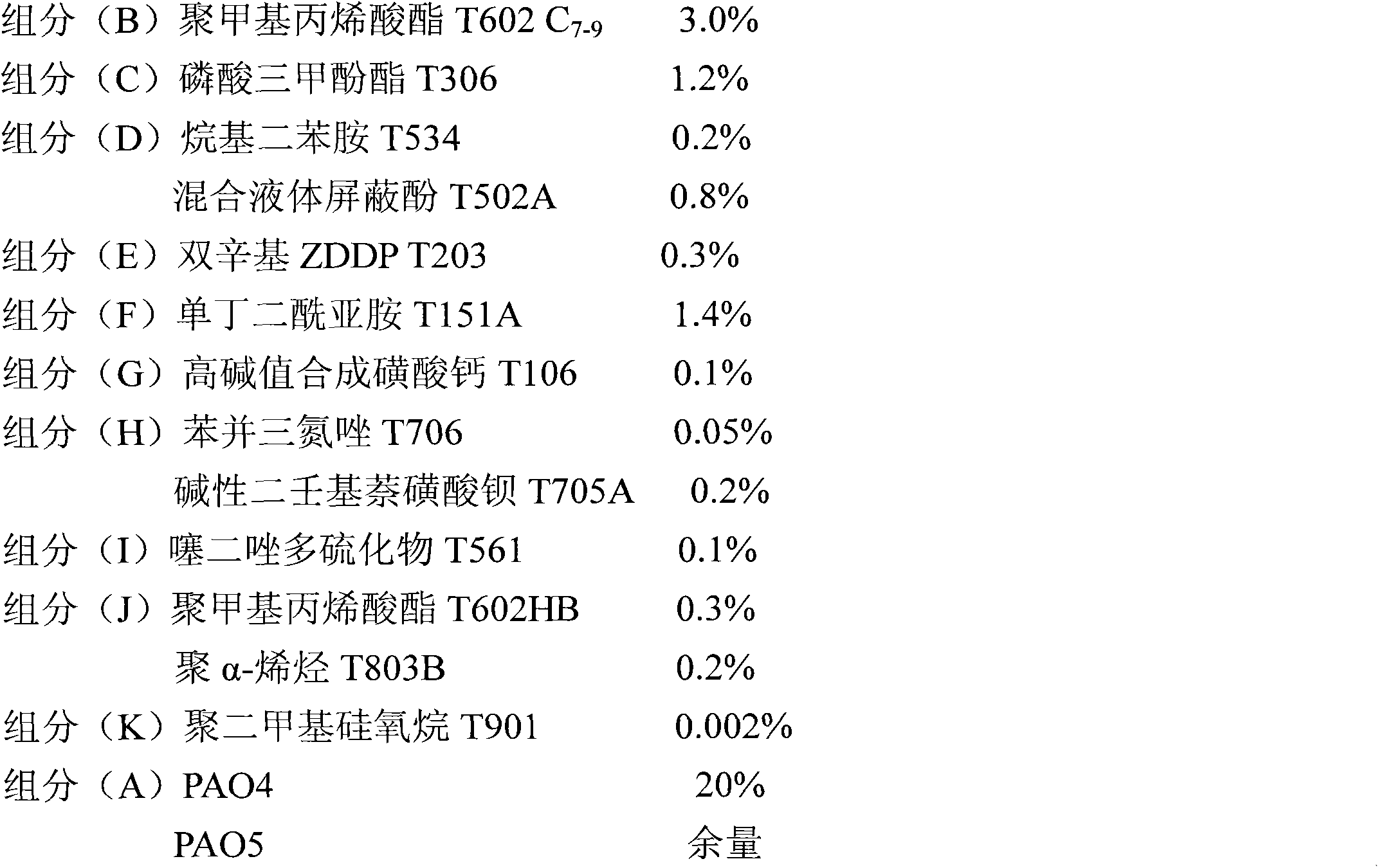

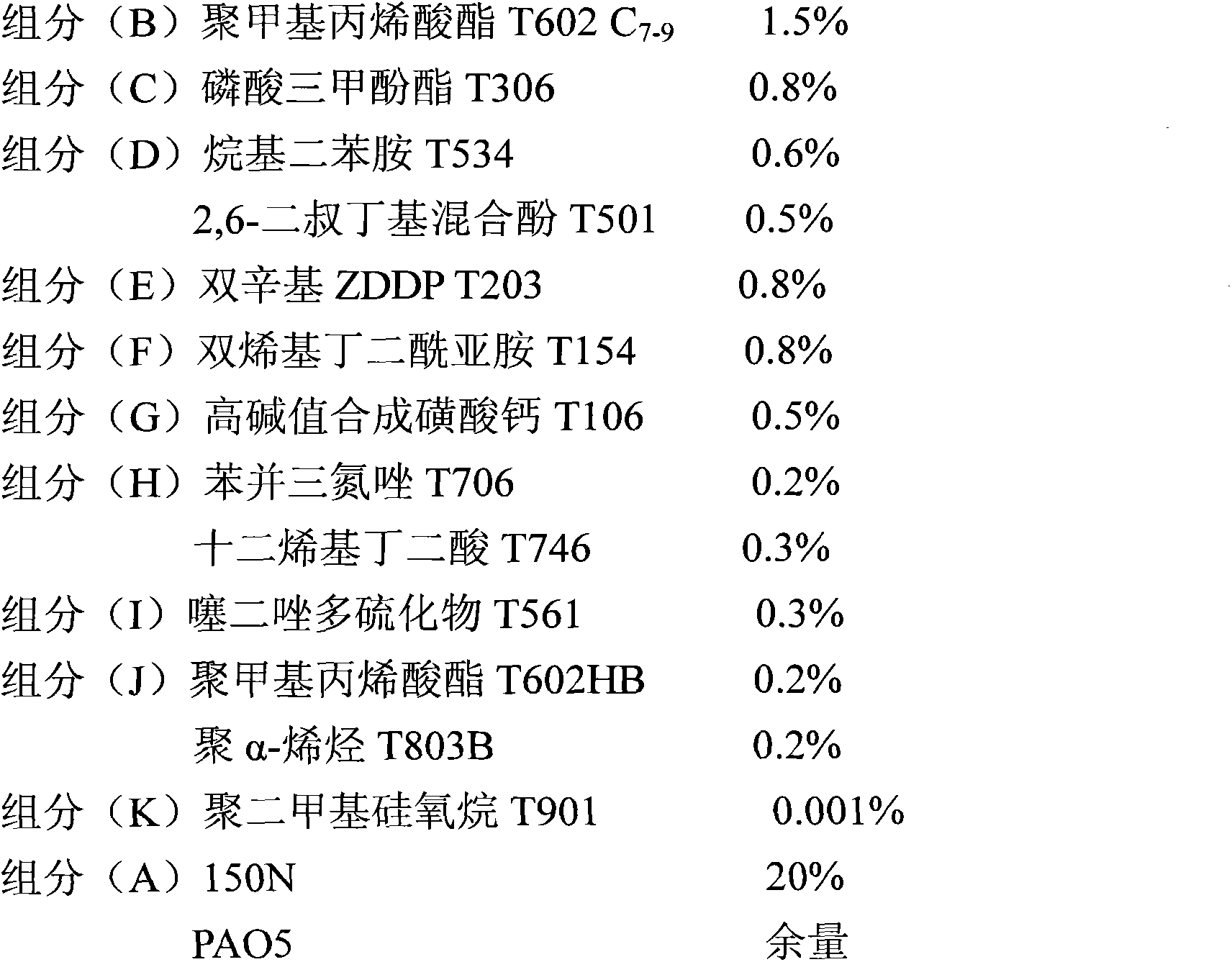

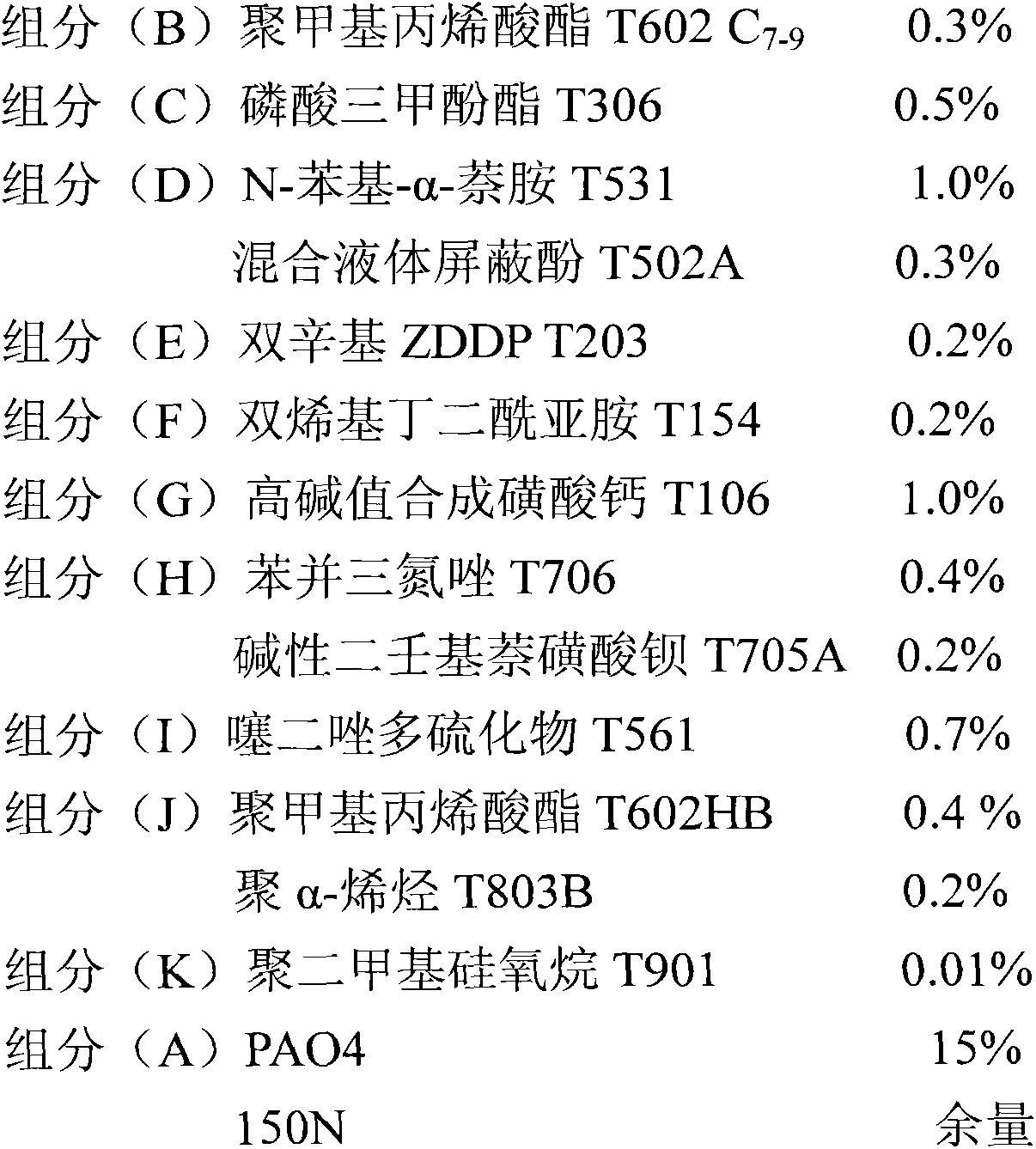

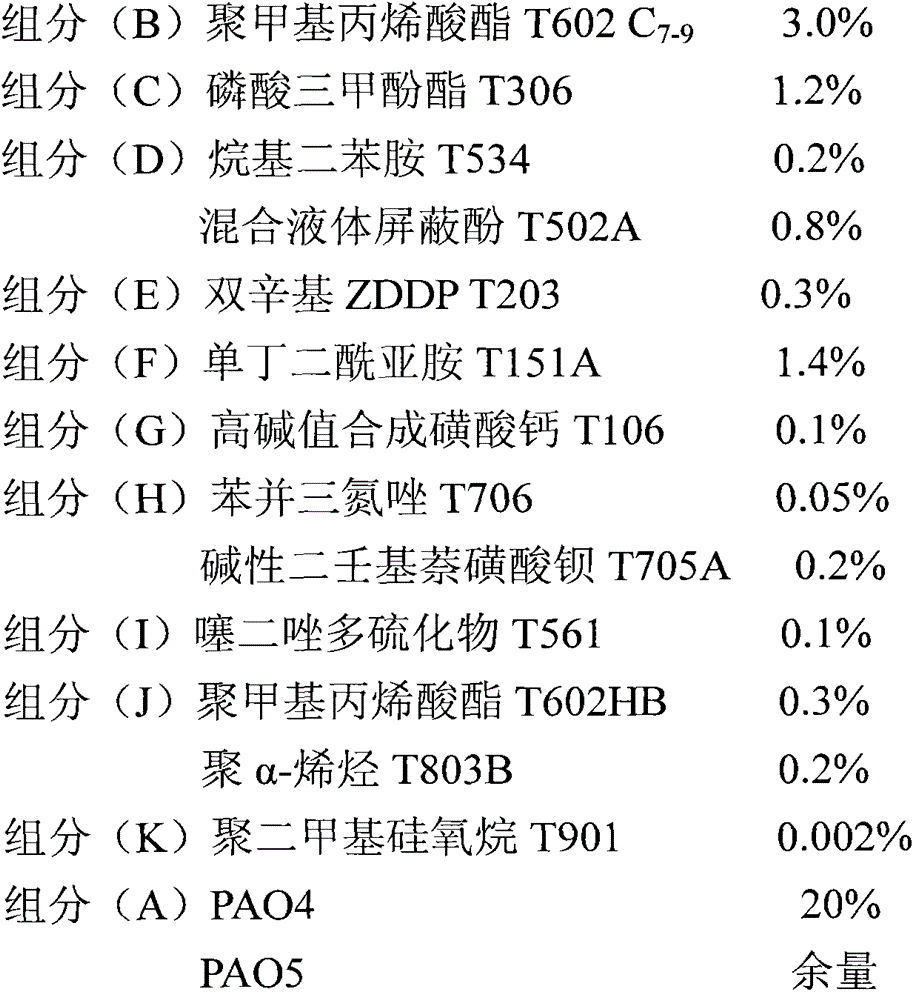

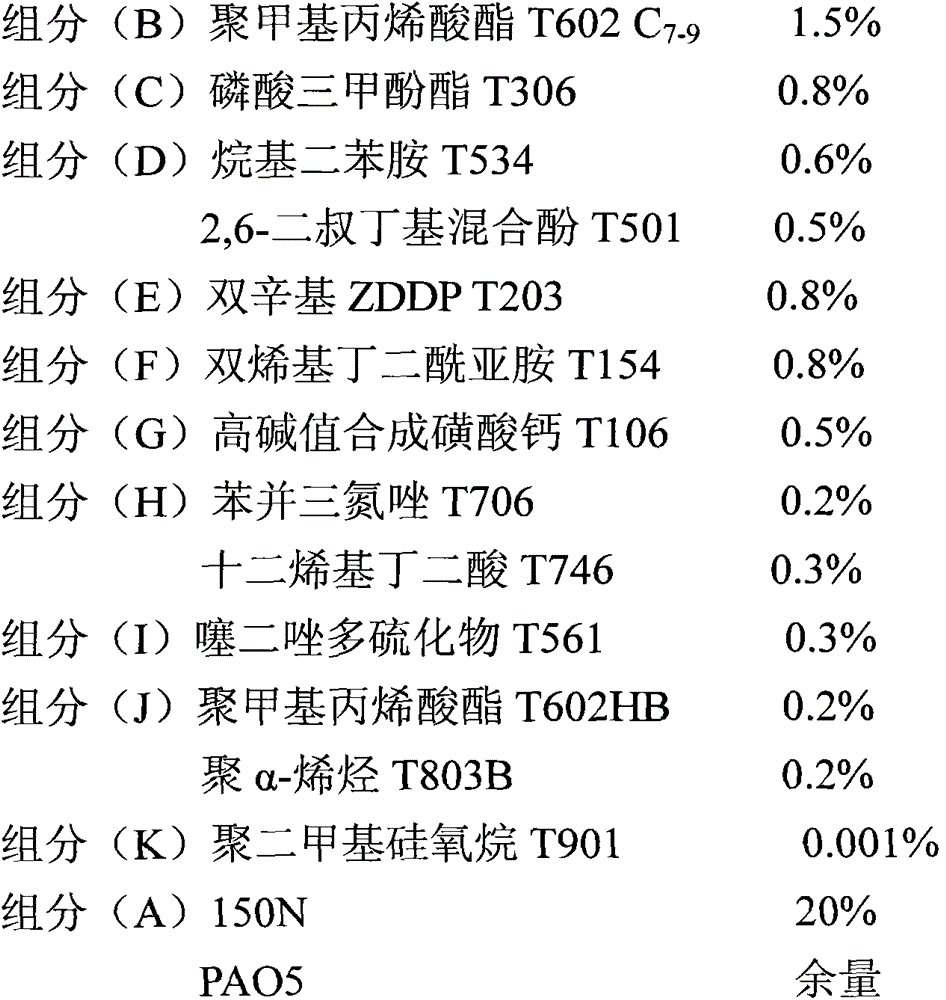

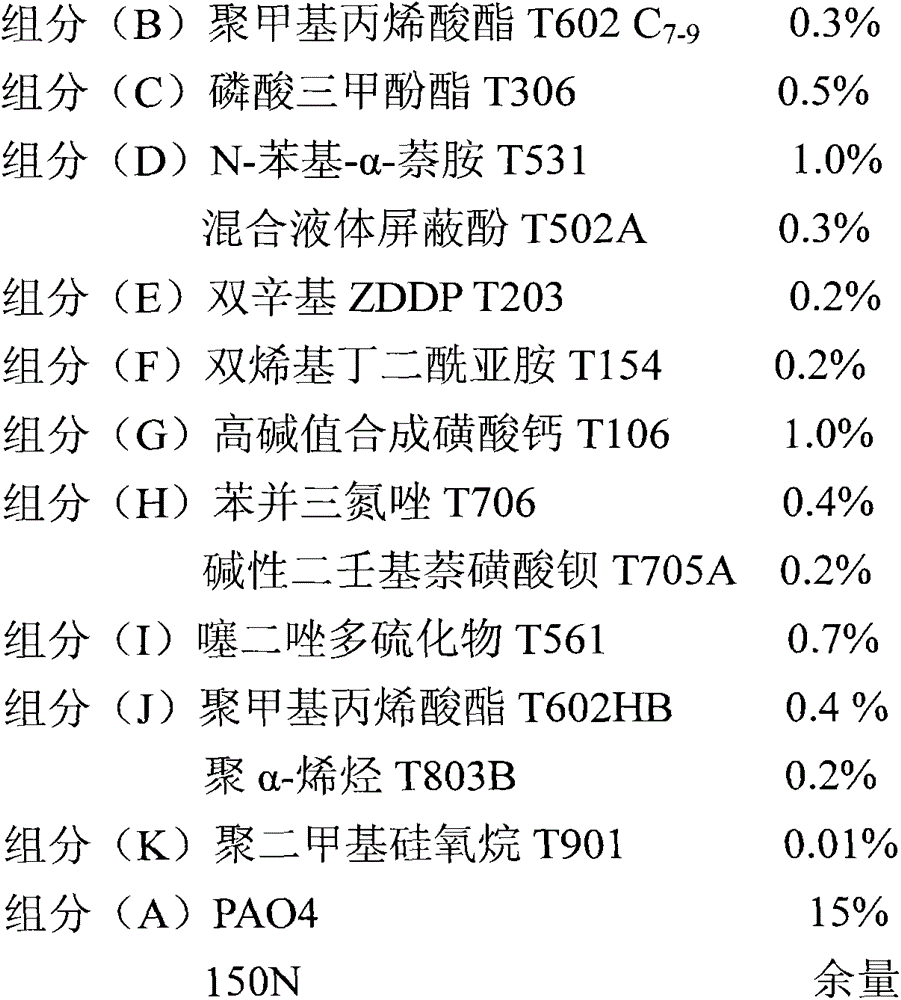

Wear resistance improvement automatic transmission fluid

The invention discloses a wear resistance improvement automatic transmission fluid, relates to an automobile automatic transmission fluid, and mainly aims at solving the problems of non ideal wear resistance and antioxidant properties of automobile automatic transmission fluids in the prior art. The composition comprises base oil accounting for 85.0 to 97.0% of the total weight; a viscosity index improver accounting for 0.2 to 10.0% of the total weight; an anti-wear reagent at extreme pressure, accounting for 0.2 to 2.0% of the total weight; an antioxidant accounting for 0.05 to 2.0% of the total weight; an antioxidant anticorrosion anti-wear agent accounting for 0.02 to 1.0% of the total weight; a dispersant accounting for 0.1 to 3.0% of the total weight; a detergent accounting for 0.05 to 2.0% of the total weight; an anti rust agent accounting for 0.05 to 3.0% of the total weight; a metal deactivator accounting for 0.02 to 3.0% of the total weight; a pour point depressant accounting for 0.2 to 8.0% of the total weight; and an antifoaming agent accounting for 0.0001 to 0.02% of the total weight. The wear resistance improvement automatic transmission fluid has the advantages of good wear resistance and antioxidant properties.

Owner:LIAONING RUNDI AUTOMOTVE ENVIRONMENTAL PROTECTIONTECH

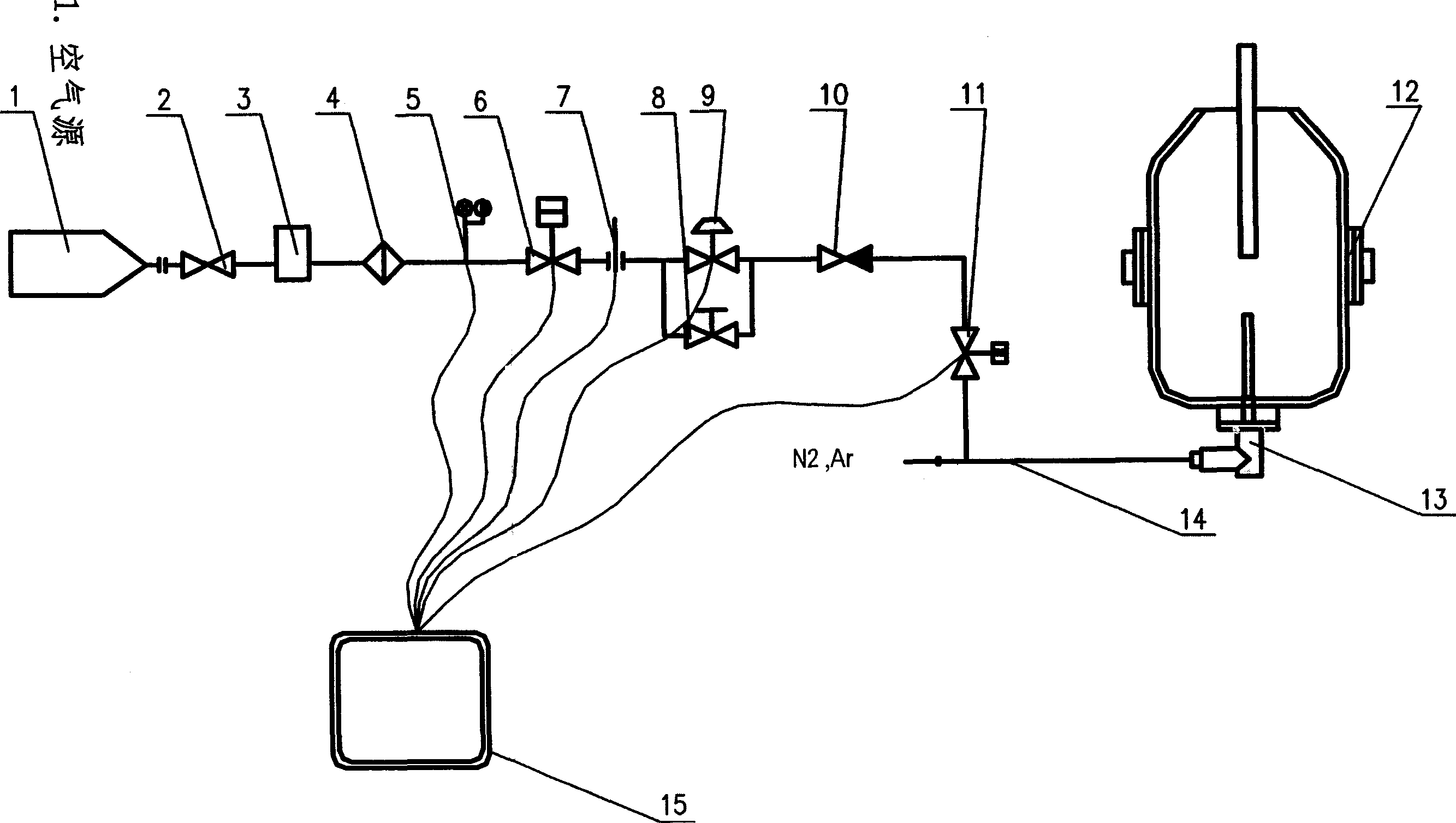

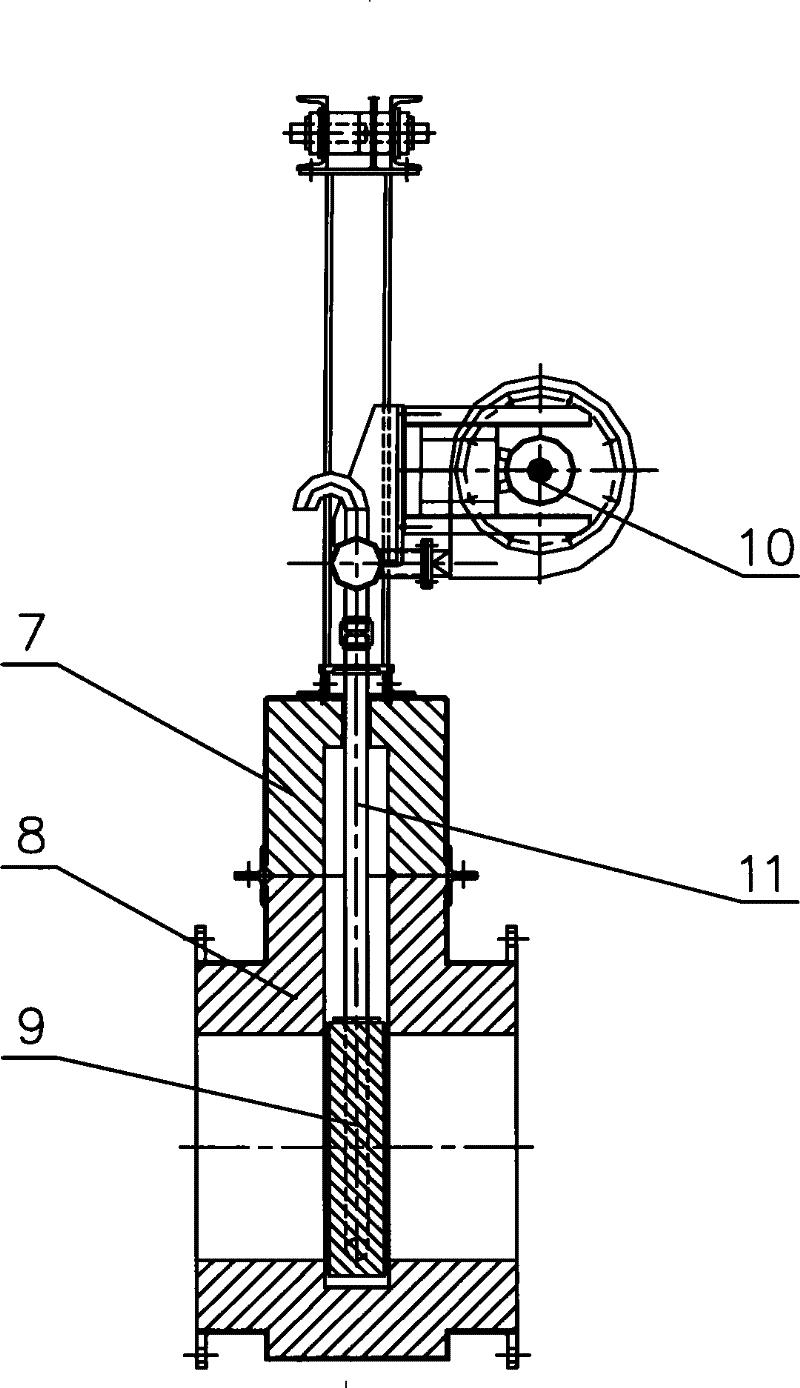

Combined-blowing converter bottom gas supply element blocking-preventing device and method

ActiveCN1743466AGuaranteed metallurgical effectExtend your lifeManufacturing convertersComputer control systemSlag

This invention blow-stop ventilation device of a bottom blow gas supply element of a multi-blow converter is composed of an air dehydrator, a pneumatic fast cut valve, a pneumatic regulation valve, a gas flowmeter, a pressure tester, a computer control system, a blow-step gas source and gas transportation pipe lines interconnected by the gas transportation pipe lines. Said method takes air as the gas supply element and utilizes 20% oxygen in the air to oxidize the blockage-slag-metal mushroom head continuously to keep it at reasonable state to ensure the life time of the supply element the same with the converter lining.

Owner:CENT IRON & STEEL RES INST

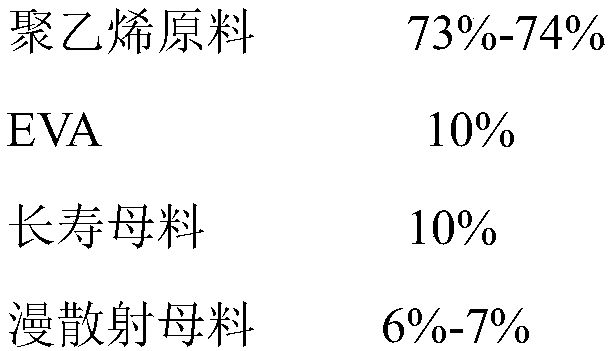

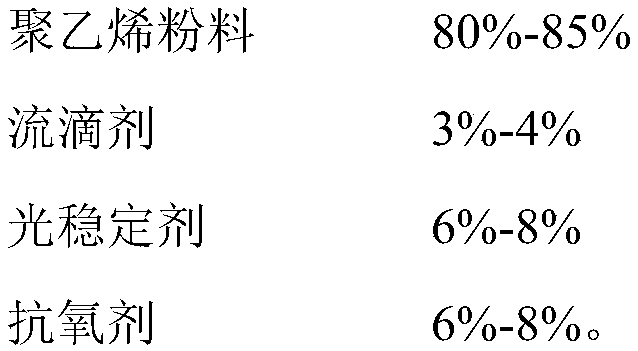

Diffuse scattering polyethylene greenhouse membrane and preparation method thereof

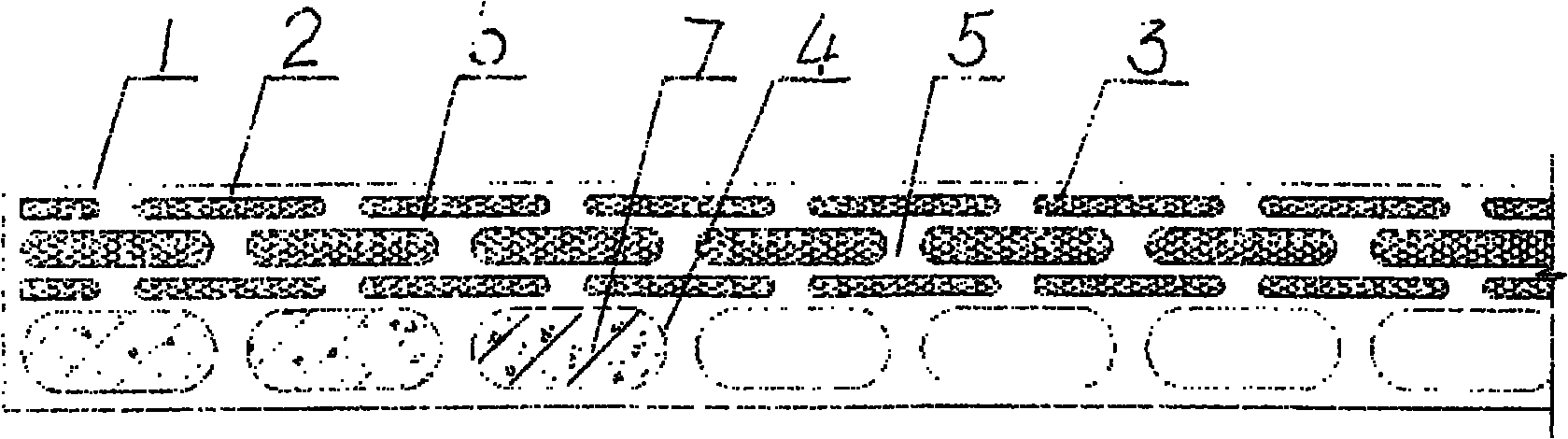

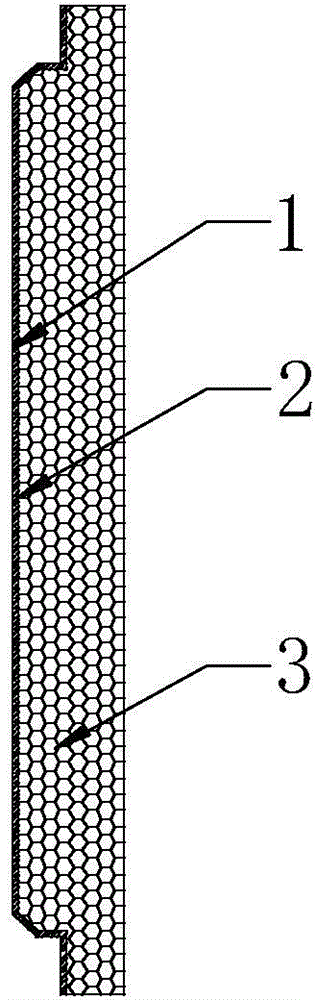

InactiveCN108081719AWith dripping functionLife SynchronizationSynthetic resin layered productsPlant protective coveringsThermal insulationGreenhouse

The invention relates to a diffuse scattering polyethylene greenhouse membrane and a preparation method thereof. The diffuse scattering polyethylene greenhouse membrane comprises an outer layer, a middle layer and an inner layer. The outer layer is a greenhouse membrane dripping layer, the middle layer is a greenhouse membrane thermal insulation layer and the inner layer is a greenhouse membrane long-life layer. The outer layer contains 6-7wt% of diffuse scattering master batches. The middle layer contains 2-3wt% of diffuse scattering master batches. The inner layer contains 1-2wt% of diffusescattering master batches. The diffuse scattering polyethylene greenhouse membrane has a dripping function and a diffuse scattering function and has a life the same to that of the agricultural membrane. The preparation method of the diffuse scattering polyethylene greenhouse membrane is scientific, reasonable, simple and easy.

Owner:SHANDONG QINGTIAN PLASTIC IND

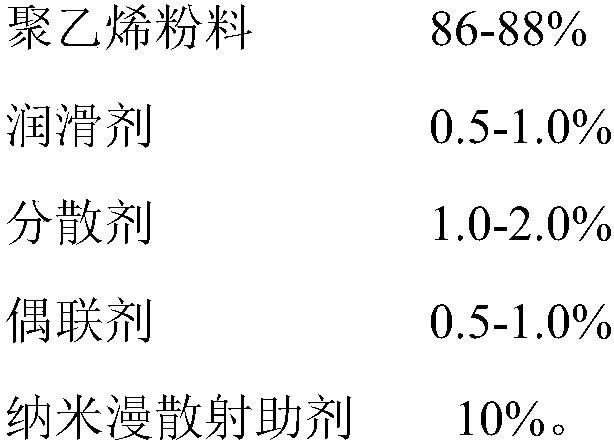

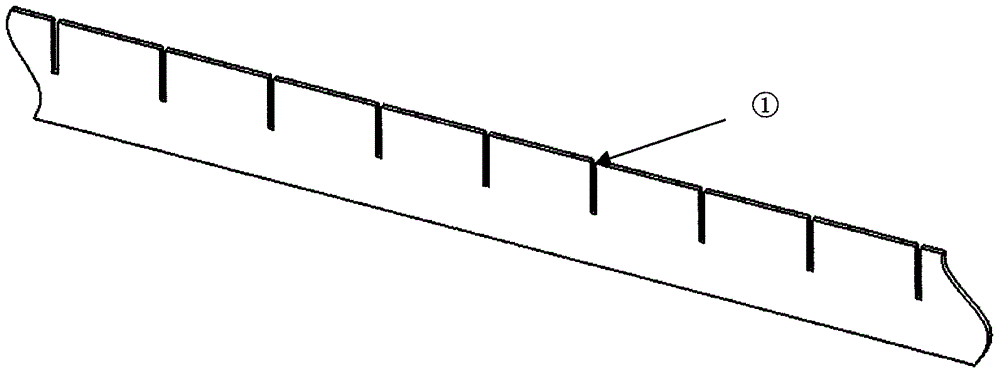

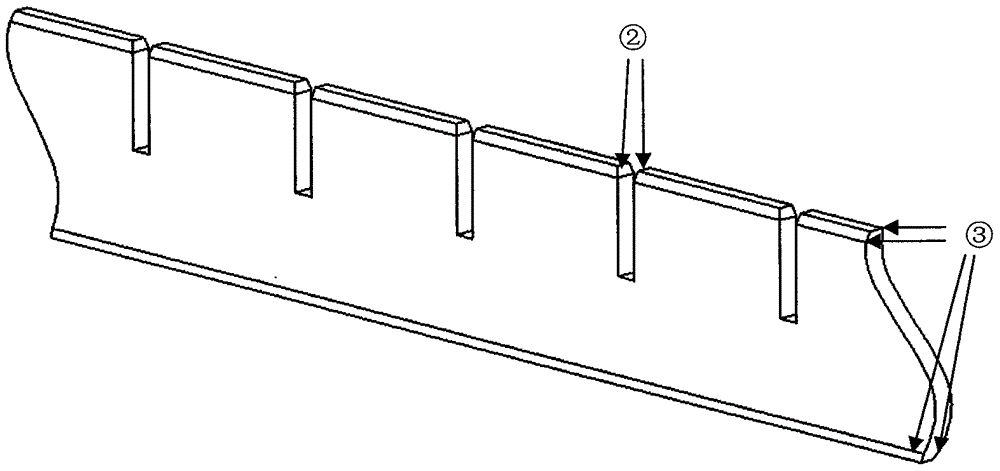

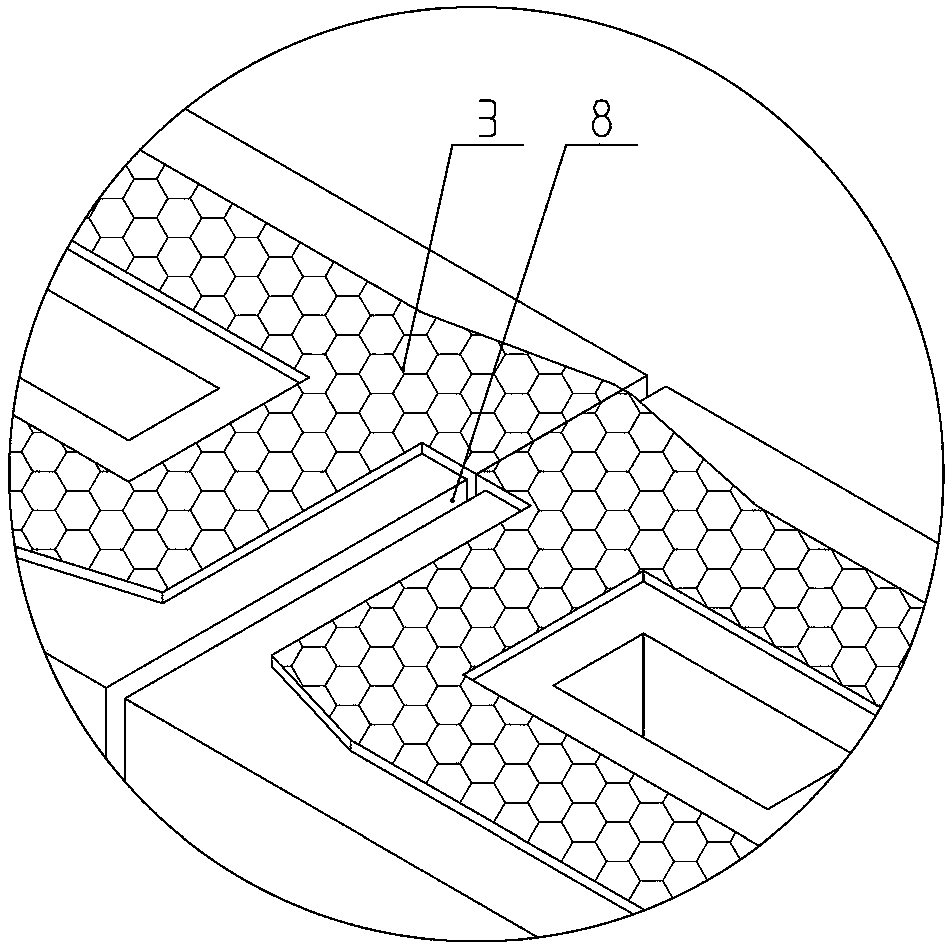

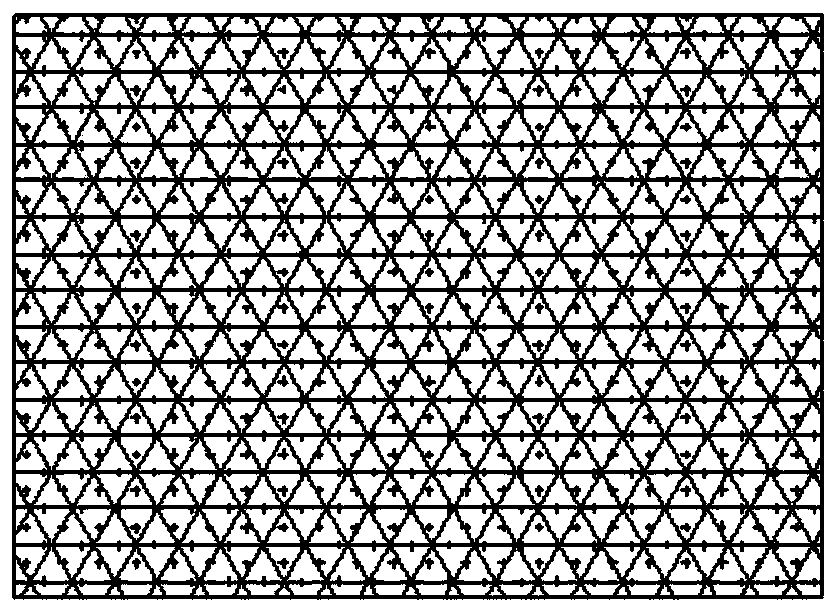

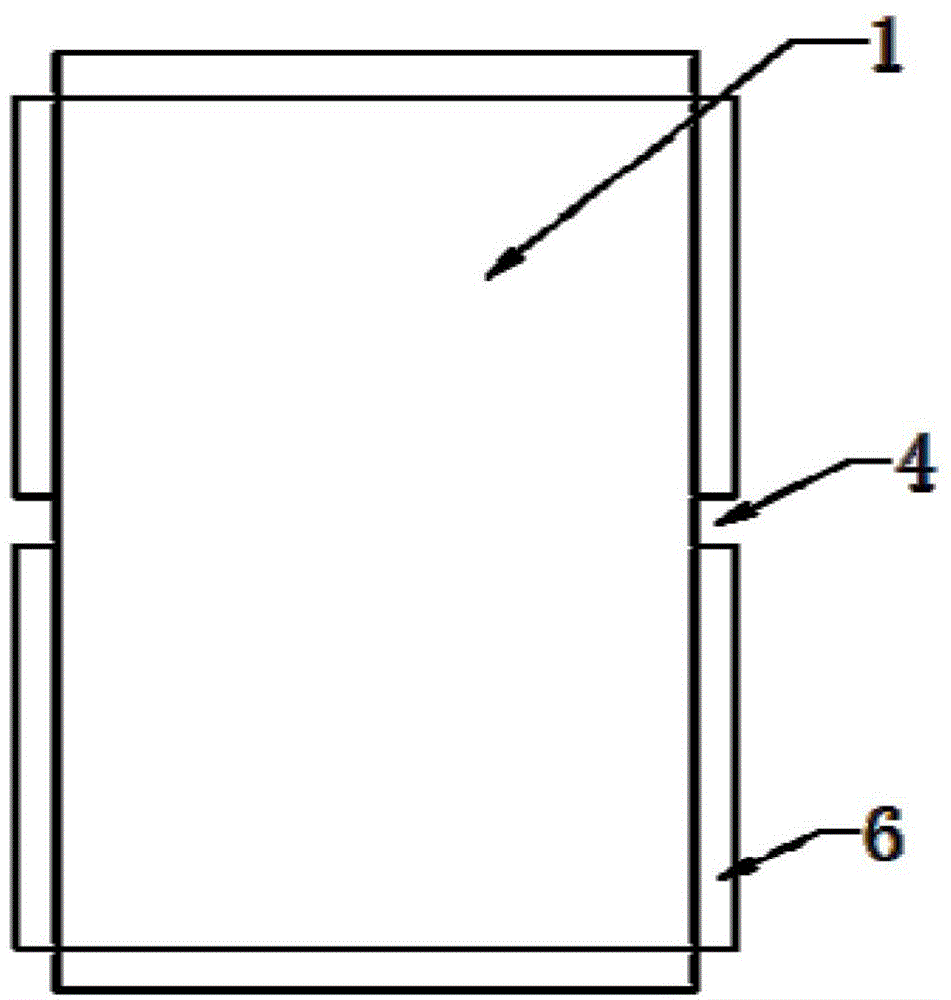

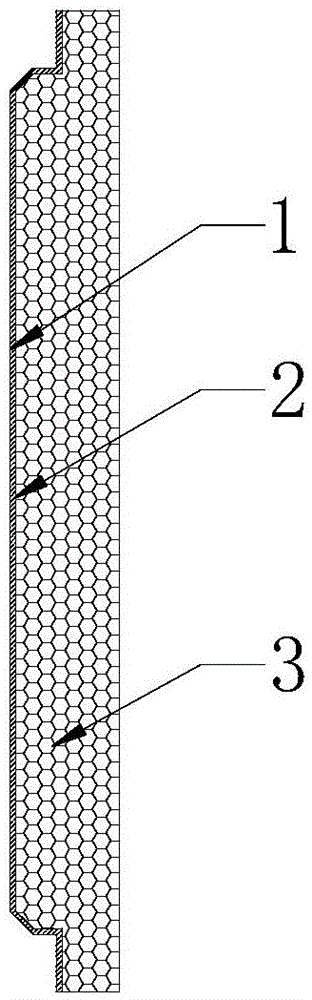

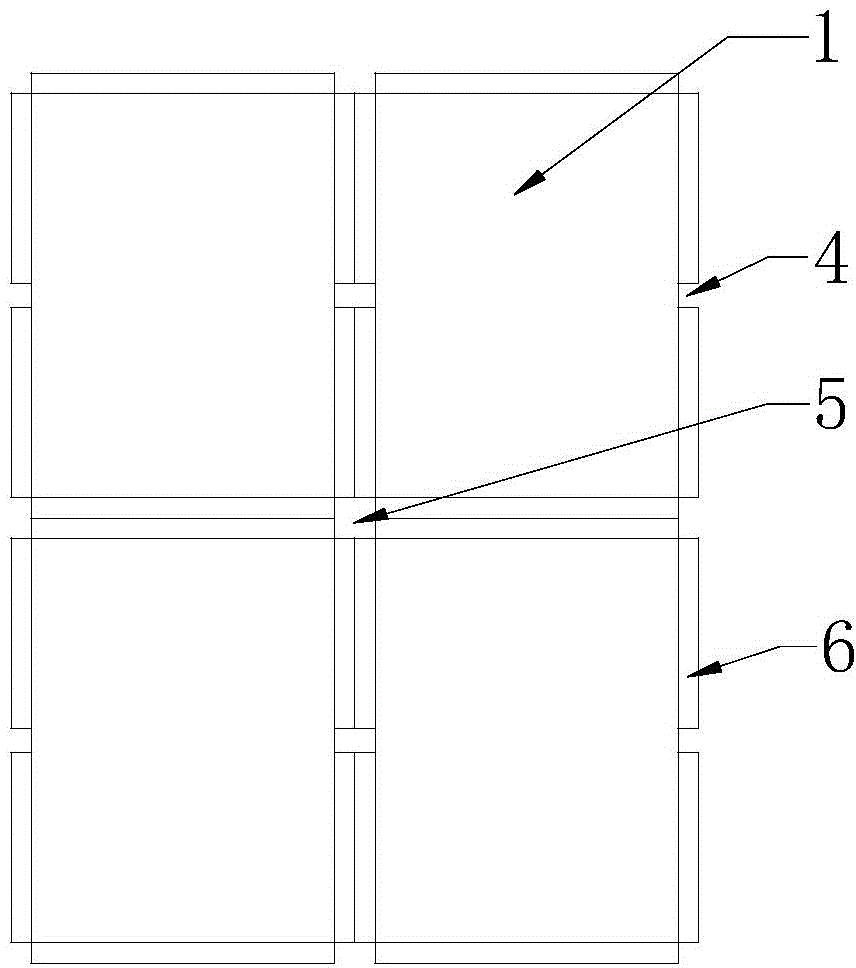

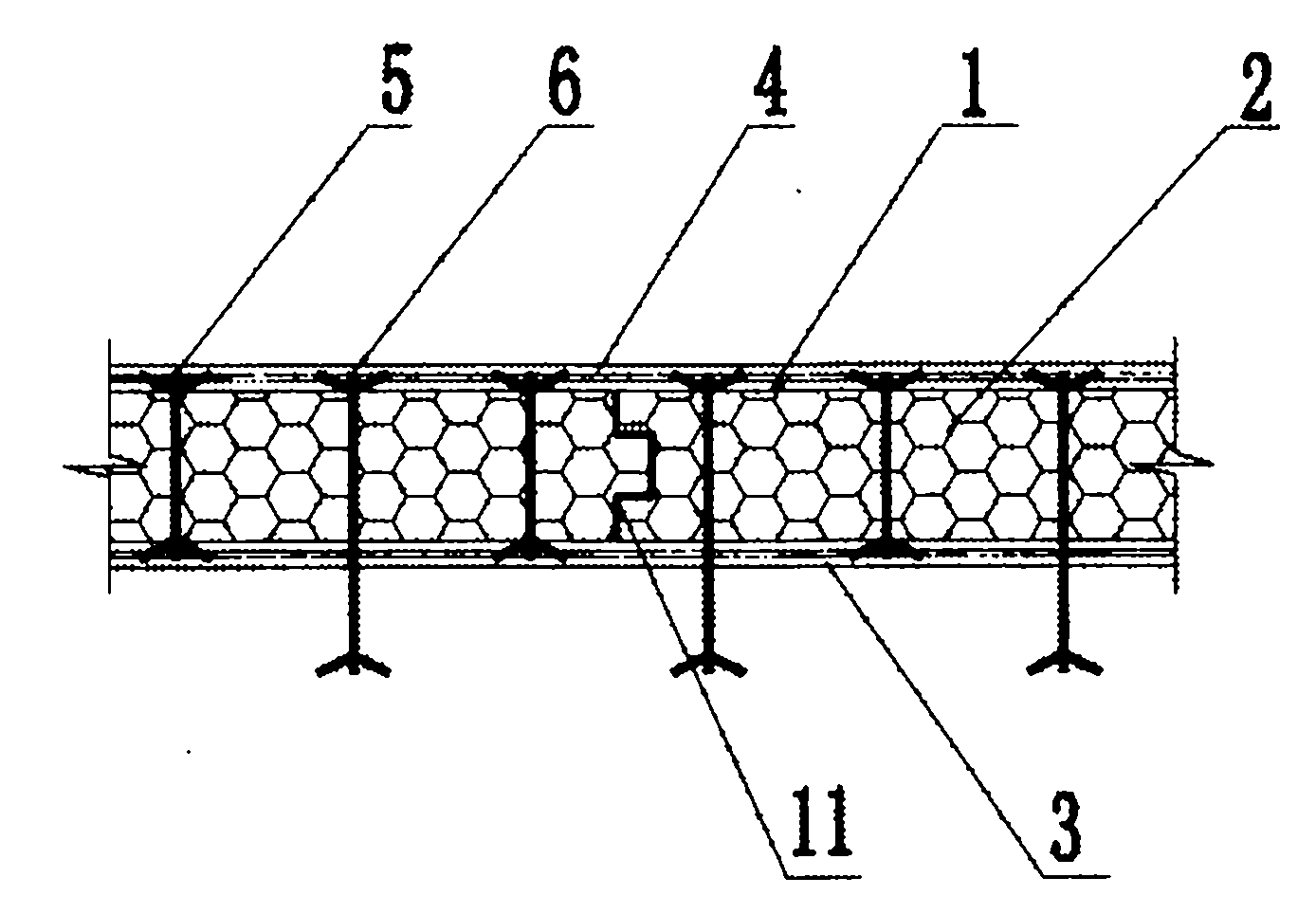

Orthogonal card core metal honeycomb plate

InactiveCN106273793AWith super load capacityNo pollutionMetal layered productsAdhesiveBonding process

A metal honeycomb plate sandwich layer is of a hexagonal honeycomb structure, and is light in weight and strong in load. Although the hexagonal honeycomb can use the least materials to define a maximum effective space, the geometrical shape of the hexagonal honeycomb can be easily changed through an external force of a section axial plane in any direction. When an axial external force is applied on any point on the plane, the hexagonal honeycomb can be easily deformed, which is beneficial to deformation processing of a honeycomb plate, but is not good for achieving the aims of light weight and high strength. In addition, an adhesive can pollute the environment. The invention relates to an orthogonal card core metal honeycomb plate, the honeycomb plate sandwich layer thereof adopts an orthogonal plug-in card structure, the defined space is a regular square prism matrix, a honeycomb core is made of materials 1 / 4 more than that of traditional hexagonal honeycomb sandwich layer, but the orthogonal plug-in card honeycomb sandwich layer structure is compacted into an integral whole, especially the rigidity along a longitudinal and a horizontal direction of a plate strip is good, and the deformation degree is small under the action of the external force, so that the orthogonal card core metal honeycomb plate provided by the invention has an ultrastrong load capacity. The honeycomb plate provided by the invention is formed by adopting rivet with same metal materials to anchor or by welding, is long in service life compared with a bonding process, and cannot pollute the environment.

Owner:吕大明 +2

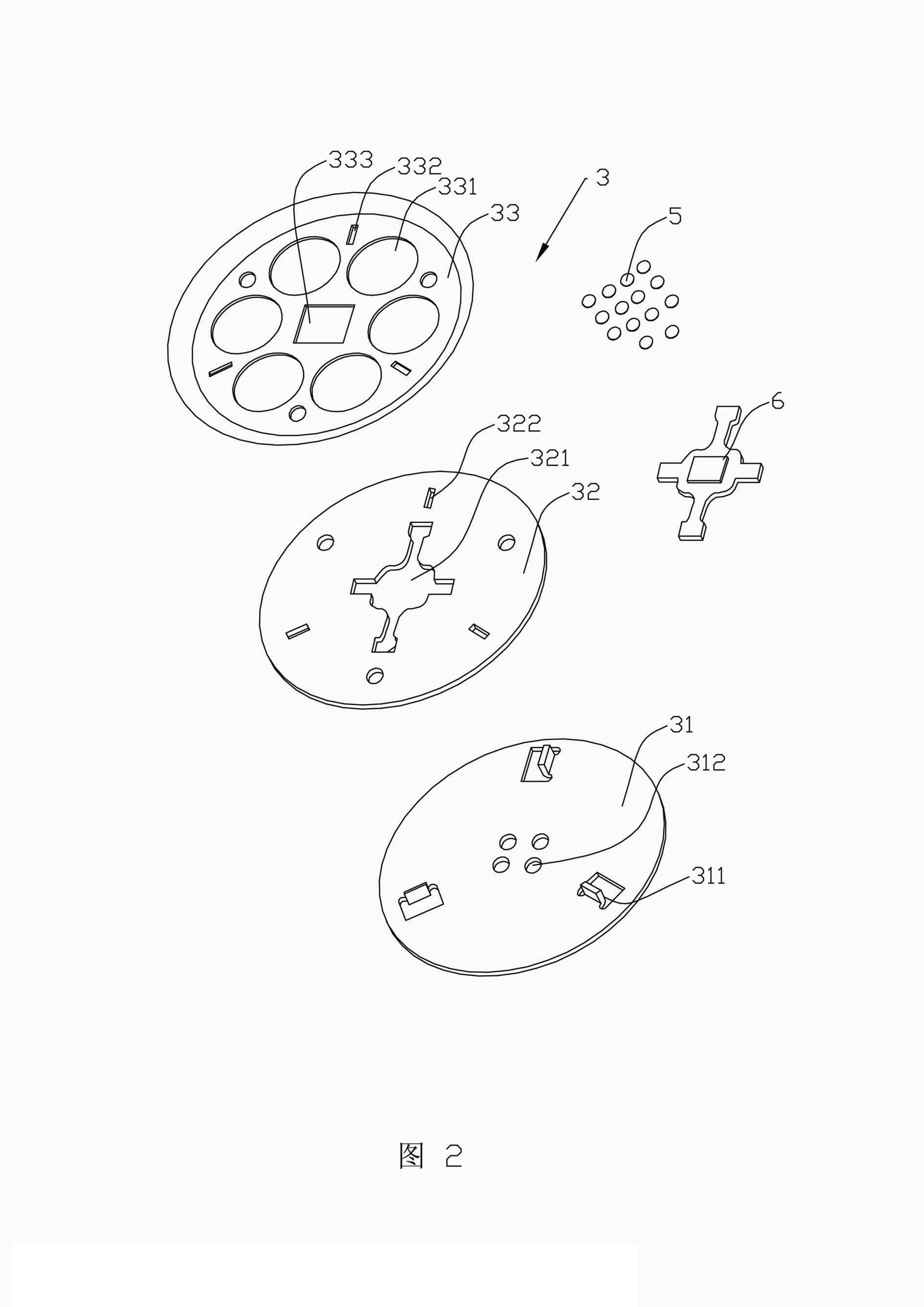

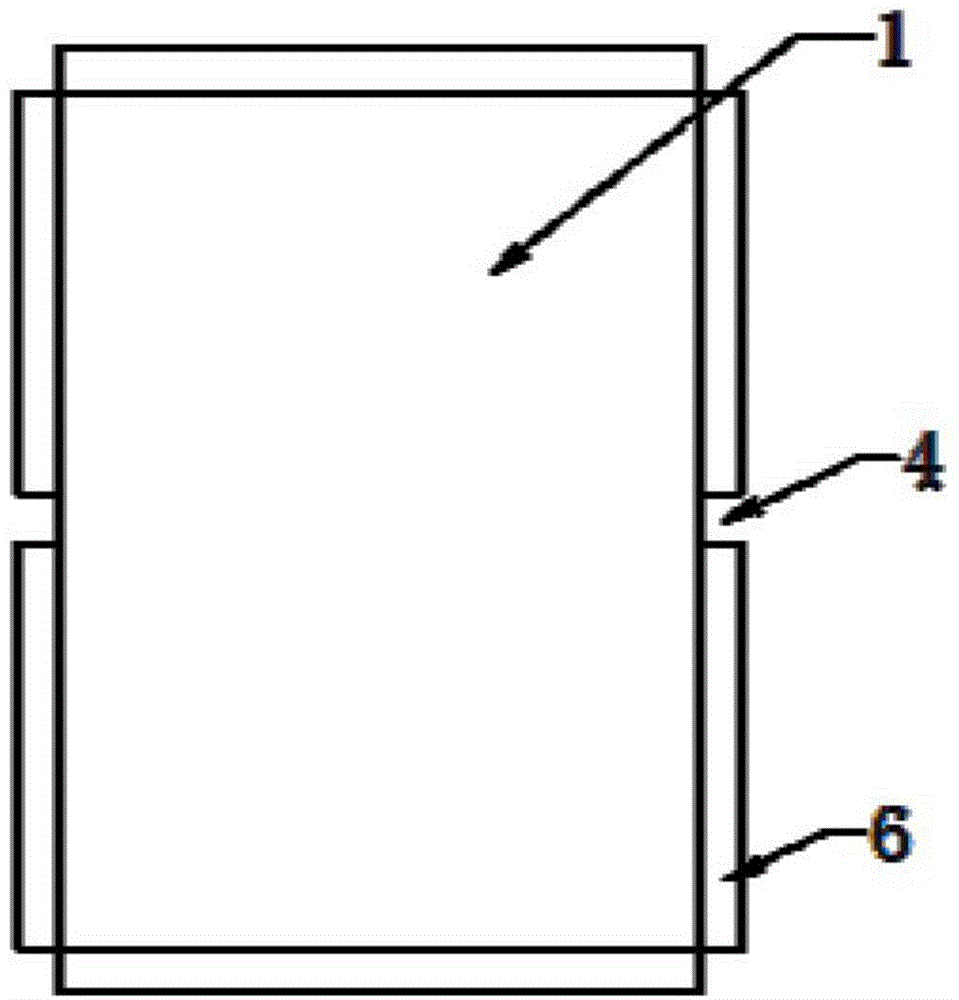

Street lamp adopting LED light source

InactiveCN102109134AGuaranteed flatnessFixed flatPoint-like light sourceLighting heating/cooling arrangementsEngineeringControl circuit

A street lamp adopting an LED light source comprises a lamp housing, a reflecting shade, a light-emitting port, a light-transmittable shade and an LED light source module, wherein the reflecting shade is arranged in the lamp housing; the light-emitting port is arranged on the lamp housing; the light-transmittable shade is arranged at the light-emitting port; the LED light source module is fixed in the reflecting shade, and comprises a first stamping sheet metal, a second stamping sheet metal, a third stamping sheet metal, a plurality of LED chips and a control circuit board; the LED chips are arranged on the second stamping sheet metal; the control circuit board is connected with the LED chips; the second stamping sheet metal is provided with a mounting port used for fixing the control circuit board; a plurality of openings for limiting an area with point fluorescent powder glue are formed on the third stamping sheet metal; the LED chips are stuck on the second stamping sheet metal in positions corresponding to the openings; and the first stamping sheet metal, the second stamping sheet metal and the third stamping sheet metal are fixed with one another through a connecting mechanism. The street lamp adopting the LED light source has the advantages of good heat dissipation performance, low cost and long service life.

Owner:厦门宝晨照明科技有限公司

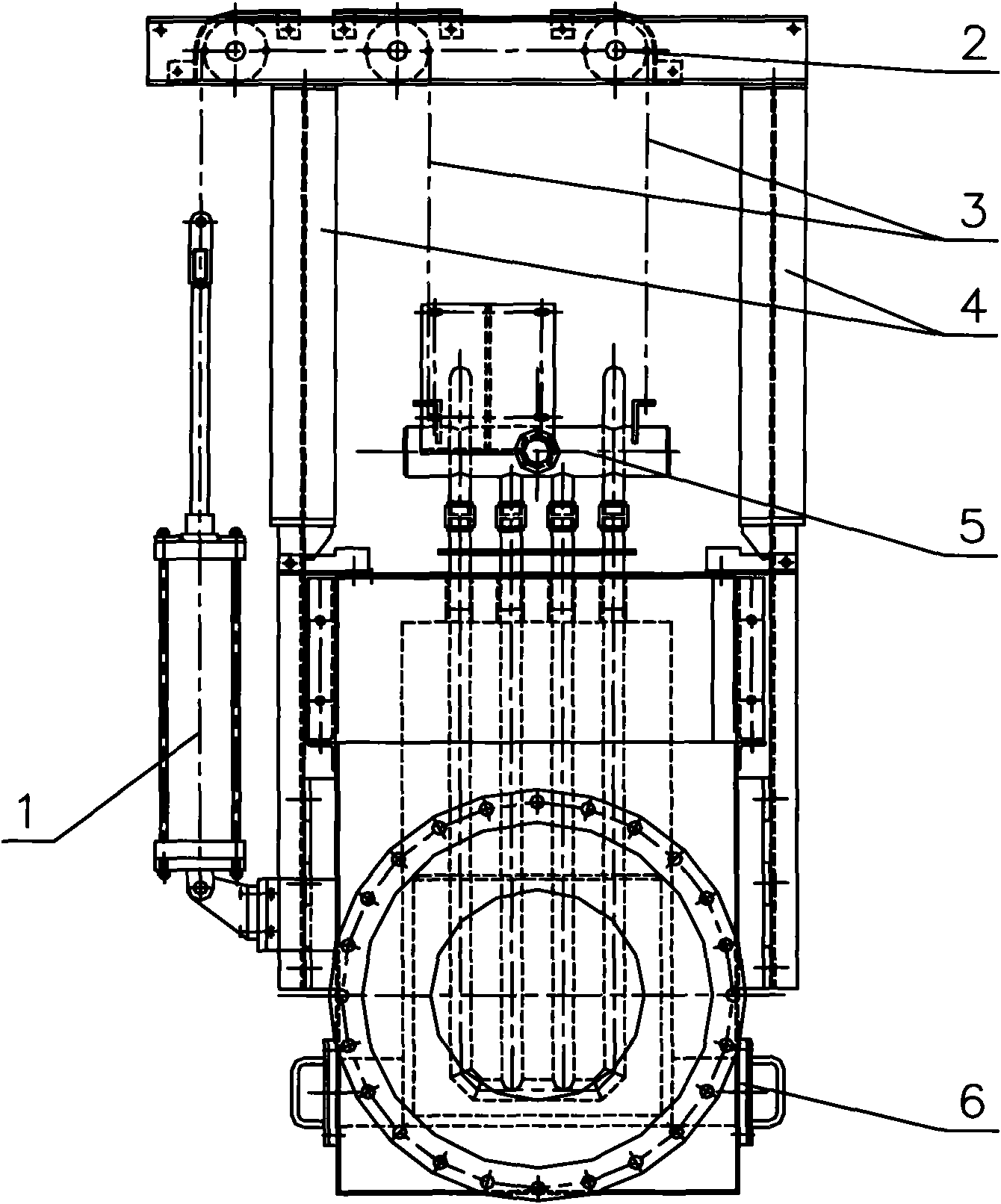

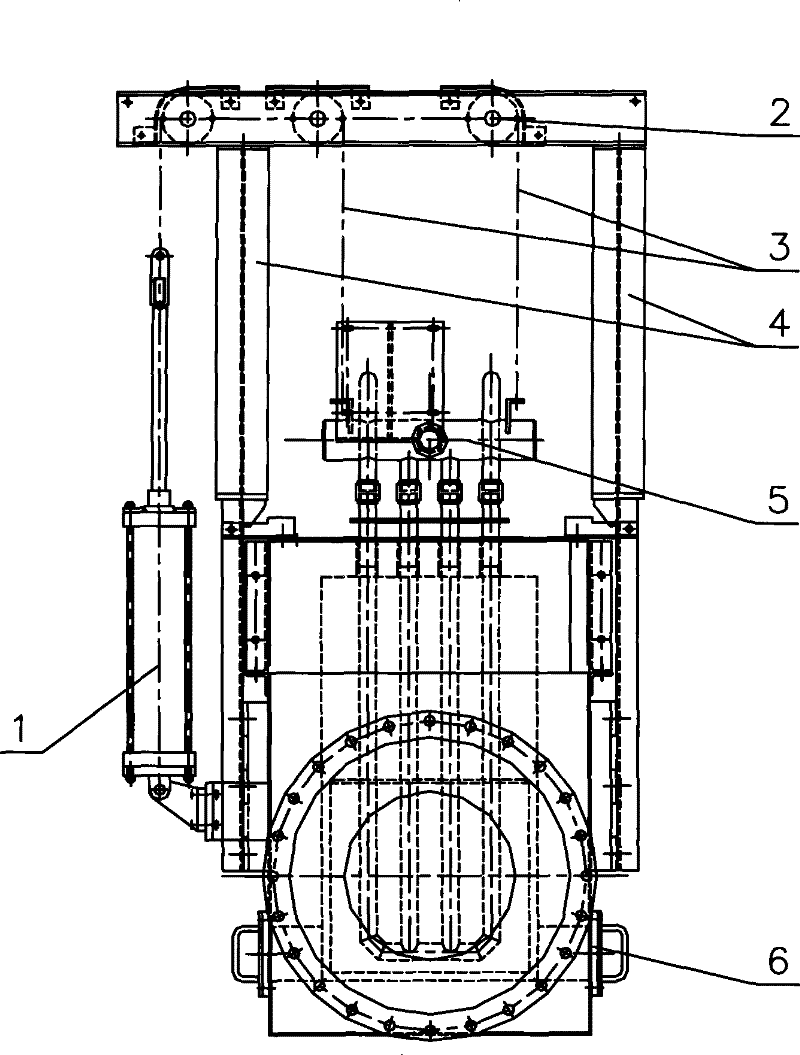

High-temperature resistant air cooling smoke gate device

ActiveCN101581385ALife SynchronizationResist erosionOperating means/releasing devices for valvesValve members for heating/coolingRefractoryRoller chain

The invention provides a high-temperature resistant air cooling smoke gate device which comprises an air cooling gate plate, a gate plate seat, a blowing mechanism and a drive mechanism, wherein the gate plate is made of unformed refractory materials, and the inner part of the gate plate adopts a plurality of hollow steel pipes connected in parallel as a cooling air passage of the gate plate and an anchoring and supporting skeleton of the gate plate; outlets of the steel pipes are exposed outside the gate plate and connected with the blowing mechanism and the drive mechanism; and two bush roller chains drive the gate plate to participate in the pressure control of a furnace cavity by taking a drive cylinder as a power source. The high-temperature resistant air cooling smoke gate device has the advantages of novel design, reliable operation, convenient installation, low operation cost, easy maintenance and high operability and practicability and can be widely applied to various flame furnaces including an aluminum melting furnace, a heat preserving furnace or a mixing furnace in the electrolytic aluminum or aluminum processing industry.

Owner:SUZHOU LONGRAY THERMAL TECH

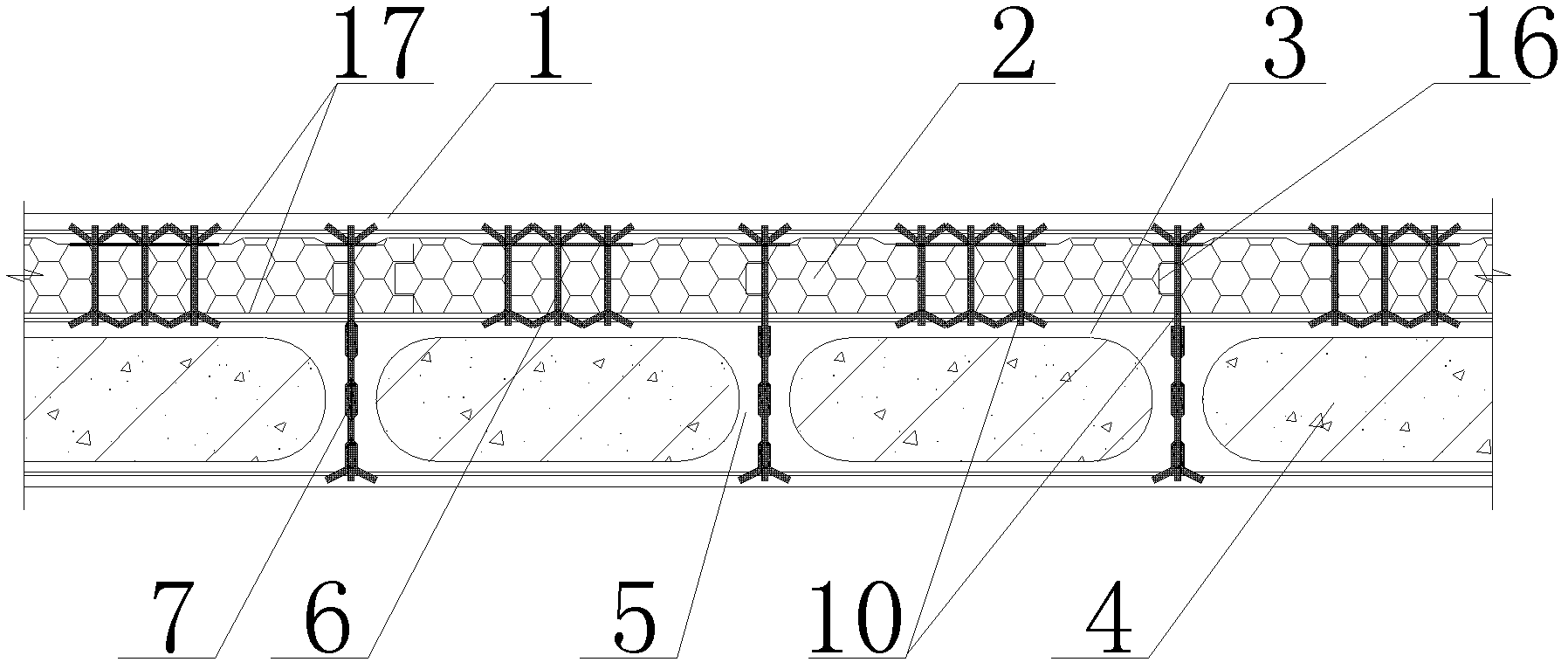

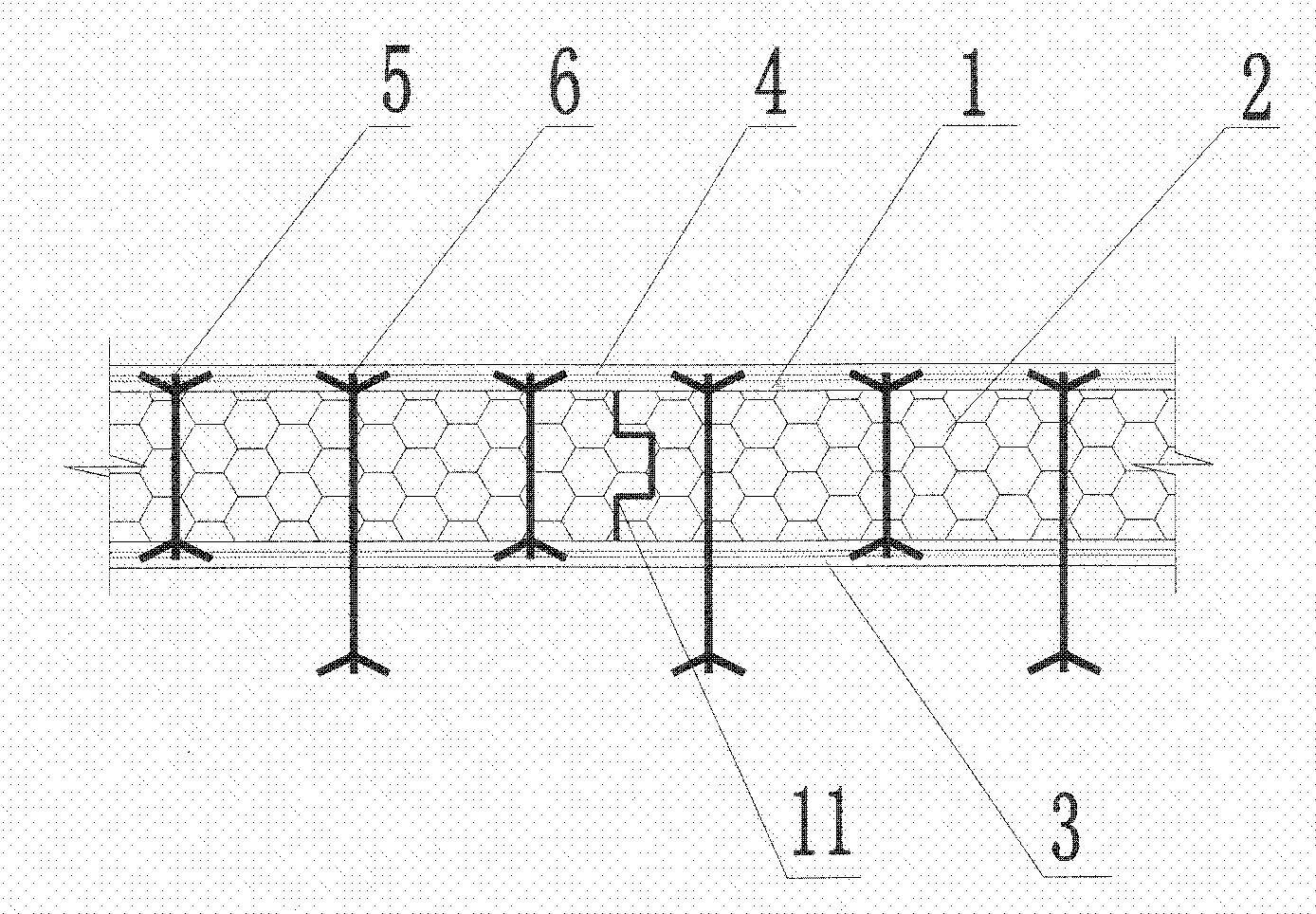

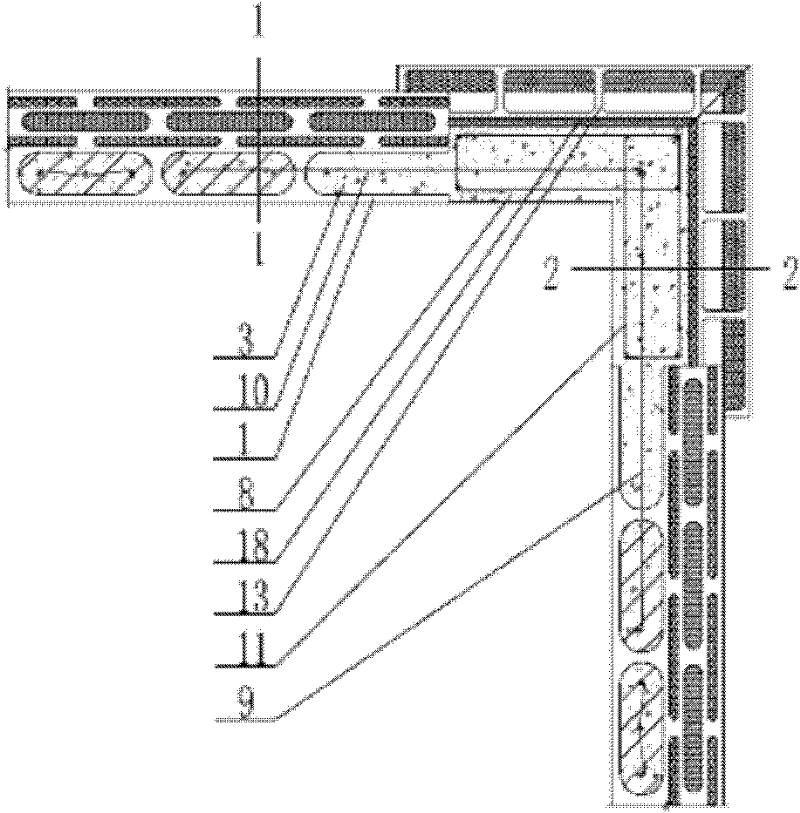

Concrete close-column and gypsum composite external wall panel without cold bridge

InactiveCN102359224ALife SynchronizationRaise the level of modernizationHeat proofingBuilding reinforcementsFiberResidence

The invention relates to a concrete close-column and gypsum composite external wall panel without a cold bridge, comprising high-strength gypsum, cement, pulverized fuel ash, waterproofing agent, fiber bars, connecting bars A, connecting bars B, light heat insulation material and plates with concrete preset cavities in the first process and on-site pouring concrete in the cavity in the second process and is manufactured by using a high-strength gypsum board layer, a light heat insulation material layer, a high-strength gypsum preset concrete cavity plate layer and a reinforced concrete close-column poured in a wall board preset concrete cavity from outside to inside; all the layers are connected by the connecting bars A and the connecting bars B which are uniformly distributed, two ends of the connecting bars are vertically split into 4-10 pieces, the high-strength gypsum board layer and the preset concrete cavity plate layer are internally provided with the fiber bars, a preset concrete cavity is provided with steel bars on site and is poured synchronous with the reinforced concrete of the integral structure of a building to form a reinforced concrete close-column; and the high-strength gypsum preset concrete cavity plate layer and the reinforced concrete close-column both participate in structural stress of the building. The wall panel integrates a plurality of functions including enclosing, bearing, sound insulation, heat insulation, seismic resistance and fire prevention and is suitable for industrialization of production modes of residences.

Owner:程松林

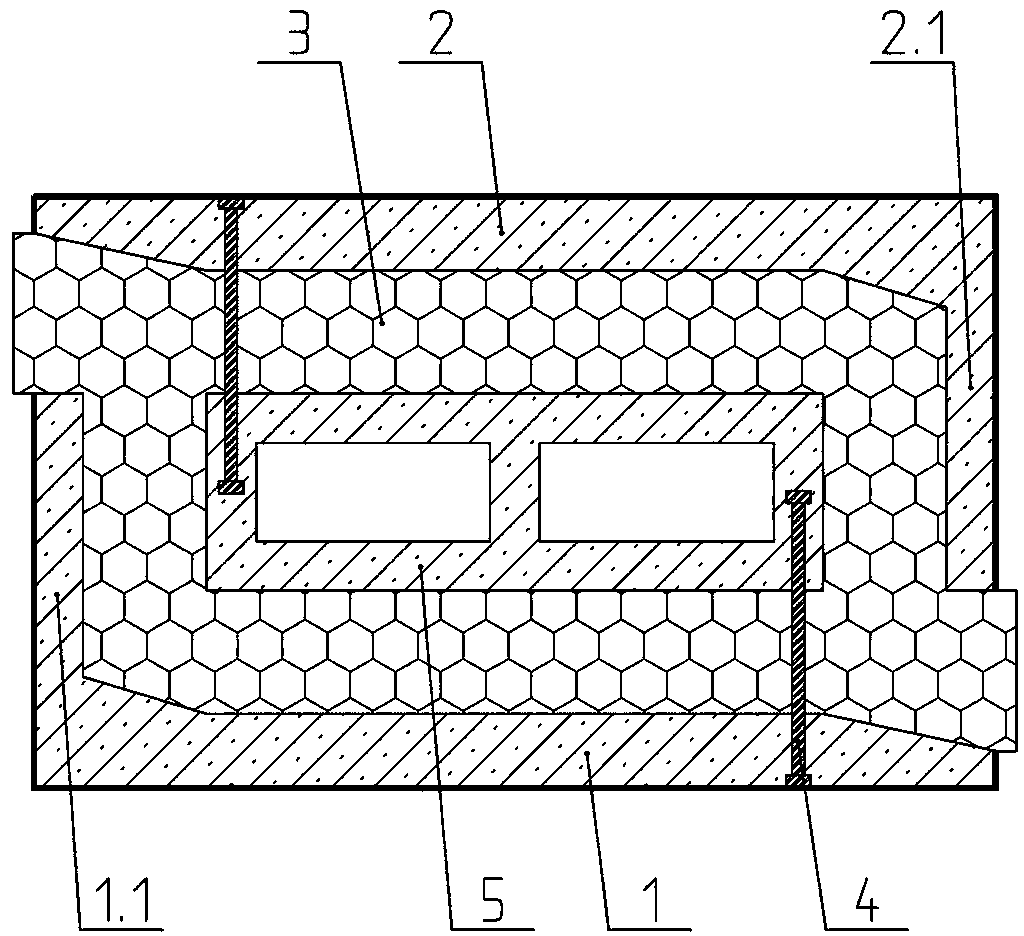

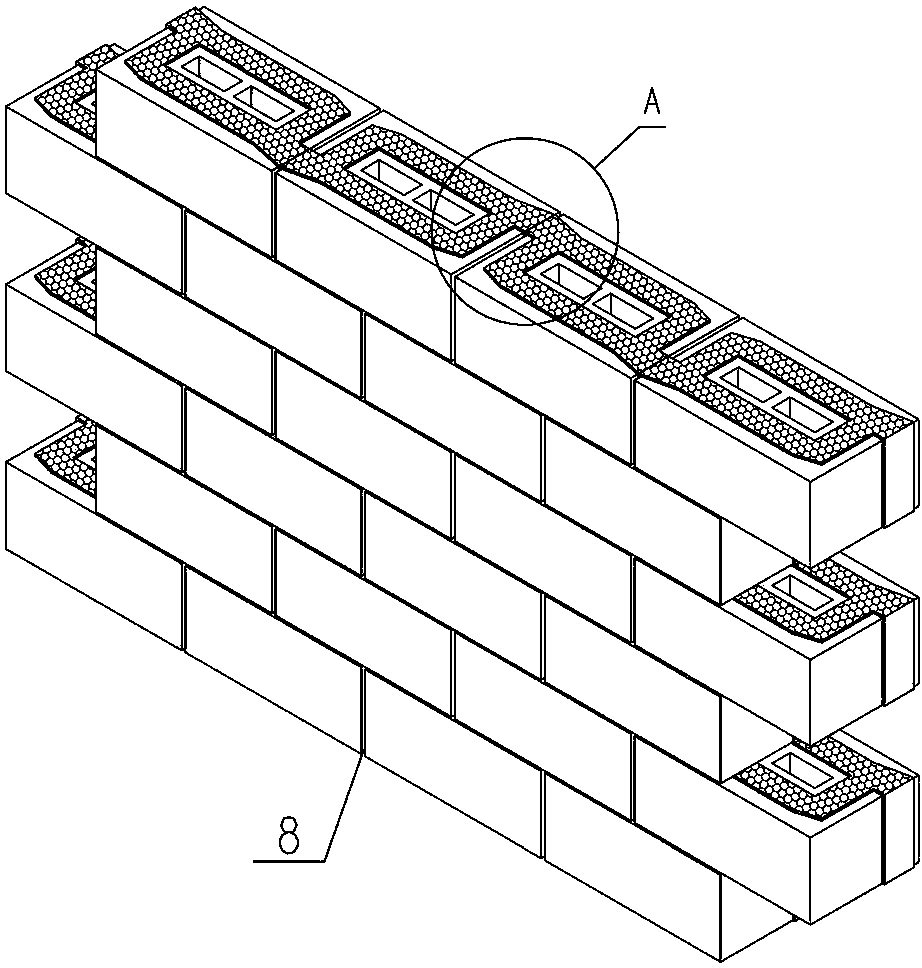

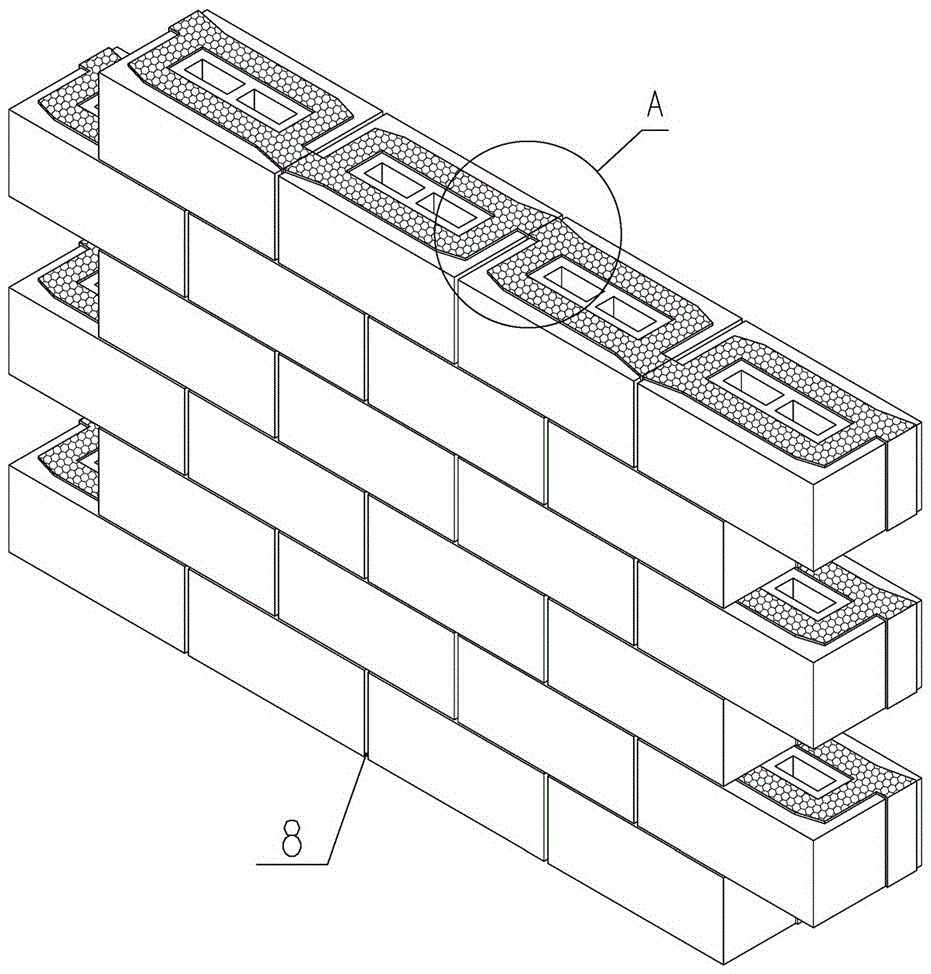

All-obstruction bridge concrete composite self-heat-preservation integrated building block

ActiveCN104278790ASynchronous lifespanLife SynchronizationConstruction materialStructural engineeringConcrete composites

Owner:刘立才

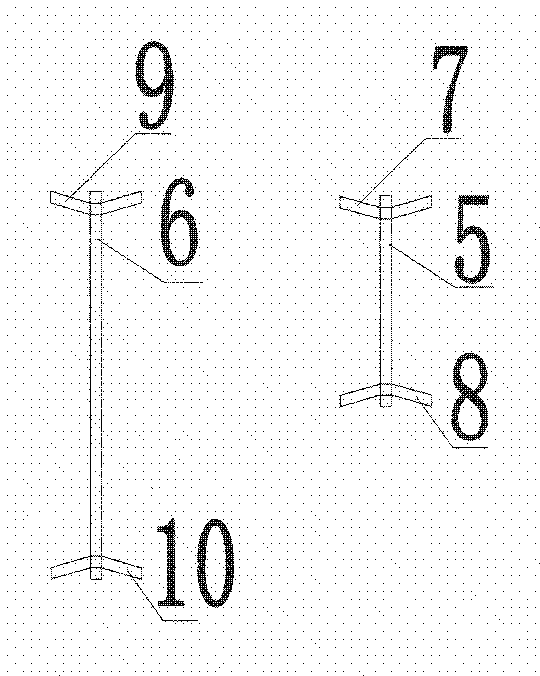

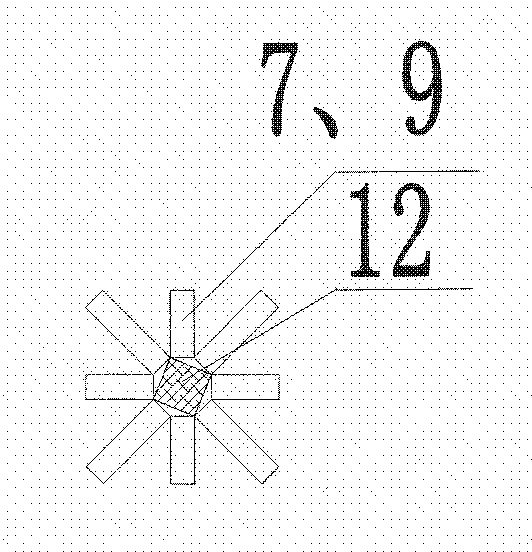

Four-step energy-saving cold-bridge-free heat insulation plate for dwelling house

ActiveCN102352678ALife SynchronizationRaise the level of modernizationCovering/liningsClimate change adaptationFiberMechanical engineering

The invention relates to a four-step energy-saving cold-bridge-free heat insulation plate for a dwelling house, which comprises high-strength gypsum, cement, flyash, waterproof agents, fiber ribs, connecting ribs A, connecting ribs B and light heat insulation materials, wherein an outer side high-strength gypsum plate layer, a light heat insulation material layer and an inner side high-intensity gypsum layer are sequentially arranged from outside to inside, all layers are connected with the connecting ribs A and the connecting ribs B in uniform distribution and staggered arrangement, the fiber ribs are arranged in the high-strength gypsum plate layer, umbrella ends at both ends of the connecting ribs A extend into the high-strength gypsum plate layer, umbrella ends at one end of the connecting ribs B extend into the outer side high-strength gypsum plate layer, and umbrella ends at the other end of the connecting ribs B pass through the inner side high-strength gypsum plate layer to beconnected with a concrete wall. The four-step energy-saving cold-bridge-free heat insulation plate for the dwelling house is used for the outer eave wall concrete exposed position of the building, the wall plate integrates multifunctions of decoration, sound isolation, heat insulation, fireproof effect, waste utilization, environment protection, energy saving, consumption reduction, light weight and high intensity into a whole, is also used as an outer side template of the external eave concrete wall or column limb of the building and is suitable for the industrialization of the dwelling production mode.

Owner:程松林

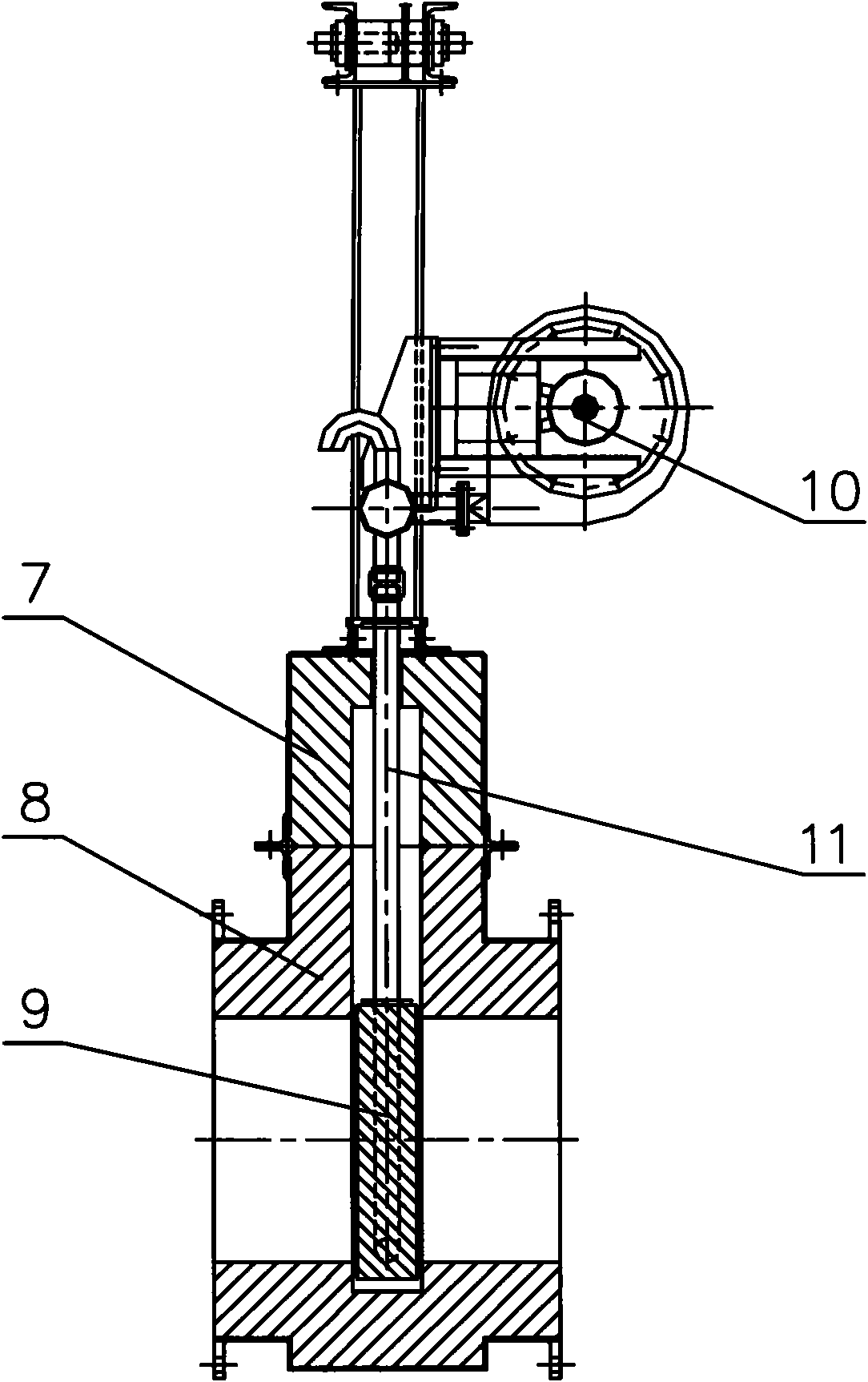

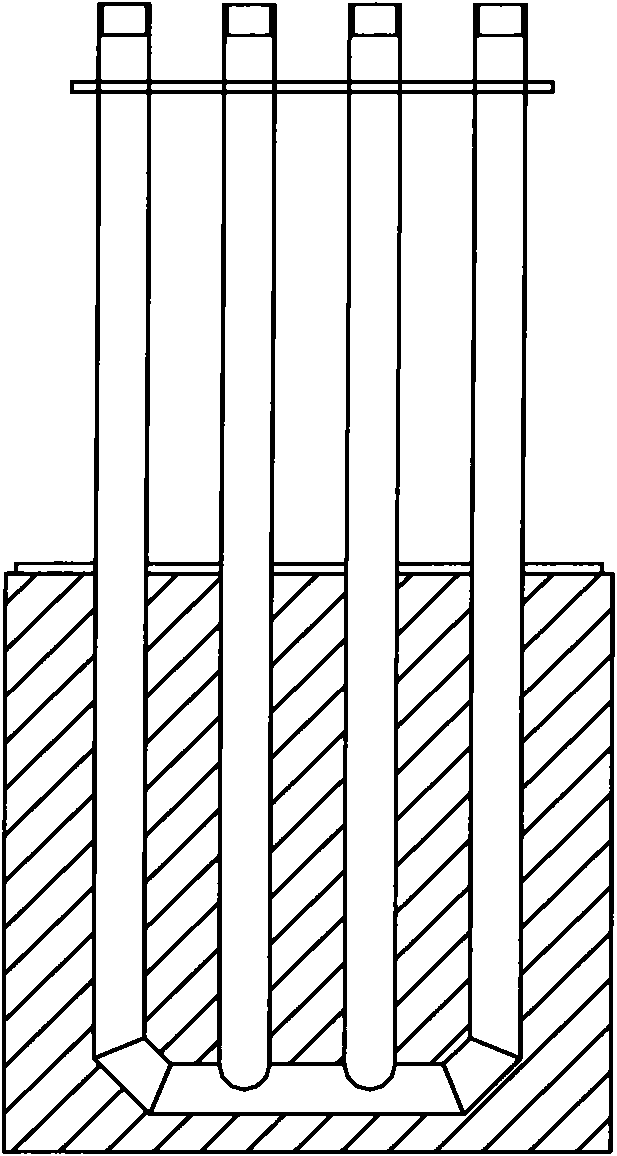

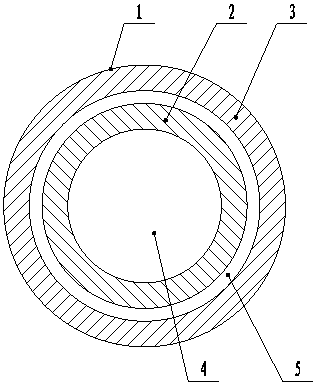

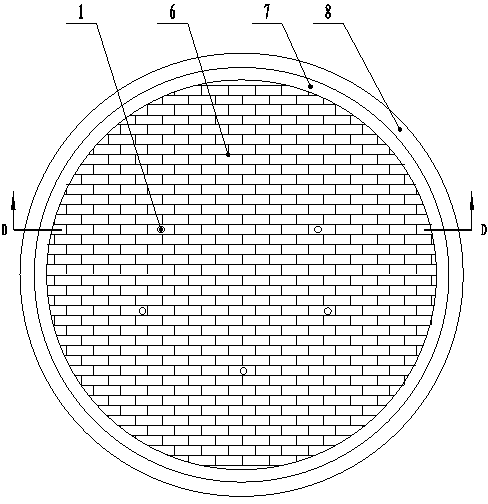

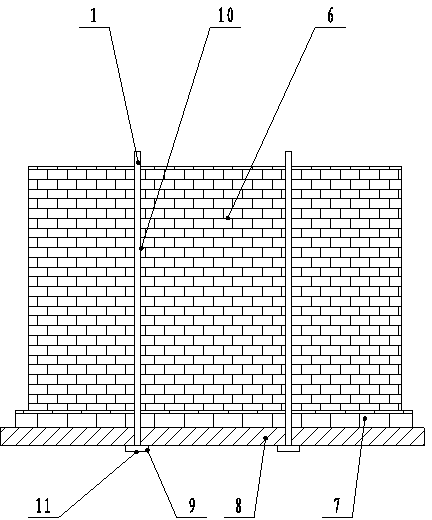

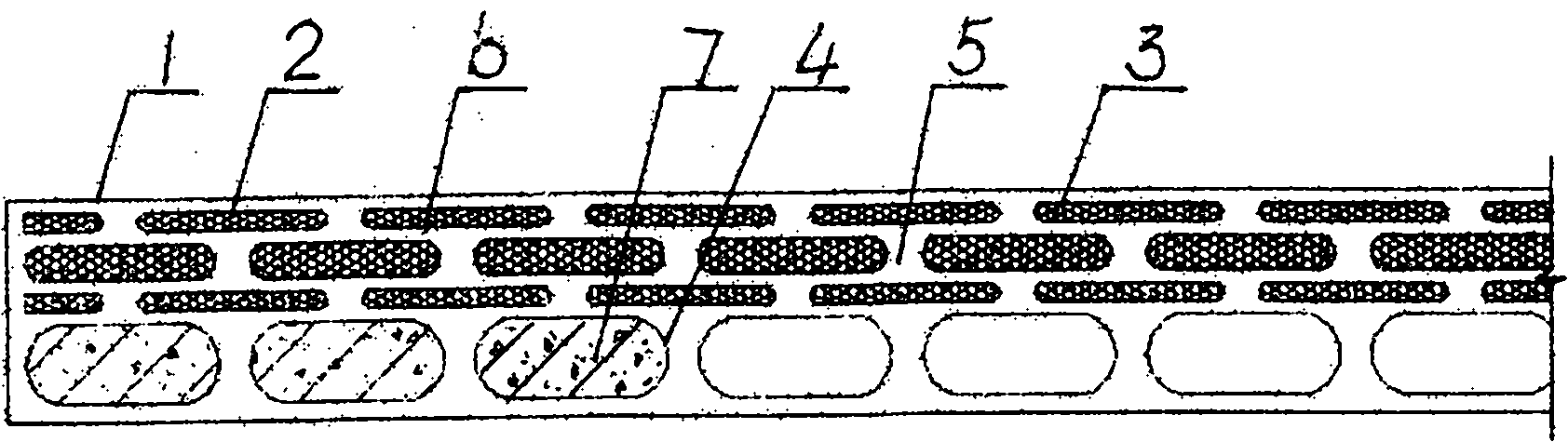

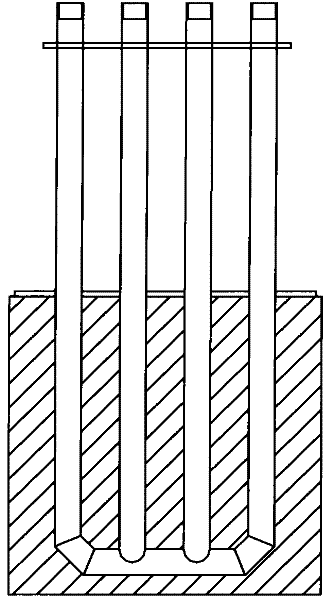

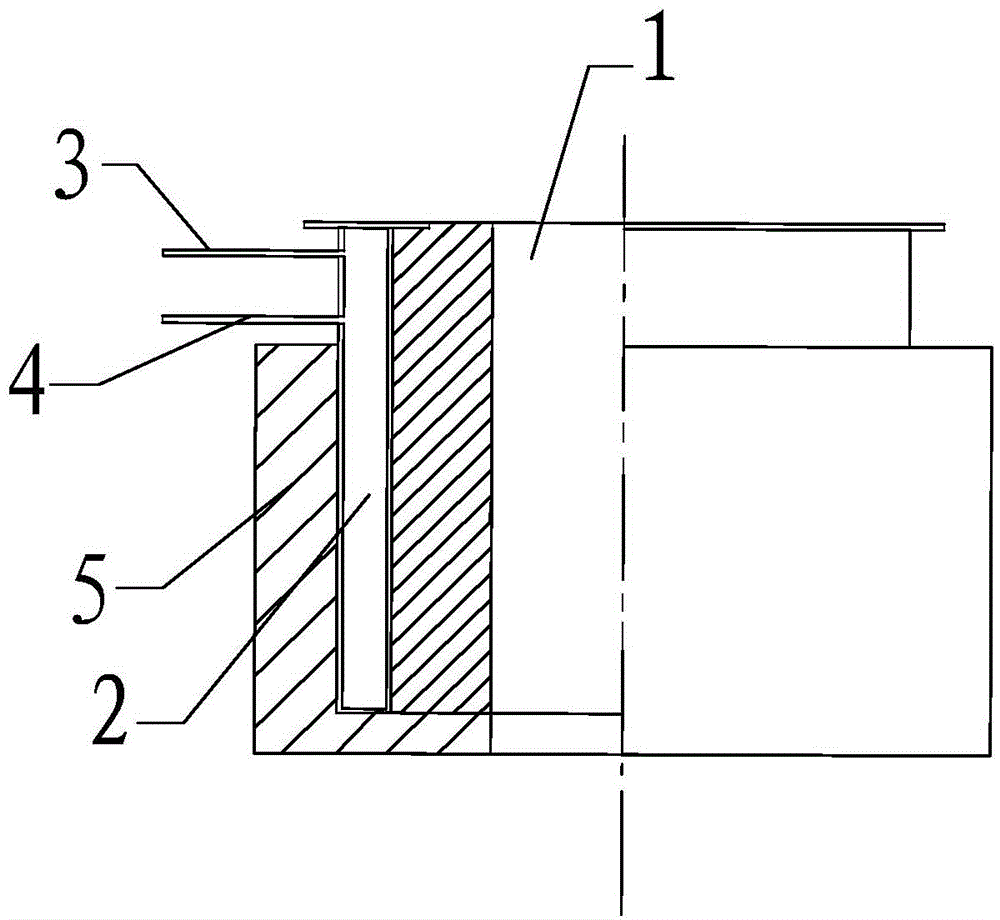

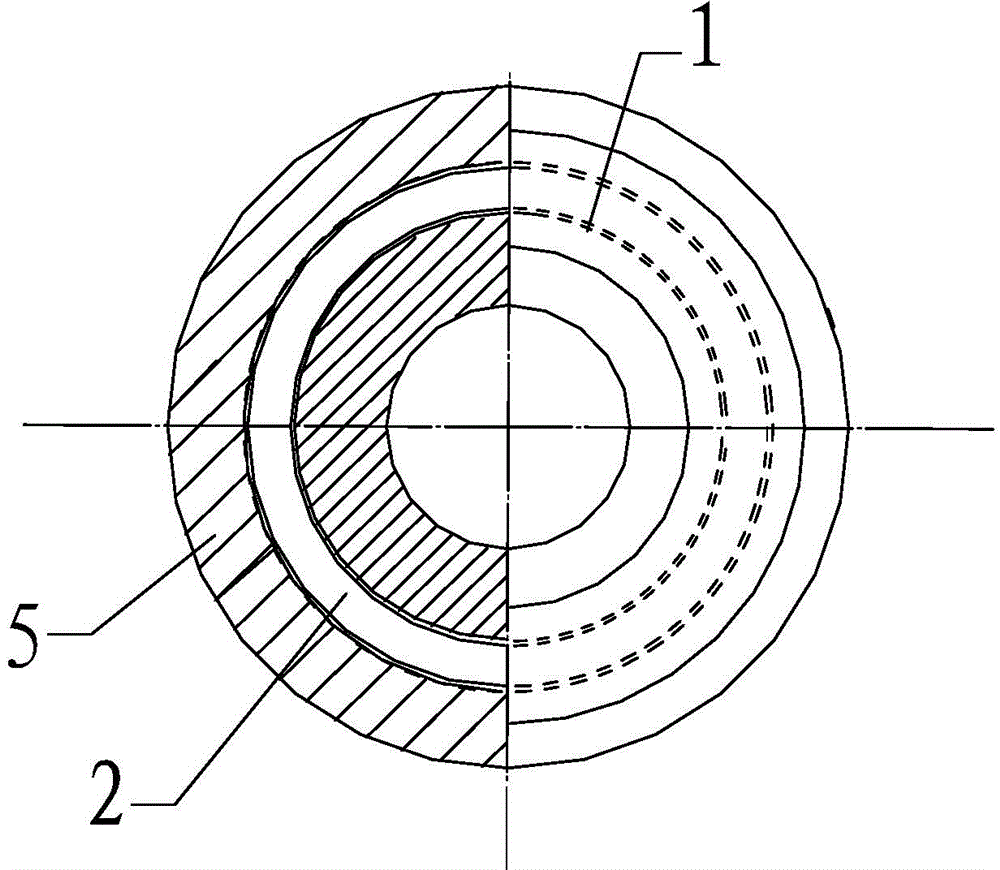

Bottom blowing gas supply method for stainless steel converter and stainless steel converter bottom thereof

ActiveCN103451361AReduce erosion rateLife SynchronizationManufacturing convertersThermodynamicsEngineering

The invention relates to a bottom blowing gas supply method for a stainless steel converter and a stainless steel converter bottom thereof. The bottom blowing gas supply method for the stainless steel converter comprises the step of supplying gas via a gap between an annular tube of a bottom gun and a central tube and a gas supply hole of the central tube, and is characterized in that the ratio of the annular sectional area of the gap between the annular tube of the bottom gun and the central tube to the sectional area of the gas supply hole of the central tube ranges from 0.4 to 0.6. The stainless steel converter bottom comprises working layer bricks, a permanent layer and a furnace bottom shell, wherein a furnace bottom flange is arranged under the furnace bottom shell; 4-6 bottom gun holes are drilled in the working layer bricks before construction. The stainless steel converter bottom is characterized in that the axis of each bottom gun hole is aligned to the hole center of the furnace bottom flange, the difference between the axis of each bottom gun hole and the hole center of the furnace bottom flange on the horizontal plane is not greater than 0.1 mm, and all bottom guns are arranged at the centers of the bottom gun holes. The bottom blowing gas supply method for the stainless steel converter and the stainless steel converter bottom thereof have the advantage that the furnace age is prolonged to more than 700 times from 450 times of an existing gas supply method.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Concrete multi-columned gypsum composite external wall panel

InactiveCN102162286ALife SynchronizationRaise the level of modernizationBuilding componentsFiberRebar

The invention provides a concrete multi-columned gypsum composite external wall panel. The preparation method of the composite external wall panel comprises the following steps: making multi-cavity plates from high-strength gypsum, a waterproofing agent, fiber-reinforced polymer (FRP) bars and light heat-insulating materials; according to weather conditions of regions with different latitudes, determining 3-6 cavity plate layers, arranging the cavity layers with equal length in a staggered manner, and uniformly distributing the FRP bars on plate walls and ribs; and arranging the light heat-insulating materials at 2-5 cavity layers at the outer side, reserving concrete cavities at the inner side, configuring reinforced bars on site, and casting the configured reinforced bars along with reinforced concrete of an overall building structure so as to form multi-columned reinforced concrete in the plates. The gypsum plate bodies and the multi-columned reinforced concrete in the plate cavities participate in load-bearing and anti-seismic stress of a building structure. The wall panel has the functions of enclosure, load bearing, sound insulation, heat preservation, seismic resistance, fire prevention and the like; and the wall panel has the advantages of integrated multiple functions such as energy conservation and consumption reduction as well as environmental protection, economy and applicability, capability of realizing industrial production and integrated application, and the structural mechanism of the wall panel has universality and advancing performance for coping with four-step energy conservation of a residential house.

Owner:天津开发区福林发展有限公司

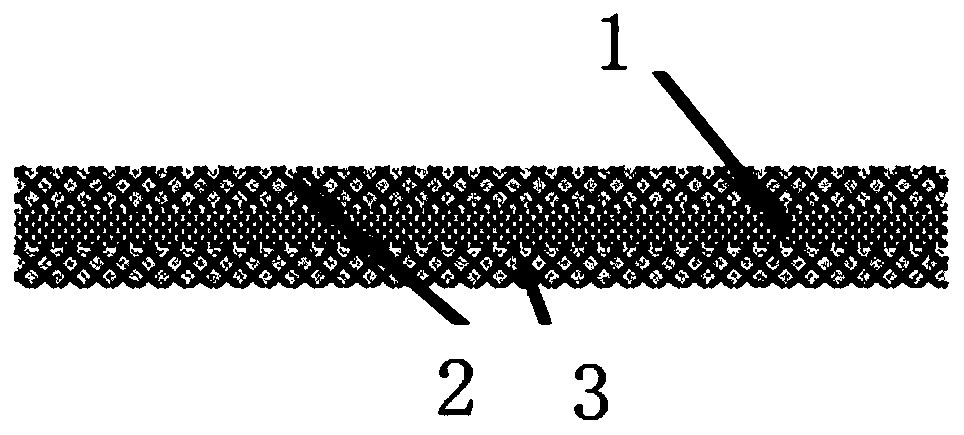

Fiber reinforced cement-based thin cloth and infilled wall composite structure and construction process thereof

InactiveCN109914845AExcellent energy savingImprove insulation effectConstruction materialBuilding repairsComposite constructionEpoxy

The invention provides a fiber reinforced cement-based thin cloth and infilled wall composite structure and a construction process thereof. Fiber reinforced cement-based thin cloth sequentially comprises a first thin cloth layer, a cement base layer and a second thin cloth layer from bottom to top, and the first thin cloth layer, the cement base layer and the second thin cloth layer are fixed intoa whole through the bonding effect of the cement base layer. Aerated concrete self-heat-preservation building blocks are adopted as wall materials of an infilled wall, after building is completed, epoxy resin glue is sprayed to the surface of the wall, the fiber reinforced cement-based thin cloth is laid along the wall, water is evenly sprayed to the laid wall, the thin cloth and the wall are fully combined, and thus the infilled wall composite structure is formed. The composite structure is a wall structure which is reasonable in structure and synchronous in service life of all layers, the durability and shock resistance are remarkably improved besides energy conservation and heat preservation, the problems that a self-heat-preservation material serving as a frame infilled wall is lightand not high in strength, cracks are likely to be generated and the like are solved, material preparation is simple, the cost is low, and the construction technology is simple and convenient.

Owner:YANCHENG INST OF TECH

Method for replacing converter bottom blowing seat brick

ActiveCN110184412ALife SynchronizationRealize the bottom blowing of the whole furnaceManufacturing convertersProcess efficiency improvementFull serviceEngineering

The invention discloses a method for replacing a converter bottom blowing seat brick. The method specifically comprises the following steps of stopping and cooling a converter, determining a patchingposition at the bottom of the converter, patching, installing a new converter bottom blowing seat brick, maintaining the new converter bottom blowing seat brick, and thermally replacing a bottom blowing element. According to the method, the old converter bottom blowing seat brick is replaced with the converter bottom blowing seat brick, and therefore the problems that the bottom blowing element isblocked and cannot be used after serious erosion in the later service period of the converter are solved; multiple replacement of bottom blowing at the same bottom blowing point of the converter is achieved, and the service life of the bottom blowing element is synchronous with that of the single-service converter, thus, the full-service bottom blowing of the converter is ensured, and the methodhas important significance for achieving the full-service bottom blowing and the repeated quick replacement of the bottom blowing at the same bottom blowing point; and the converter bottom and jointsafter the bottom blowing replacement have no redness and steel infiltration.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

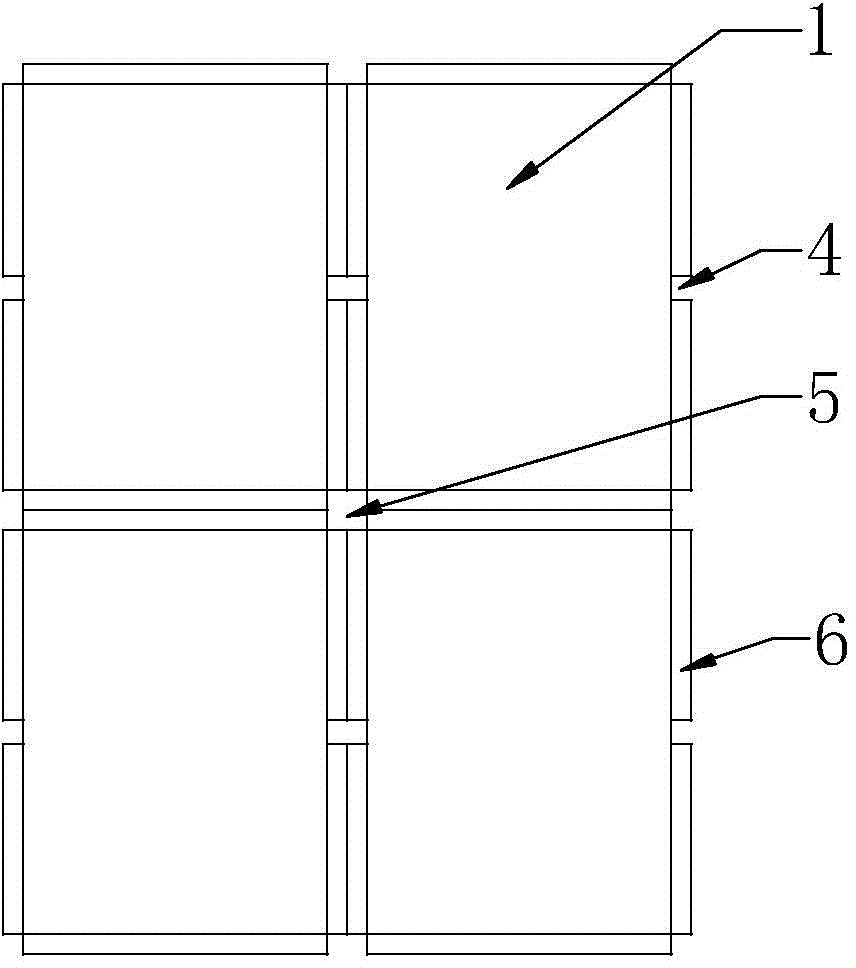

Novel thermal-insulation and decoration integrated plate and preparation method thereof

InactiveCN105298053AImprove the overall decorative effectSolve wall cracksCovering/liningsThermal insulationWeather resistance

The invention discloses a novel thermal-insulation and decoration integrated plate. The novel thermal-insulation and decoration integrated plate is sequentially provided with a decoration plate layer, a bonding layer and a thermal-insulation material layer from inside to outside, wherein the decoration plate layer is subjected to punch forming by a metal material; three mounting grooves are respectively formed in two sides of the integrated plate; the mounting grooves of the adjacent integrated plates are jointed to form mounting holes; the integrated plate is fixedly connected with a wall through anchoring nails arranged in the mounting holes; and sealing slots are respectively formed in the periphery of the integrated plate. The invention also discloses a preparation method of the thermal-insulation device integrated plate. The preparation method comprises the following steps: passivation of a metal panel, primary coating, surface coating, film mulching, cutting and extrusion forming of a composite metal thermal-insulation and decoration plate. A whole decorating effect is improved comprehensively, and the problem of cracking of the wall is solved thoroughly; and a construction technology is simple, working procedures are small, industrialized production is realized really, and by rolling groove forming and a six-hole anchoring mounting method, the working period is greatly shortened; and composite cost is relatively low, the service life of facing is long and is equal to that of a building, and weather resistance of a system can be above 50 years.

Owner:丁勋华

Degradable antibacterial toy material and preparation method thereof

InactiveCN110256830AStrong antibacterial activityEasy to processCoatingsPolyvinyl alcoholChitin formation

The invention especially relates to a degradable antibacterial toy material and a preparation method thereof, belonging to the technical field of degradable materials. The degradable antibacterial toy material comprises a degradable antibacterial outer film and a degradable toy core blank. The degradable antibacterial toy material is characterized in that the degradable antibacterial outer film comprises deacetylated chitin, polymethylethylene carbonate, polyvinyl alcohol, polyhydroxybutyrate, stearic acid, a tetrabutyl titanate aid solution, etc.; the degradable toy core blank is straw; and the degradable antibacterial outer film is melted to form a thin film which coats the outer surface of the toy core blank to form a toy. According to the invention, deacetylated chitin, polymethylethylene carbonate, starch and the like are used as raw materials of the degradable antibacterial outer film; the prepared material has the characteristics of simple process, convenient operation, complete biodegradability and the like; and straw is used as the main component of the toy core blank and has the advantages of complete degradability and good processability.

Owner:惠州市惠阳区键力塑胶制品有限公司

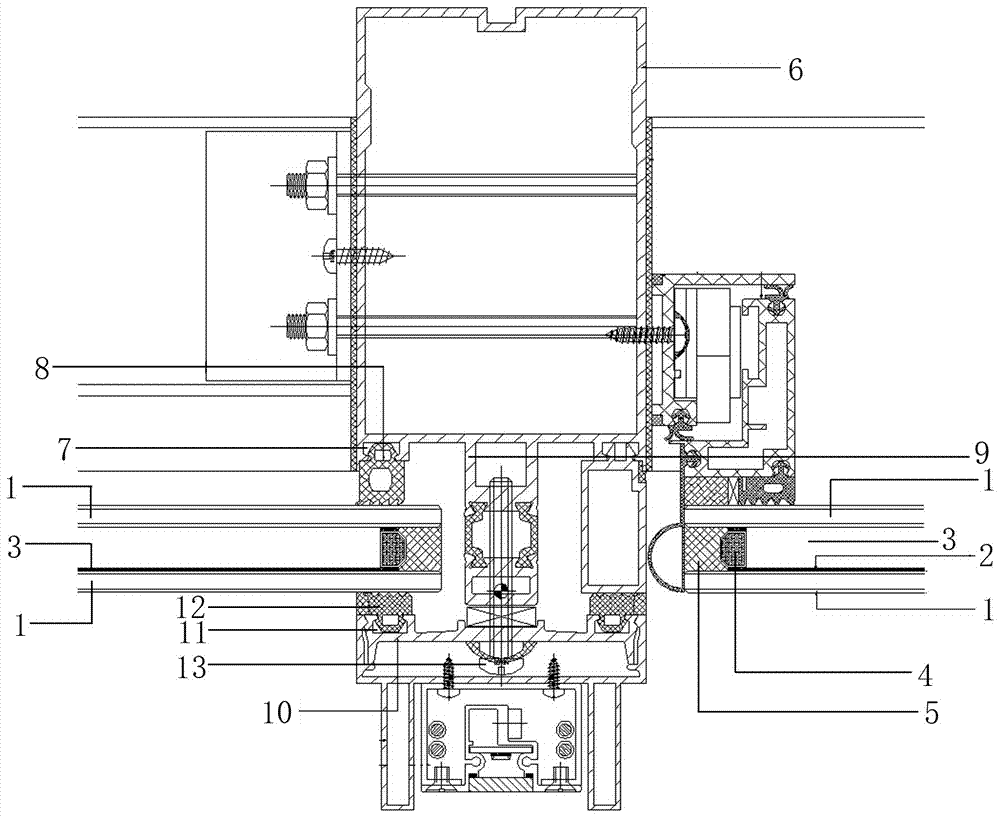

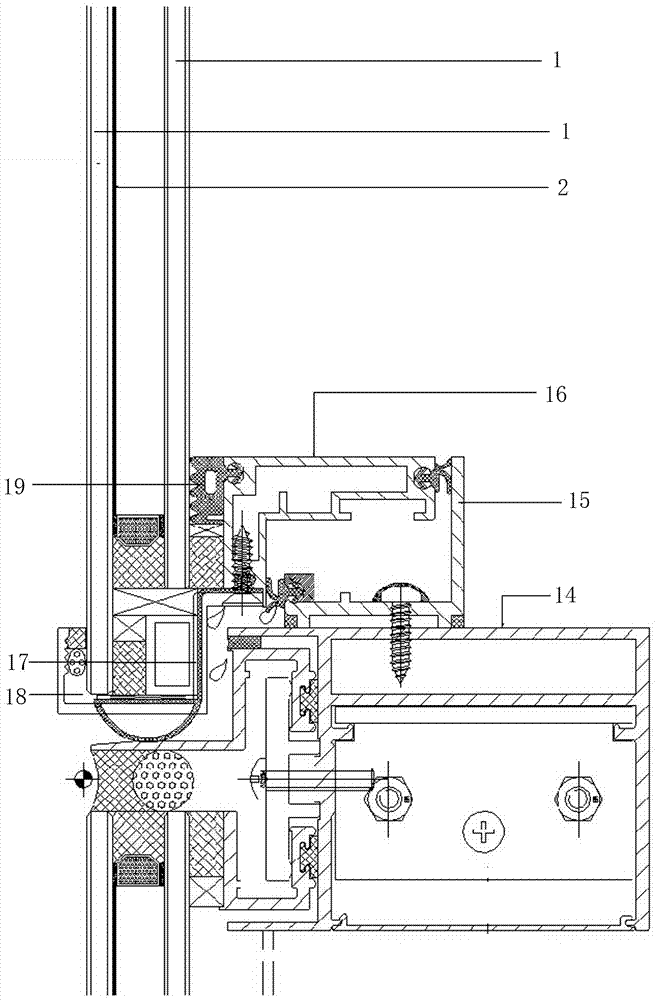

Curtain wall node structure made from low-radiation film-mounted hollow glass instead of laminated hollow glass

InactiveCN107130714ALife SynchronizationPlay the role of energy-saving sunshadeWallsWing arrangementsEngineeringActual use

The invention discloses a low-emissivity film-attached hollow glass curtain wall node structure replacing laminated insulating glass. The low-emission film-attached hollow glass is composed of two pieces of semi-tempered ultra-white glass, and the inner surface of the semi-tempered ultra-white glass located on the outside is covered with a A low-radiation anti-riot film, a hollow interlayer is formed between two pieces of semi-tempered ultra-clear glass, an aluminum frame is set between the edges of the two pieces of semi-tempered ultra-clear glass, and the outer edge of the aluminum frame is filled with sealant. The curtain wall hollow glass is made of Three pieces become two pieces; the low-emissivity functional film attached to the outer glass of the glass curtain wall completely prevents the glass from bursting and falling; Choose different color films according to the requirements of architectural design to produce a good building facade effect; after attaching low-radiation functional film to make insulating glass, since the low-radiation functional film is in a hollow and oxygen-isolated environment, the life of the functional film is basically the same as that of glass Synchronize.

Owner:SHANGHAI LONGREN CONSTR GRP

Four-step energy-saving cold-bridge-free heat insulation plate for dwelling house

ActiveCN102352678BLife SynchronizationRaise the level of modernizationCovering/liningsClimate change adaptationFiberEaves

Owner:程松林

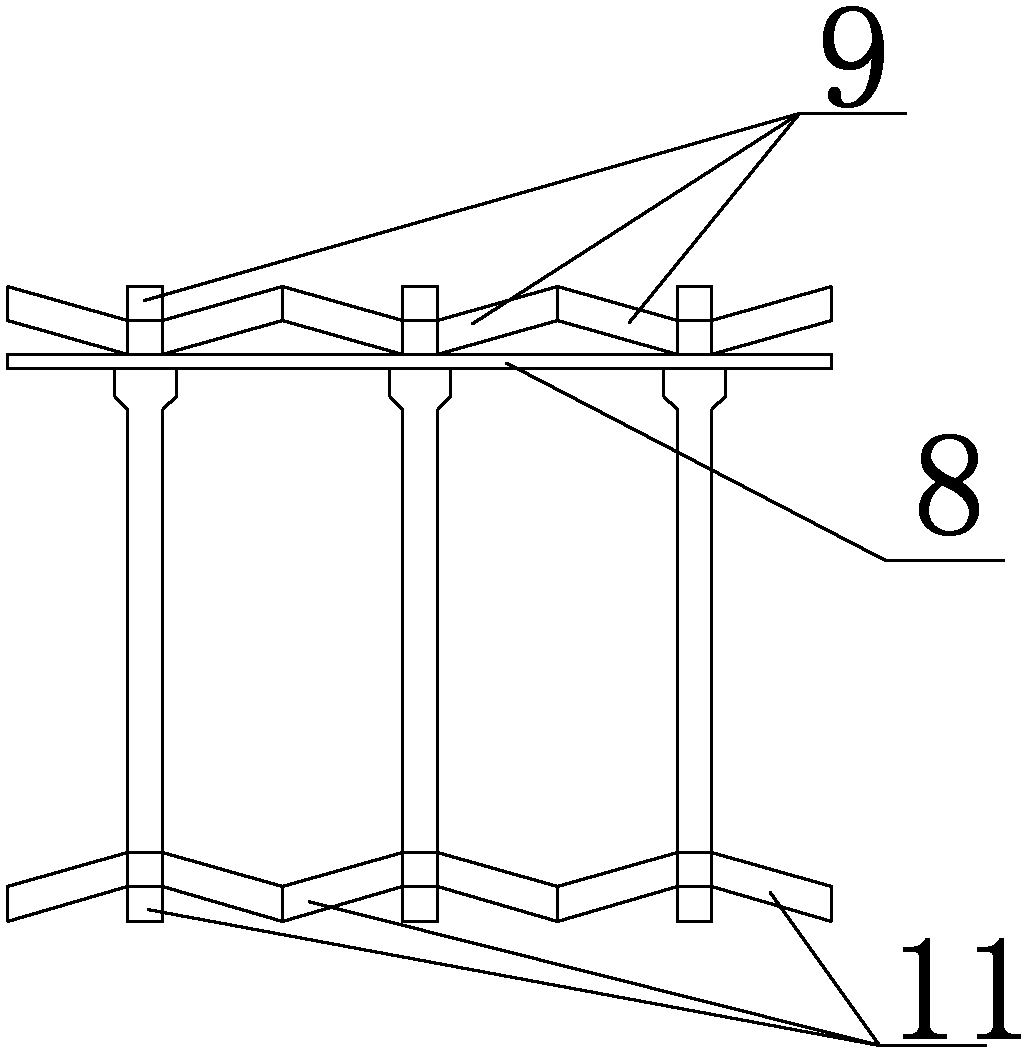

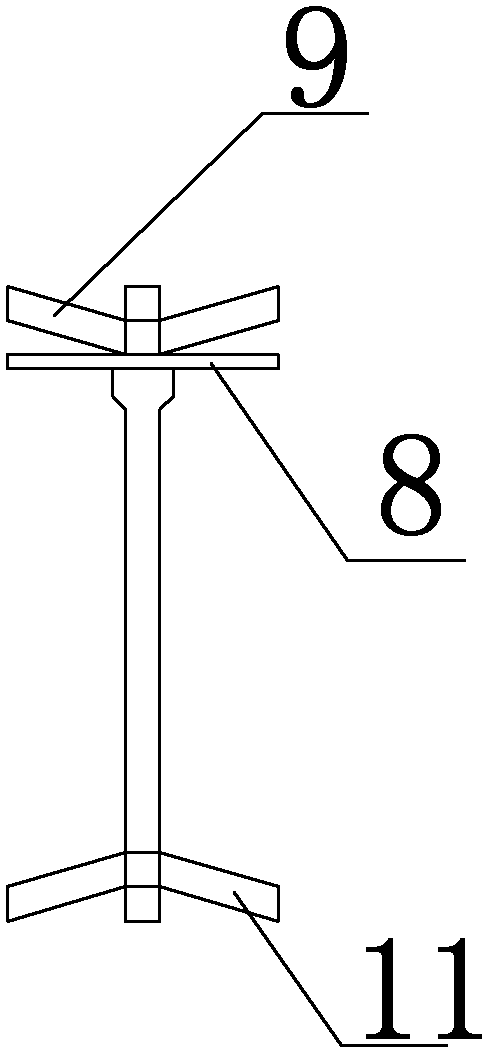

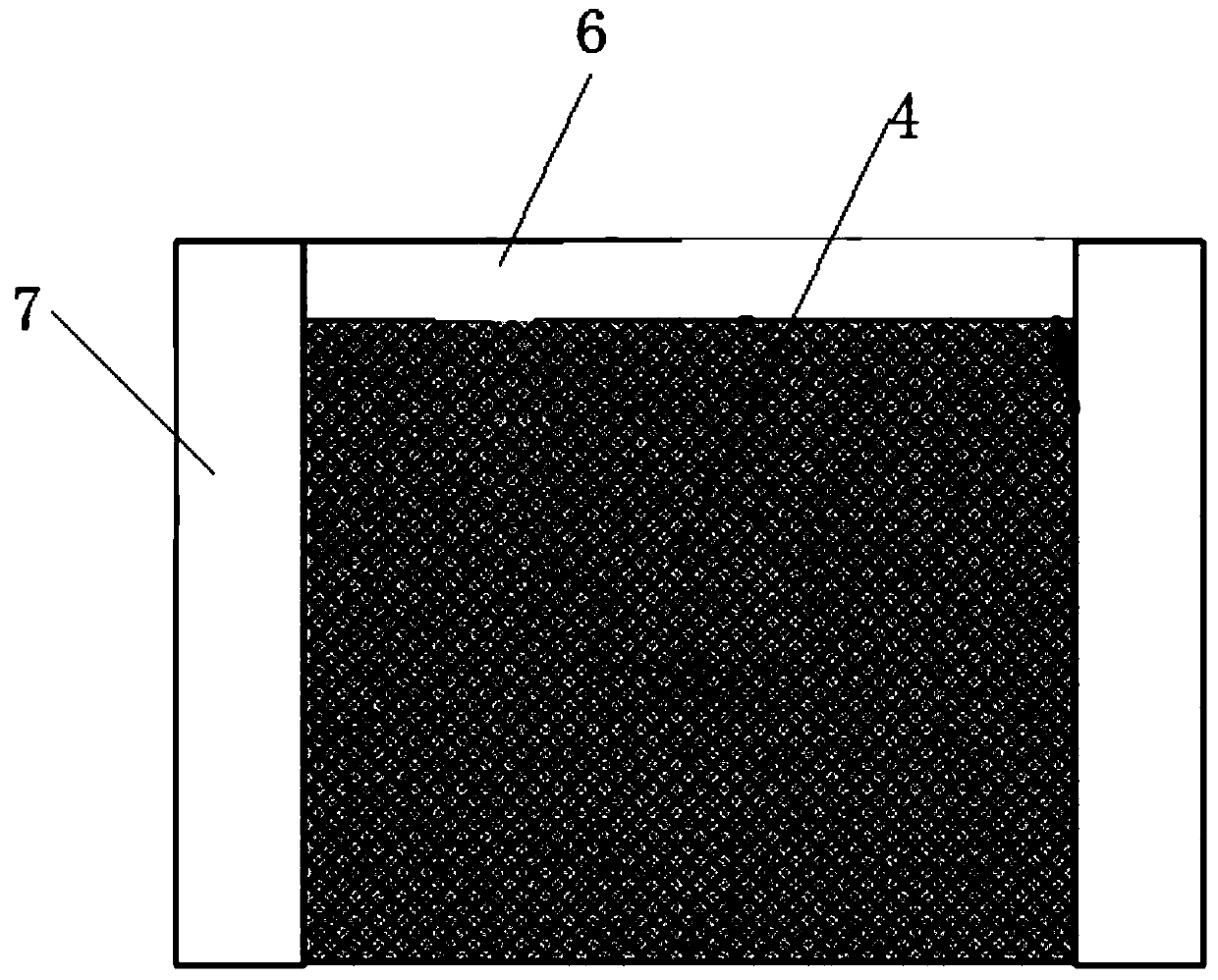

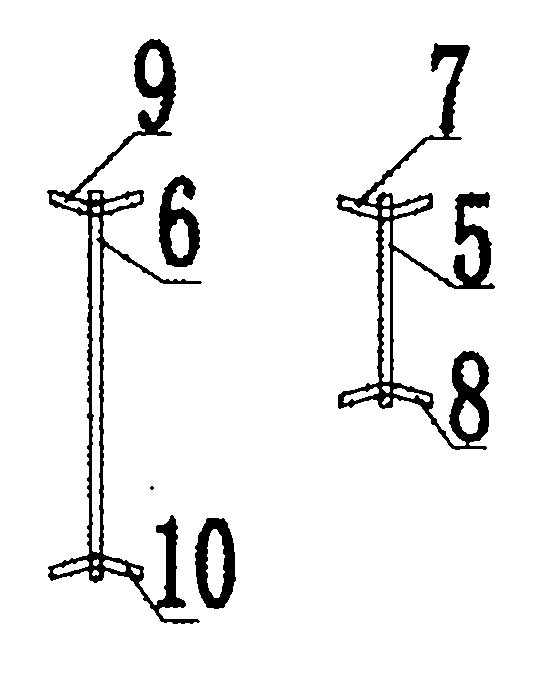

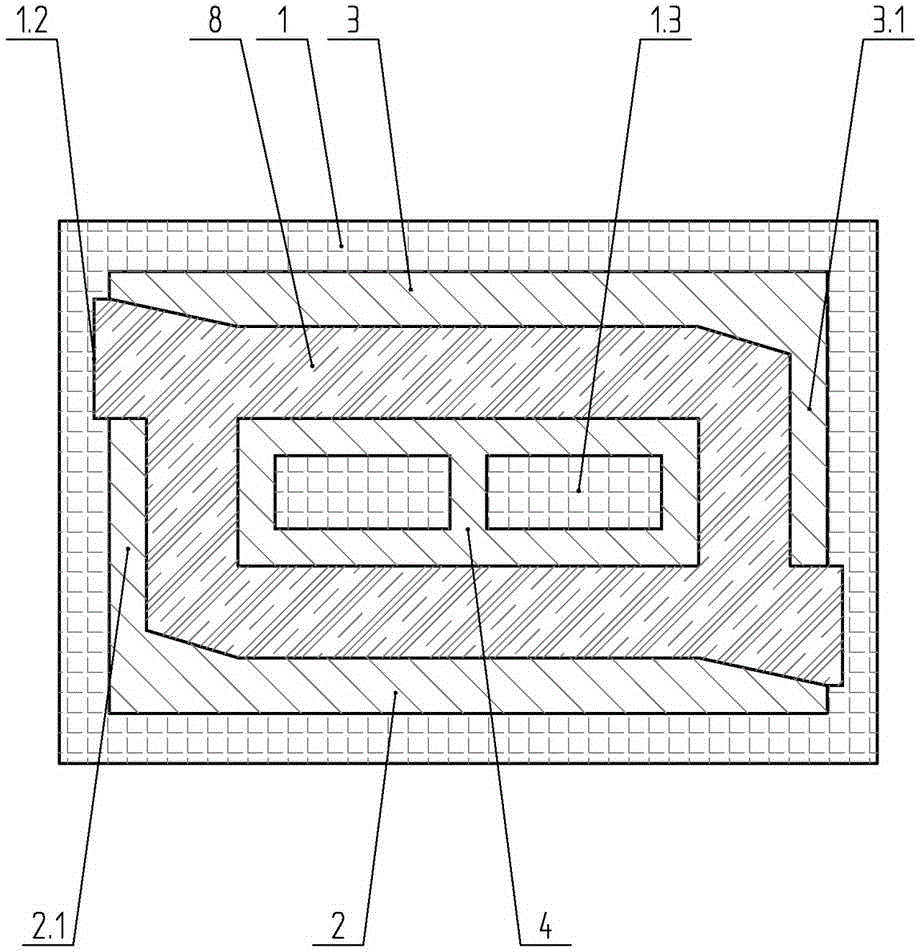

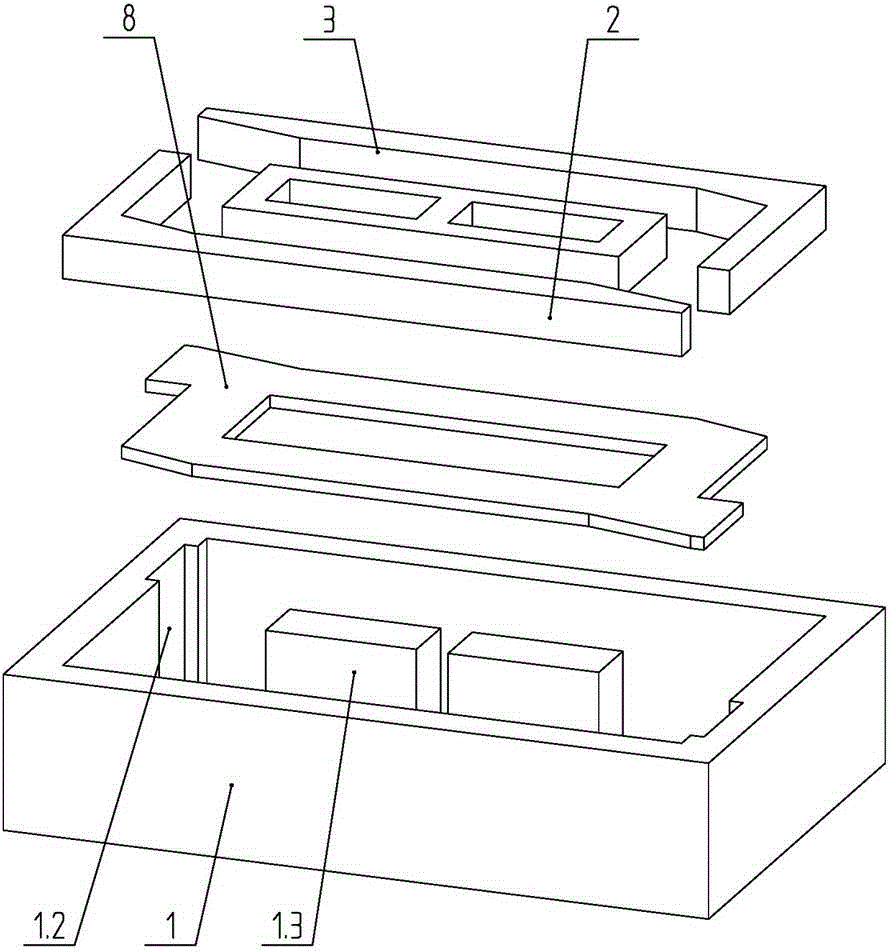

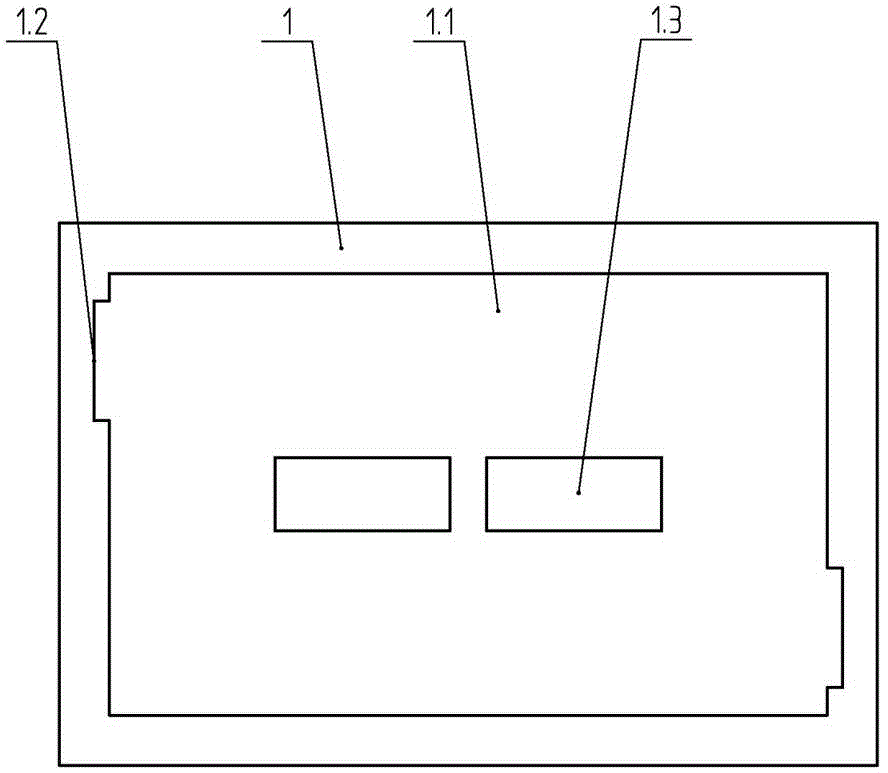

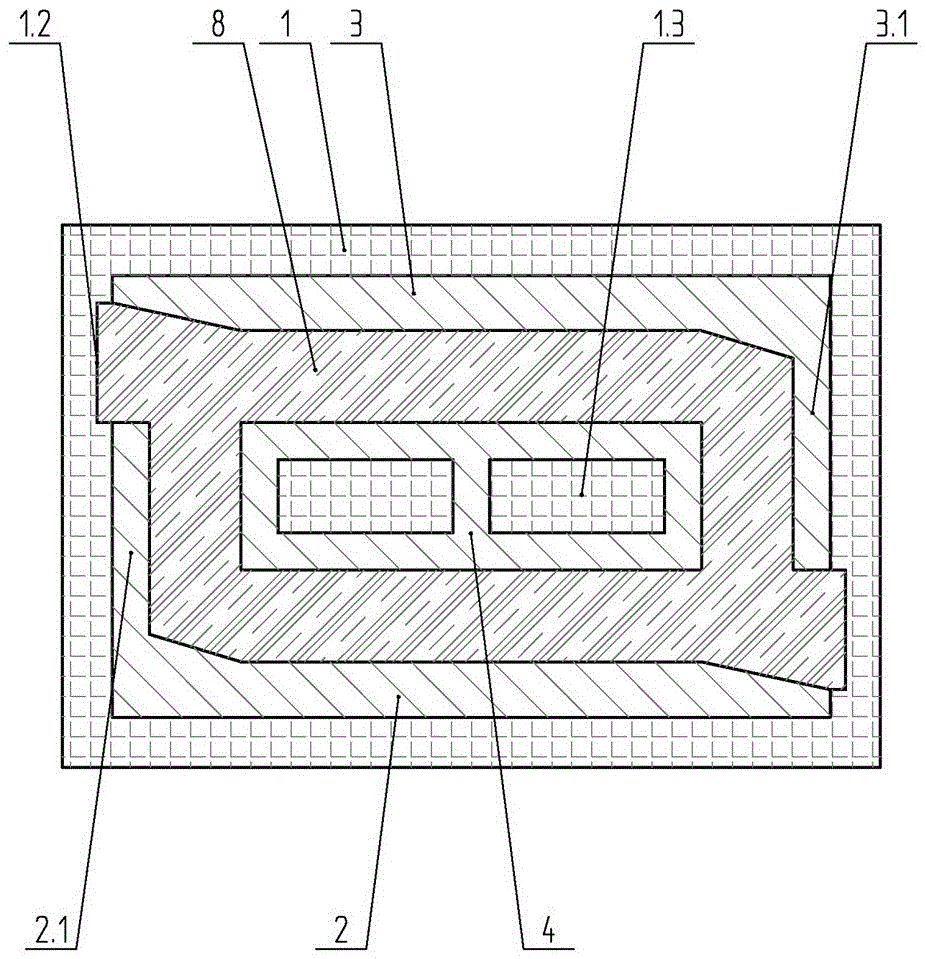

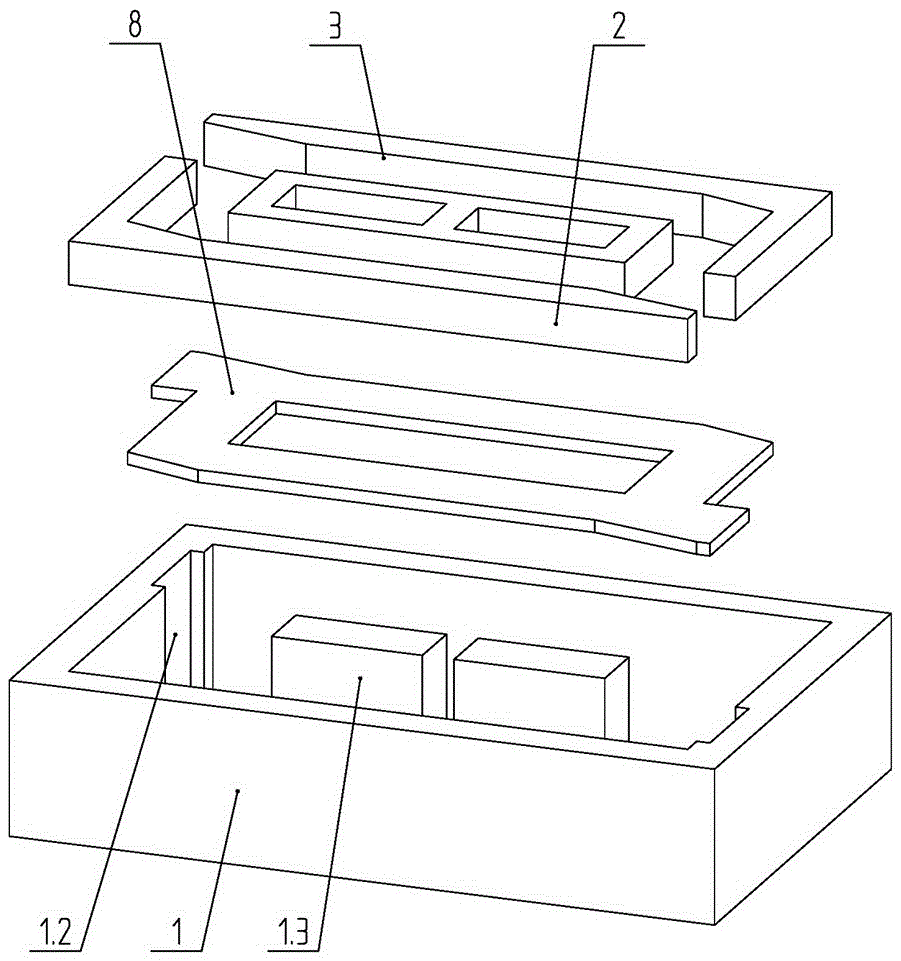

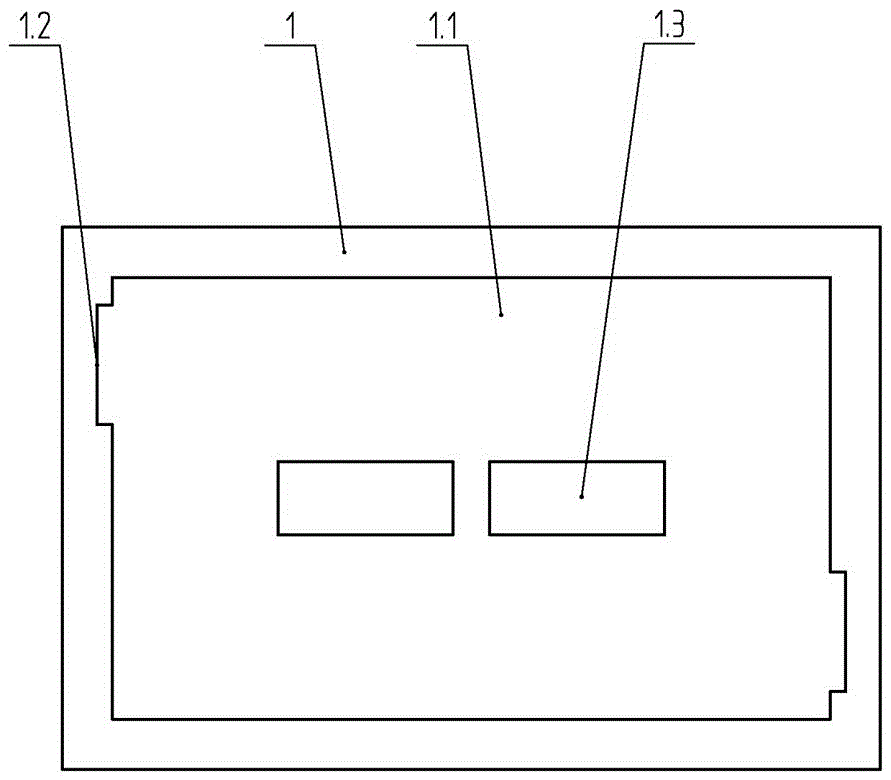

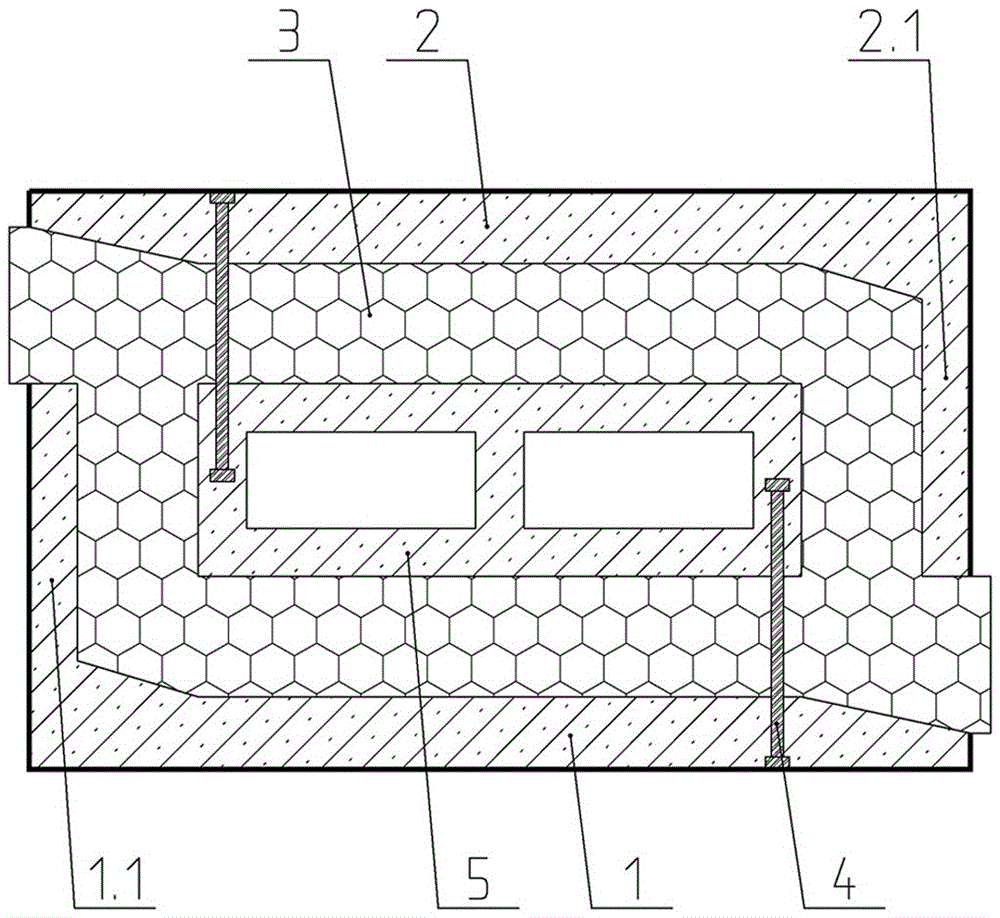

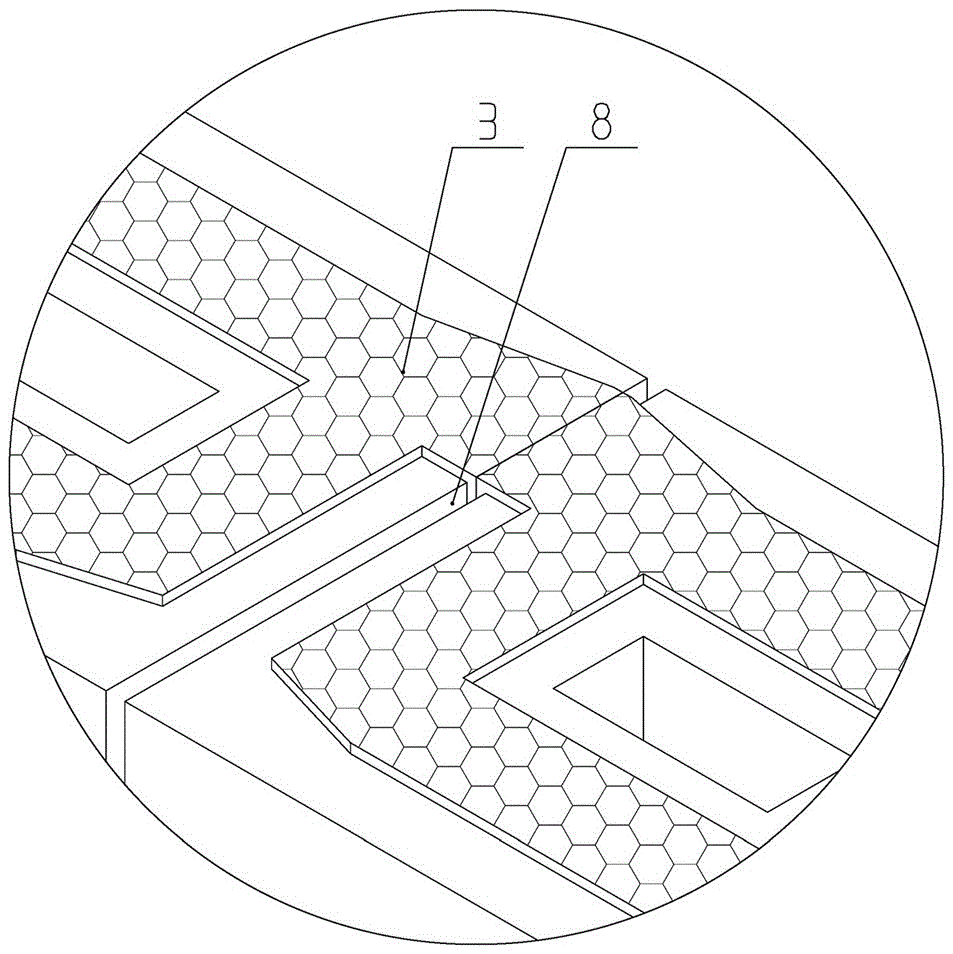

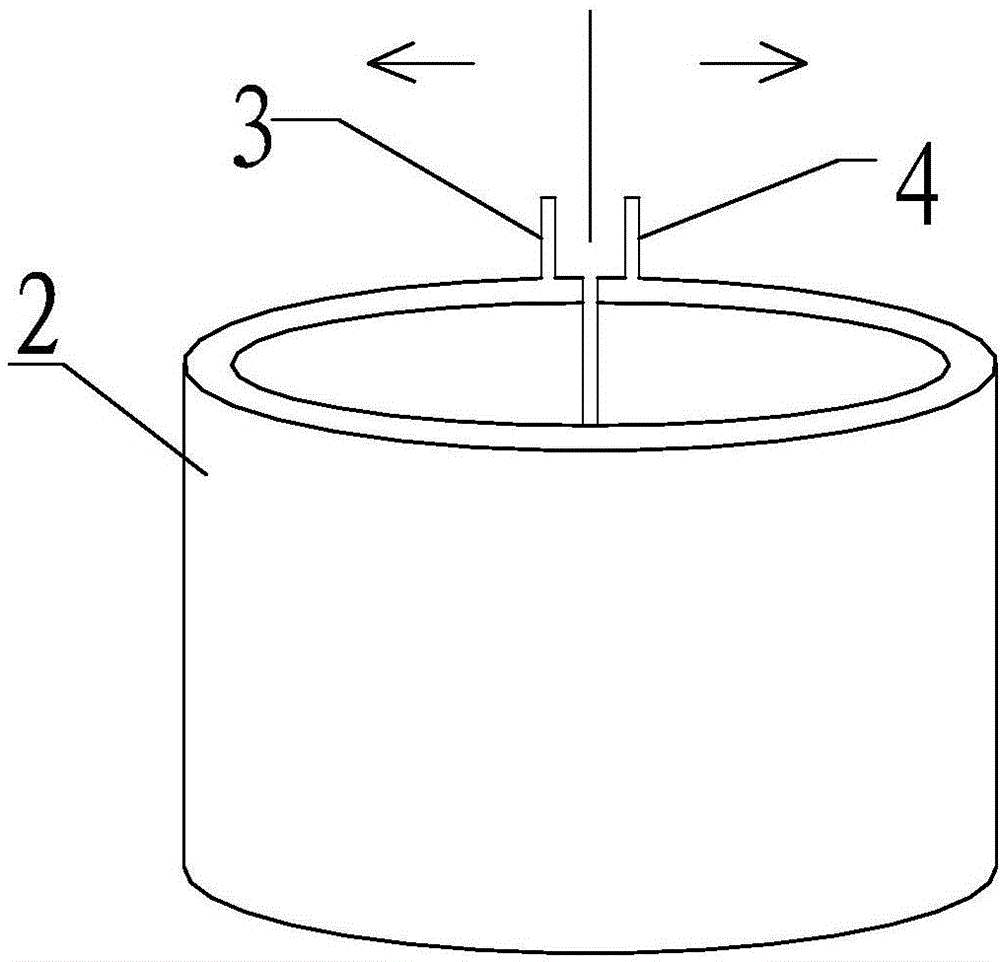

Mold for manufacturing fully-blocking bridge concrete compound insulation block

A mold for manufacturing a fully-blocking bridge concrete compound insulation block comprises an outer mold, a pressing mold and a mold cover. The outer mold is provided with a rectangular inner cavity which penetrates through the upper end face and the lower end face of the outer mold, and the opposite inner walls of the rectangular inner cavity are each provided with a first vertical groove. The outer contour of the pressing mold is matched with the contour of the rectangular inner cavity. The outer contour of the mold cover is matched with the inner contour of the pressing mold. The mold has the advantages that the mold has the unique shape, so that it is guaranteed that a concrete shell of the manufactured block is completely partitioned by a polystyrene board and therefore a hot bridge can not be formed; the energy-saving efficiency reaches 75%, the latest national mandatory standard at the present stage is met, the conventional defects that cracks, empty plumps, leakage, disengaging and the like are likely to happen in technology when heat insulation materials are externally attached to and hung to the outer portion of a building body at present are completely overcome, the construction cost is lowered, the process procedures are reduced, the construction period is shortened, and the worries to the heating and refrigerating cost, which is continuously increased, of owners in later period are relieved.

Owner:刘立才

Street lamp adopting LED light source

InactiveCN102109134BGuaranteed flatnessImprove cooling effectPoint-like light sourceLighting heating/cooling arrangementsEngineeringControl circuit

A street lamp adopting an LED light source comprises a lamp housing, a reflecting shade, a light-emitting port, a light-transmittable shade and an LED light source module, wherein the reflecting shade is arranged in the lamp housing; the light-emitting port is arranged on the lamp housing; the light-transmittable shade is arranged at the light-emitting port; the LED light source module is fixed in the reflecting shade, and comprises a first stamping sheet metal, a second stamping sheet metal, a third stamping sheet metal, a plurality of LED chips and a control circuit board; the LED chips arearranged on the second stamping sheet metal; the control circuit board is connected with the LED chips; the second stamping sheet metal is provided with a mounting port used for fixing the control circuit board; a plurality of openings for limiting an area with point fluorescent powder glue are formed on the third stamping sheet metal; the LED chips are stuck on the second stamping sheet metal inpositions corresponding to the openings; and the first stamping sheet metal, the second stamping sheet metal and the third stamping sheet metal are fixed with one another through a connecting mechanism. The street lamp adopting the LED light source has the advantages of good heat dissipation performance, low cost and long service life.

Owner:厦门宝晨照明科技有限公司

A heat preservation and decoration integrated board installing process

InactiveCN105804411ASolve crackingLife SynchronizationBuilding material handlingTectorial membranePaper adhesive tape

The invention provides a heat preservation and decoration integrated board installing process comprising the steps of checking and treating a base layer wall body; arranging grid division marking lines; moistening the wall body with water; gradually rubbing, pasting and pressing heat preservation and decoration integrated boards with back adhesive to proper positions meeting the requirement for flatness; removing flashes and burrs on the end surfaces of grid division gaps and redundant adhesive on adhesive applying portions; snapping the lines according to the design width of the grid division gaps; attaching paper adhesive tape to the lines and pasting the paper adhesive tape firmly; performing blade coating of high quality elastic weather-proof pointing glue; 24 hours after the pointing glue is applied, drill holes at cross intersecting positions or the middle portions of board joints at the intervals of 3-5m; applying pointing glue in the holes and on the peripheries of venting plugs and embedding the venting plugs in the holes; tearing protecting film and cleaning board surfaces and performing completion acceptance. The process of the embodiment improves the overall decoration effect comprehensively and radically solves the problem of wall body cracking. The construction process is simple, has fewer working procedures, and realizes factory production truly; through the pressure groove forming and six-hole anchoring installing method, the working period is greatly reduced.

Owner:丁勋华

Middle and high-rise mixed structure system configured by concrete close-column and gypsum composite wall plates and reinforced concrete light frame

ActiveCN102226349BNo idle functionRegular shapeHeat proofingDwelling buildingReinforced concreteFloor slab

Owner:天津开发区福林发展有限公司

A mold for making concrete composite thermal insulation blocks of fully blocked bridges

A mold for manufacturing a fully-blocking bridge concrete compound insulation block comprises an outer mold, a pressing mold and a mold cover. The outer mold is provided with a rectangular inner cavity which penetrates through the upper end face and the lower end face of the outer mold, and the opposite inner walls of the rectangular inner cavity are each provided with a first vertical groove. The outer contour of the pressing mold is matched with the contour of the rectangular inner cavity. The outer contour of the mold cover is matched with the inner contour of the pressing mold. The mold has the advantages that the mold has the unique shape, so that it is guaranteed that a concrete shell of the manufactured block is completely partitioned by a polystyrene board and therefore a hot bridge can not be formed; the energy-saving efficiency reaches 75%, the latest national mandatory standard at the present stage is met, the conventional defects that cracks, empty plumps, leakage, disengaging and the like are likely to happen in technology when heat insulation materials are externally attached to and hung to the outer portion of a building body at present are completely overcome, the construction cost is lowered, the process procedures are reduced, the construction period is shortened, and the worries to the heating and refrigerating cost, which is continuously increased, of owners in later period are relieved.

Owner:刘立才

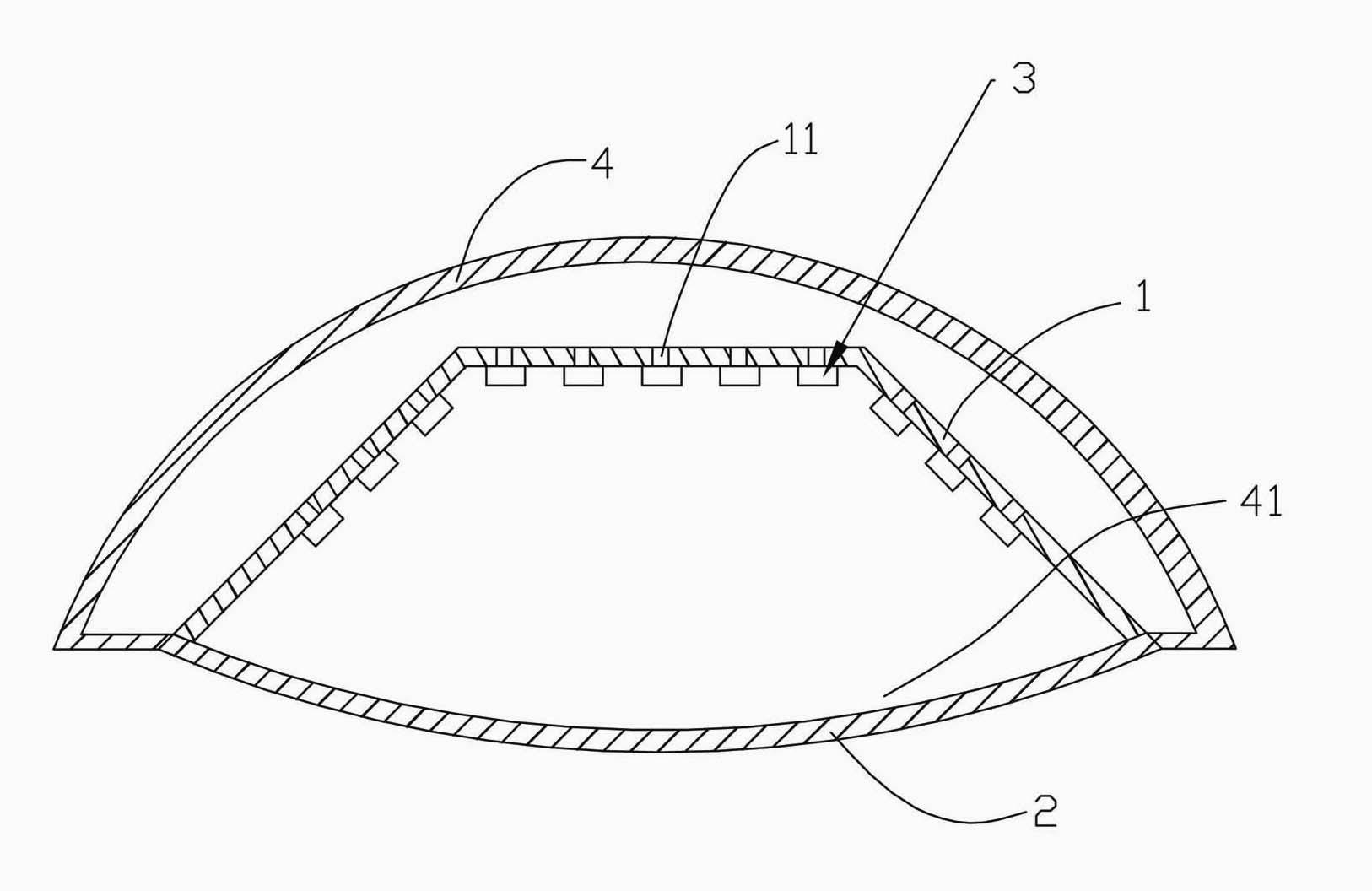

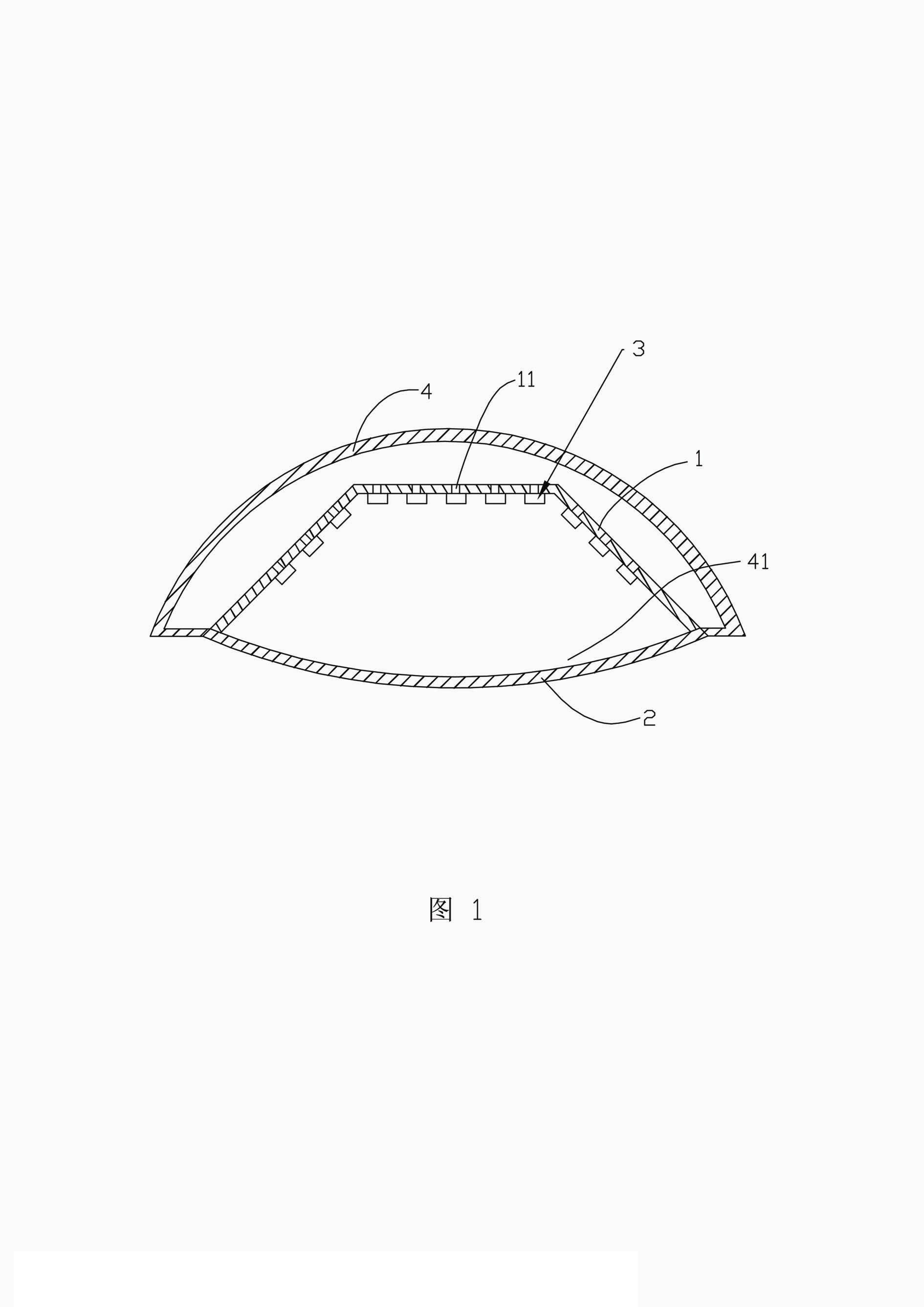

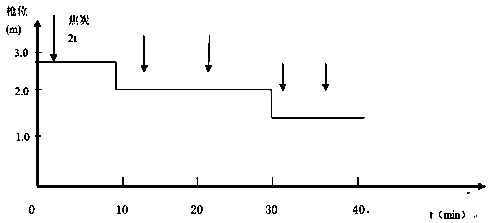

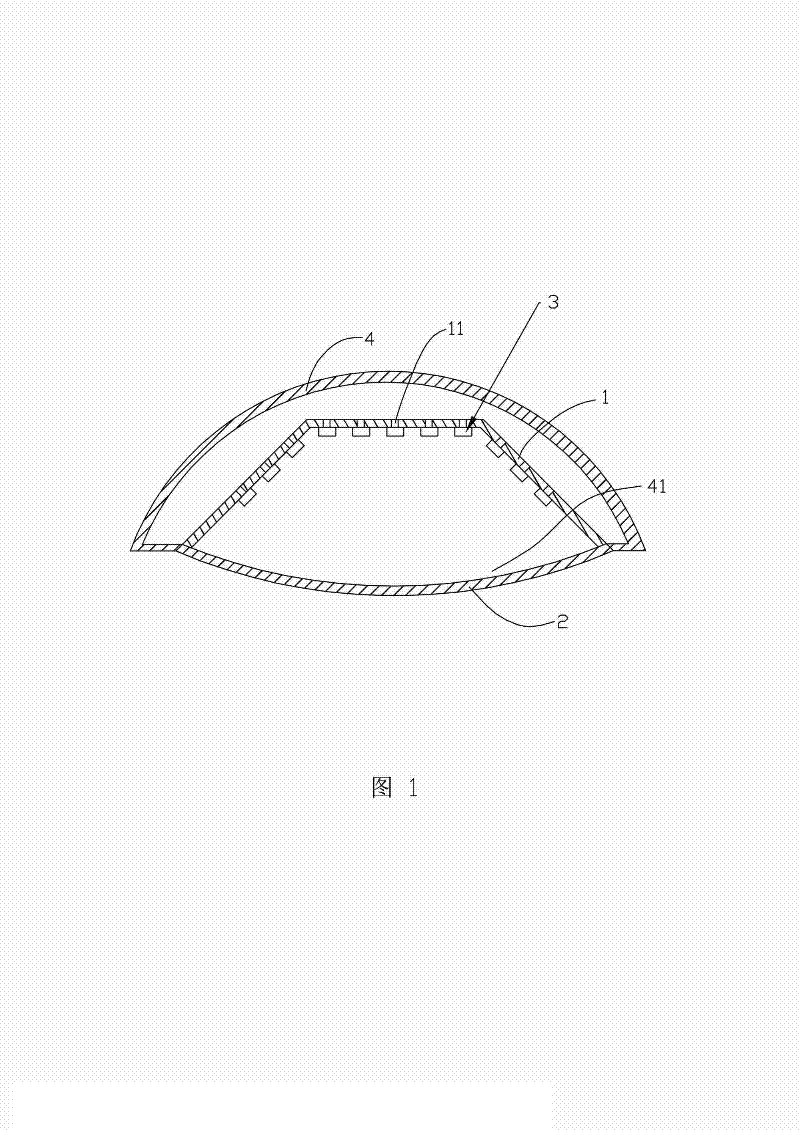

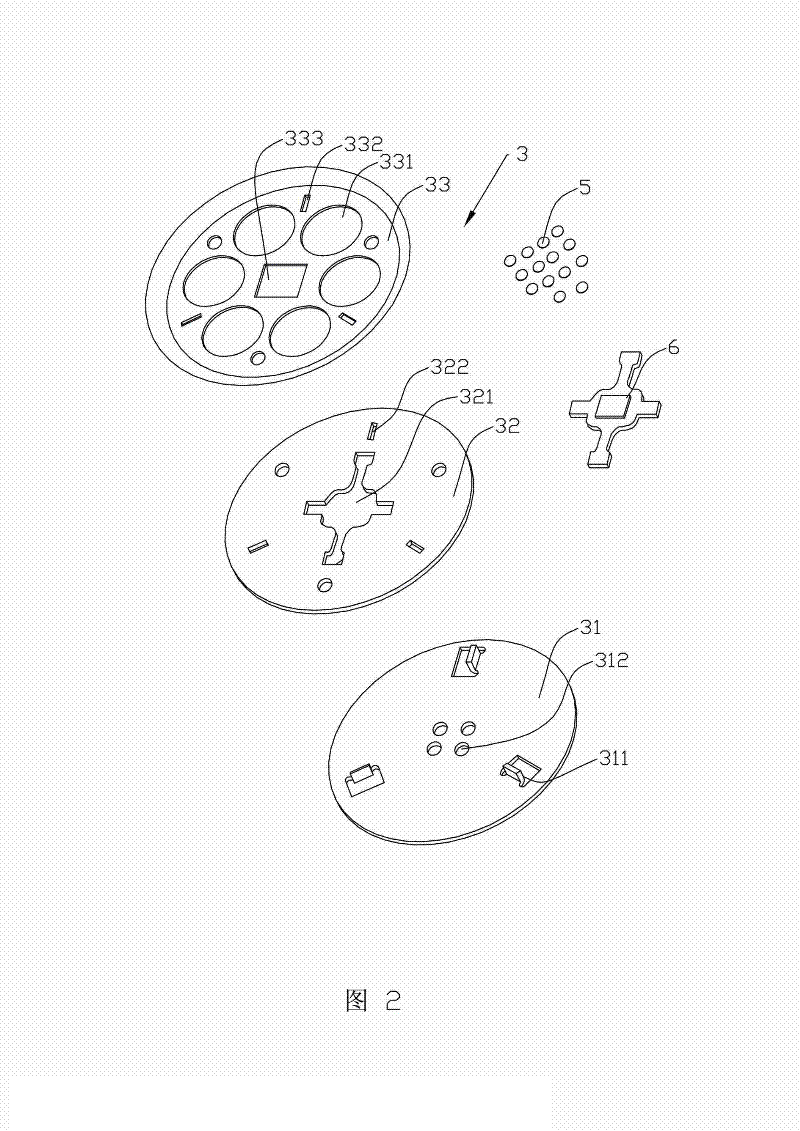

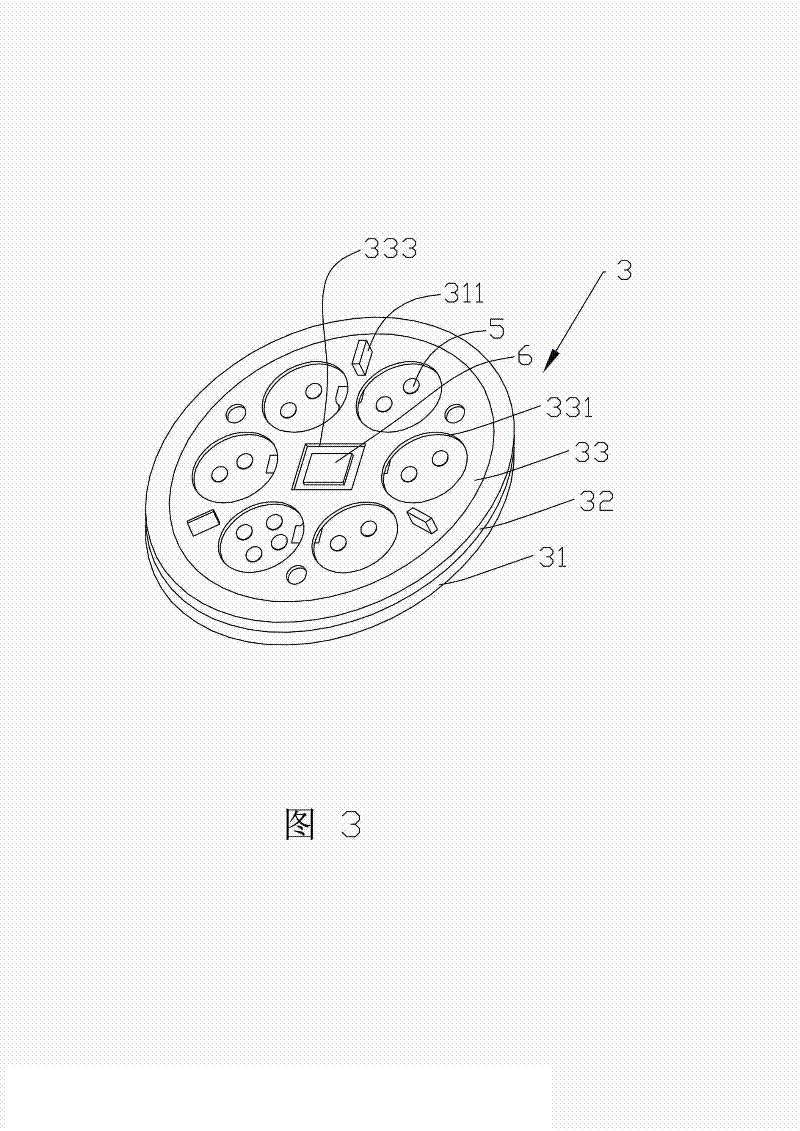

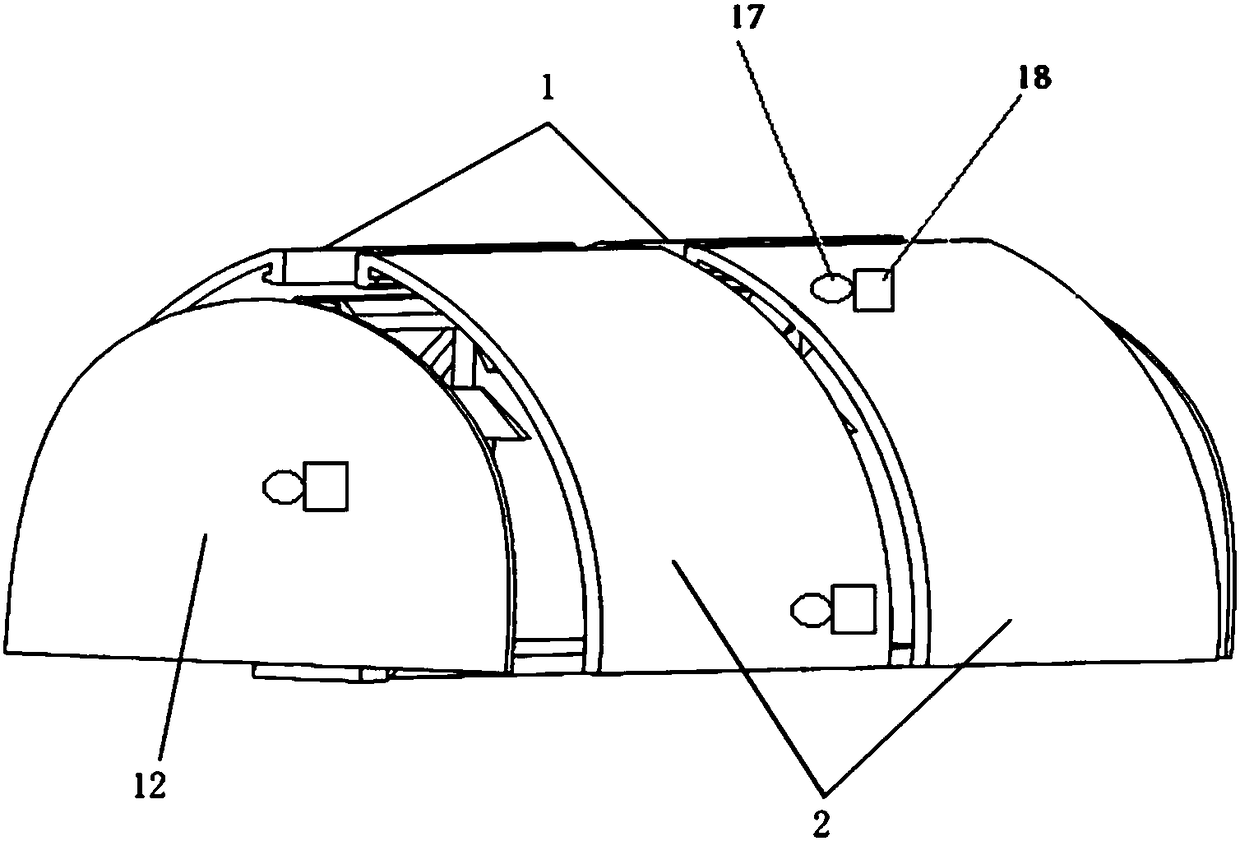

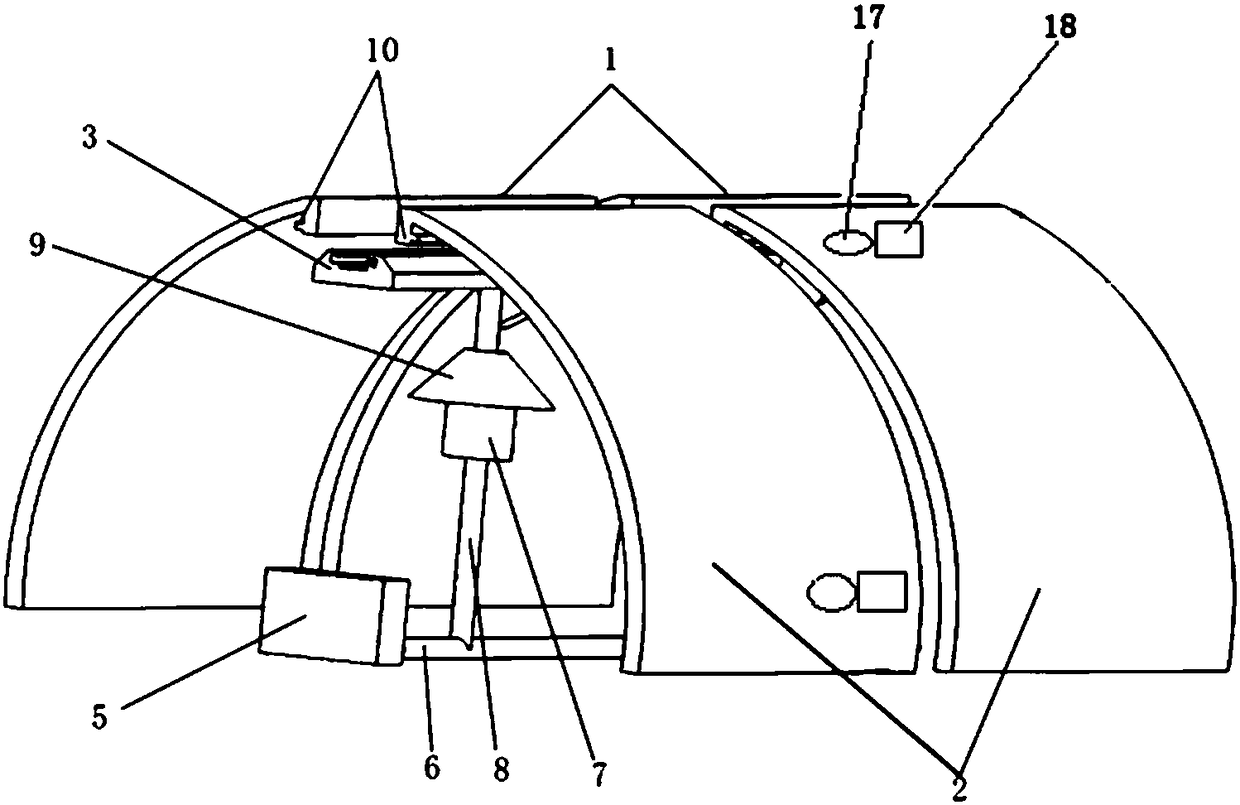

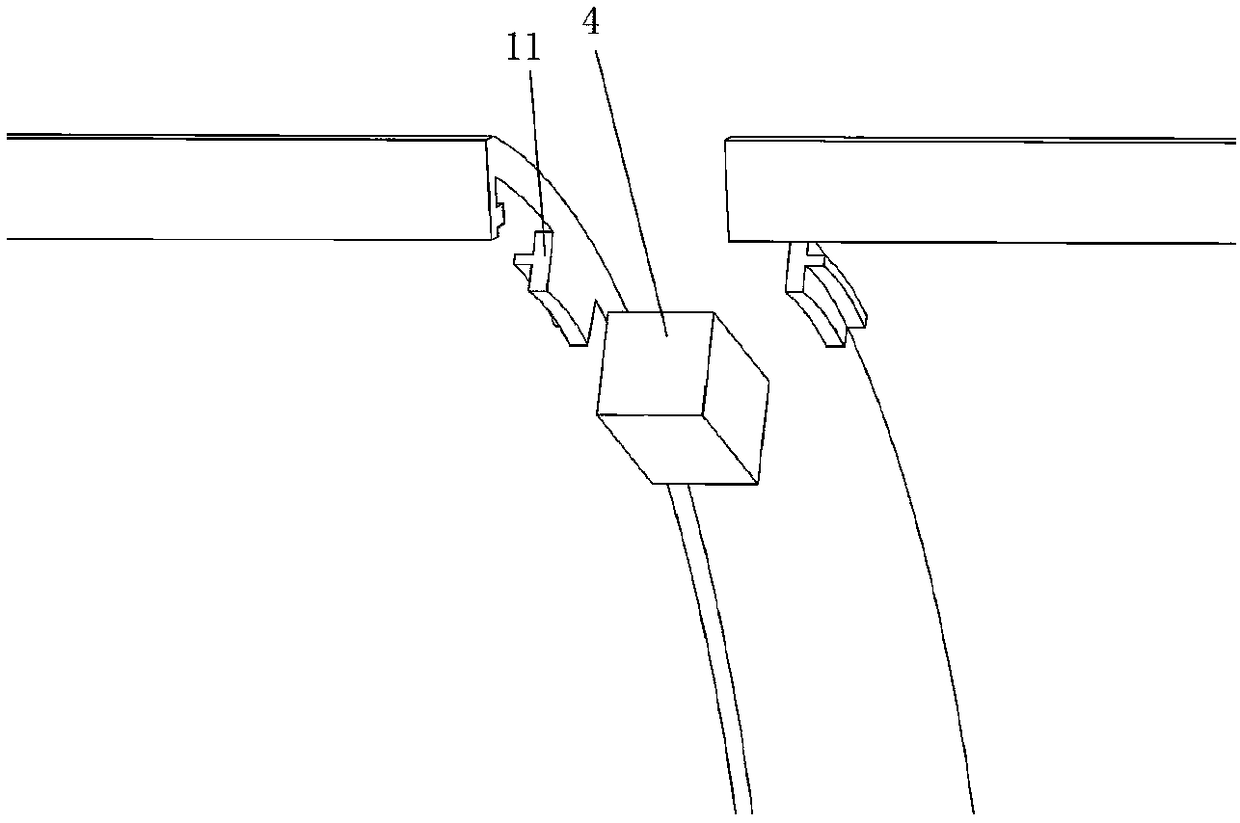

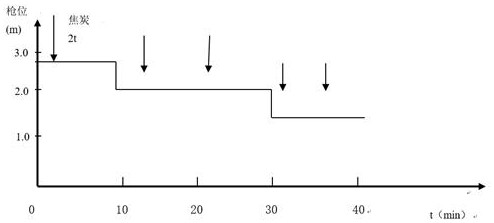

Temperature regulation shield for controlling growth period of peach trees

InactiveCN108076916ALower heat transfer coefficientReduce heat lossClimate change adaptationGreenhouse cultivationAmygdalus persicaEngineering

The invention discloses a temperature regulation shield for controlling a growth period of peach trees. The temperature regulation shield comprises an arc-shaped shield body and a support frame for supporting the shield body, and further comprises a temperature control device, wherein the shield body is provided with a through hole and a hole lid for opening or closing the through hole; a drip fogdispersal layer covers the side, which is close to the peach trees, of the inner side of the shield body; and a PET reflective film covers the outer side of the shield body. The temperature regulation shield has the characteristics of good insulating effect, a function of drip fog dispersal and capability of controlling the growth period of the peach trees. The temperature regulation shield is suitable for culture of the peach trees.

Owner:河北田康农业科技有限公司

A Method for Replacing Bottom Blowing Bricks of Converter

ActiveCN110184412BLife SynchronizationRealize the bottom blowing of the whole furnaceManufacturing convertersProcess efficiency improvementProcess engineeringControl theory

The invention discloses a method for replacing the bottom blowing seat brick of a converter, which specifically comprises the following steps: stopping the furnace to cool the furnace, determining the digging position of the bottom of the converter, digging and repairing, installing a new bottom blowing seat brick of the converter, and maintaining the new bottom blowing seat brick of the converter , Heat replacement of bottom blowing components. By replacing the bottom blowing block of the converter, the present invention solves the problems of blockage of the bottom blowing components in the late stage of the converter operation and unusable problems after severe erosion, and realizes multiple quick change of bottom blowing and bottom blowing at the same bottom blowing point of the converter. The service life of the blowing components is synchronized with the furnace age of the single furnace operation of the converter, so as to ensure the bottom blowing of the whole furnace operation of the converter. And the seams after the bottom blowing and quick change did not appear redness and steel penetration.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

A concrete composite self-insulation integrated block for a fully blocked bridge

ActiveCN104278790BSynchronous lifespanLife SynchronizationConstruction materialConcrete compositesBuilding construction

Owner:刘立才

High-temperature resistant air cooling smoke gate device

ActiveCN101581385BLife SynchronizationResist erosionOperating means/releasing devices for valvesValve members for heating/coolingRefractoryRoller chain

The invention provides a high-temperature resistant air cooling smoke gate device which comprises an air cooling gate plate, a gate plate seat, a blowing mechanism and a drive mechanism, wherein the gate plate is made of unformed refractory materials, and the inner part of the gate plate adopts a plurality of hollow steel pipes connected in parallel as a cooling air passage of the gate plate and an anchoring and supporting skeleton of the gate plate; outlets of the steel pipes are exposed outside the gate plate and connected with the blowing mechanism and the drive mechanism; and two bush roller chains drive the gate plate to participate in the pressure control of a furnace cavity by taking a drive cylinder as a power source. The high-temperature resistant air cooling smoke gate device hasthe advantages of novel design, reliable operation, convenient installation, low operation cost, easy maintenance and high operability and practicability and can be widely applied to various flame furnaces including an aluminum melting furnace, a heat preserving furnace or a mixing furnace in the electrolytic aluminum or aluminum processing industry.

Owner:SUZHOU LONGRAY THERMAL TECH

An automatic transmission fluid with improved anti-wear properties

The invention discloses a wear resistance improvement automatic transmission fluid, relates to an automobile automatic transmission fluid, and mainly aims at solving the problems of non ideal wear resistance and antioxidant properties of automobile automatic transmission fluids in the prior art. The composition comprises base oil accounting for 85.0 to 97.0% of the total weight; a viscosity index improver accounting for 0.2 to 10.0% of the total weight; an anti-wear reagent at extreme pressure, accounting for 0.2 to 2.0% of the total weight; an antioxidant accounting for 0.05 to 2.0% of the total weight; an antioxidant anticorrosion anti-wear agent accounting for 0.02 to 1.0% of the total weight; a dispersant accounting for 0.1 to 3.0% of the total weight; a detergent accounting for 0.05 to 2.0% of the total weight; an anti rust agent accounting for 0.05 to 3.0% of the total weight; a metal deactivator accounting for 0.02 to 3.0% of the total weight; a pour point depressant accounting for 0.2 to 8.0% of the total weight; and an antifoaming agent accounting for 0.0001 to 0.02% of the total weight. The wear resistance improvement automatic transmission fluid has the advantages of good wear resistance and antioxidant properties.

Owner:LIAONING RUNDI AUTOMOTVE ENVIRONMENTAL PROTECTIONTECH

A cooling device and cooling method for the downcomer of the rh refining furnace in a steel plant

The invention provides a cooling device and a cooling device for a declining tube of an RH refining furnace of a steel mill. The cooling device comprises a cooling chamber coating the declining tube, wherein the cooling chamber is in a cylinder shape coiled by a hollow square plate and is welded to the outer wall of the declining tube, and a cold air inlet pipe and a hot air outlet pipe are respectively arranged on the cylinder-shaped cooling chamber; a refractory castable layer is arranged on the outer wall of the cooling chamber. According to the cooling device, the cooling air chamber is welded to the outer part of a steel structure of the declining tube, an air inlet pipe hole and an air outlet pipe hole are formed in the cooling air chamber, and an air flow passage is arranged in the steel structure of the declining tube; when molten steel is fed into the RH refining furnace, the air enters the RH refining furnace through an air inlet, is exhausted from an air outlet through the air passage arranged in the RH refining furnace and takes out heat from the steel structure of the declining tube, so that the declining tube is cooled, the cooling effect is good, and the declining tube can be cooled in a short time.

Owner:武汉精鼎科技股份有限公司

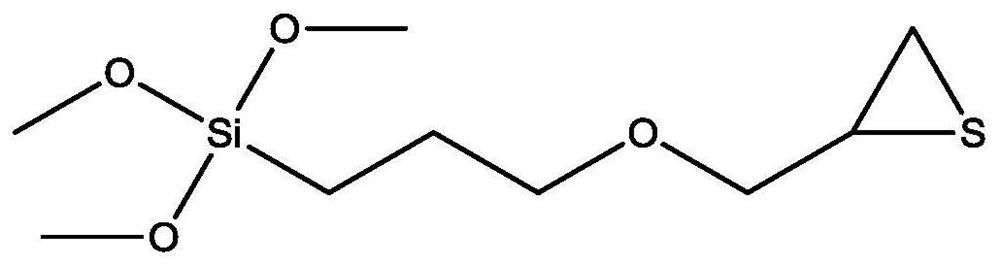

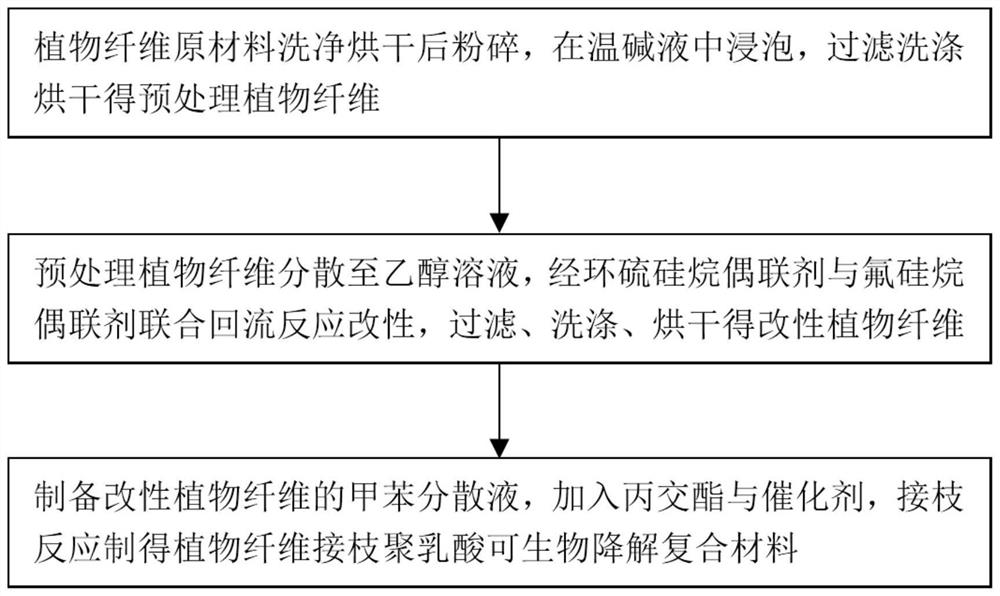

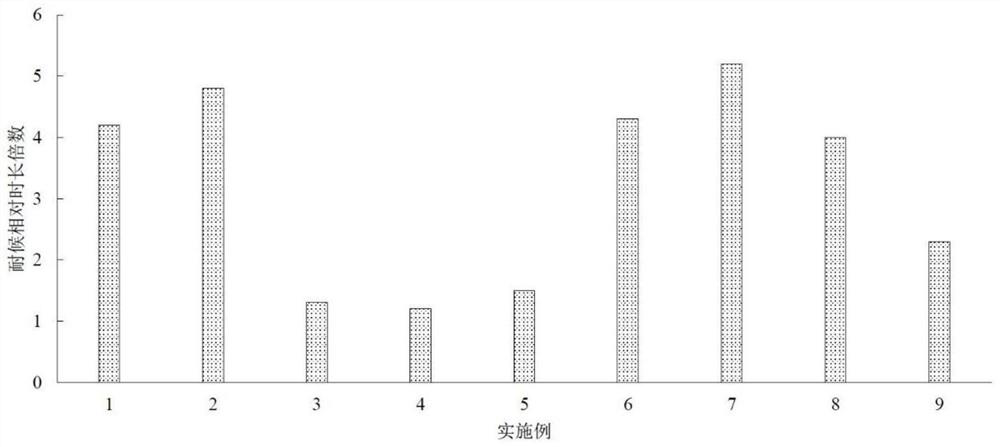

Preparation method of biodegradable composite material

InactiveCN112480430AImprove impact performanceHigh tensile strengthBiocideFlexible coversLactidePlant fibre

The invention relates to the technical field of environment degradable composite materials, in particular to a preparation method of a biodegradable composite material. The preparation method comprises the following steps: cleaning plant fiber raw materials, drying, pulverizing, soaking in warm alkali liquor, filtering, washing until the washing liquor is neutral, and drying to obtain pretreated plant fiber; adding an episulfide silane coupling agent and a fluorosilane coupling agent into the ethanol solution of the pretreated plant fibers, and carrying out a heating reflux reaction to obtainmodified plant fibers; preparing methylbenzene dispersion liquid of the modified plant fibers, adding lactide and a catalyst, and reacting to obtain the biodegradable composite material. According tothe preparation method of the biodegradable composite material, agricultural waste is used as a raw material, the cost is low, the biodegradable composite material can be naturally and completely biodegraded after being used, environmental pollution cannot be caused, and the composite material has an excellent antibacterial effect and weather resistance after being optimized and modified.

Owner:杭州鹿扬科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com