Continuous material belt type metal part efficient electroplating and cutting integrated flow line

A technology of assembly line and metal parts, which is applied in the field of high-efficiency electroplating and cutting integrated assembly line for continuous strip-type metal parts, which can solve the problems such as the inability to meet the cleanliness requirements of medical products, the inability to meet the assembly and use of finished products, and the difficulty in reducing the cutting processing time. , to achieve the effect of reducing handling and transportation links, saving space utilization costs, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the drawings and embodiments:

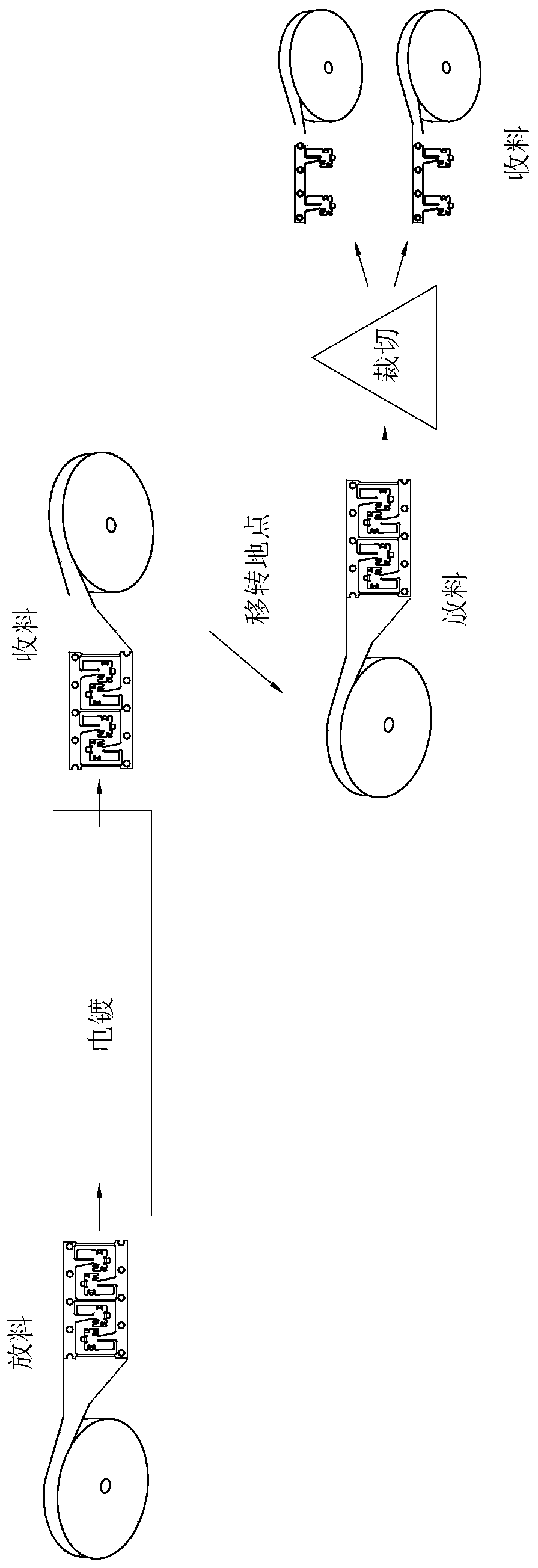

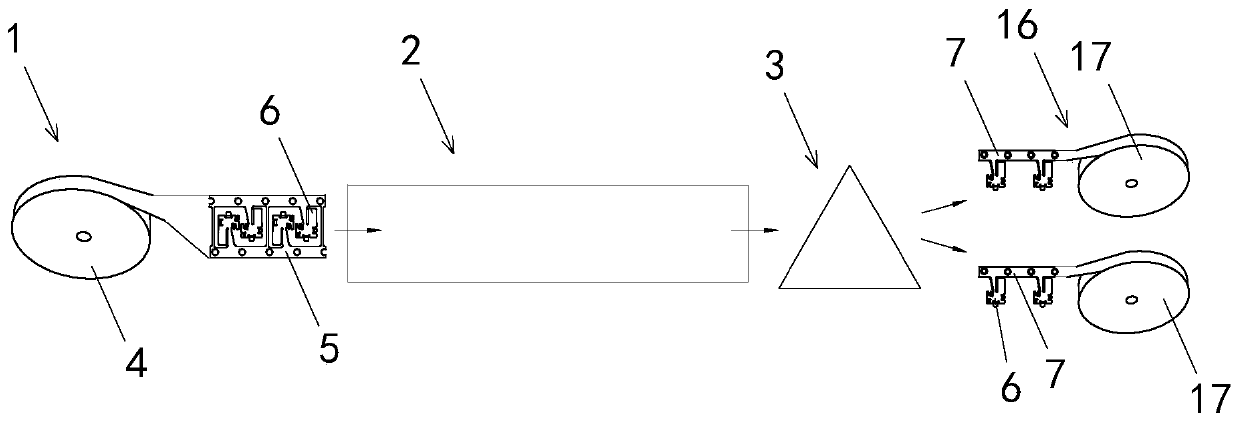

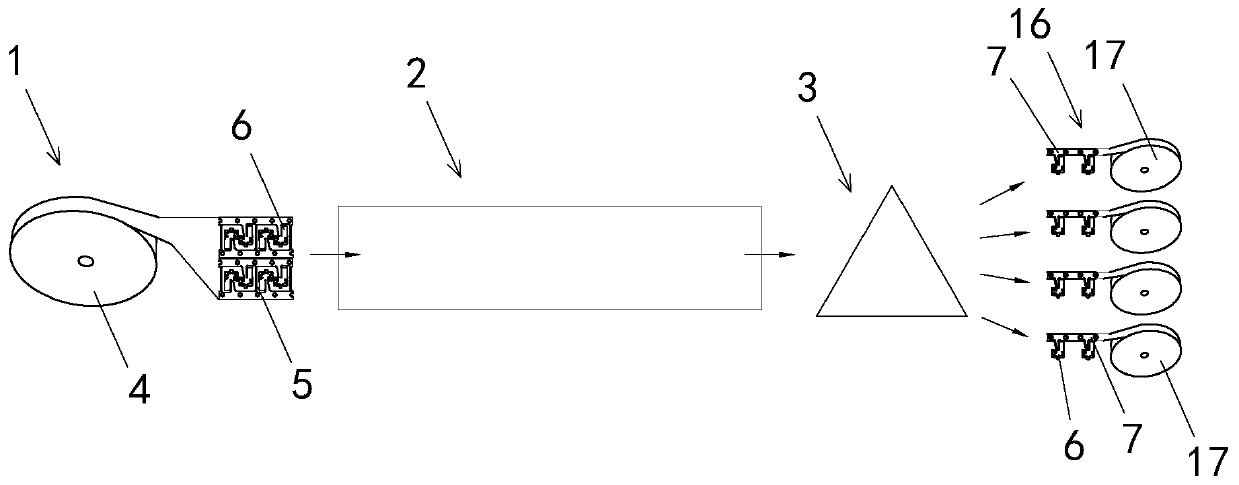

[0040] Example: see attached Figure 2~7 As shown, a continuous strip-type metal piece high-efficiency electroplating and cutting integrated assembly line; according to the processing order, it includes a discharge unit 1, an electroplating unit 2, and a cutting unit 3 from front to back along the X axis.

[0041] The unwinding unit 1 includes a rotation positioning mechanism (not shown in the figure) for a first material roll 4, which is a continuous material strip type material metal product to be electroplated after being packaged in a package, The positioning mechanism may be a rotating shaft, the length of the rotating shaft corresponds to the Y-axis direction, and is rotatably connected to a frame (not shown in the figure) of the assembly line; the first roll 4 is sleeved on the rotating shaft with its rotation center On; the first roll 4 is horizontally discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com