Five-layer coextrusion greenhouse film with functions of high dustproofing and long-lasting light conversion and preparation method

A greenhouse film and light conversion technology, which is applied in the direction of botany equipment and methods, chemical instruments and methods, layered products, etc., can solve the problems of dust prevention, light conversion, and dripping and defogging functions that cannot coexist, and achieves the preparation method Scientific and reasonable, fast crop growth and many results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

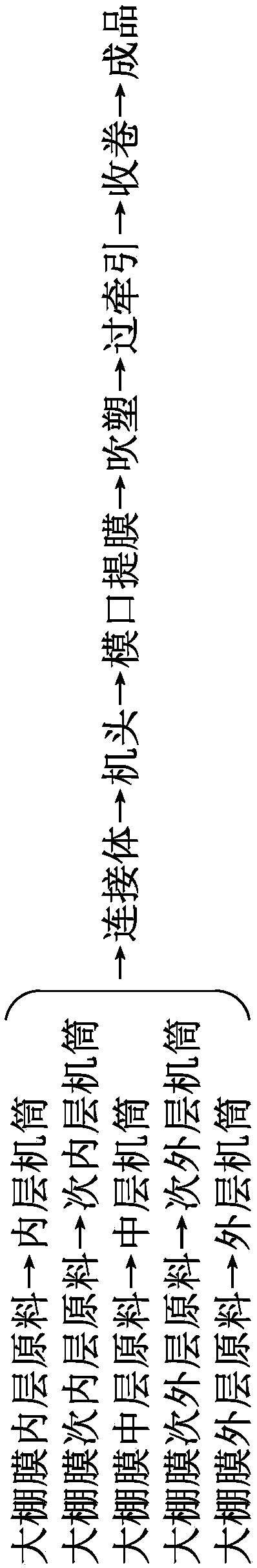

Method used

Image

Examples

Embodiment 1

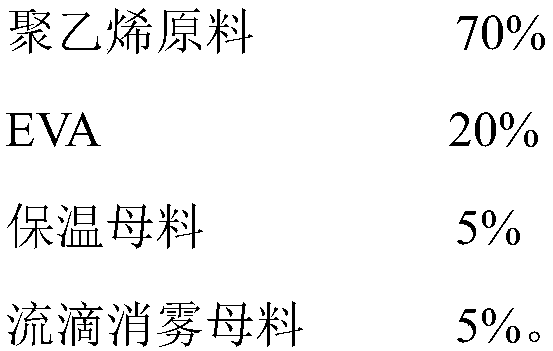

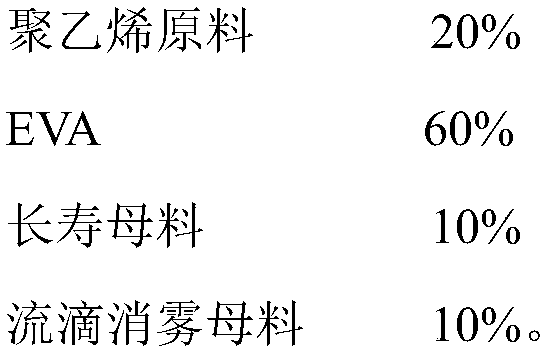

[0078] The inner layer, sub-inner layer, middle layer, outer layer, and sub-outer layer greenhouse film proportioning described in this embodiment 1 are added according to the ratio given in the formula, specifically:

[0079] The proportion of the inner layer of the greenhouse film: 80% polyethylene raw material (200kg) + 10% longevity masterbatch (25kg) + 10% dustproof masterbatch (25kg) (a total of 250kg is poured into the mixer and mixed evenly), of which polyethylene raw material Mix low-density polyethylene and metallocene polyethylene in a mass ratio of 3:7;

[0080] The ratio of the second inner layer of the greenhouse film: 87% polyethylene raw material (217.5kg) + 10% longevity masterbatch (25kg) + 3% light conversion masterbatch (7.5kg) (a total of 250kg is poured into the mixer and mixed evenly), of which The polyethylene raw material is mixed by low-density polyethylene and metallocene polyethylene in a mass ratio of 7:3;

[0081] The ratio of the middle layer of...

Embodiment 2

[0118] The ratio of the inner layer, sub-inner layer, middle layer, outer layer and sub-outer layer of greenhouse film described in this embodiment 2 is added according to the ratio given in the formula, specifically: inner layer of greenhouse film, sub-inner layer, middle layer, outer layer and The proportioning of second outer layer is all identical with embodiment 1.

[0119] The weight of each package of the longevity masterbatch, thermal insulation masterbatch and dripping anti-mist masterbatch is 25kg, and the proportioning ratio is the same as in Example 1.

[0120] Described dustproof master batch weighs 25kg per bag, is to be made of the raw material of following weight:

[0121]

[0122] The light-changing masterbatch weighs 25kg per package and is made of raw materials with the following weights:

[0123] Polyethylene powder 23.75kg

[0124] Organic synthetic rare earth light conversion agent (Hunan Normal University) 1.25kg.

[0125] The preparation method of...

Embodiment 3

[0127] The inner layer, sub-inner layer, middle layer, outer layer, and sub-outer layer greenhouse film proportioning described in this embodiment 3 are added according to the ratio given in the formula, specifically: the greenhouse film inner layer, sub-inner layer, middle layer, outer layer and The proportioning of second outer layer is all identical with embodiment 1.

[0128]The weight of each package of the longevity masterbatch, thermal insulation masterbatch and dripping anti-mist masterbatch is 25kg, and the proportioning ratio is the same as in Example 1.

[0129] Described dustproof master batch weighs 25kg per bag, is to be made of the raw material of following weight:

[0130]

[0131] The light-changing masterbatch weighs 25kg per package and is made of raw materials with the following weights:

[0132] Polyethylene powder 23kg

[0133] Organic synthetic rare earth light conversion agent (Hunan Normal University) 2kg.

[0134] The preparation method of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com