Multi-factor efficient optimization design method for motor bar surface electric field

A surface electric field and optimization design technology, applied in neural learning methods, design optimization/simulation, genetic models, etc., can solve the problems of high risk, high test cost, low efficiency, etc., to improve the accuracy of the model and overcome the high cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with example the present invention will be further described, but not as limiting the present invention.

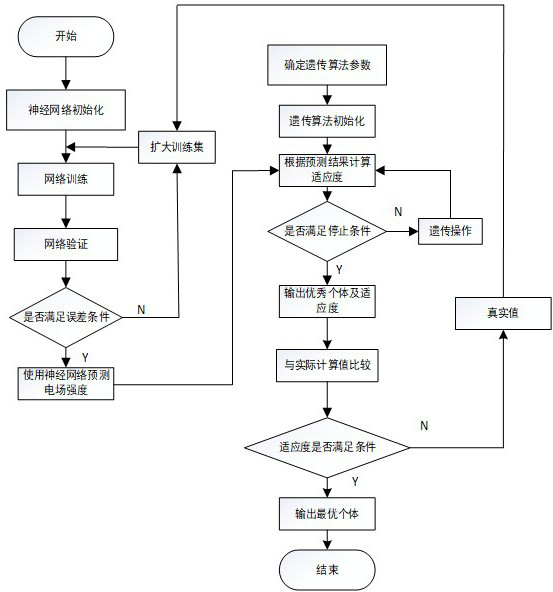

[0024] figure 1 The flow chart of the multi-factor optimization design method for the surface electric field of the motor bar is shown. The following is an example of the optimization of the end structure of the stator bar of the hydro-generator with a rated voltage of 24kV and a rated capacity of 1000MW:

[0025] Step S1, select the optimization target and obtain the initial training data set:

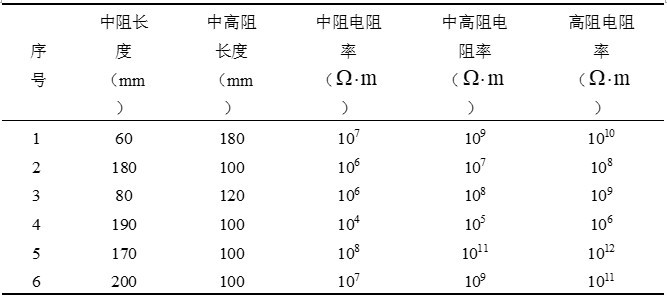

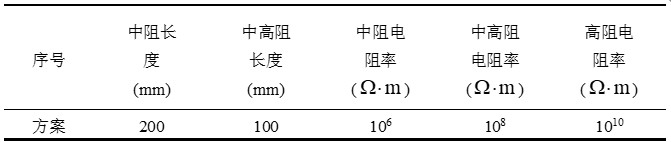

[0026] The optimization goal in this example is to adjust the length of medium resistance, length of medium and high resistance, resistivity of medium resistance, resistivity of medium and high resistance, and resistivity of high resistance of anti-corona layer of motor wire rod so that the maximum tangential electric field on the surface of motor wire rod is lower than 1.5kV / cm. Combined with the finite element simulation model of the end of the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com