RH vacuum refining explosion preventing device and control method thereof

An explosion-proof device and vacuum refining technology, which is applied in the field of steelmaking machinery, can solve problems such as explosions and internal gas explosions, and achieve the effects of simple structure, convenient control, and improved safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

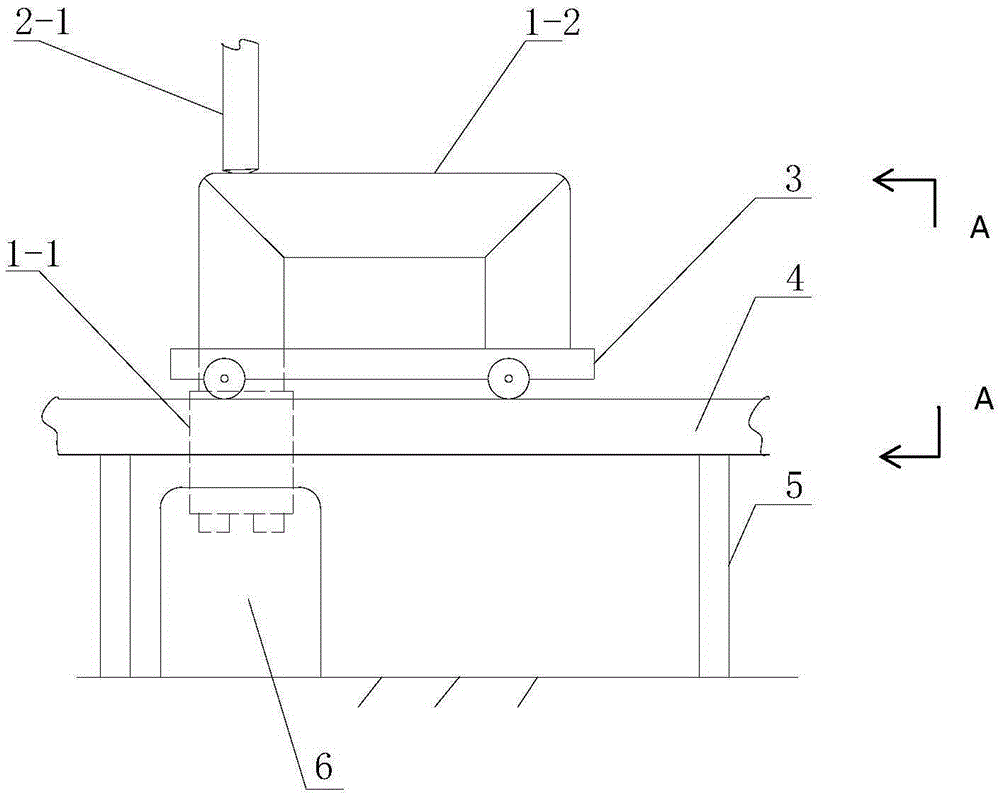

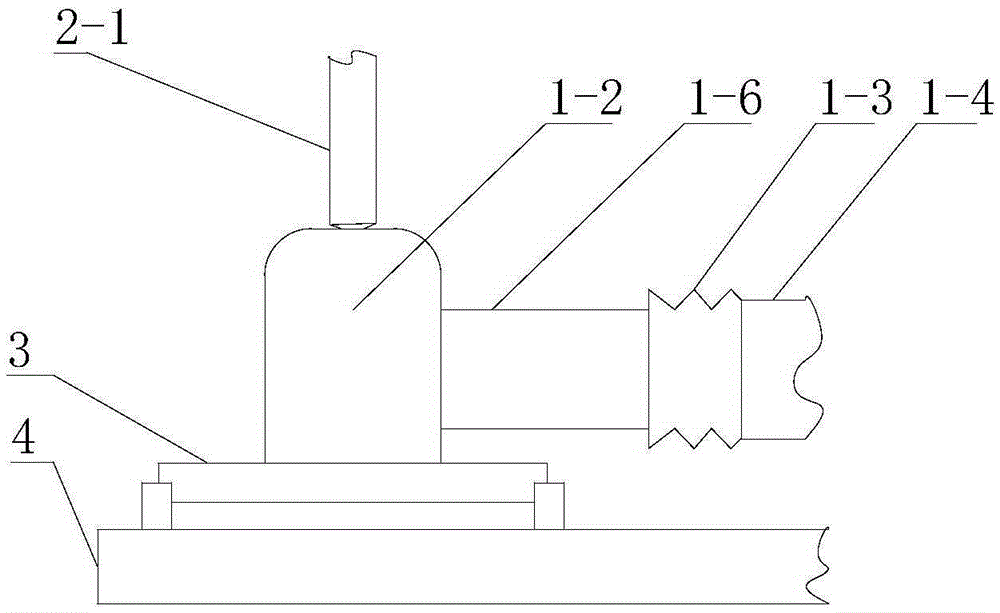

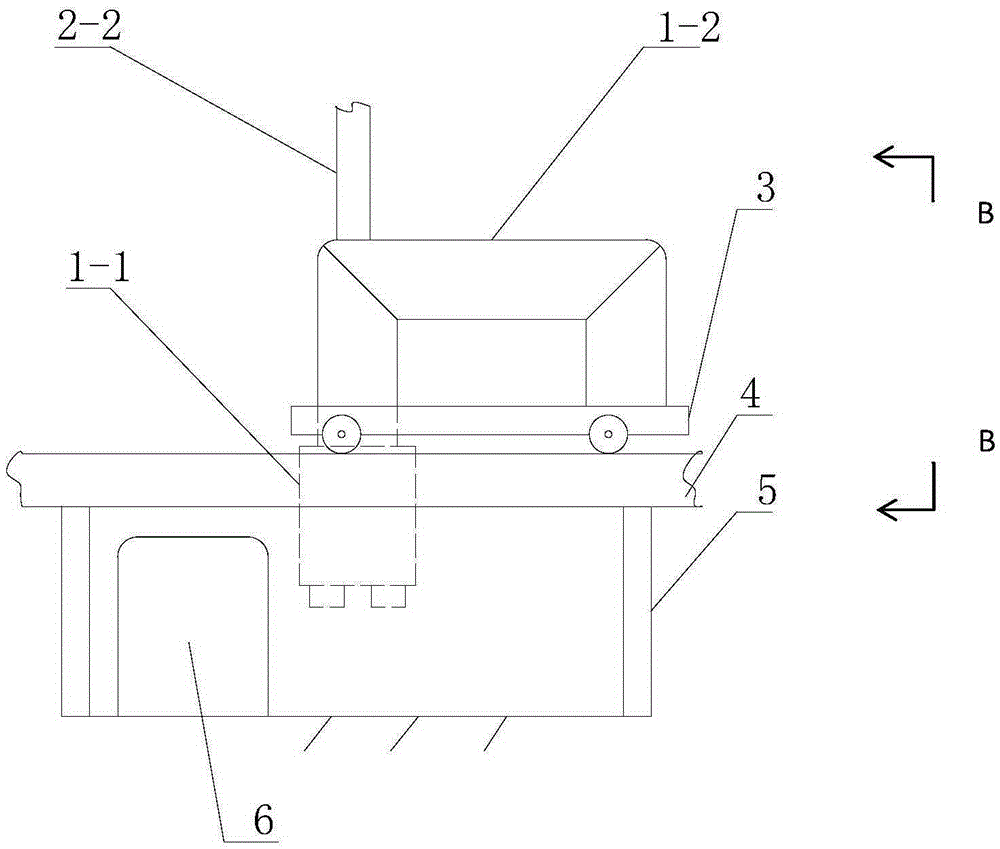

[0039] A RH vacuum refining explosion-proof device and its control method according to the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0040] like Figure 5 Shown, a kind of RH vacuum refining explosion-proof device of the present invention comprises: some cylinders, support frame 7 (as Image 6 shown), hemispherical cover 8, air pipe 83, electromagnetic reversing valve 85, cylinder reversing valve 96, wherein, the explosion-proof device in this implementation is provided with the first cylinder 91, the second cylinder 92, the third cylinder 93 and the first cylinder 91 Four-cylinder 94. like Image 6 As shown, the shape of the hemispherical cover 8 is a hollow hemispherical structure, the hemispherical cover 8 is erected on the support frame 7, the concave surface of the hemispherical cover 8 is parallel to the plane of the hot elbow connection port 1-6, and makes it The concave surface is opposite to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com