Oil-sludge separation discharging device

A discharge device and oil sludge separation technology, applied in the petroleum industry, hydrocarbon oil treatment, pyrolysis treatment of sludge, etc., can solve problems such as deflagration accidents, achieve the effect of preventing deflagration accidents and compact volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

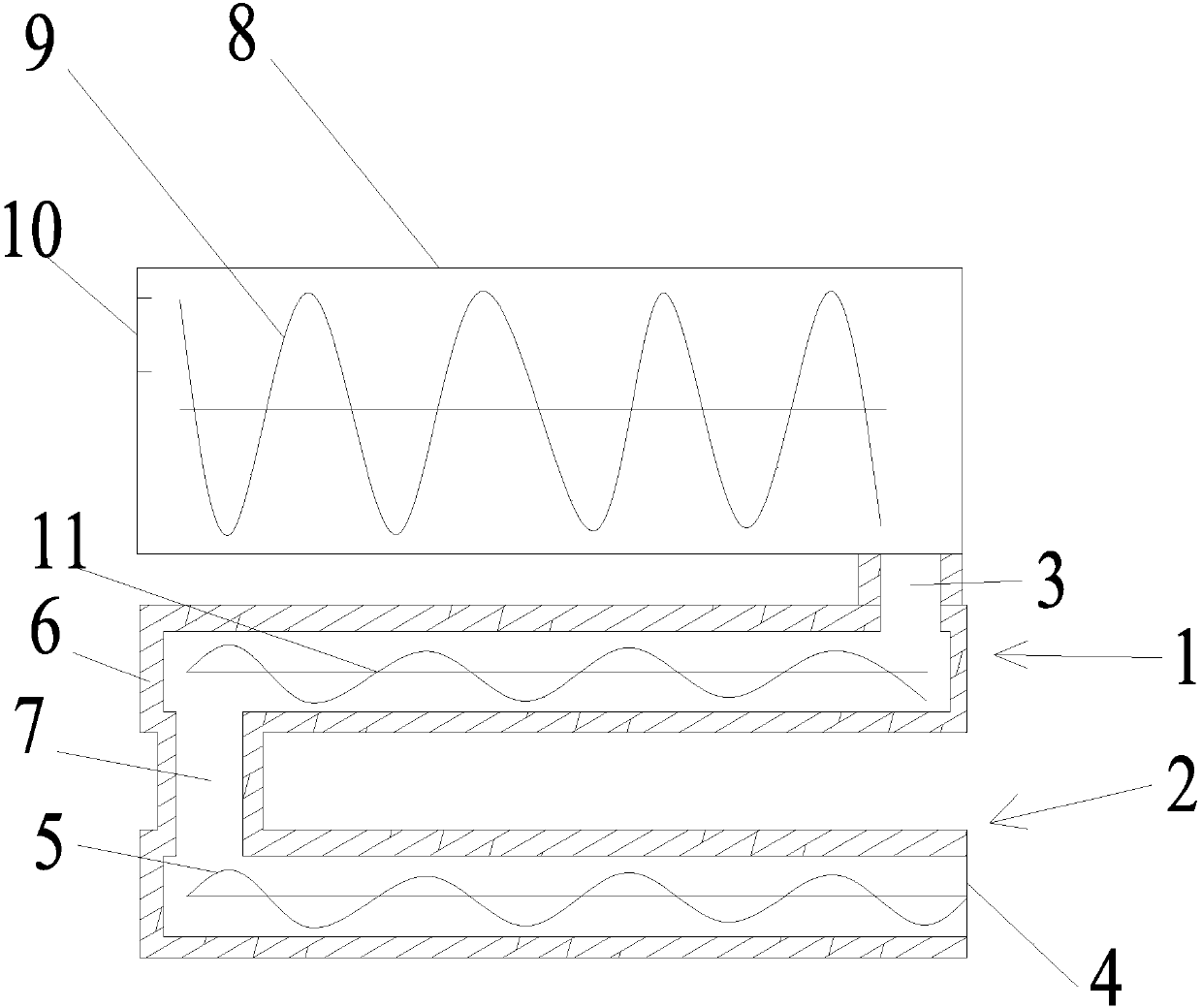

[0025] Such as figure 1 As shown, an oil sludge separation and discharging device of the present invention is arranged at the slag outlet 3 of the rotary kiln 8 of the oil sludge separation device. The rotary kiln 8 is provided with a third screw conveyor 9, which is used to transport the raw oil sludge to be processed from the feed port 10 to the slag outlet 3. During the above transportation process, the original oil sludge is decomposed by high temperature. The temperature of the slag discharged from the slag outlet 3 is generally about 600°C.

[0026] The oil sludge separating and discharging device of the present invention comprises a first conveying pipeline 1 and a second conveying pipeline 2 arranged in parallel up and down. Wherein, one end of the first conveying pipe 1 is connected with the slag outlet 3, and the other end is connected with a connecting p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com