Gold blocking paper printing method

A hot stamping paper and printing technology, which is applied in the field of hot stamping paper printing, can solve the problems of hot stamping patterns, etc., and achieve the effects of improving production efficiency, reducing transportation links, and facilitating flattening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

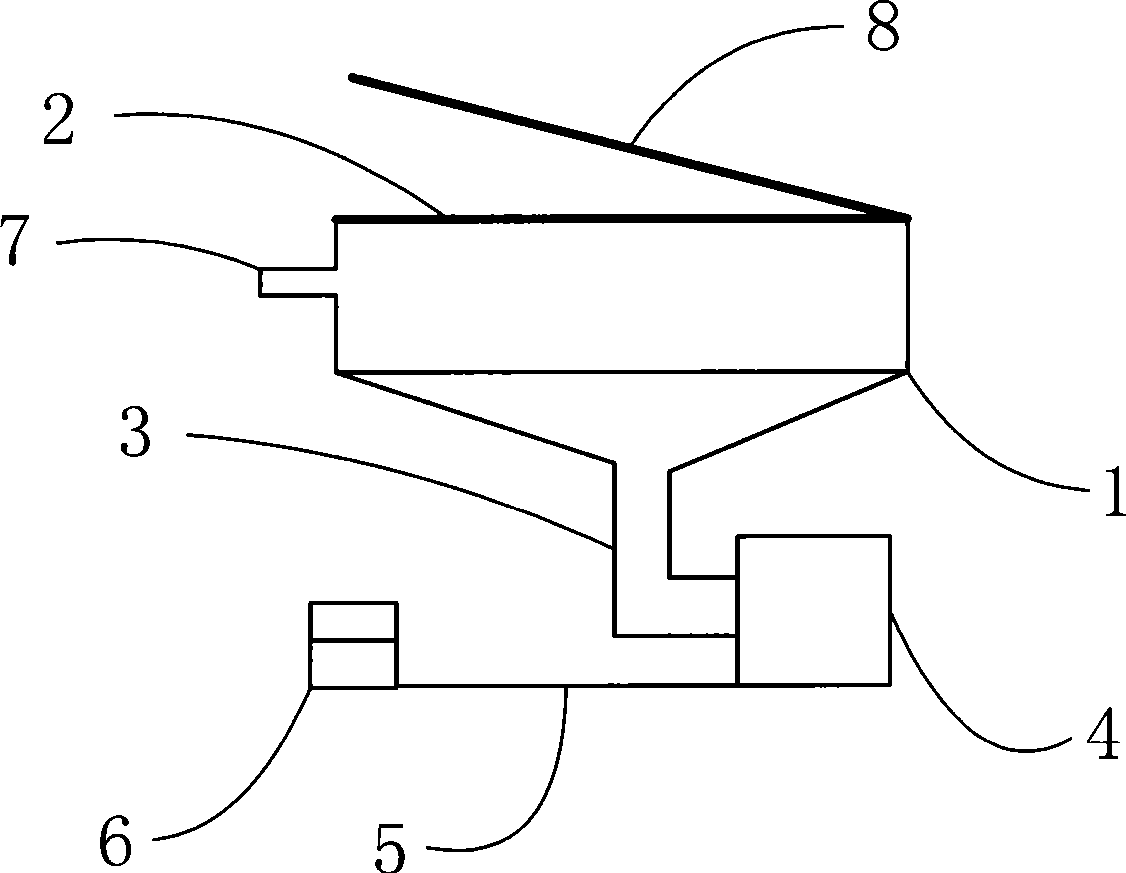

Image

Examples

Embodiment

[0020] To gilt the Olympic logo pattern on the swimsuit, engrave the pre-made pattern on the printing plate, inlay it on the printing plate, then spread the gilding paper on the printing table, step on the foot switch, turn on the power, and make the vacuum pump run. Draw out the air in the casing; press down the printing plate, print glue paste on the bronzing paper, then lift up the printing plate, release the foot switch, manually open the air release valve, let the outside air into the casing, remove the Hot stamping paper printed with Olympic pattern glue, after packaging, it becomes a finished hot stamping paper with glue printed on it.

[0021] Put the hot stamping paper printed with the Olympic logo pattern on the swimwear, apply heat and pressure to the hot stamping paper with an electric iron or hot stamping machine, and the gold Olympic pattern will be transferred and attached to the swimwear.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com