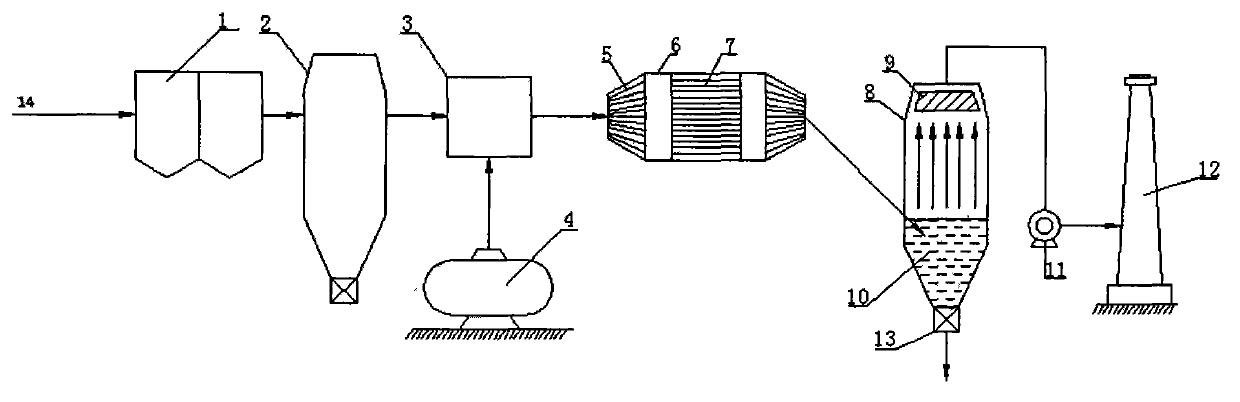

Engineering system for removing NOx from flue gas in low temperature at rear end of desulfurizing tower

A desulfurization tower and flue gas technology, which is applied in the direction of air quality improvement, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of large amount of desulfurization tower reconstruction, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] As shown in the figure, the flue gas enters the spray desulfurization tower 2 after being desulfurized through the dust collector 1, and then the compressed air 4 is sprayed into the flue gas through the air mixer 4, mixed and rectified by the static mixer, and under the action of the catalyst 7, NO and O in the air 2 The reaction produces NO which is soluble in water x Enter the bubbling absorption tower 8 and react with the absorbent 9 to form salts that are dissolved in the absorbent, and the purified flue gas is discharged from the chimney 12 through the induced draft fan 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com