A cooling device and cooling method for the downcomer of the rh refining furnace in a steel plant

A cooling device and refining furnace technology, which is applied to the cooling device field of the down pipe of the RH refining furnace in the steel plant, can solve the problems of affecting the vacuum operation, loss of the refractory lining, de-soldering, etc. The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

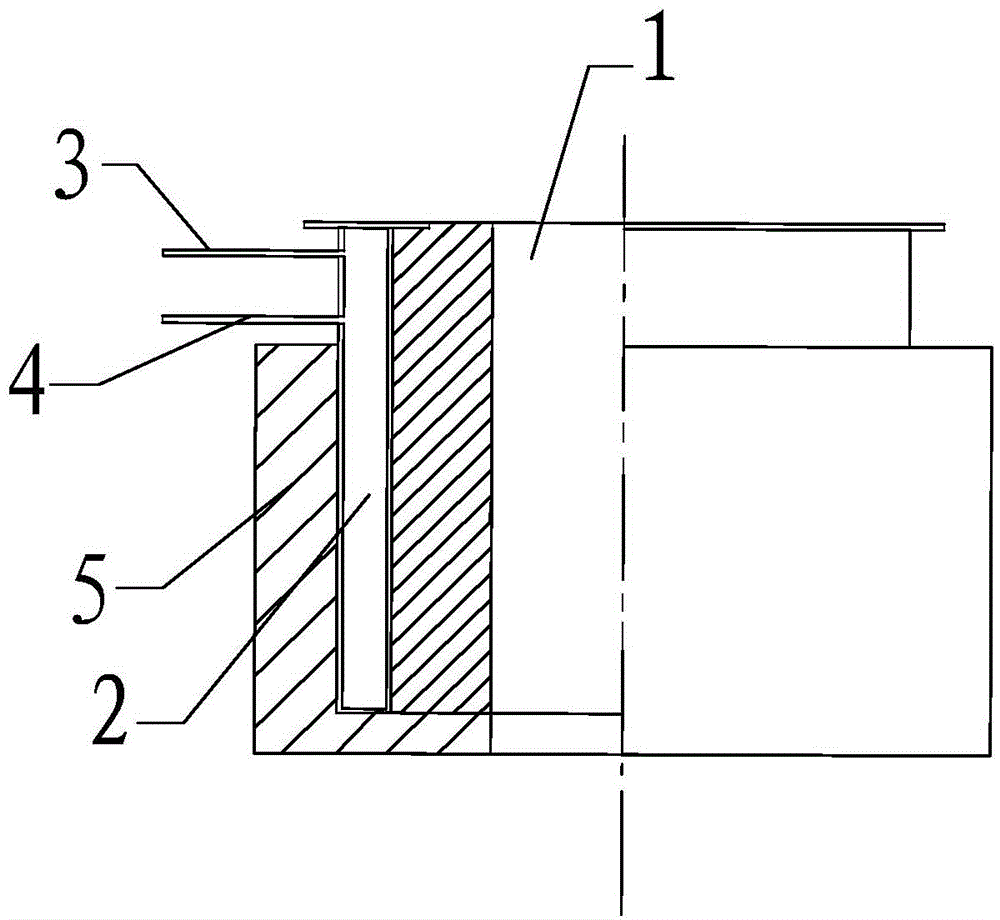

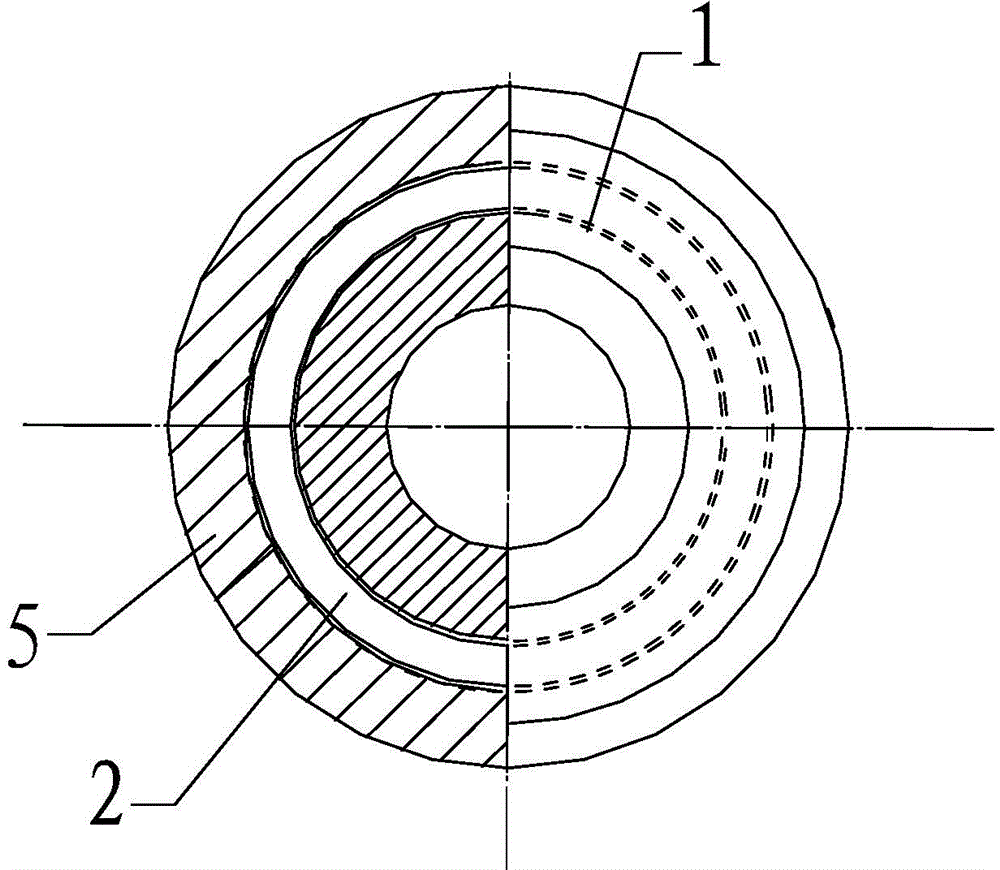

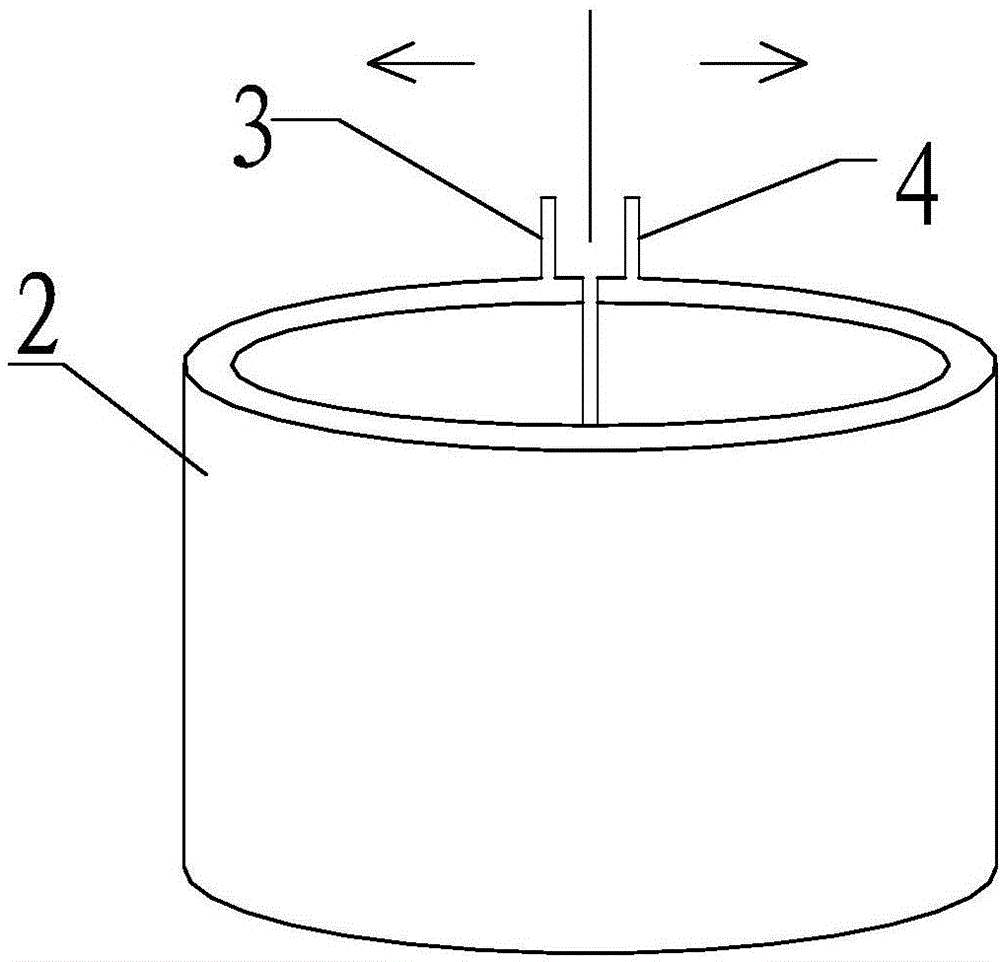

[0029] Embodiment 1, the cooling device of the downcomer of the RH refining furnace of the above-mentioned steel plant is used in a steelmaking plant of Wuhan Iron and Steel Co., Ltd., and during specific use, the device is directly welded on the outer wall of the downcomer of the RH refining furnace, as figure 1As shown, while processing molten steel, the cold air intake pipe 3 is first connected with the air supply pipe, and some air blowing equipment such as a cold air fan is externally connected, and then the cold air is blown into the cooling chamber 2 through the cold air intake pipe 3; Immersed in molten steel, the cold air inlet pipe 3 and the hot air outlet pipe 4 are above the liquid steel level, the cold air enters the cooling chamber 2 and flows in the cooling chamber to cool the downcomer 1, and the cold air entering the cooling chamber 2 after cooling becomes hot air from the hot air Trachea 4 leads out. In this way, the cooling of the main steel structure and an...

Embodiment 2

[0030] Embodiment 2, the cooling device of the downcomer of the RH refining furnace of the above-mentioned steel mill is used in the No. 3 steelmaking plant of Wuhan Iron and Steel. figure 1 As shown, while processing molten steel, the cold air intake pipe 3 is first connected with the air supply pipe, and some air blowing equipment such as a cold air fan is externally connected, and then the cold air is blown into the cooling chamber 2 through the cold air intake pipe 3; Immersed in molten steel, the cold air inlet pipe 3 and the hot air outlet pipe 4 are above the molten steel liquid level,

[0031] The cold wind enters the cooling chamber 2 and flows in the cooling chamber to cool the downcomer 1. After cooling, the cold wind entering the cooling chamber 2 becomes hot blast and is exported from the hot blast outlet pipe 4. In this way, the cooling of the main steel structure and anchors is formed, and the service life of the downcomer is prolonged.

[0032] The test data o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com