Concrete close-column and gypsum composite external wall panel without cold bridge

A technology of exterior wall panels and dense concrete columns, applied to structural elements, building components, insulation, etc., can solve the problems of out-of-sync insulation material life, high cost, and many processes, so as to improve the overall modernization level, improve standardization, reduce The effect of dehumidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

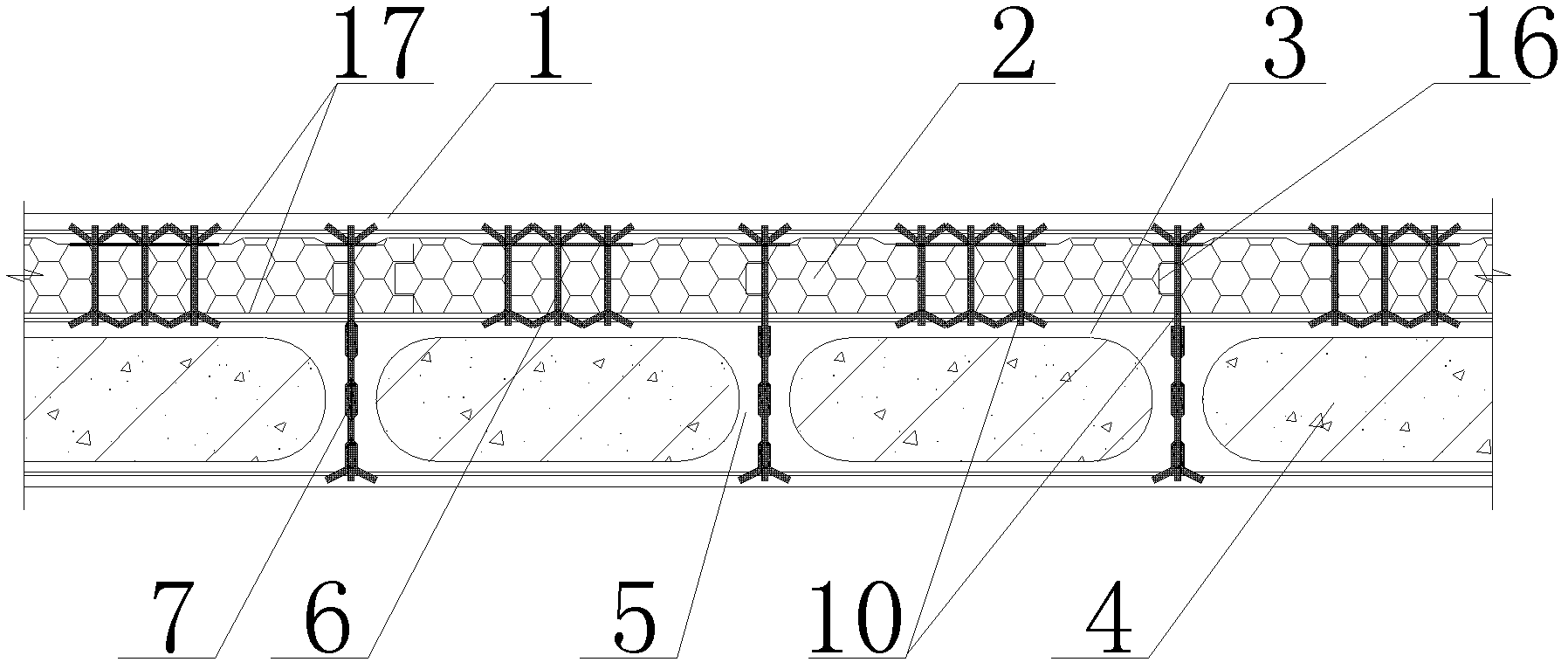

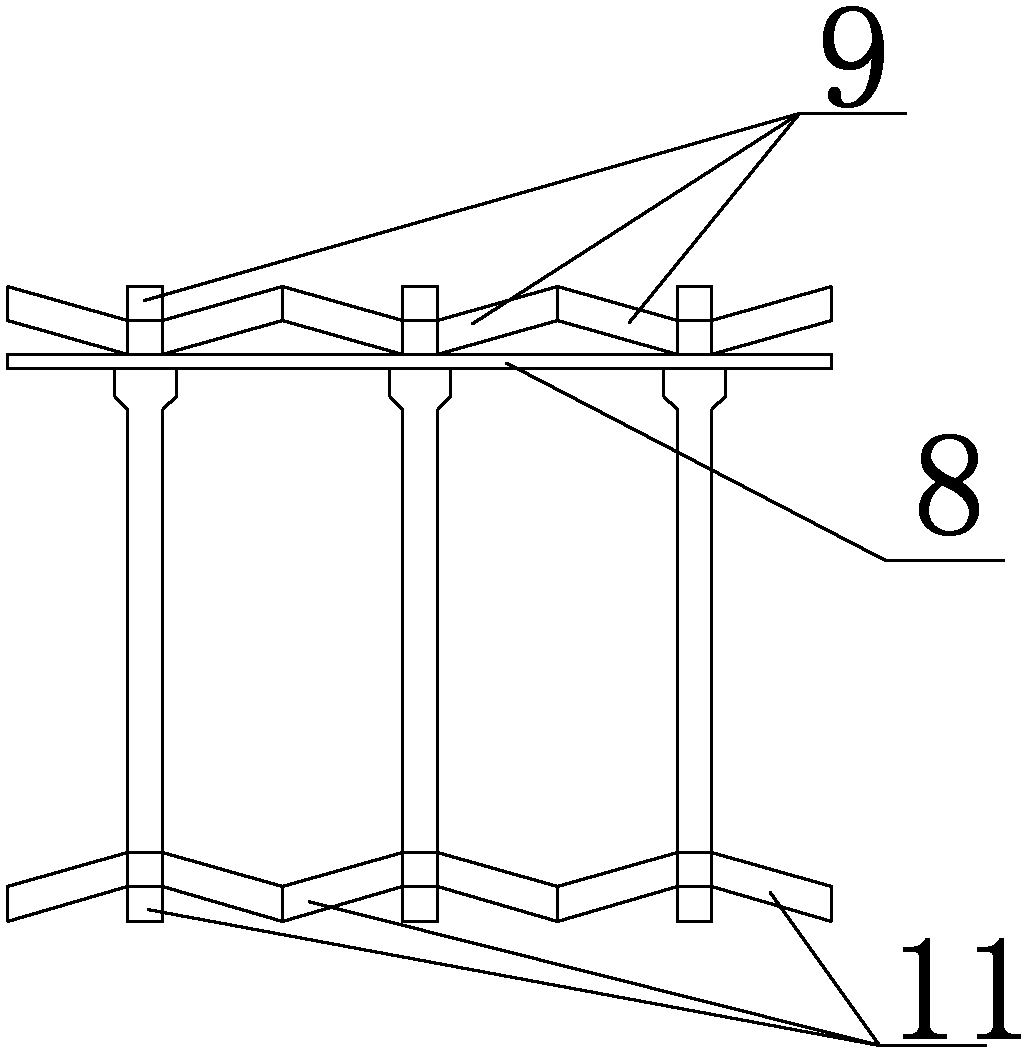

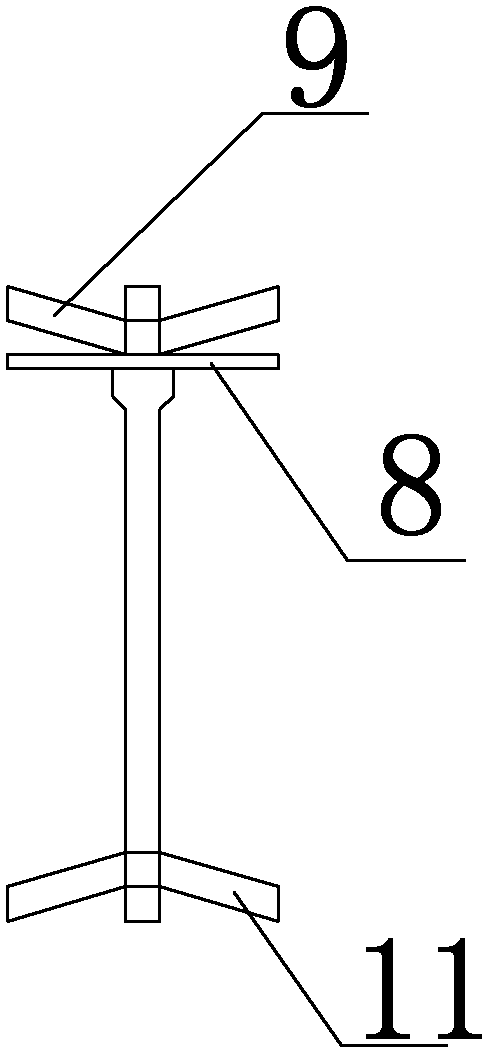

[0025] In order to further understand the characteristics and effects of the present invention, the following embodiments are given as examples, and detailed descriptions are as follows in conjunction with the accompanying drawings, please refer to Figure 1-Figure 7 .

[0026] Such as figure 1 Shown: Concrete dense column gypsum composite non-cold bridge exterior wall panels from outside to inside are high-strength gypsum board layer 1, light insulation material layer 2, high-strength gypsum reserved concrete cavity board layer 3; high-strength gypsum reserved The cast-in-place concrete dense columns 4 are arranged in the concrete cavity slab layer 3, and the cast-in-place concrete dense columns 4 are separated by the cavity ribs 5 and arranged side by side; A connecting ribs 6 and B connecting ribs 7 are evenly distributed on each layer along the length and width directions , wherein the A connecting rib 6 is connected with the outer wall of the high-strength gypsum board l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com