Method for preparing p-tert octyl phenol

A technology of tertoctylphenol and phenol, which is applied in the field of preparation of p-tertoctylphenol, achieves good application prospects, overcomes the difficulties of separation and treatment, and overcomes the effect of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

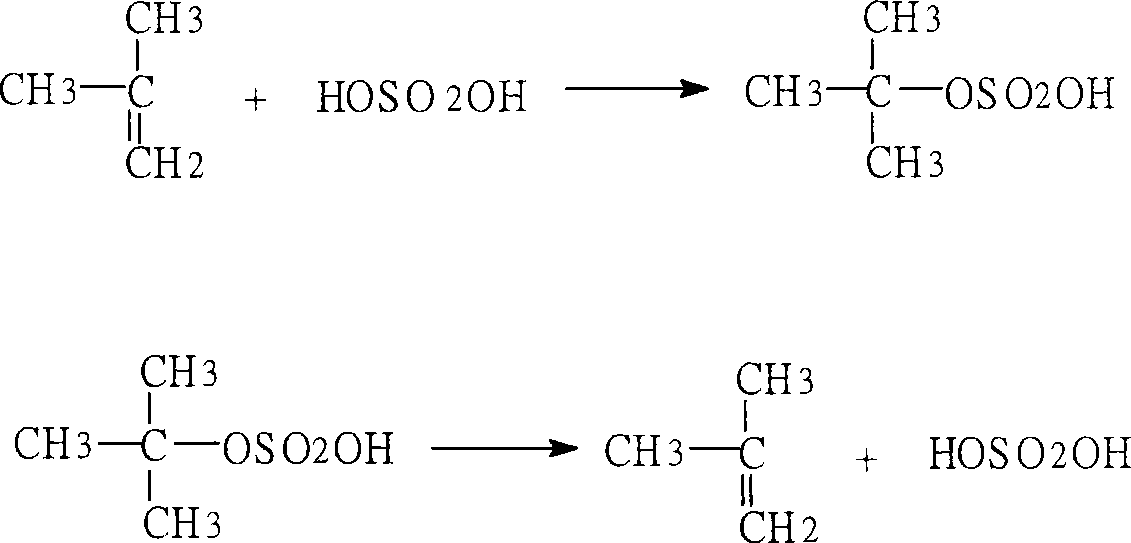

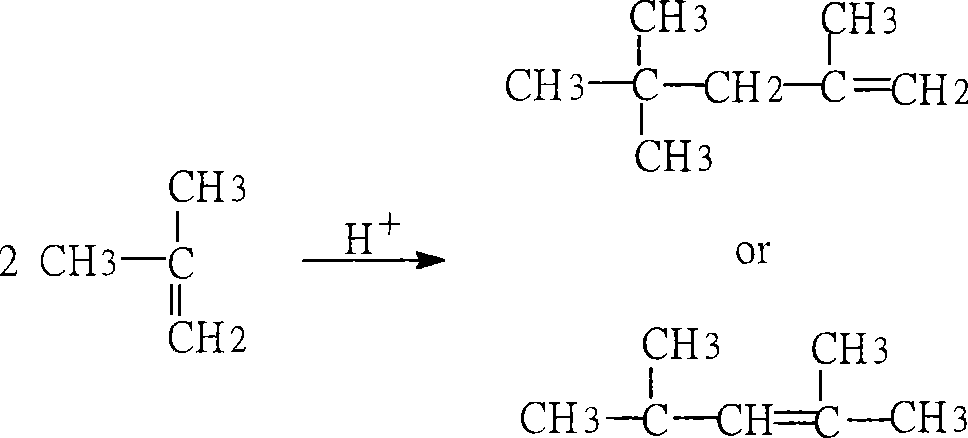

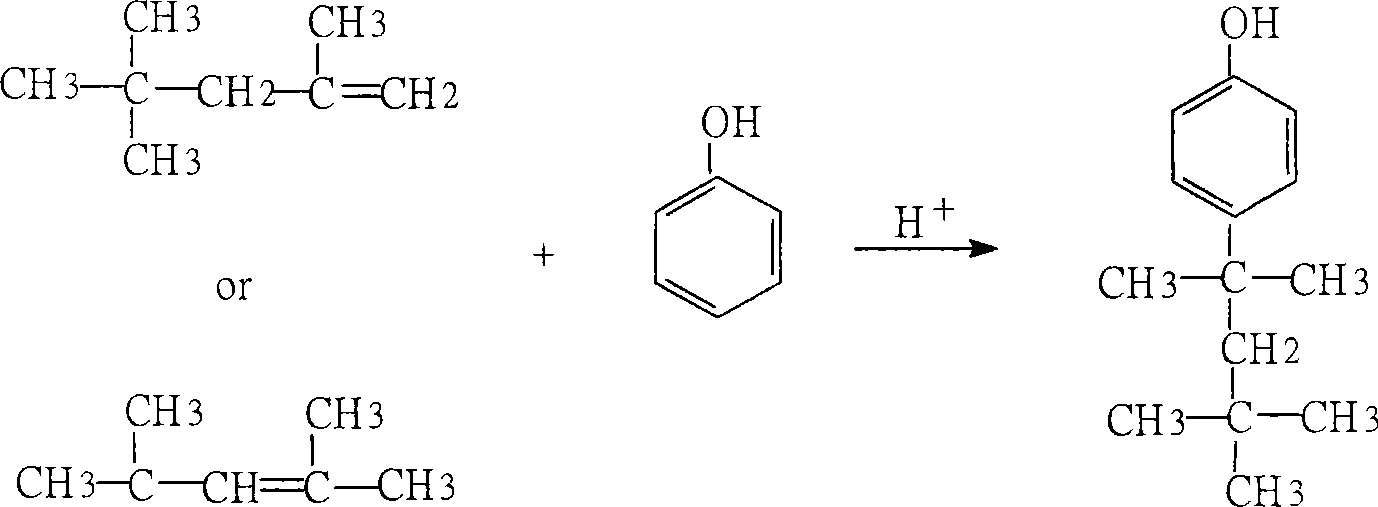

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1, p-tertoctylphenol preparation method

[0020] Adopt the preparation method of p-tertoctylphenol of the present invention, with the content of about 80% C 4 The addition mixture (by-product) is used as the raw material; the isobutylene dimer with the content of the target fraction > 98% obtained by distillation and cutting at 75°C-105°C is used as an alkylating agent; Na-type sulfonated styrene-ethylene di Alkene copolymer strongly basic anion exchange resin, converted into H-type sulfonated styrene-ethylene-diene copolymer strongly acidic cation exchange resin after acidification, as an alkylation catalyst, undergoes alkylation reaction with phenol at 100°C , The alkylation mixture was cut by distillation at 220°C-270°C to obtain p-teroctylphenol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com