Method for replacing converter bottom blowing seat brick

A converter bottom blowing and converter technology, which is applied in the field of metallurgy, can solve the problems that the bottom blowing point cannot be replaced multiple times, and the converter bottom blowing seat brick cannot be replaced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for replacing the bottom blowing seat brick of a converter, comprising the steps of:

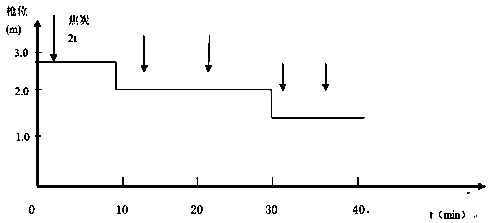

[0033] Step A, the converter is shut down and the furnace is cooled

[0034] The converter is shut down and cooled for 7 days. After the converter is shut down, the converter is parked vertically. The primary dedusting fan of the converter runs at high speed for 8 hours. Afterwards, the furnace mouth of the converter is moved forward to a horizontal position, and an axial flow fan is installed in front of the converter to blow air into the furnace. Speed up the cooling of the furnace, use an infrared thermometer to measure the temperature in the furnace, and lower it to 37°C to replace the furnace base brick;

[0035] Step B. Determining the filling position of the converter bottom

[0036] Park the converter after the cooling furnace in step A vertically, release the oxygen lance high-pressure water and oxygen chain, lower the lance to zero, and pass the oxygen lance head...

Embodiment 2

[0046] A method for replacing the bottom blowing seat brick of a converter, comprising the steps of:

[0047] Step A, the converter is shut down and the furnace is cooled

[0048] The converter was shut down and cooled for 8 days. After the converter was shut down, the converter was parked vertically. The primary dedusting fan of the converter was operated at high speed for 9 hours. Then, the furnace mouth of the converter was moved forward to a horizontal position, and an axial flow fan was installed in front of the converter to blow air into the furnace. Speed up the cooling of the furnace, use an infrared thermometer to measure the temperature in the furnace, and lower it to 40°C to replace the furnace base brick;

[0049] Step B. Determining the filling position of the converter bottom

[0050] Park the converter after the cooling furnace in step A vertically, release the oxygen lance high-pressure water and oxygen chain, lower the lance to zero, and pass the oxygen lan...

Embodiment 3

[0060] A method for replacing the bottom blowing seat brick of a converter, comprising the steps of:

[0061] Step A, the converter is shut down and the furnace is cooled

[0062] The converter is shut down and cooled for 10 days. After the converter is shut down, the converter is parked vertically. The primary dedusting fan of the converter runs at high speed for 10 hours. Then, the furnace mouth of the converter is moved forward to a horizontal position, and an axial flow fan is installed in front of the converter to blow air into the furnace. Speed up the cooling of the furnace, use an infrared thermometer to measure the temperature in the furnace, and lower it to 42°C to replace the furnace base brick;

[0063] Step B. Determining the filling position of the converter bottom

[0064] Park the converter after the cooling furnace in step A vertically, release the oxygen lance high-pressure water and oxygen chain, lower the lance to zero, and pass the oxygen lance head cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com