Lithium ion battery graphite anode material and preparation method thereof

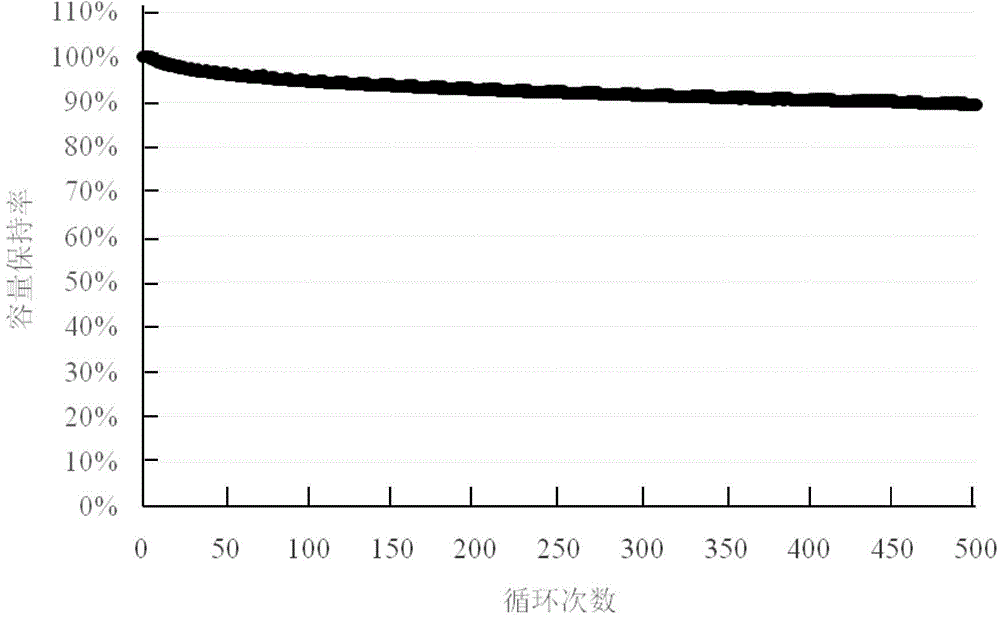

A lithium-ion battery, graphite anode technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor cycle performance of graphite anode materials, large pores inside graphite particles, poor charge and discharge performance, etc., and achieve a discharge platform. And the effect of high platform retention rate, excellent comprehensive performance, improved discharge capacity and cycle efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

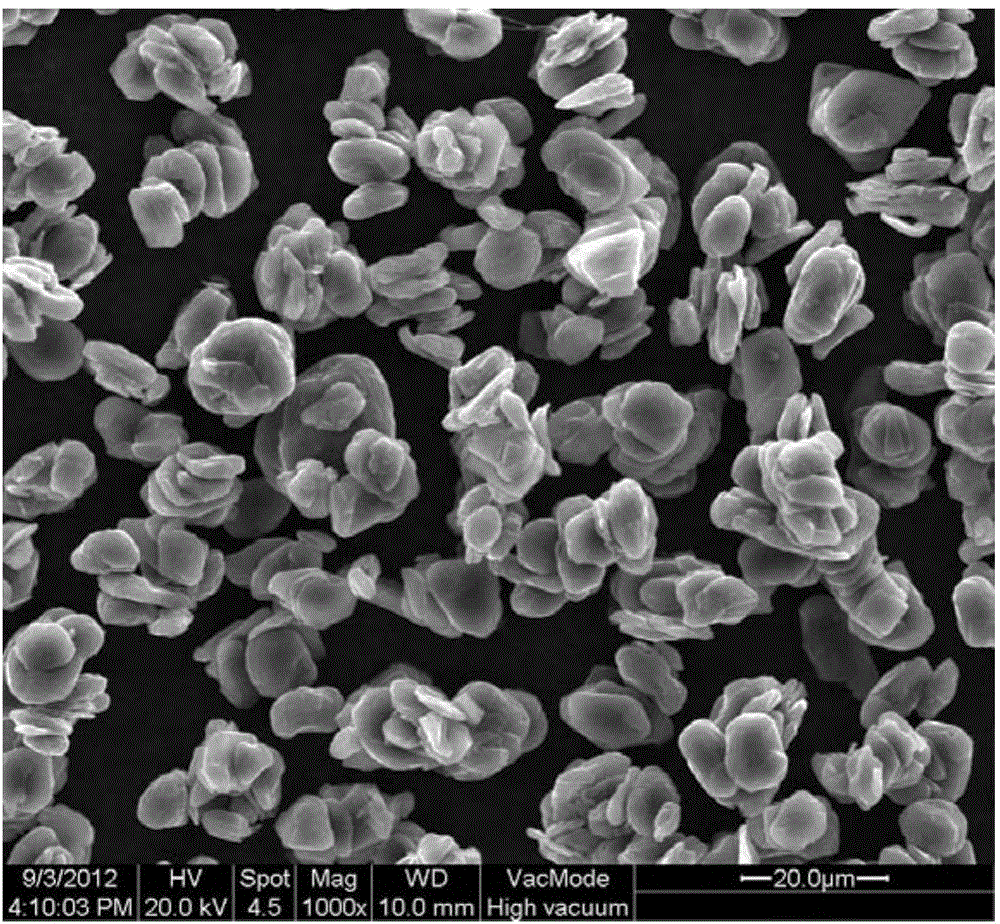

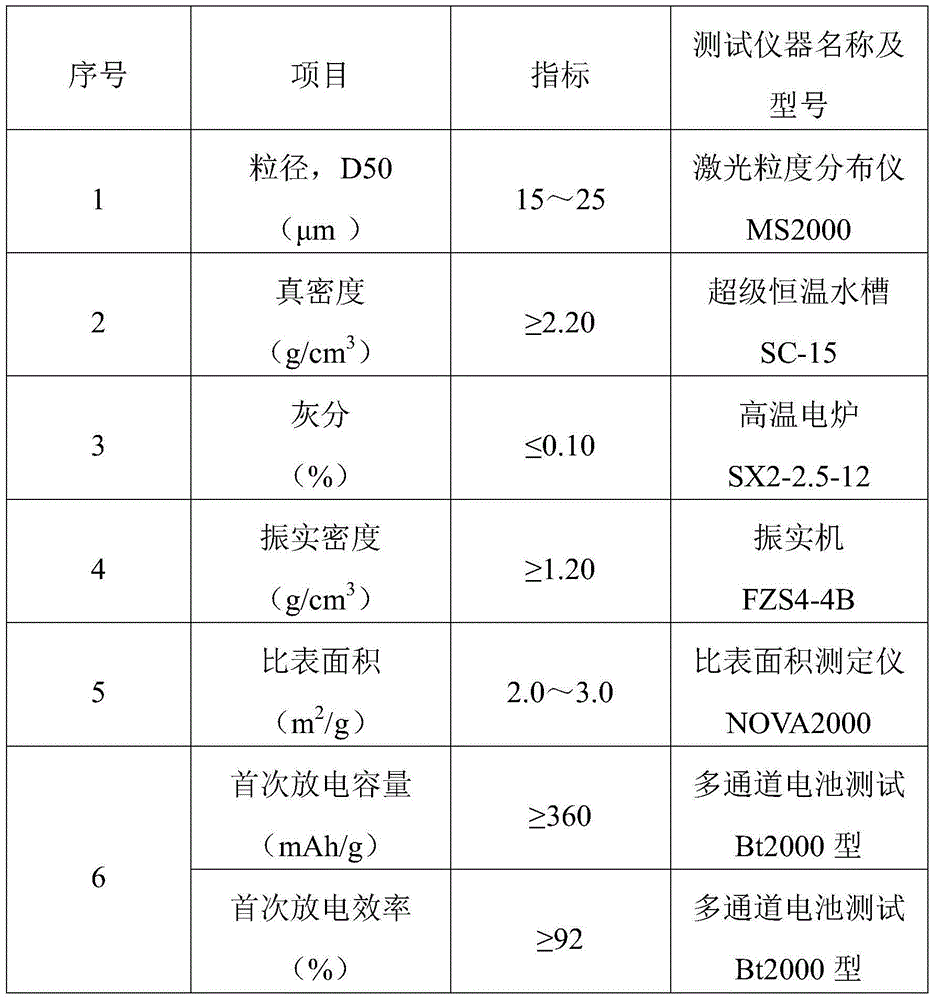

Embodiment 1

[0033] The petroleum asphalt is crushed to less than 0.1mm, and 20kg of spherical natural graphite (D50 is 19.1μm) and 5kg of asphalt powder are alternately added to the kneading pot under stirring, and kneading is carried out. The kneading temperature is 100°C. Press it into flakes in the machine, pulverize it, put it into a hot isostatic press, use argon gas medium, heat up and pressurize, keep it at 500 ° C for 1 hour at a calcination temperature and a pressure of 50 MPa, and then cool down naturally. Under the protection of nitrogen, carbonization treatment was carried out at a temperature of 1300° C. for 300 minutes, and then the reaction product was cooled to room temperature, and then graphitized at a high temperature (2800° C.) for 48 hours. And carry out crushing and classification, first coarse crushing, then fine crushing, adjust the frequency of the main machine of the fine crushing classifier to 15.35 Hz, set the external classification speed to 1000 rpm, and obtai...

Embodiment 2

[0036] The petroleum asphalt is crushed to less than 0.1mm, and 20kg of spherical natural graphite (D50 is 19.5μm) and 5kg of asphalt powder are alternately added to the kneading pot under stirring, and kneading is carried out. The kneading temperature is 120 ° C. Press it into flakes in the machine, pulverize it, put it into a hot isostatic press, use argon gas medium, heat up and pressurize, keep it at 500 ° C for 1 hour at a calcination temperature and a pressure of 50 MPa, and then cool down naturally. Under the protection of nitrogen, carbonization treatment was carried out at a temperature of 1100° C. for 360 minutes, and then the reaction product was cooled to room temperature, and then graphitized at a high temperature (3000° C.) for 48 hours. And carry out crushing and classification, first coarse crushing, then fine crushing, adjust the frequency of the main machine of the fine crushing classifier to 5.26 Hz, set the external classification speed to 1200 rpm, and obta...

Embodiment 3

[0038]The modified coal tar pitch is crushed to less than 0.1mm, and 12.5kg of spherical natural graphite (D50 is 20.1μm) and 12.5kg of asphalt powder are alternately added to the kneading pot under stirring, and kneading is carried out. The kneading temperature is 160°C. , pressed into flakes in a tablet machine, pulverized, put into a hot isostatic press for molding, using argon gas medium, heating and pressurizing, keeping at 500°C roasting temperature and 60MPa pressure for 1 hour, and then cooling down naturally. Under the protection of nitrogen, carbonization treatment was carried out at a temperature of 1500° C. for 180 minutes, and then the reaction product was cooled to room temperature, and then graphitized at a high temperature (3000° C.) for 24 hours. And carry out crushing and classification, first coarse crushing, then fine crushing, adjust the frequency of the main machine of the fine crushing classifier to 54Hz, set the external classification speed to 1300 rpm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com