Ultra-clean vacuum sealing method for optical lens

An optical lens and vacuum sealing technology, which is applied in the field of pollutant control, can solve the problems of high cost and vacuum pollution, achieve the effect of simple and easy replacement, overcome the problem of high cost, and solve the problem of vacuum pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

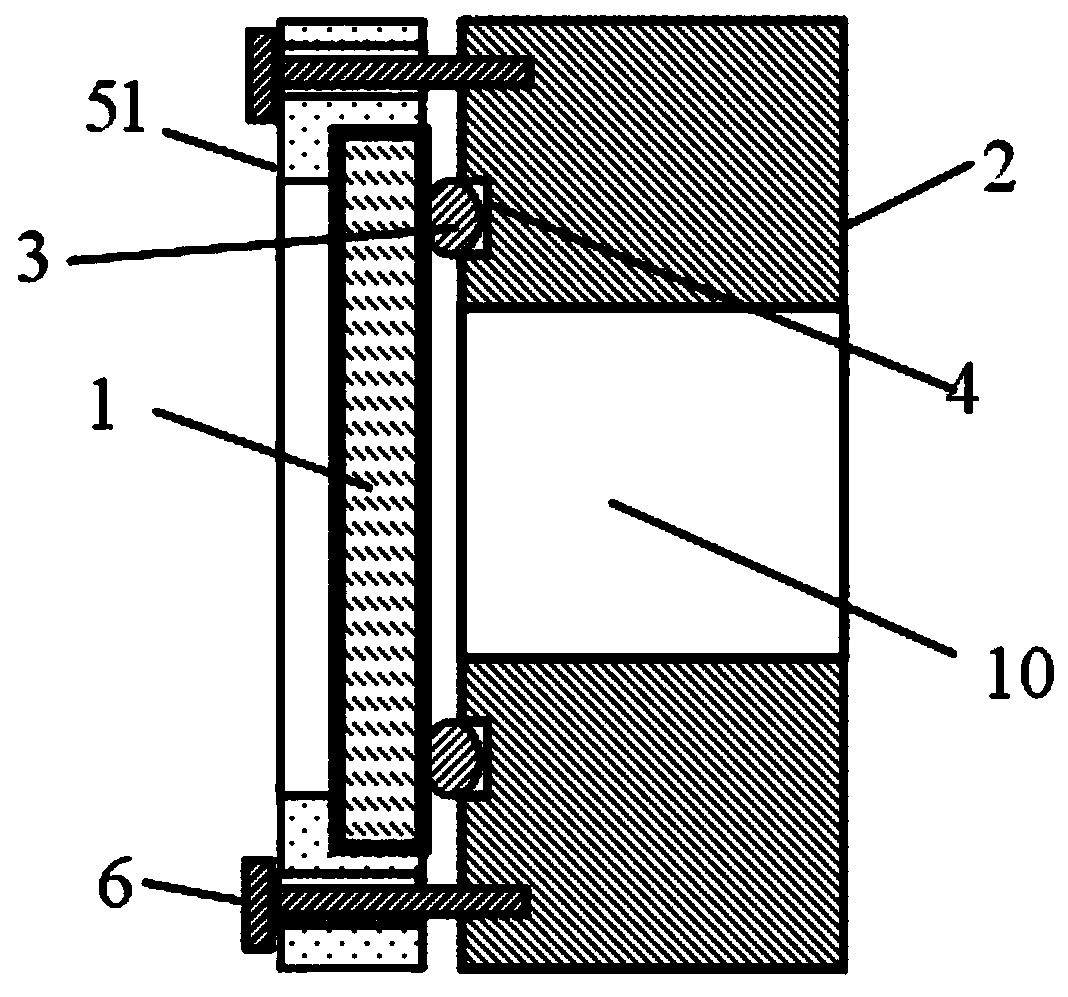

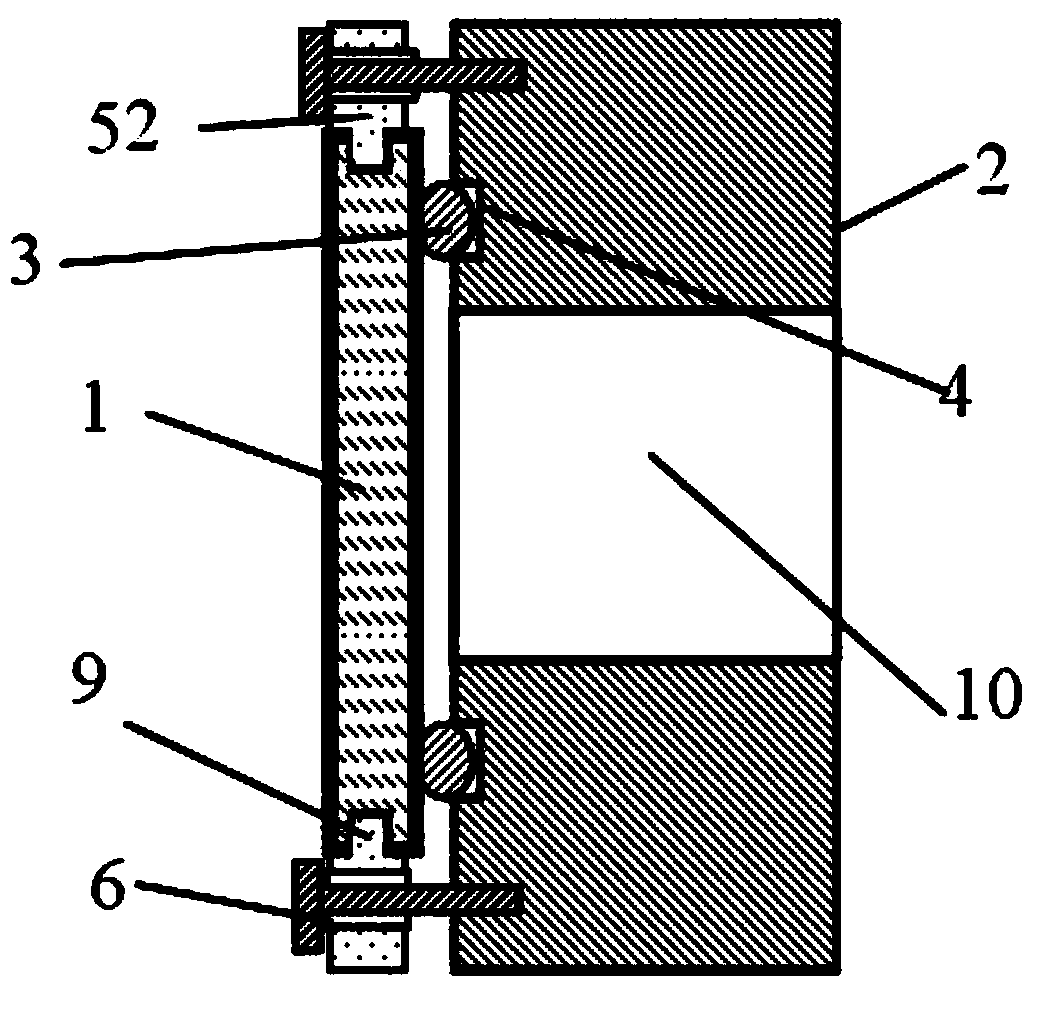

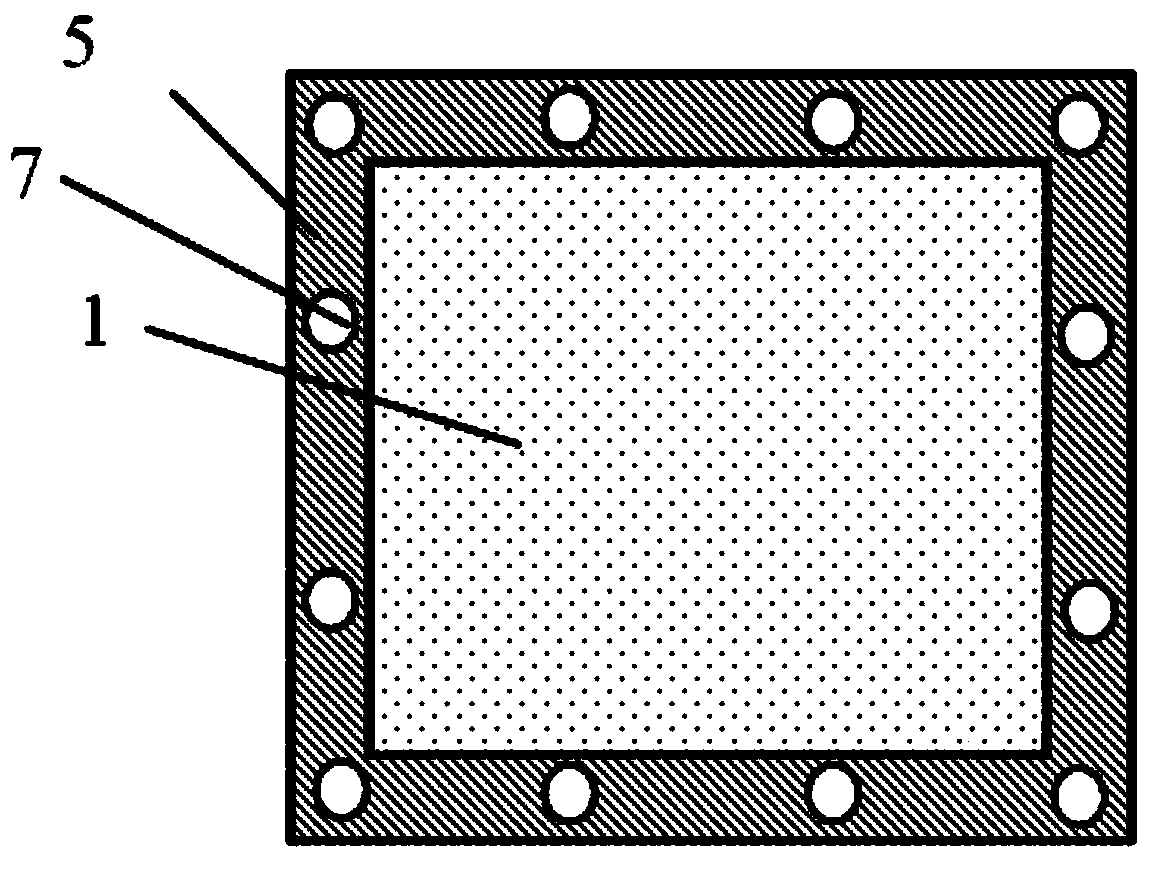

[0024] as attached figure 1 or attached figure 2 As shown, an ultra-clean vacuum sealing method for an optical lens, the installation device 2 and the optical lens 1 are sealed and fixed by a soft metal sealing ring 3 to control the pollution of organic pollutants caused by the rubber sealing ring. The soft metal sealing ring 3 is made of aluminum, tin, lead, indium, gold, silver or their alloy materials. The cross section of the soft metal sealing ring 3 is circular or rectangular or circular or crescent-shaped, the shape of the soft metal sealing ring 3 and the sealing groove 4 is circular or square, and the soft metal sealing ring 3 The circumference corresponds to the circumference of the sealing groove 4. The cross-section of the soft metal sealing ring 3 can be circular or square or circular or crescent-shaped, and a sealing ring with a circular cross-section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com