Support method for fully-mechanized coal mining face full-negative-pressure withdrawing channel

A fully-mechanized mining face and retraction channel technology, which is applied in the field of retraction channel support, can solve problems such as tail lane channel blockage, poor anti-push capability, and complicated procedures, so as to reduce labor intensity, improve racking efficiency, and economical The effect of out-of-shelf mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

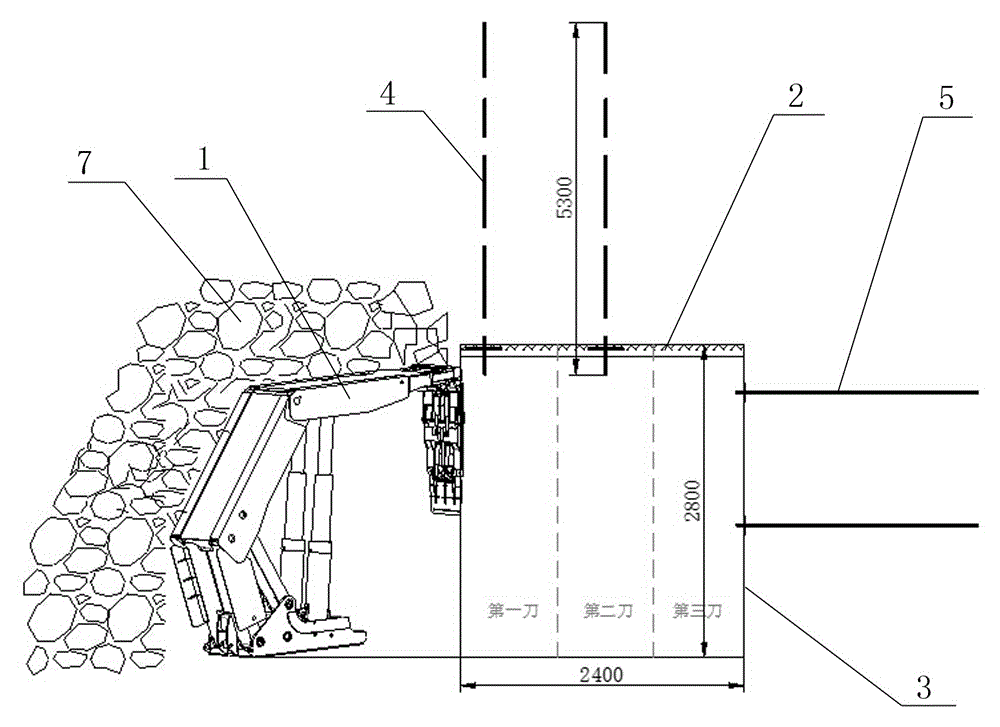

[0020] A full negative pressure retraction channel support method for a fully mechanized mining face in a high-gas mine. After the final mining of the fully mechanized mining face is completed, the coal mining machine 1 is used to cut coal to form a self-drilling retraction channel, such as figure 1 As shown, the cutting distance of each shearer is 800mm, then the shearer can cut coal with three cuts to form the width of the retraction channel, and support it with high-strength bolts (cables), and cancel the cover frame. The way of retaining the wooden piles is to use one-time support to realize full negative pressure ventilation during the removal of the racks.

[0021] The section size of the withdrawal channel is 2400×2800mm; after the withdrawal channel is formed, the specific support plan is as follows:

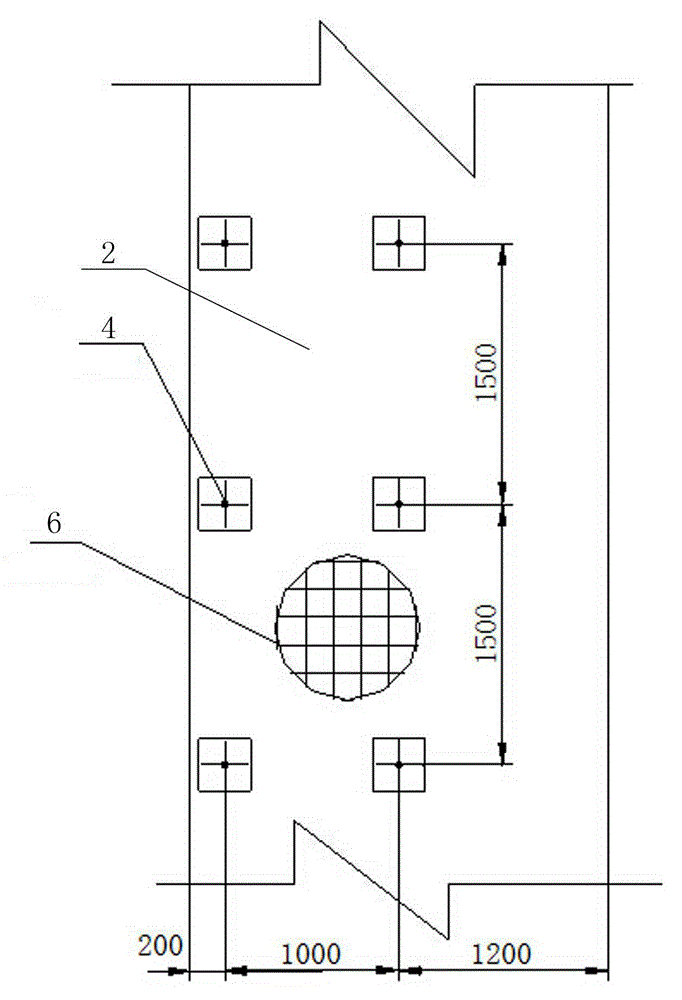

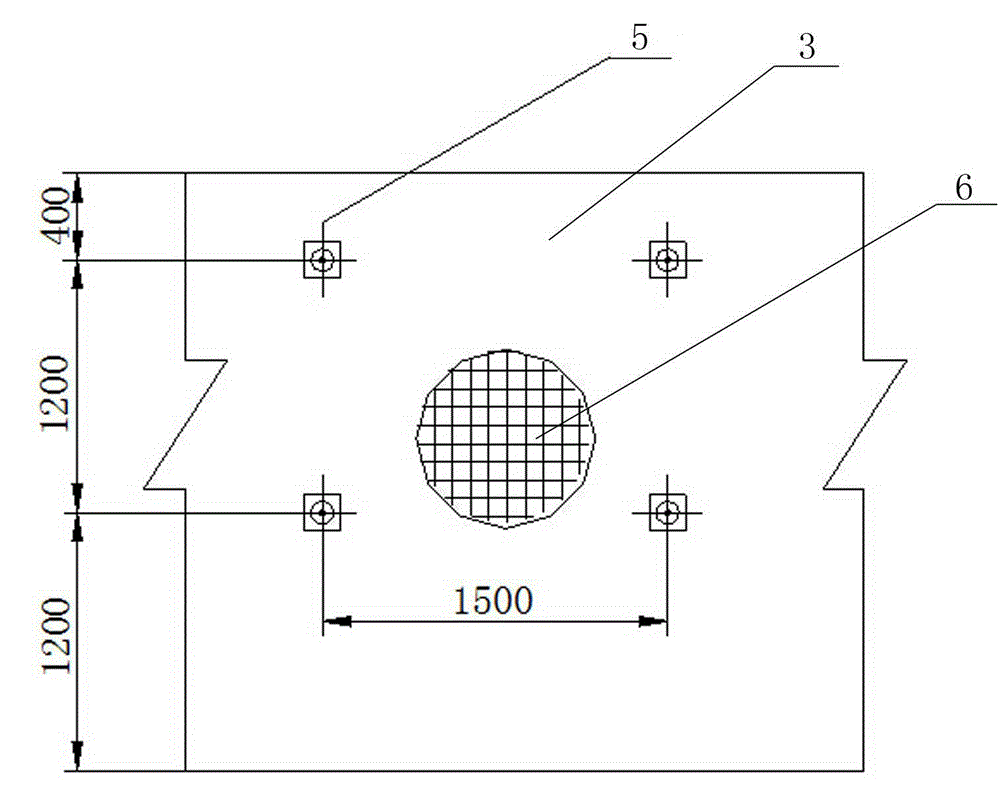

[0022] Such as figure 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com