Novel thermal-insulation and decoration integrated plate and preparation method thereof

An integrated board and decorative board technology, applied in covering/lining, construction, building structure, etc., can solve the problems of complex construction process, single decoration level, difficult supervision, etc., and achieve simple construction process, low comprehensive cost, and construction period. the effect of shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

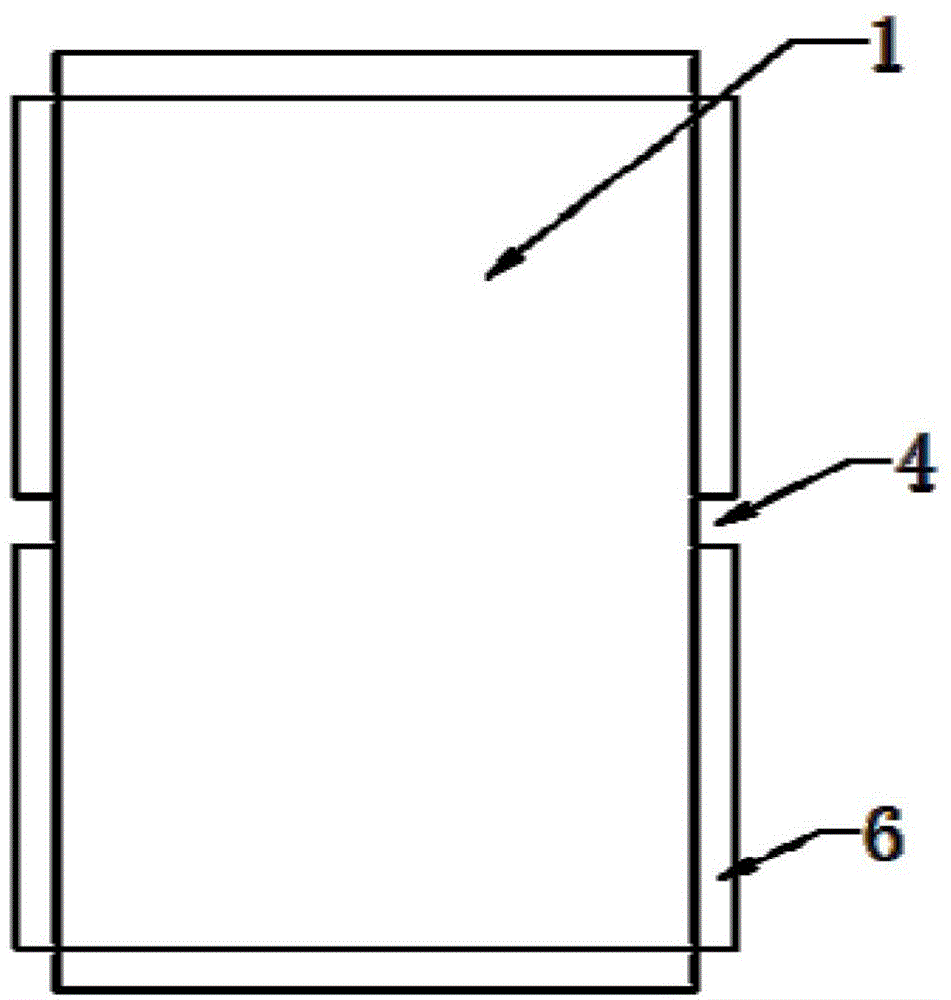

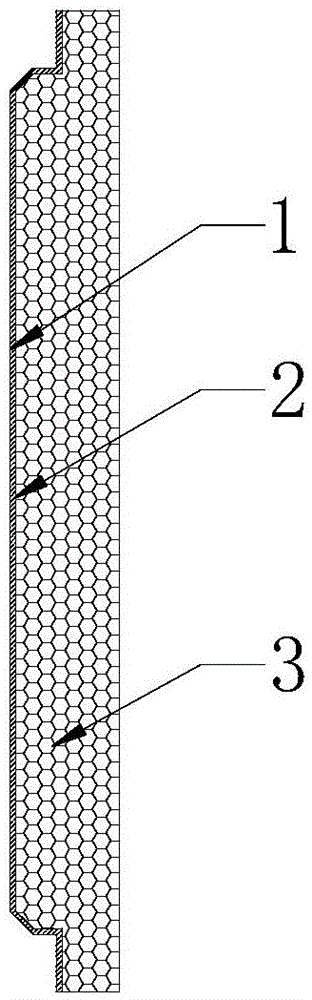

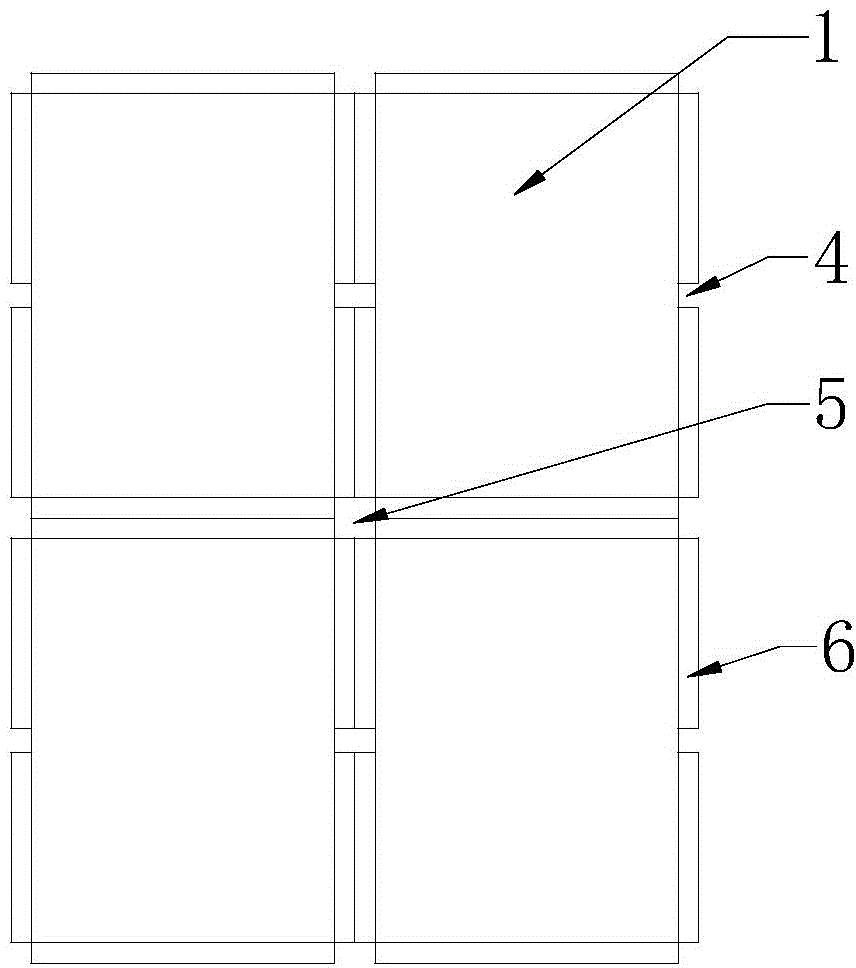

[0021] The new thermal insulation and decoration integrated board of the embodiment of the present invention is provided with a decorative board layer 1, a bonding layer 2 and a thermal insulation material layer 3 in sequence from the inside to the outside. The decorative board layer 1 is stamped and formed by a metal material. Groove 4 and the installation grooves between adjacent integrated panels are combined into installation holes 5, and the integrated panels are fixedly connected to the wall through anchor nails arranged in the installation holes 5; sealing slots 6 are arranged around the integrated panels.

[0022] The preparation method of the above-mentioned novel thermal insulation and decoration integrated board comprises the following steps:

[0023] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com