Flue gas purifying and treating apparatus

A treatment device and flue gas purification technology, which is applied in combination devices, chemical instruments and methods, water shower coolers, etc., can solve the problem that the flue gas purification treatment device is difficult to meet the dust and particulate matter emission standards of industrial enterprises.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

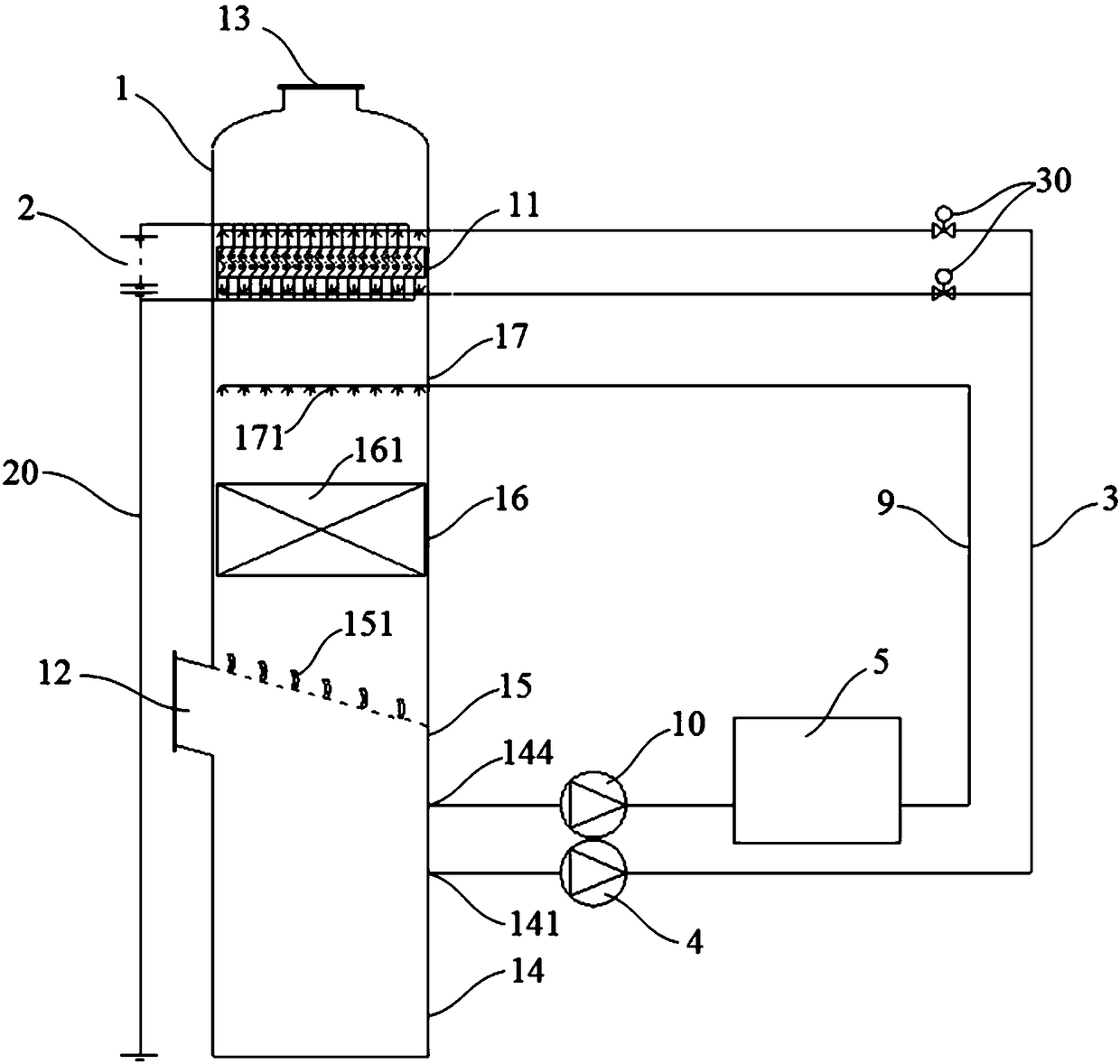

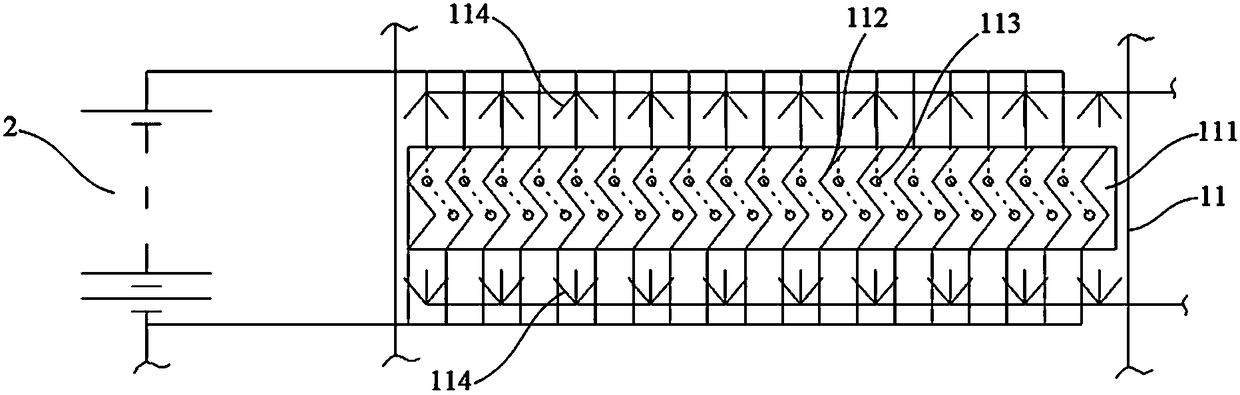

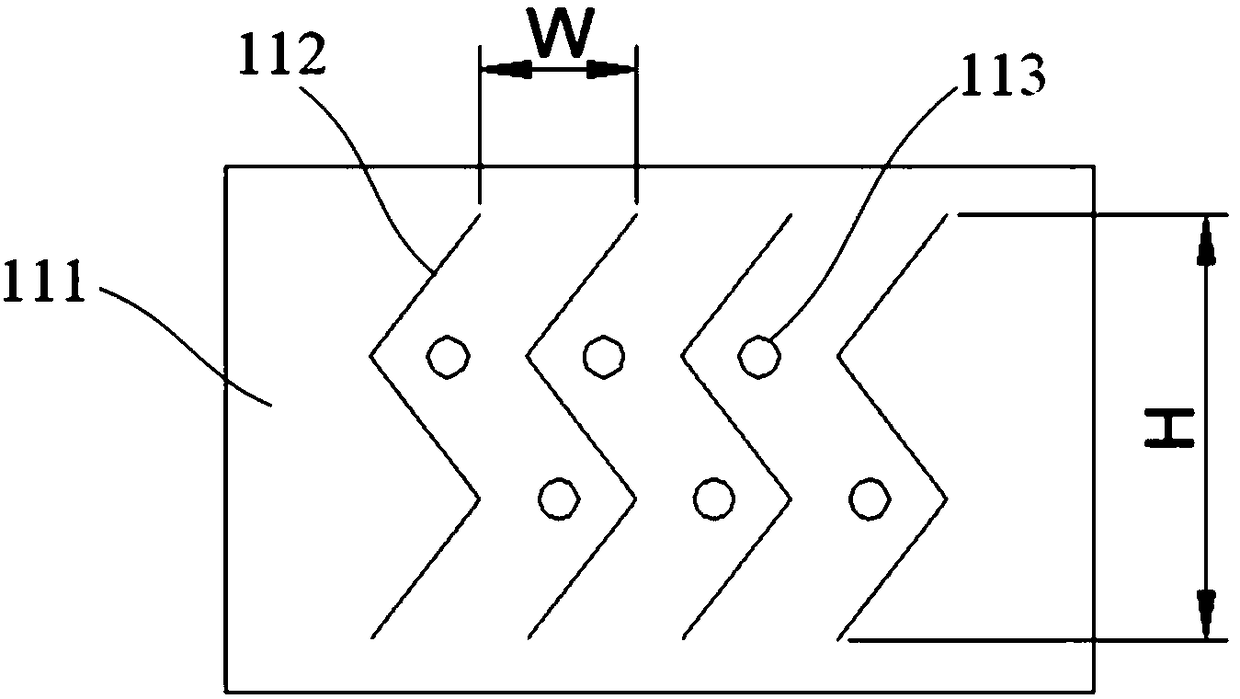

[0058] like Figure 1 to Figure 4 Shown is the first embodiment of the flue gas purification treatment device of the present invention. It includes a purification tower 1 and a power supply 2 located outside the purification tower 1. A flue gas inlet 12 and a flue gas outlet 13 are provided on the purification tower 1. The flue gas inlet 12 is located under the purification tower 1, and the flue gas outlet 13 is located at the purification tower 1. The top of the purification tower 1 is provided with an ultra-clean section 11, and the ultra-clean section 11 includes a substrate 111 positioned in the purification tower 1, a plurality of anode plates 112 fixed on the substrate 111 and a plurality of cathode wires 113, and a plurality of cathodes The wires 113 are evenly distributed between a plurality of anode plates 112, the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com