Wear resistance improvement automatic transmission fluid

An automatic transmission fluid, anti-wear technology, applied in the field of lubricating oil, can solve the problems of unsatisfactory anti-wear performance and anti-oxidation performance, and achieve the effect of excellent anti-wear performance and anti-oxidation performance

Active Publication Date: 2014-08-13

LIAONING RUNDI AUTOMOTVE ENVIRONMENTAL PROTECTIONTECH

View PDF5 Cites 20 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

CN102268316A discloses a kind of automatic transmission fluid composition that meets DEXRON-III, DEXRON-VI and Allison C-4 specification requirements, and dispersant in this transmission fluid is by succinimide and succinate and phosphorus-containing additive , boronating agent and fatty alcohol contact reaction, but their anti-wear performance and anti-oxidation performance are not ideal

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

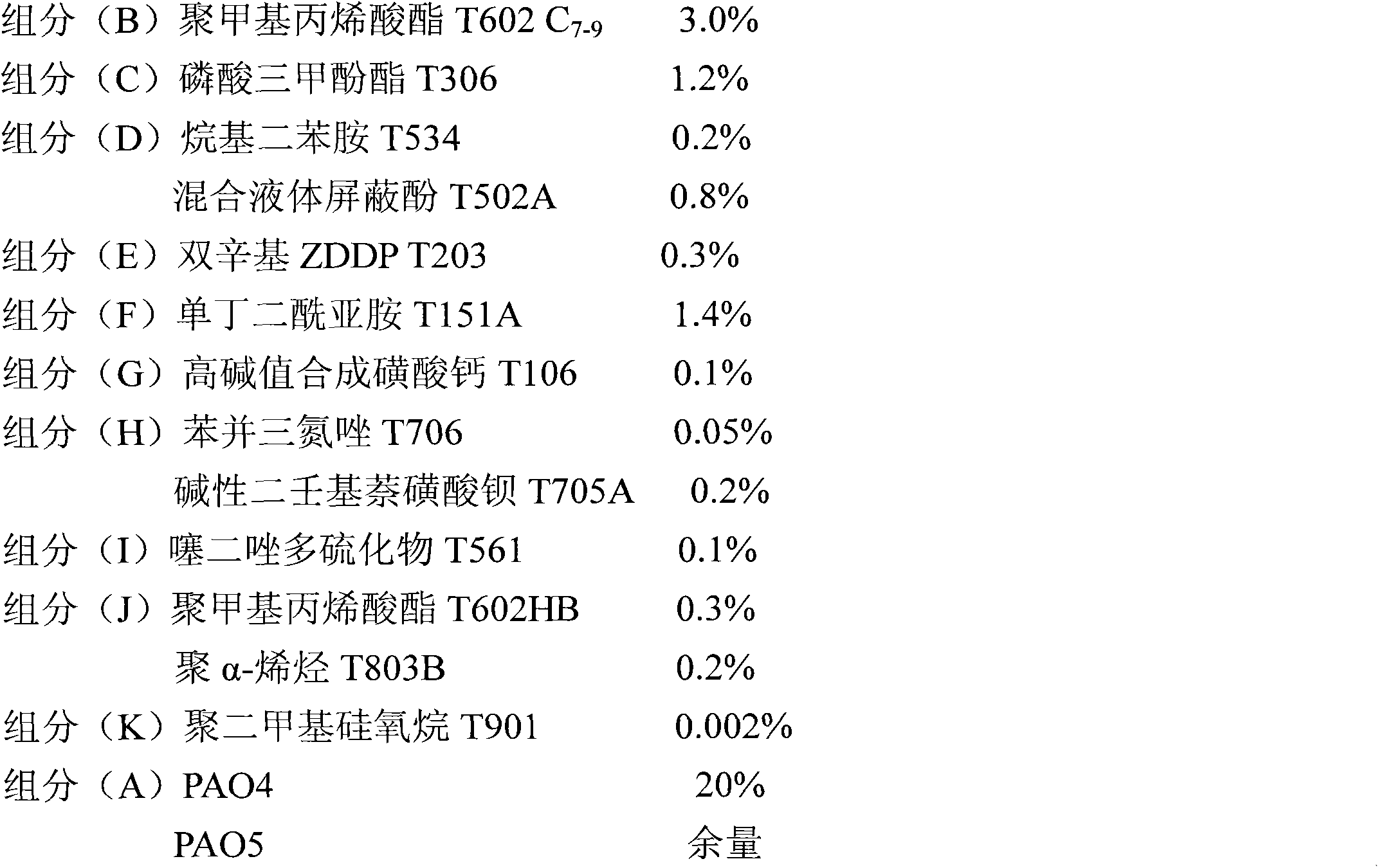

Embodiment 1

[0036] An automatic transmission fluid composition, based on the total weight of the composition, comprising the following components:

[0037]

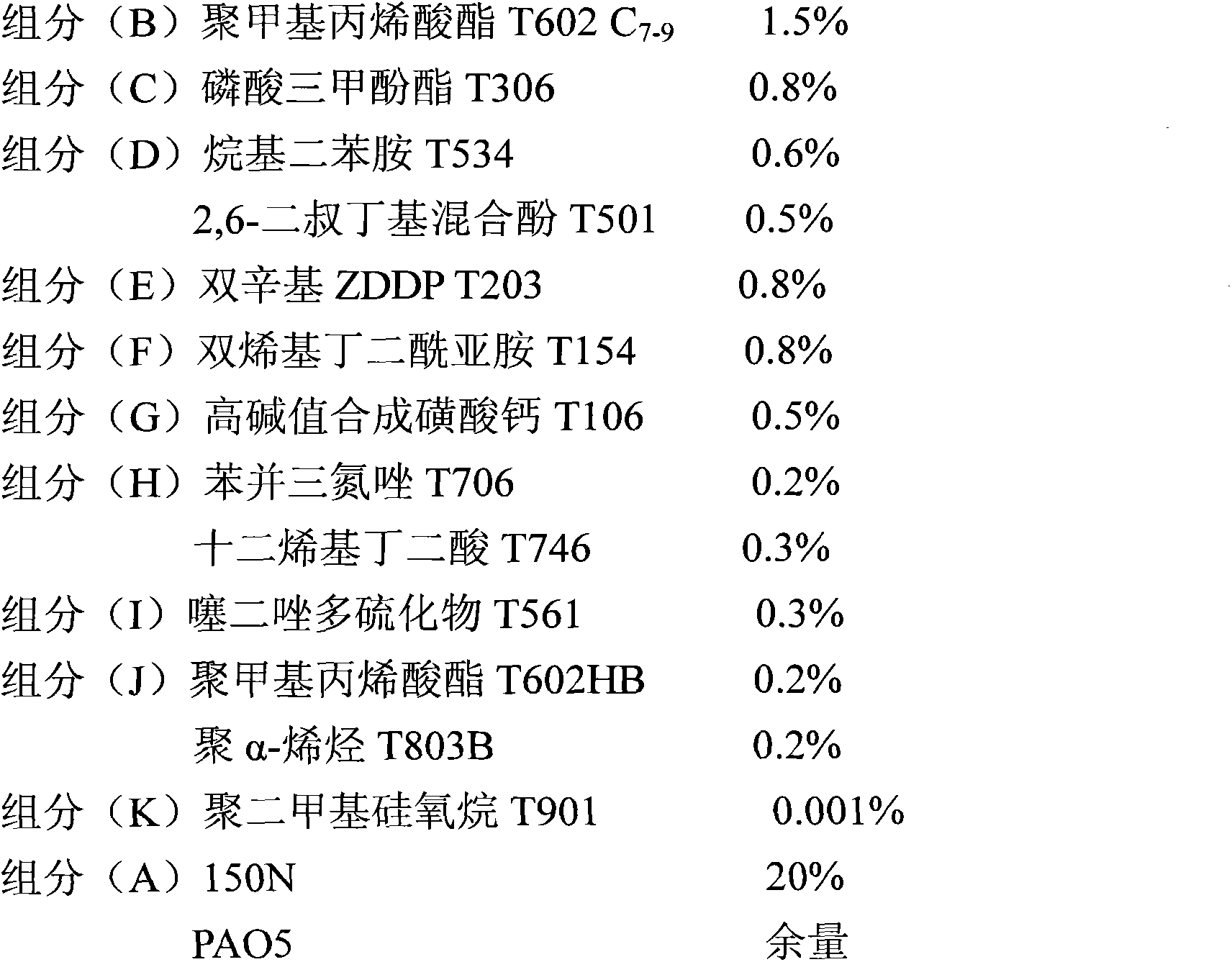

Embodiment 2

[0039] An automatic transmission fluid composition, based on the total weight of the composition, comprising the following components:

[0040]

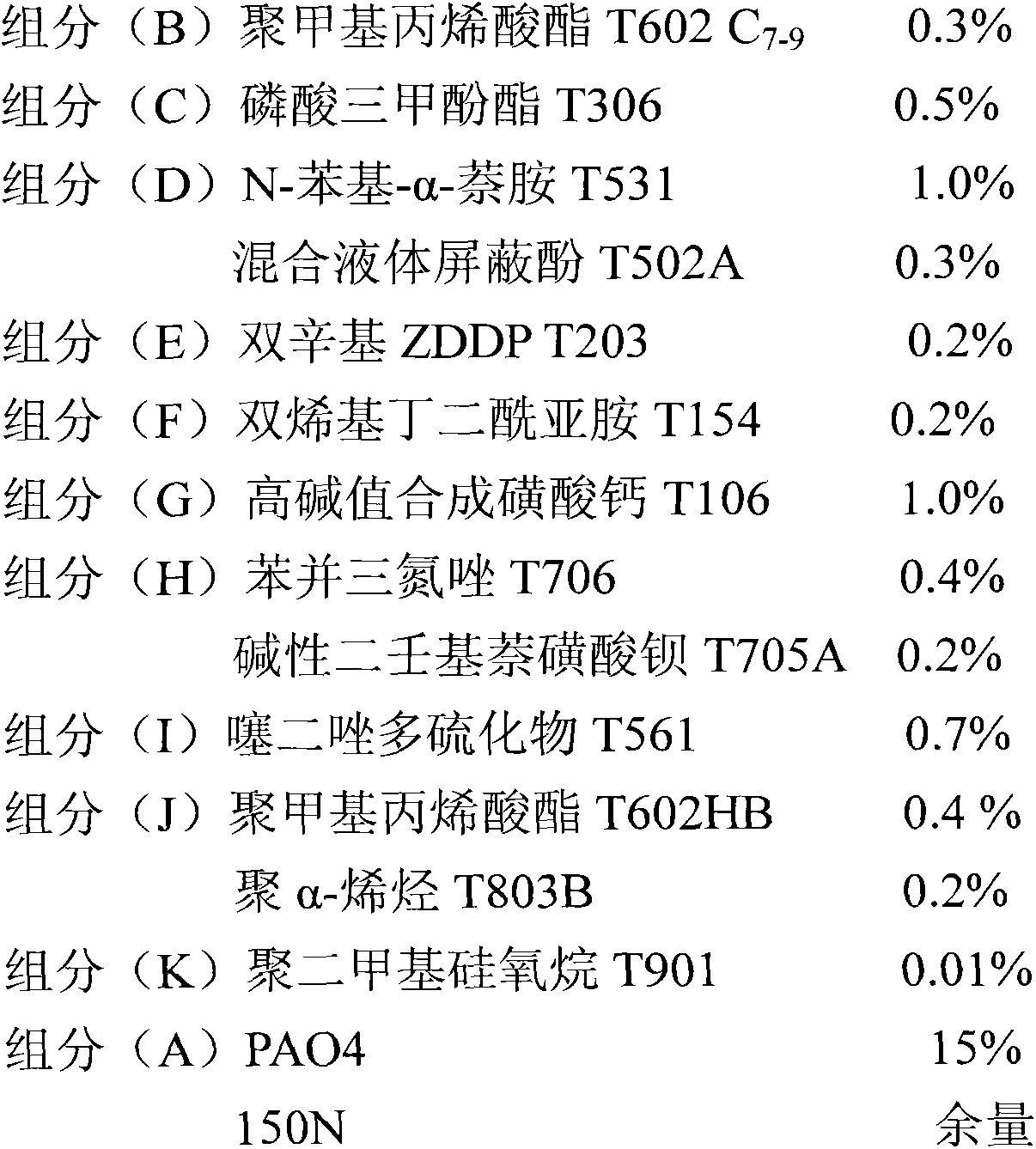

Embodiment 3

[0042]An automatic transmission fluid composition, based on the total weight of the composition, comprising the following components:

[0043]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a wear resistance improvement automatic transmission fluid, relates to an automobile automatic transmission fluid, and mainly aims at solving the problems of non ideal wear resistance and antioxidant properties of automobile automatic transmission fluids in the prior art. The composition comprises base oil accounting for 85.0 to 97.0% of the total weight; a viscosity index improver accounting for 0.2 to 10.0% of the total weight; an anti-wear reagent at extreme pressure, accounting for 0.2 to 2.0% of the total weight; an antioxidant accounting for 0.05 to 2.0% of the total weight; an antioxidant anticorrosion anti-wear agent accounting for 0.02 to 1.0% of the total weight; a dispersant accounting for 0.1 to 3.0% of the total weight; a detergent accounting for 0.05 to 2.0% of the total weight; an anti rust agent accounting for 0.05 to 3.0% of the total weight; a metal deactivator accounting for 0.02 to 3.0% of the total weight; a pour point depressant accounting for 0.2 to 8.0% of the total weight; and an antifoaming agent accounting for 0.0001 to 0.02% of the total weight. The wear resistance improvement automatic transmission fluid has the advantages of good wear resistance and antioxidant properties.

Description

technical field [0001] The invention relates to an automobile automatic transmission fluid, which is mainly used in an automobile automatic transmission system and belongs to the field of lubricating oil. Background technique [0002] Automobile transmission fluid is mainly used in the automatic transmission system of automobiles, acting as an intermediate medium and lubricating. It is usually required to have good viscosity-temperature properties, corrosion resistance, wear resistance, thermal oxidation stability, and anti-foaming properties. In order to meet the above performance, general automatic transmission fluid needs to add various additives such as viscosity index improver, dispersant, antioxidant, extreme pressure and antiwear agent, rust inhibitor, metal deactivator, pour point depressant, antifoaming agent, etc. [0003] With the development of automatic transmissions, automatic transmission fluids are also constantly being upgraded. The specifications of automat...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10M161/00C10M141/06C10M141/08C10N30/10C10N30/06

Inventor 王宝峰邹建波刘霞孙慧

Owner LIAONING RUNDI AUTOMOTVE ENVIRONMENTAL PROTECTIONTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com