Biomass gasification hot charcoal co-production system with independent oxidation chamber

A biomass and oxidation chamber technology, used in combustion equipment, manufacturing of combustible gas, lighting and heating equipment, etc., can solve the problems of poor biomass carbon quality, poor adjustability, and low biomass gasification and cracking efficiency. The effect of high-quality gas-carbon co-production, high flue gas heat, and increased thermal-carbon co-production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

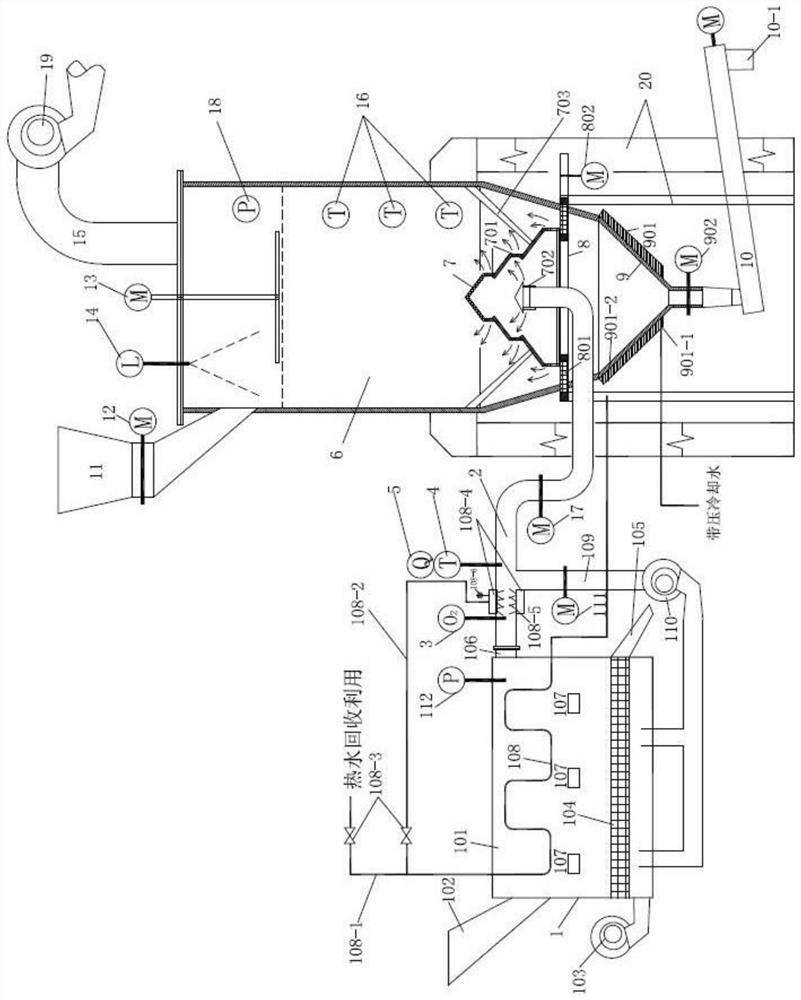

[0044] like figure 1 As shown, a biomass gasification thermal carbon co-production system with independent oxidation furnace is characterized in that it includes independent oxidation furnace and gasification furnace, and the oxidation furnace and the gasification furnace 6 pass through the flue gas pipe 2 connection, the flue gas pipe 2 is provided with a flue gas pipe valve 17, the flue gas pipe 2 is also connected to one end of the flue gas circulation pipe 109, and the other end of the flue gas circulation pipe 109 is connected to the oxidation furnace The oxidation chamber 101 of 1 is connected to each other, the flue gas circulation pipe 109 is respectively provided with a flue gas circulation valve 111 and a flue gas circulation fan 110, and the flue gas pipe 2 is connected to the oxidation furnace at the flue gas pipe valve 17. An oxygen detection device 3, a temperature sensor 4 and a flow meter 5 are respectively provided on the pipeline between 1 and 1, and the gasi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com