High-pressure-charging long-service-life diesel engine oil and manufacturing method thereof

A diesel engine oil, long-life technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of poor high temperature performance of viscosity index improvers, unfavorable oil cleanliness and oxidation resistance, and reduced diesel vehicle pressure, etc. Achieve excellent high temperature detergency, inhibit the generation of carbon deposits and paint films, and prolong the oil change interval.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

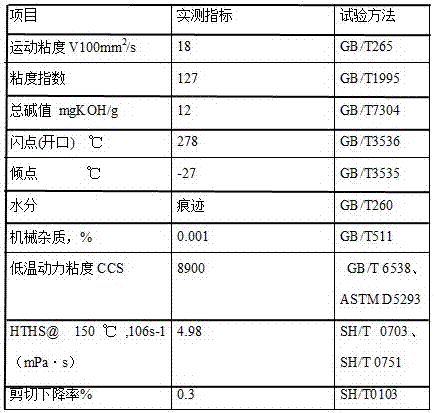

[0019] Embodiment 1: A kind of diesel engine oil of high pressurization and long life, prepare paraffin base type II 500N 928kg, viscosity is 100mm under 100 ℃ 2 / s Polyalphaolefin (150) 48kg, Polyester PriEco (4035) 24kg, Superbasic Calcium Sulfonate 20kg, Polyisobutylene Polysuccinimide 80kg, Sulfurized Calcium Alkylphenate 15kg, Phosphobisoctyl Base 15kg of octyl salt, 0.01kg of oil-soluble graphene, 3kg of amine-type high-temperature antioxidant, 1kg of polymethacrylate depressant, and 0.01kg of composite antifoaming agent;

[0020] Production method: put 500N, polyalphaolefin (150), polyester PriEco (4035) into the reaction kettle, heat up to 60°C-70°C, stir for 10 minutes, then put in superbasic calcium sulfonate, sulfurized alkylphenol in turn Calcium, polyisobutylene polysuccinimide, amine-type high-temperature antioxidant, polymethacrylate, thiophosphobisoctyl basic octyl salt, composite antifoaming agent, oil-soluble graphene, constant temperature 60°C-70°C Stir for...

Embodiment 2

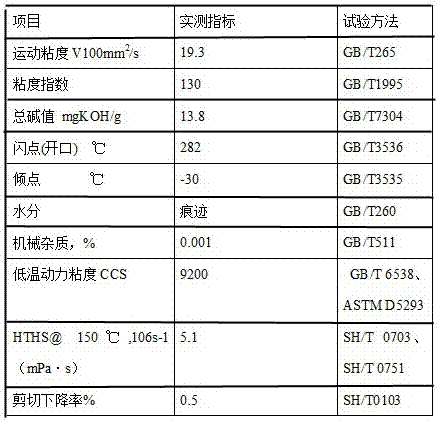

[0023] Embodiment 2: A kind of diesel engine oil with high supercharging and long life, prepare paraffin base III type 650N 915kg, the viscosity is 300mm under 100 ℃ 2 / s polyalphaolefin (200) 80kg, trimethylolpropane oleate 5kg, superbasic calcium sulfonate 22kg, polyisobutylene polysuccinimide 85kg, sulfurized alkylphenate calcium 13kg, thiophosphobioctine 15kg basic octyl salt, 0.01kg oil-soluble graphene, 4kg amine high temperature antioxidant, 1kg polymethacrylate pour point depressant, 0.013kg composite antifoaming agent;

[0024] Production method: put 650N, polyalphaolefin (200), trimethylolpropane oleate into the reaction kettle, raise the temperature to 60°C-70°C and stir for 10 minutes, then put in superbasic calcium sulfonate, sulfurized alkyl Calcium phenate, polyisobutylene polysuccinimide, amine-type high-temperature antioxidant, polymethacrylate, bis-octyl basic octyl salt of sulfur phosphorus, composite anti-foaming agent, oil-soluble graphene, constant temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com