Refrigerator compressor piston pin hole combination processing method

A technology for refrigerator compressors and piston pin holes, which is applied to mechanical equipment, machines/engines, and liquid displacement machinery, etc., and can solve problems such as small piston inner cavity space, easy-to-touch milling cutters, and different chamfer sizes , to achieve the effect of shortening the production cycle, improving processing efficiency and broadening the market space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

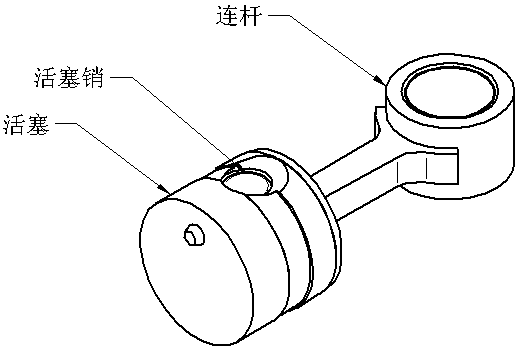

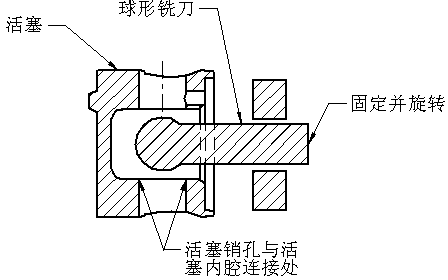

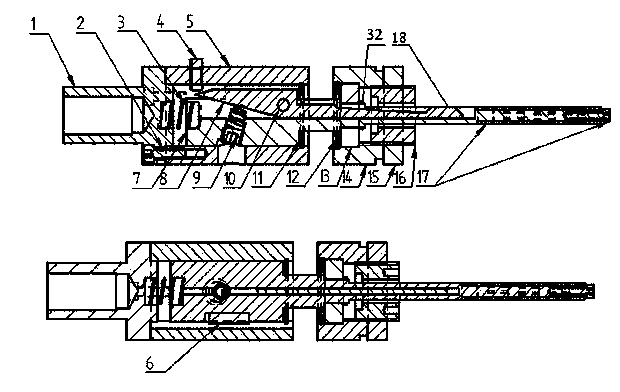

[0025] Attached below Figure 1-5 The present invention is described in further detail with specific embodiment:

[0026] A method for combined processing of piston pin holes of refrigerator compressors, characterized in that it includes combined processing tools and processing steps:

[0027] The combined processing tool is: including a flange tool handle assembly, a sliding sleeve assembly, a sliding tool bar shaft assembly, and a bearing assembly. The sliding sleeve assembly is composed of a sliding sleeve 5, a stroke adjustment screw 4, and a thrust retaining spring 11. The sliding knife bar shaft assembly is composed of a key pin 6, a stepped shaft knife bar 7, an inner chamfering blade 8, and a stroke limit adjustment Bolt 9, pin shaft 10, rolling device 17 are made up, and described bearing assembly is made up of thrust circlip 2 12, thrust circlip 3 32, cutter bar bearing 13, bearing sleeve 14, fastening nut 15, inner chamfer position Regulating block 16 forms;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com