Diffuse scattering polyethylene greenhouse membrane and preparation method thereof

A diffuse scattering, greenhouse film technology, applied in the fields of botanical equipment and methods, chemical instruments and methods, plant protection, etc., can solve the problems of single function, weak independent research and development ability, and few functional film varieties, and achieve the utilization of greenhouse area. , The effect of promoting photosynthesis and increasing the number of nodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

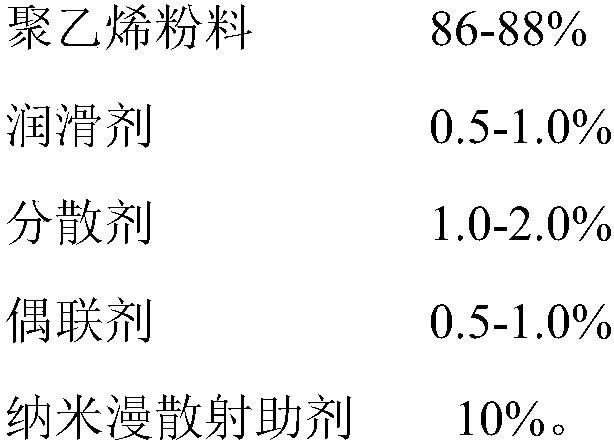

[0058] In this embodiment, the outer layer, the middle layer, and the inner layer all add diffuse scattering masterbatch, and the total ratio in the film is 10%.

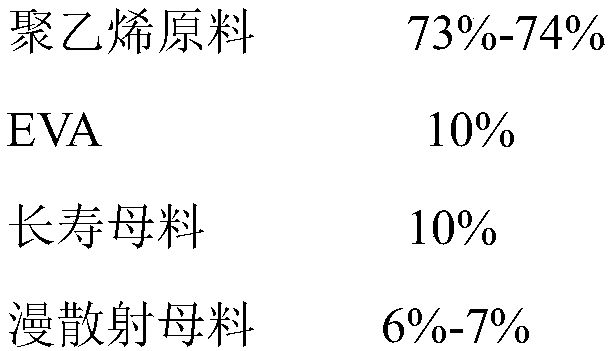

[0059] The ratio of the inner layer of the greenhouse film: 73% polyethylene raw material (182.5kg) + 10% EVA (25kg) + 10% longevity masterbatch (25kg) + 7% diffuse scattering masterbatch (17.5kg) (total 250kg poured into the mixture Machine mixing evenly);

[0060] The proportion of the middle layer of the greenhouse film: 88% polyethylene raw material (220kg) + 10% thermal insulation masterbatch (25kg) + 2% diffuse scattering masterbatch (5kg) (a total of 250kg is poured into the mixer and mixed evenly);

[0061] The ratio of the outer layer of the greenhouse film: 89% polyethylene raw material (222.5kg) + 10% dripping masterbatch (25kg) + 1% diffuse scattering masterbatch (2.5kg) (a total of 250kg is poured into the mixer and mixed evenly);

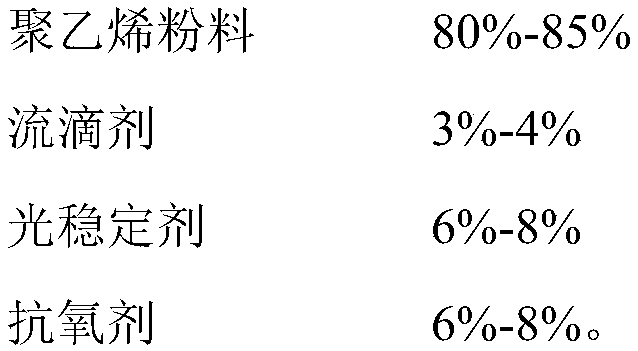

[0062] The weight of each pack of the longevity masterbatch is 25kg, and...

Embodiment 2

[0075] In this embodiment, the outer layer, the middle layer, and the inner layer all add diffuse scattering masterbatch, and the total ratio in the film is 10%.

[0076] The proportion of the inner layer of the greenhouse film: 74% polyethylene raw material (185kg) + 10% EVA (25kg) + 10% longevity masterbatch (25kg) + 6% diffuse scattering masterbatch (15kg) (total 250kg is poured into the mixer and mixed uniform);

[0077] The ratio of the middle layer of the greenhouse film: 87% polyethylene raw material (217.5kg) + 10% thermal insulation masterbatch (25kg) + 3% diffuse scattering masterbatch (7.5kg) (a total of 250kg is poured into the mixer and mixed evenly);

[0078] The ratio of the outer layer of the greenhouse film: 89% polyethylene raw material (222.5kg) + 10% dripping masterbatch (25kg) + 1% diffuse scattering masterbatch (2.5kg) (a total of 250kg is poured into the mixer and mixed evenly);

[0079] The weight of each pack of the longevity masterbatch is 25kg, and ...

Embodiment 3

[0092] In this embodiment, the outer layer, the middle layer, and the inner layer all add diffuse scattering masterbatch, and the total ratio in the film is 10%.

[0093] The ratio of the inner layer of the greenhouse film: 73.5% polyethylene raw material (183.75kg) + 10% EVA (25kg) + 10% longevity masterbatch (25kg) + 6.5% diffuse scattering masterbatch (16.25kg) (a total of 250kg poured into the mixture Machine mixing evenly);

[0094] The proportion of the middle layer of the greenhouse film: 88% polyethylene raw material (220kg) + 10% thermal insulation masterbatch (25kg) + 2% diffuse scattering masterbatch (5kg) (a total of 250kg is poured into the mixer and mixed evenly);

[0095] The ratio of the outer layer of the greenhouse film: 88.5% polyethylene raw material (221.25kg) + 10% dripping masterbatch (25kg) + 1.5% diffuse scattering masterbatch (3.75kg) (a total of 250kg is poured into the mixer and mixed evenly);

[0096] The weight of each pack of the longevity maste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com