Method for inhibiting scale on surface of blunt metal material

A metal material and anti-scaling technology, which is applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of high cost and tediousness, and achieve high cost, broad application prospects, and anti-scaling Obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] The pretreatment involved in the specific embodiment of the present invention is as follows:

[0024] Put the sample into the organic solvent acetone or metal cleaning agent for ultrasonic cleaning to remove the oil and impurities on the surface. Finally, wash with deionized water, dry, and set aside.

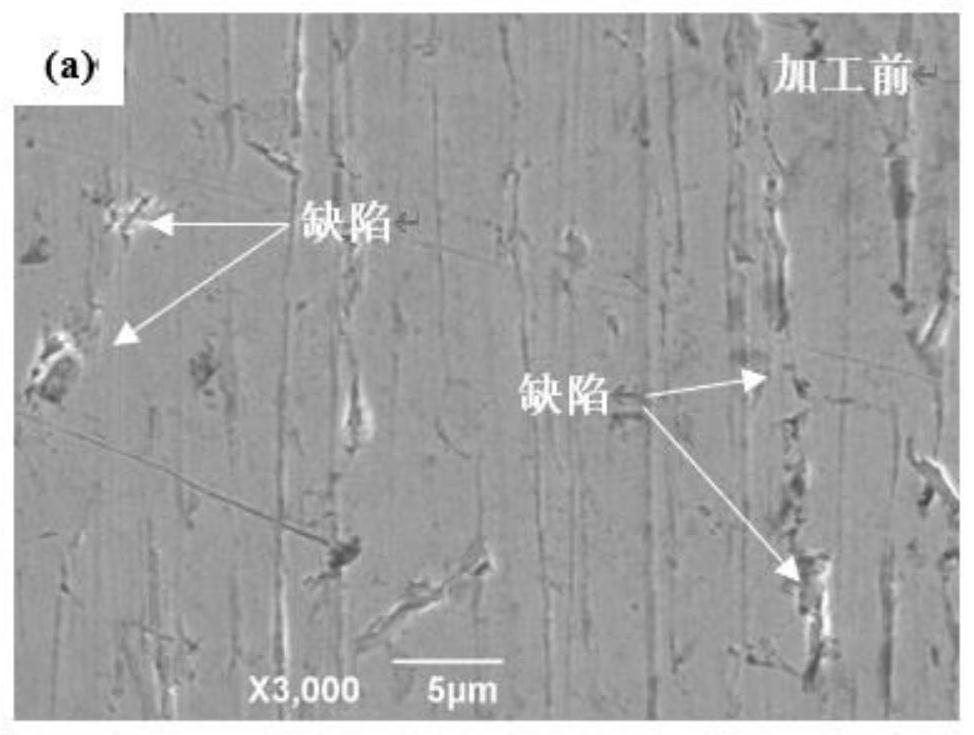

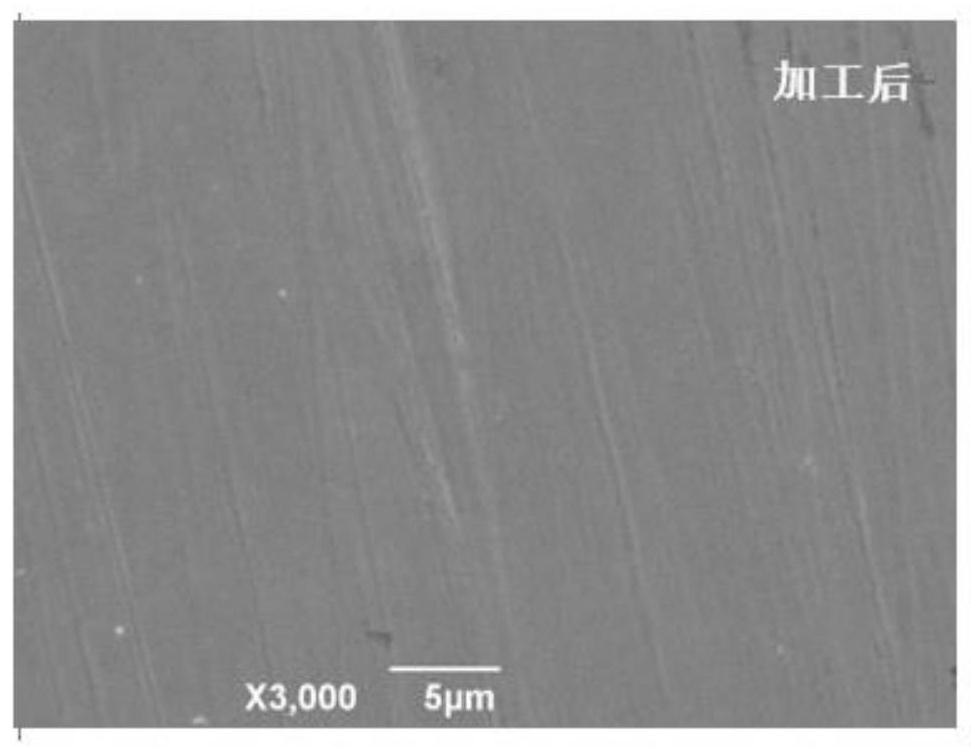

[0025] After the degreasing treatment is completed, the specific surface processing steps are as follows:

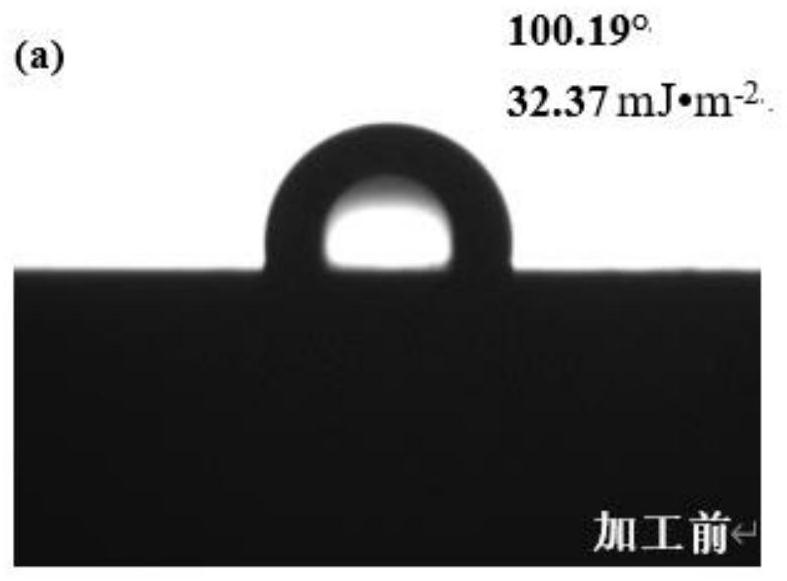

[0026] First, fix the 316L stainless steel that has been degreased on the machine tool, and then set the process parameters of ultrasonic rolling processing. The main parameters are: processing line speed 2m / min, step distance 0.08mm, pressure 1MPa, pneumatic ball, rolling 5 Second-rate. Then, start the power switch, and perform ultrasonic rolling treatment on the surface of 316L stainless steel. The surface of 316L stainless steel after ultra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com