SMA asphalt concrete modifier and preparation method thereof

A technology of asphalt concrete and modifier, applied in the field of asphalt concrete, can solve the problem that SBS modifier and lignin fiber are difficult to melt and granulate together, so as to improve cohesiveness and high temperature performance, reduce granulation temperature, prevent The effect of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] 1. Prepare materials

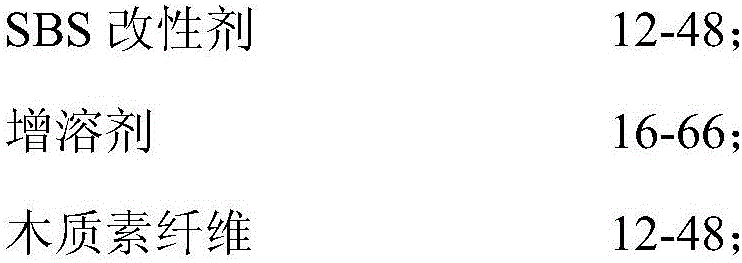

[0074] Weigh each component according to the following parts by weight ratio,

[0075]

[0076] Among them, SBS is linear 791H produced by Yueyang Petrochemical. The lignocellulose is in flocculent form and is produced by JRS Company in Germany. The solubilizer is a mixture of furfural extract oil obtained from the naphthenic crude oil produced by Zhonghai Bitumen minus the third line after furfural refining and naphthenic oil produced from Zhonghai Bitumen in a ratio of 1:1. The co-solvent is EVA produced by Yanshan Petrochemical with a vinyl acetate content of 19% and a melt index of 16 g / 10 min. The crosslinking agent is powdered sulfur with a content of 99.5%, produced by Maoming Petrochemical. The accelerator is a mixture of commercially available zinc oxide and commercially available zinc dibenzyl dithiocarbamate at a ratio of 1:1.

[0077] 2. Preparation of SMA asphalt concrete modifier

Embodiment 2

[0083] 1. Prepare materials

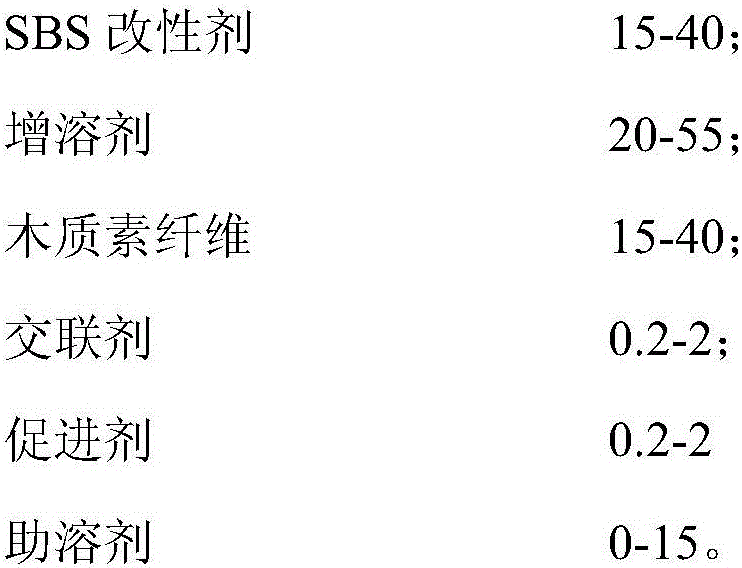

[0084] Weigh each component according to the following parts by weight ratio,

[0085]

[0086] Among them, SBS is Star 4303 produced by Yueyang Petrochemical. The lignocellulose is in flocculent form and is produced by JRS Company in Germany. The solubilizing agent is a mixture of naphthenic crude oil produced from Zhonghai bitumen minus third-line furfural extraction oil and 110# bitumen in a ratio of 1:1. The co-solvent is EVA produced by Yanshan Petrochemical with a vinyl acetate content of 16% and a melt index of 19g / 10min. The crosslinking agent is powdered sulfur with a content of 99.5%, produced by Maoming Petrochemical. The accelerator is a mixture of commercially available zinc oxide: zinc dibenzyl dithiocarbamate: stearic acid in a ratio of 3:1:1.

[0087] 2. Preparation of SMA asphalt concrete modifier

[0088] 2.1 Mix the SBS powder with the co-solvent and solubilizer uniformly at 160°C for 40 minutes. At this time, the SBS po...

Embodiment 3

[0093] 1. Prepare materials

[0094] Weigh each component according to the following parts by weight ratio:

[0095]

[0096] Among them, SBS is a mixture of linear 791H produced by Yueyang Petrochemical and star 4303 at a ratio of 1:1. The lignocellulose is in flocculent form and is produced by JRS Company in Germany. The solubilizer is a mixture of 200# asphalt and naphthenic oil produced by Zhonghai Bitumen in a ratio of 1:1. The auxiliary solvent is EVA with a vinyl acetate content of 28% and a melt index of 400 g / 10 min produced by DuPont Company of the United States. The cross-linking agent is liquid sulfur with a content of 99.5%, which is produced by Maoming Petrochemical. The accelerator is a mixture of commercially available zinc oxide: zinc ethylphenyl dithiocarbamate: stearic acid in a ratio of 3:1:1.

[0097] 2. Preparation of SMA asphalt concrete modifier

[0098] 2.1 Mix the SBS powder with the co-solvent and solubilizer uniformly at 130°C for 30 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com