Method for supplementing fermentation raw material by microbial fermentation tail gas CO2 immobilized by microalgae culture

A microbial fermentation method and microbial fermentation technology, applied in specific-purpose bioreactor/fermenter, biochemical equipment and methods, bioreactor/fermenter combination, etc., to achieve reduced consumption, environmental friendliness, and good sustainability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Cultivation of Tetragalenia subcordiformum to immobilize CO in the tail gas of ethanol production by fermentation of yeast 2 , will contain about 40% (V / V) CO 2 The ethanol fermentation tail gas is directly passed into the photobioreactor to cultivate Tetraspermium subcardioid, so that it can fix CO 2 And accumulate a large amount of starch, which is released through ultrasonic-enzymatic hydrolysis to generate glucose, which is used as a raw material supplement for yeast fermentation to produce ethanol.

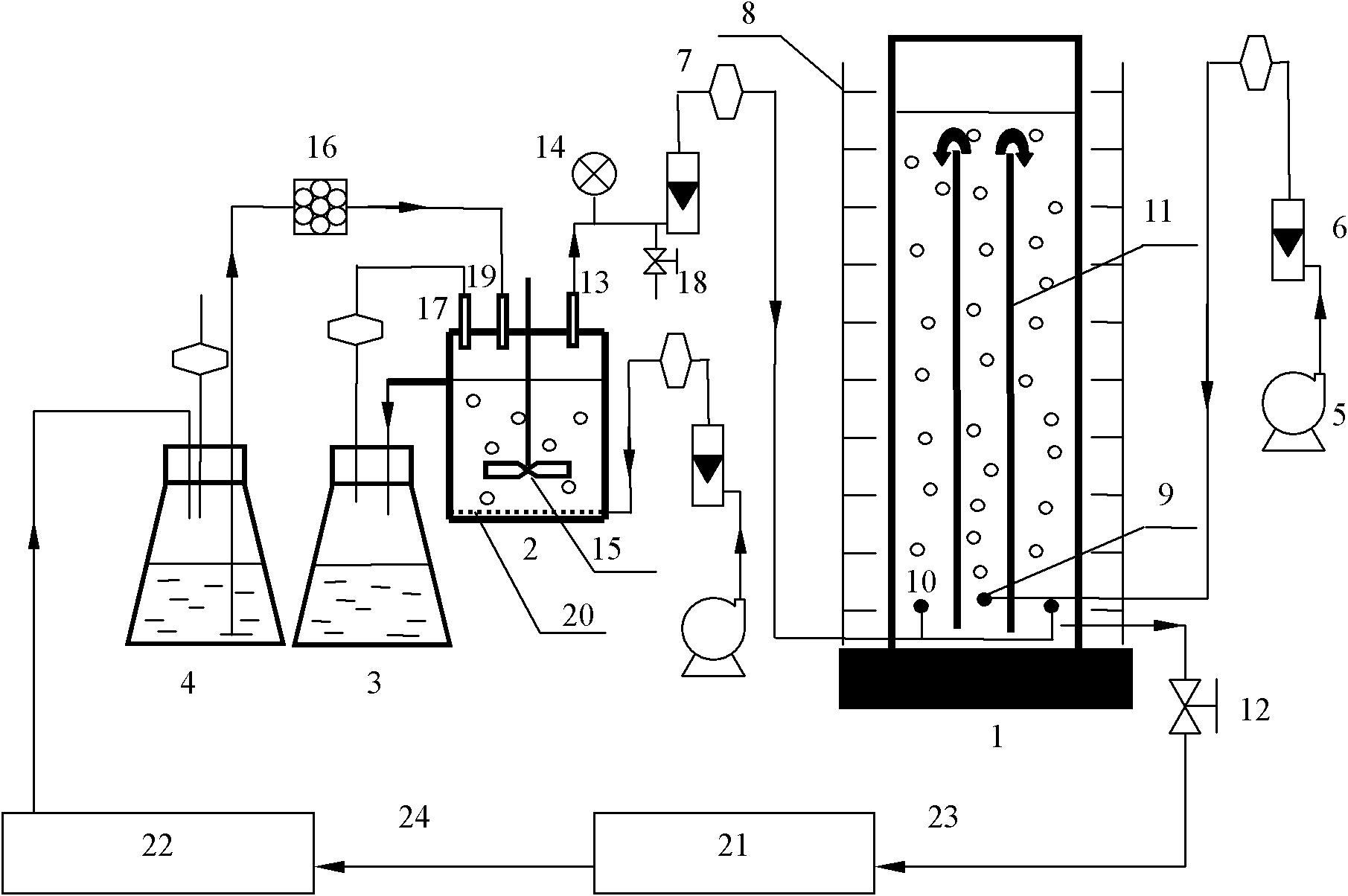

[0032] The system devices such as figure 1 As shown, it includes a microbial fermenter 2 and a photobioreactor 1; the microbial fermenter 2 is provided with a stirring paddle 15, and the compressed air passes through a rotameter to adjust the flow rate and passes through a 0.22 μm microporous membrane 7 to filter and sterilize bacteria and then pass into the microbial fermentation The bottom of the tank 2 is dispersed into small bubbles by the gas disperser 20 for fe...

Embodiment 2

[0048] Cultivation of Tetragalenia subcordiformum to immobilize CO in the tail gas of ethanol production by fermentation of yeast 2 , will contain about 40% (V / V) CO 2 The ethanol fermentation tail gas is directly passed into the photobioreactor to cultivate Tetraspermium subcardioid, so that it can fix CO 2 And a large amount of starch is accumulated, and the acid-thermal hydrolysis method is used to release the starch to generate glucose, which is used as a raw material supplement for yeast fermentation to produce ethanol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com