Layout method for underground dense-medium shallow-slot coal preparation in coal mine

A dense-medium shallow groove and layout method technology, which is applied to safety devices, mining equipment, earthwork drilling and mining, etc., to achieve the effects of reducing production costs, solving gangue pollution, and saving transportation links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

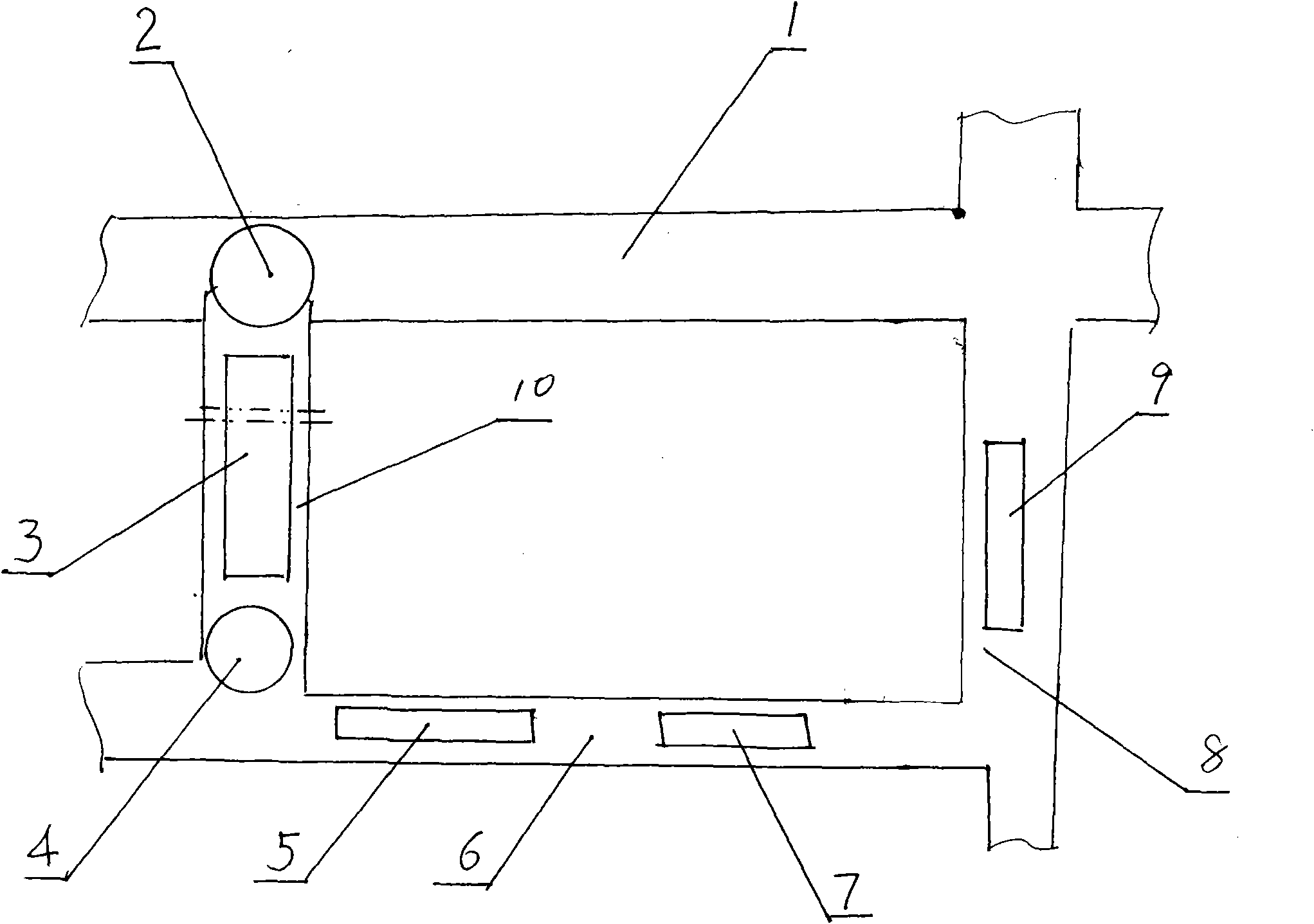

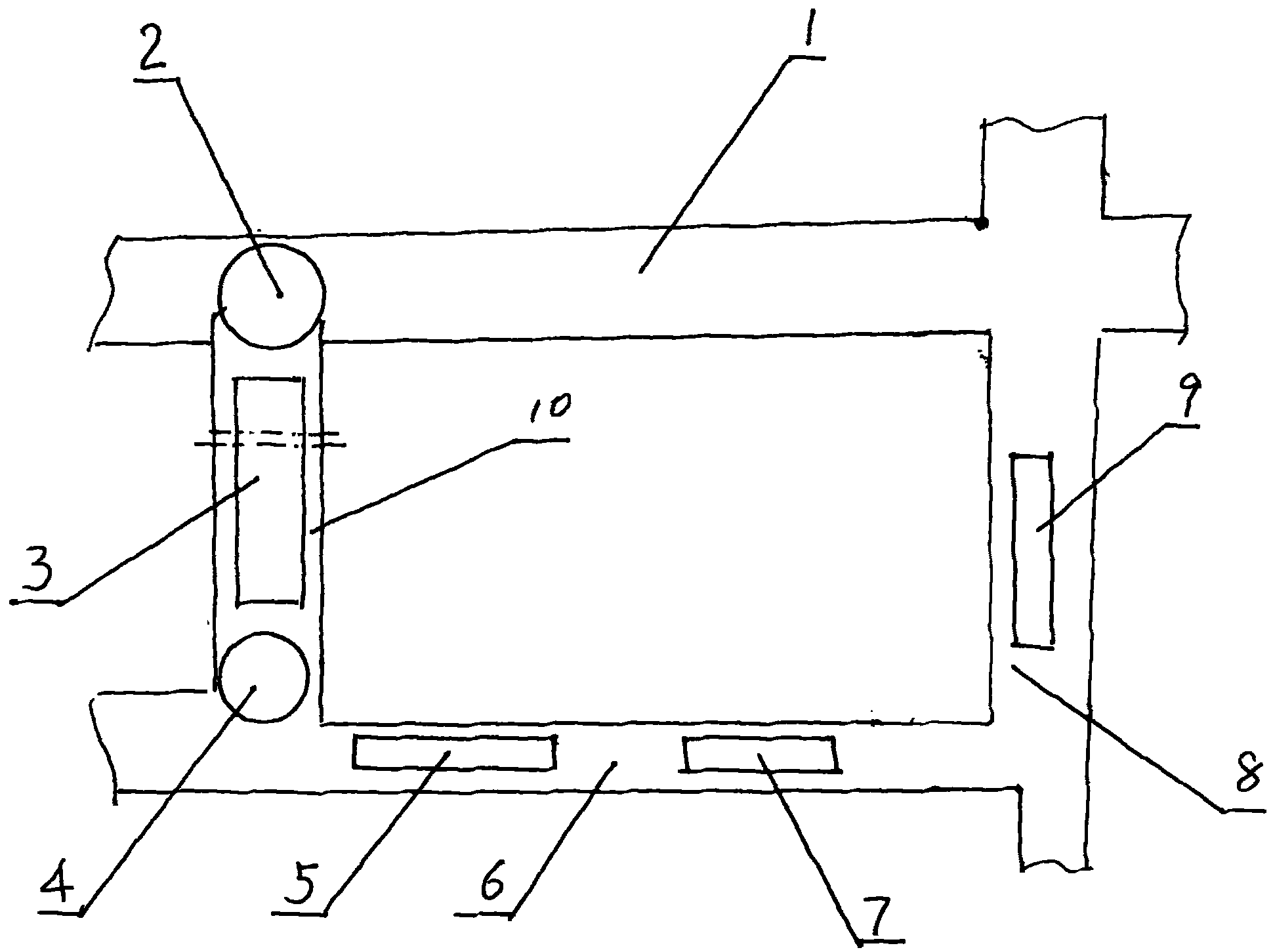

[0013] The following takes the second mining area of the coal mine as an example to combine figure 1 To further explain the technical plan, the second mining area of a coal mine is currently mining the first and seventh layers of coal, and the transportation roadway and coal bunker have been built in the second mining area. gangue to backfill the goaf. Based on the above existing situation, the implementation steps are as follows:

[0014] The first step: develop gangue bin 4 in the rock formation of the mining area within 50m of the same horizontal plane as the existing coal bunker 2;

[0015] The second step: open up the first through roadway 10 between the coal bunker 2 and the gangue bin 4, and the section of the roadway can meet the size requirements of the installation of the coal gangue dense medium shallow groove separator 3;

[0016] The third step: start from gangue bin 4 to open up the second through roadway 6 in the direction of the goaf parallel to the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com