Open pit coal mine self-moving-type continuous coal mining and loading equipment and arrangement method thereof

An open-pit coal mine, self-moving technology, which is applied in open-pit mining, earthwork drilling, special mining, etc., can solve the problems of poor adaptability of hard rock or coal seam, inconvenient mining and transportation, high hardness requirements, etc., to avoid a large number of Dust, no need for truck transportation, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

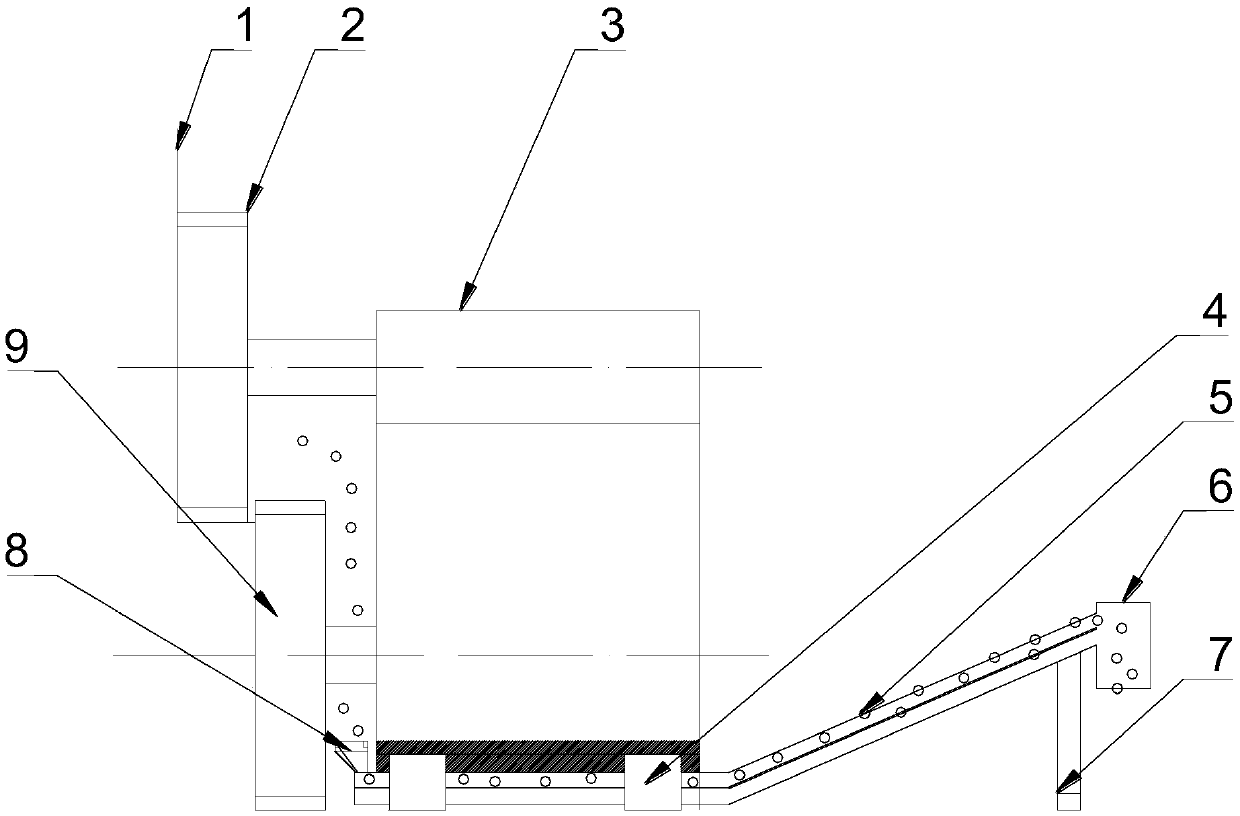

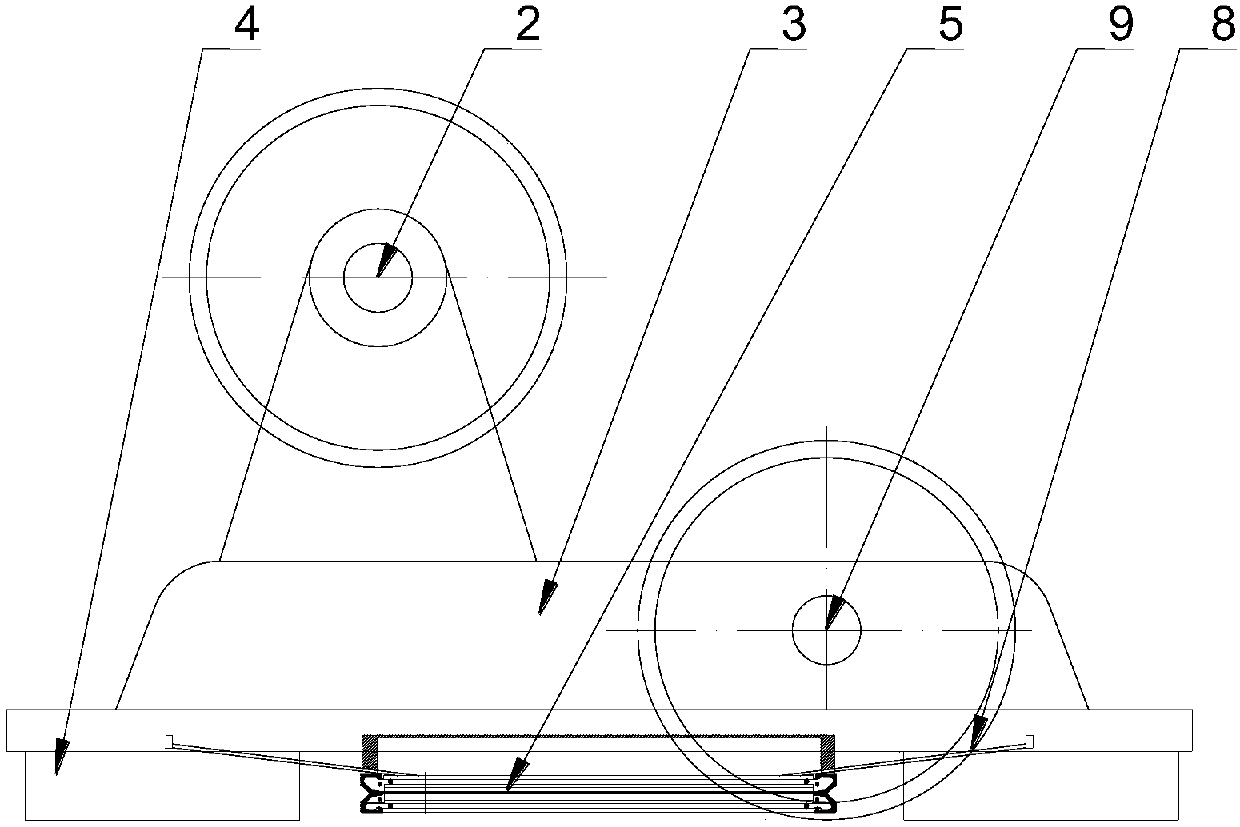

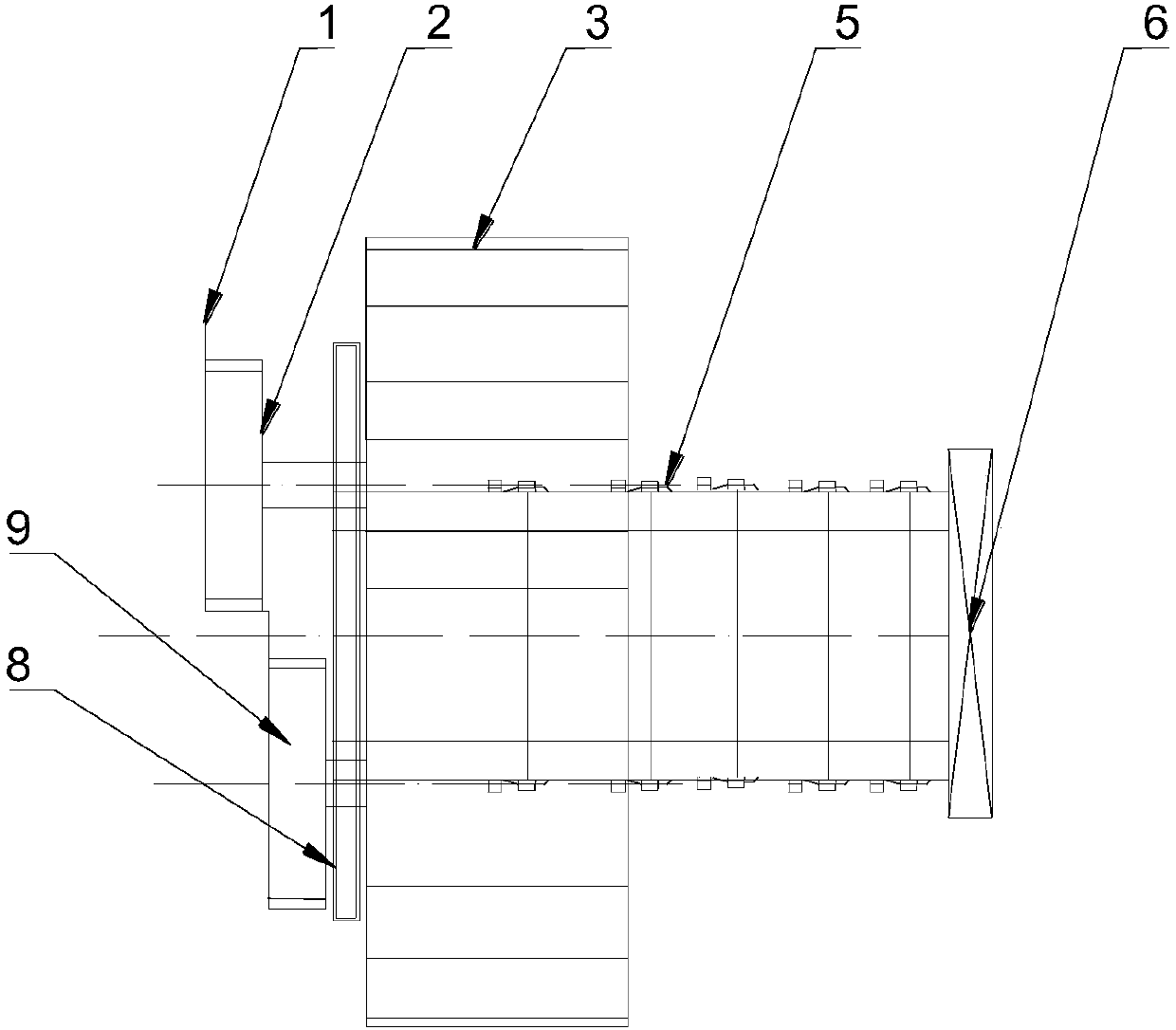

[0022] The open-pit coal mine self-moving continuous coal mining equipment involved in this device mainly includes a bottom self-moving crawler vehicle 4, a coal dropper 3, and two large-scale cutting drums 2 and 9 arranged in a centralized manner. The crawler vehicle 4 is equipped with a driving device and has a self-moving function. The coal faller 3 is located on the crawler vehicle 4 and is rigidly connected with the crawler vehicle. The cutting drums 2 and 9 are installed on the coal faller 3, which is a direct coal fall mechanism. The double cutting drums 2 and 9 are arranged one up and one down, and a certain distance is set between the end faces of the cutting drums to divide the minin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com