Environmental-friendly synthetic organosilicon leather and method for producing same

A silicone synthetic leather, environmentally friendly technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, textile/flexible product manufacturing, etc. problems, to achieve the effect of easily adapting to the thickness and speed of the adhesive, easy mass production, and strong physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

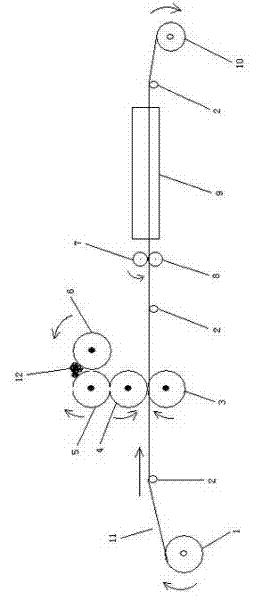

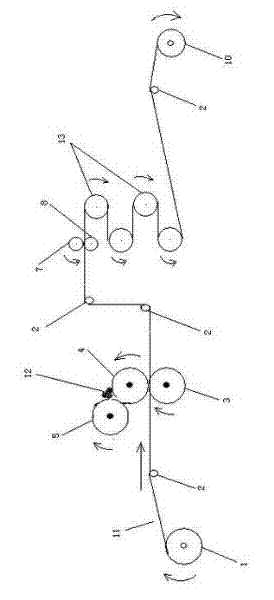

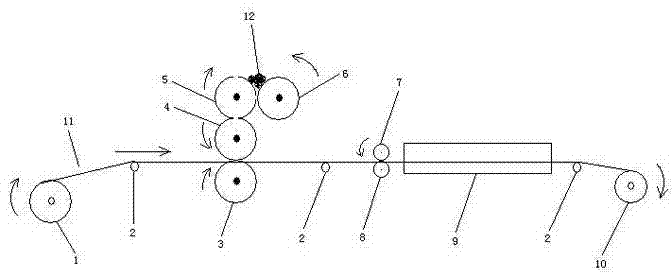

Method used

Image

Examples

Embodiment 1

[0051] 1. Prepare and mix silicone rubber:

[0052] Polymethyl vinyl siloxane raw rubber (viscosity average molecular weight 600,000, vinyl mole percentage 0.05%) 90kg, polymethyl vinyl siloxane raw rubber (viscosity average molecular weight 600,000, vinyl mole percent content of 0.5%) 70kg, the viscosity is 50mm at 25℃ 2 10 kg of hydroxy silicone oil per s, 3 kg of dimethyldiethoxysilane, put into a 500-liter vacuum kneader, mix evenly, and then add 95 kg of fumed silica AEROSIL200 (manufactured by Evonik Degussa) to Add several times, finally add 0.5 kg of zinc stearate, after forming a large group, control the temperature at 170 ° C, vacuum degree of about 0.09 Mpa, heat treatment for 4 hours, filter and cool.

[0053] 2. Preparation of calendering rubber:

[0054] Put the above mixed silicone rubber into another 500-liter kneader, add 6kg of hydrogen-containing silicone oil with a hydrogen content of 1.0%, 0.12kg of ethynyl cyclohexanol and 0.5kg of black color masterbat...

Embodiment 2

[0062] Polymethyl vinyl siloxane raw rubber (viscosity average molecular weight 600,000, vinyl mole percent 0.05%) 80kg, polymethyl vinyl siloxane raw rubber (viscosity average molecular weight 600,000, vinyl mole percent content 0.25%) 80kg, viscosity is 50mm at 25℃ 2 7.6kg of hydroxy silicone oil per s, 80kg of fumed silica M-5 (manufactured by Cabot), 0.39kg of glyceryl stearate, 5kg of hydrogen-containing silicone oil with a hydrogen content of 0.8%, allyl maleate 0.2kg of ester, 0.22kg of platinum catalyst (platinum content 4000ppm).

[0063] The preparation process and testing method are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com