Automatic heat preservation, energy saving and air-entrapping concrete brick wall and manufacturing method thereof

A technology of air-entrained concrete and self-insulation, applied in the field of building wall insulation, to achieve the effect of improving comprehensive performance, good water retention, and good powder binding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

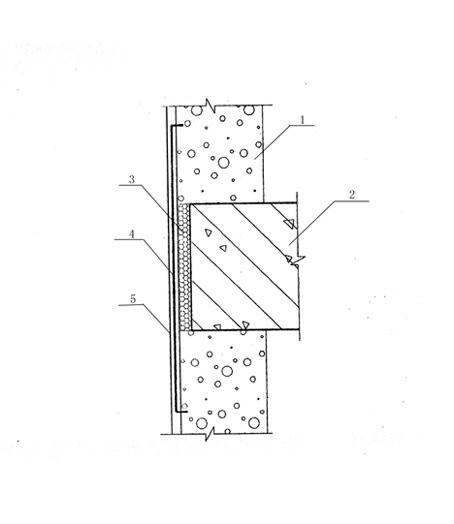

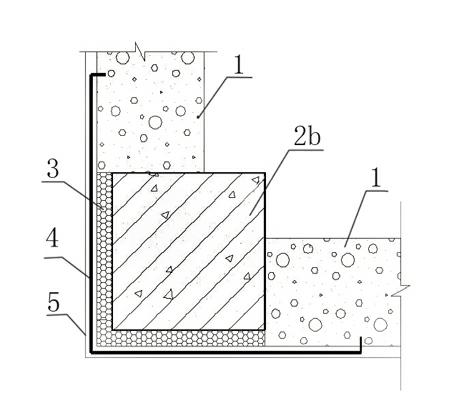

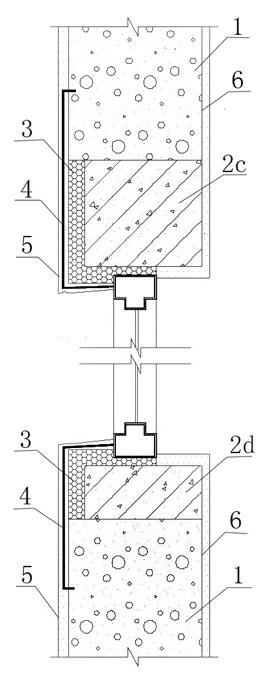

Image

Examples

Embodiment 1

[0037] Among them, the energy-saving aerated concrete block is prepared according to the following raw materials in proportion by weight: fly ash containing SiO2>40% (by mass percentage) or river sand or tailings containing SiO2≥70% (by mass percentage) 70 parts of ore, containing A (CaO 2 + mgO) ≥ 65% (by mass percentage) 35 parts of lime, 25 parts of cement, 50 parts of wollastonite powder, 5 parts of gypsum, 20 parts of heat insulating material, 0.6 part of aluminum powder paste, and 0.6 part of foam stabilizer. Among them, the thermal insulation material is any one of vitrified microbeads, expanded perlite, closed-cell perlite, mineral wool, ceramic fiber, glass fiber, rock wool, sepiolite, expanded vermiculite, diatomite and ceramic sand. One, wherein the particle size of perlite is not greater than 2.0 mm, the particle size of ceramic sand or shale ceramsite is not greater than 2.5 mm, and the particle size of vitrified microbeads is not greater than 2 mm. The wall bui...

Embodiment 2

Embodiment 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com