Composite modifier and high-scattering-resistance drainage asphalt concrete prepared through same

A composite modifier and drainage asphalt technology, which is applied to other household appliances, household appliances, ceramic products, etc., can solve the problems of high preparation cost, poor scattering resistance of drainage asphalt mixed soil, and complicated operation, so as to improve adhesion , Good heat aging resistance and water damage resistance, the effect of inhibiting condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] 1. Prepare materials

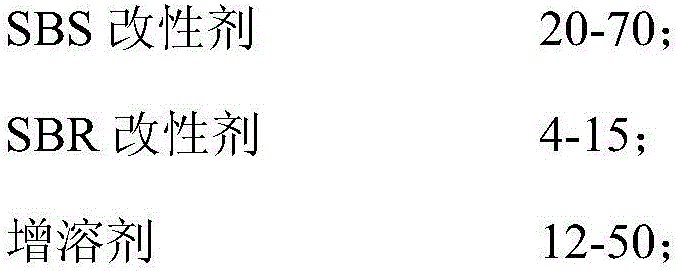

[0082] Weigh each component according to the following parts by weight ratio,

[0083]

[0084]Among them, SBS is linear 791H produced by Yueyang Petrochemical. SBR is a powdered styrene-butadiene rubber with a solid content of 80% produced by Shandong Xianyuan Chemical Industry. The solubilizer is a mixture of furfural extract oil obtained from the naphthenic crude oil produced by Zhonghai Bitumen minus the third line after furfural refining and naphthenic oil produced from Zhonghai Bitumen in a ratio of 1:1. The crosslinking agent is powdered sulfur with a content of 99.5%, produced by Maoming Petrochemical. The accelerator is a mixture of commercially available zinc oxide and commercially available zinc dibenzyl dithiocarbamate at a ratio of 1:1. The fiber is a polyester fiber BoniFiber produced by DuPont Company of the United States, the length is 6 mm, and the elongation at break is 50%. The comprehensive additive is made by mixing com...

Embodiment 2

[0091] 1. Prepare materials

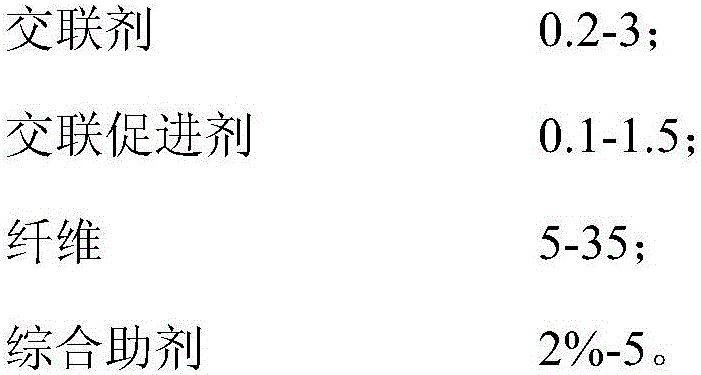

[0092] Weigh each component according to the following parts by weight ratio,

[0093]

[0094] Among them, SBS is Star 4303 produced by Yanshan Petrochemical. SBR is a powdered styrene-butadiene rubber with a solid content of 80% produced by Shandong Xianyuan Chemical Industry. The solubilizer is a mixture of catalytic cracking (FCC) oil slurry produced by Zhenhai Refining & Chemical Co., Ltd. and naphthenic oil produced by Zhonghai Bitumen in a ratio of 2:1. The crosslinking agent is powdered sulfur with a content of 99.5%, produced by Maoming Petrochemical. The accelerator is a mixture of commercially available zinc oxide: zinc dibenzyl dithiocarbamate: stearic acid in a ratio of 3:1:1. The fiber is a polyester fiber produced by Ningbo Dacheng New Material Co., Ltd., its length is 8mm, and its elongation at break is 40%. The comprehensive additive is made by mixing commercially available p-phenylenediamine antioxidant 4010, ethanol, fatt...

Embodiment 3

[0101] 1. Prepare materials

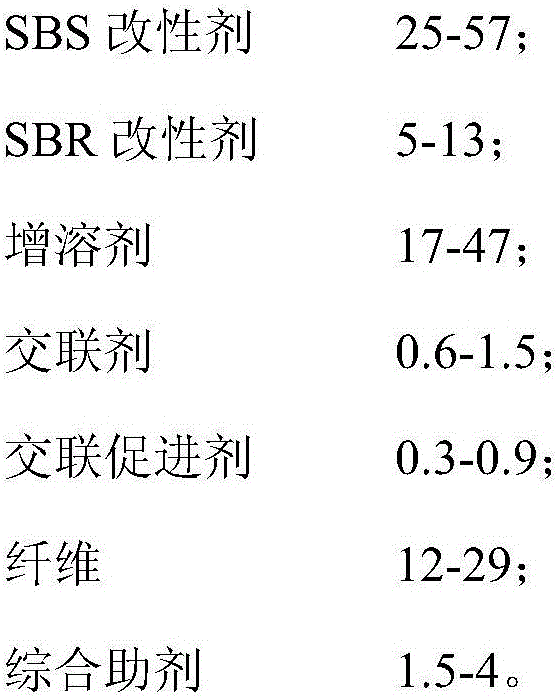

[0102] Weigh each component according to the following parts by weight ratio,

[0103]

[0104] Among them, SBS is the line type 501S produced by LG. SBR is a powdered styrene-butadiene rubber with a solid content of 100% produced in Shandong Qiaolong. The solubilizer is a mixture of naphthenic crude oil produced from Zhonghai Bitumen minus the third-line furfural-refined extracted oil and naphthenic oil produced from Zhonghai Bitumen in a ratio of 1:2. The crosslinking agent is powdered sulfur with a content of 99.5%, produced by Maoming Petrochemical. The accelerator is a mixture of commercially available zinc oxide: zinc dibenzyl dithiocarbamate: stearic acid in a ratio of 4:1:1. The fibers are flocculent lignin fibers produced by JRS Company in Germany. The comprehensive additive is made by mixing commercially available p-phenylenediamine antioxidant 4010, ethanol, fatty acid, and sodium lignosulfonate in a ratio of 3:1:2.5:2.

[0105]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com